Decoding Custom PCB Board Cost: A Comprehensive Guide

In today's technology-driven world, custom printed circuit boards (PCBs) are the backbone of countless electronic devices. From simple gadgets to advanced medical equipment, the demand for custom PCBs is constantly growing. Understanding the nuances of 'custom pcb board cost' is crucial for both hobbyists and professional engineers. This article provides a comprehensive breakdown of what impacts the price of a custom PCB, guiding you through the complexities to help you make informed decisions and optimize your budget.

Key Factors Influencing Custom PCB Board Cost

The cost of a custom Printed Circuit Board (PCB) is not a fixed value; it's a composite determined by several interconnected factors. Understanding these primary determinants—board size, number of layers, material selection, and design complexity—is crucial for accurate budgeting and cost-effective PCB design. Each of these aspects contributes uniquely to the final price, and careful consideration during the design phase can lead to significant cost savings.

- Board Size

Larger PCBs inherently require more materials and processing time, thus increasing costs. The area of the board directly correlates with the amount of raw material needed, the processing time, and the chemicals used in manufacturing. - Number of Layers

The complexity of a PCB increases dramatically with each additional layer. More layers require more processing steps, specialized equipment and, consequently, increase costs. A single-sided board is less expensive than a double-sided board, which in turn is less expensive than a multi-layer board. - Material Selection

The choice of material significantly affects both the performance and cost of the PCB. Common materials like FR-4 offer a balance of performance and cost, while higher-performance materials like Rogers are significantly more expensive. These costs are due to the unique properties and the more complex fabrication steps required for specialized materials. - Design Complexity

A complex design with fine traces, numerous vias, and high component density requires more precise manufacturing processes, thereby increasing costs. Intricate layouts require more testing time and the use of more advanced fabrication equipment, impacting the price significantly.

Material Selection: Impact on PCB Pricing

The choice of materials in PCB manufacturing significantly influences both the performance and cost of the final product. Different materials offer varying electrical, thermal, and mechanical properties, directly impacting the price point. Selecting the appropriate material is a critical step in the design process and requires a careful consideration of project requirements and budget constraints.

| Material | Cost (Relative) | Dielectric Constant (Approximate) | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| FR-4 | Low to Moderate | 4.5 | General purpose PCBs, most consumer electronics | Widely available, cost-effective, good mechanical strength | Higher dielectric loss at high frequencies, limited thermal performance |

| Rogers (e.g., 4350B) | High | 3.66 | High-frequency applications, RF circuits, aerospace | Low dielectric loss, stable dielectric constant over frequency, excellent thermal properties | More expensive than FR-4, higher material cost |

| CEM-1 | Low | 4.2 | Single-sided PCBs, less demanding applications | Lower cost than FR-4, relatively good electrical properties | Lower mechanical strength, not suitable for multi-layer boards |

| Polyimide | High | 3.4 | Flexible PCBs, high-temperature applications, aerospace | Excellent thermal stability, high flexibility | High cost, sensitive to moisture |

| Metal Core (e.g., Aluminum) | Moderate to High | N/A | LED lighting, power electronics | Excellent heat dissipation, good mechanical strength | More difficult to manufacture, not suitable for fine traces |

As shown in the table, FR-4 stands out as the most commonly used material due to its balance of cost-effectiveness and reasonable performance characteristics. Rogers materials, while more expensive, offer superior performance in high-frequency applications. Material selection should always be made in the context of the specific requirements of each application.

Number of Layers: A Cost Driver

The number of layers in a Printed Circuit Board (PCB) is a primary determinant of its manufacturing cost. As the layer count increases, so does the complexity of the fabrication process, leading to higher production expenses. This section explores the cost implications of single-layer, double-layer, and multi-layer PCBs, offering a clear understanding of how layer count influences the final price.

| PCB Type | Layer Count | Typical Applications | Cost Factor | Complexity |

|---|---|---|---|---|

| Single-Layer | 1 | Simple electronics, basic circuits, LEDs | Lowest | Low |

| Double-Layer | 2 | Intermediate complexity circuits, basic digital electronics | Moderate | Medium |

| Multi-Layer | 3+ | Complex electronics, high-density circuits, advanced applications | High | High |

Each additional layer introduces the need for more precise alignment, additional lamination processes, and more advanced manufacturing techniques, all of which contribute to increased cost.

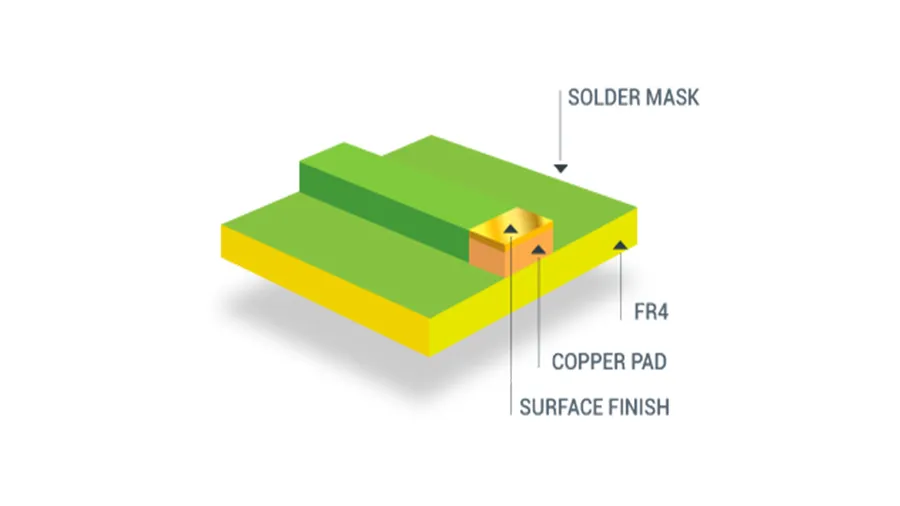

Surface Finish: Cost Implications

The surface finish of a Printed Circuit Board (PCB) is a critical factor influencing both its cost and long-term reliability. Different finishes provide varying levels of protection against oxidation and corrosion, as well as impacting solderability. Choosing the appropriate finish requires careful consideration of the project’s specific requirements and budget constraints. This section will detail some of the common PCB surface finishes, evaluating the cost implications and benefits of each.

| Surface Finish | Cost | Solderability | Corrosion Resistance | Longevity | Typical Application |

|---|---|---|---|---|---|

| HASL (Hot Air Solder Leveling) | Low | Good | Moderate | Moderate | General purpose PCBs |

| ENIG (Electroless Nickel Immersion Gold) | High | Excellent | Excellent | High | High-reliability and fine-pitch components |

| OSP (Organic Solderability Preservative) | Low | Good | Poor | Low | Cost-sensitive applications with single reflow |

| Immersion Tin | Medium | Good | Good | Moderate | Fine pitch components with moderate shelf life needs |

| Immersion Silver | Medium | Good | Good | Moderate | Fine pitch components |

Each surface finish offers a different balance of cost, performance, and durability. HASL is a cost-effective, and widely used option, while ENIG provides superior performance for high-reliability applications at a premium cost. OSP is another low cost alternative, however it's limited shelf life and single reflow constraint may be limiting for some applications.

PCB Design Complexity and its Influence on Cost

The intricacy of a Printed Circuit Board (PCB) design significantly impacts its manufacturing cost. Complex designs with a high density of components, numerous vias, and intricate trace patterns demand more sophisticated manufacturing processes, leading to increased expenses. Design complexity translates directly to longer production times, higher material utilization, and potentially higher defect rates, all of which affect the final cost.

| Design Element | Impact on Cost | Description |

|---|---|---|

| Number of Vias | Increased Cost | Vias, which are plated through-holes connecting different layers, add complexity and material usage. Microvias, which are even smaller, require specialized drilling and plating techniques, driving up costs further. |

| Trace Density and Width | Increased Cost | Fine traces and high trace density require advanced fabrication processes and precise control. Narrow traces can lead to yield issues and require more accurate imaging equipment, thus higher cost. |

| Component Density | Increased Cost | Higher component density leads to tighter spacing, requiring finer pitch SMT placement, and more precise and advanced equipment which increases the complexity of the assembly processes. |

| Board Size | Increased Cost | Larger boards use more material and may require specialized manufacturing processes, increasing the cost of PCB board. |

Manufacturing Quantity: How it Affects Unit Cost

The quantity of custom PCB boards ordered significantly influences the per-unit cost due to economies of scale. Larger production runs distribute fixed costs—such as setup fees, tooling, and initial programming—across more units, resulting in a lower cost per board. Understanding this relationship is crucial for cost-effective PCB manufacturing.

| Quantity | Setup Cost (Hypothetical) | Variable Cost per Board (Hypothetical) | Total Cost | Cost Per Board |

|---|---|---|---|---|

| 10 | $100 | $5 | $150 | $15.00 |

| 100 | $100 | $5 | $600 | $6.00 |

| 500 | $100 | $5 | $2600 | $5.20 |

| 1000 | $100 | $5 | $5100 | $5.10 |

The break-even point represents the production volume where total revenue equals total cost. While not directly applicable to PCB purchasing (which is a cost rather than revenue driver), it serves as a useful concept to understand the point at which further cost reductions become less significant. This point is different for every project, but it can be seen that the biggest savings in unit cost comes early, with diminishing savings in larger volumes. Manufacturers often have different pricing tiers based on order volume, further illustrating this economy of scale. For instance, a small order might incur a disproportionately higher setup fee per board, while larger orders can secure bulk discounts.

It's important to align your order quantity with your project needs and budget constraints. Ordering too many PCBs will lead to wasted inventory, while ordering too few may cause delays and higher unit costs for future reorders. Analyze project requirements, potential future needs, and cost implications before finalizing your order quantity. For example, if your project is a prototype or proof of concept, then it might be more effective to do a small order first and then order in larger quantities once testing is complete.

Turnaround Time: Balancing Speed and Cost

Turnaround time, the duration from placing an order to receiving the finished PCBs, significantly impacts the final cost. Expedited manufacturing processes inherently command a premium due to the resource allocation and scheduling adjustments required for faster production.

Balancing the need for speed with budget constraints is crucial. Understanding the relationship between turnaround time and cost allows for strategic project planning and cost-effective decision-making.

| Turnaround Time | Cost Impact | Suitability | Considerations |

|---|---|---|---|

| Standard (e.g., 1-2 weeks) | Lowest cost | Typical projects with flexible deadlines | Allows for efficient batching and resource allocation. |

| Expedited (e.g., 3-7 days) | Moderate increase | Projects requiring faster delivery but not immediate | May involve prioritization and adjusted scheduling. |

| Rush/Fast (e.g., 1-2 days) | Highest cost | Urgent projects with critical deadlines | Requires immediate production and may have limited availability. |

The cost increase associated with faster turnaround times is a reflection of the increased operational costs required to expedite the manufacturing process. This includes potentially re-prioritizing production schedules, using overtime labor, and faster shipping methods.

Frequently Asked Questions About Custom PCB Board Cost

This section addresses common inquiries regarding the cost of custom PCB boards, providing concise answers to help you better understand the pricing factors and make informed decisions.

- Is it expensive to make a custom PCB?

The cost of manufacturing a custom PCB is variable. It depends on several factors including the complexity of the design, the materials used, the number of layers, the surface finish, and the quantity ordered. While simple single-layer boards can be quite affordable, complex multi-layer designs with specific material requirements will naturally cost more. Therefore, 'expensive' is subjective and must be considered in the context of the specific board requirements. - Why are custom PCBs sometimes so expensive?

Custom PCBs can be expensive due to several factors. The main cost drivers are typically the need for specialized materials (e.g., high-frequency laminates), complex design specifications (e.g., fine traces, high via density), precise manufacturing processes, and the low volume of some production runs. Additionally, non-recurring engineering (NRE) costs can contribute to a higher initial price, especially if prototyping is involved. It's the combination of these factors which often leads to higher price tags. - How do I accurately calculate PCB fabrication cost?

Calculating PCB fabrication costs involves several steps. You will need to factor in the cost of materials, which is determined by the type, size, and number of layers of your board. The complexity of the design, which includes number of holes and via, trace width, and surface finishes, impacts production effort and cost. Also consider if your PCB requires specific certifications, such as UL or RoHS compliance, which add to the overall expenses. Manufacturing costs also fluctuate based on the quantity ordered and the turnaround time. Many manufacturers offer online calculators or can provide quotations if you share the design file, allowing for more accurate cost estimation. - What is the typical cost range for a PCB?

The cost of a PCB can range from a few dollars for basic, single-layer boards to hundreds or even thousands of dollars for complex, multi-layer designs with specialized materials and finishes. Therefore a specific cost range is not particularly useful, it is essential to analyze your specific design requirement, material choices, fabrication specifications, and quantity required for the accurate pricing. For prototyping purposes, small quantities of simple PCBs can be ordered from budget friendly options, while more stringent PCB requirements will increase the final price, there is no easy answer for a typical cost. - Does the size of the PCB significantly impact its cost?

Yes, the size of the PCB has a direct impact on cost. Larger boards require more materials to produce. They may also need larger equipment during the fabrication process, impacting manufacturing expense. Therefore, minimizing the physical size of your board, if possible, is a way to reduce cost. While it might seem marginal, the cost compounds with volume production. - How does quantity impact the unit price of a PCB?

The quantity ordered directly impacts the unit price due to economies of scale. With higher quantities, the per-unit price decreases significantly because the initial setup costs (like tooling and programming) are spread across more units. Therefore, consider ordering in quantities that match your production needs, while keeping in mind that warehousing inventory may introduce its own costs. - Is surface finish a significant cost factor for custom PCB?

Yes, the surface finish chosen for a custom PCB is a significant cost factor. Common finishes like HASL (Hot Air Solder Leveling) are cost-effective but have limitations. More advanced finishes, such as ENIG (Electroless Nickel Immersion Gold), offer better performance and longevity but come at a higher price. The choice of surface finish should be carefully considered according to performance requirements, while balancing budget and function.

Cost Optimization Strategies for Custom PCBs

Optimizing the cost of custom PCBs requires a strategic approach that balances functionality and budget. By employing smart design practices and effective negotiation strategies, significant cost reductions can be achieved without sacrificing quality or performance.

- Design for Manufacturability (DFM)

Adhering to DFM principles reduces manufacturing errors and rework, directly lowering costs. This involves considerations like standard component footprints, via sizes, and trace widths. - Standardize Component Selection

Using commonly available components simplifies the assembly process, and often, these components have better pricing and availability than specialized parts. This reduces lead times and avoids premium pricing for unique requirements. - Panelization

If you are planning to produce multiple boards, having them panelized within a larger board format, instead of processing them individually, will minimize wasted materials during the production process and therefore the overall cost of the individual boards. - Optimize Layer Count

Carefully assess the necessity of each layer in your design. Simplifying the board by using fewer layers can result in substantial savings, particularly for larger production runs. For example, a transition from a four-layer to a two-layer PCB can significantly cut material and manufacturing costs. - Minimize Board Size

Reducing the overall dimensions of your PCB will decrease material usage and fabrication time, leading to lower costs. This may involve reevaluating the component placement or layout to achieve the minimal footprint possible without compromising the function or performance of the board. - Strategic Material Choice

While materials like Rogers are suitable for high-frequency applications, FR-4 is a cost-effective alternative for standard applications. Only select the higher end materials when the design absolutely requires it. The use of lower-cost materials where the design requirements permit will reduce your PCB's overall cost. - Negotiate Pricing with Manufacturers

Engage with PCB manufacturers to negotiate bulk discounts and explore options for reducing your manufacturing costs. Building a relationship with your manufacturer will lead to more flexible pricing and potential cost savings down the road. - Avoid Rush Orders

Plan your manufacturing timeline to avoid rush orders. Rapid turnaround options often come at a premium price. Proper planning can reduce production overhead expenses. - Utilize Automated Assembly

Ensure your design is suitable for automated assembly processes. In doing so, you will reduce assembly time and reduce cost.

Navigating the complexities of 'custom pcb board cost' requires careful consideration of numerous factors, from material selection and design complexity to production volume. By understanding these elements and implementing cost-optimization strategies, you can secure high-quality custom PCBs that fit your project's budget and performance needs. Keep abreast of market trends and innovative manufacturing techniques to ensure your projects remain cost-effective and competitive. Ultimately, whether you're a hobbyist or an industry professional, making informed choices will lead to successful and economically viable PCB solutions. Considering the overall project, the per-unit custom pcb board cost is a key factor to consider in the initial stages.

AnyPCBA

AnyPCBA