Decoding Custom PCB Costs: A Comprehensive Guide for 2024

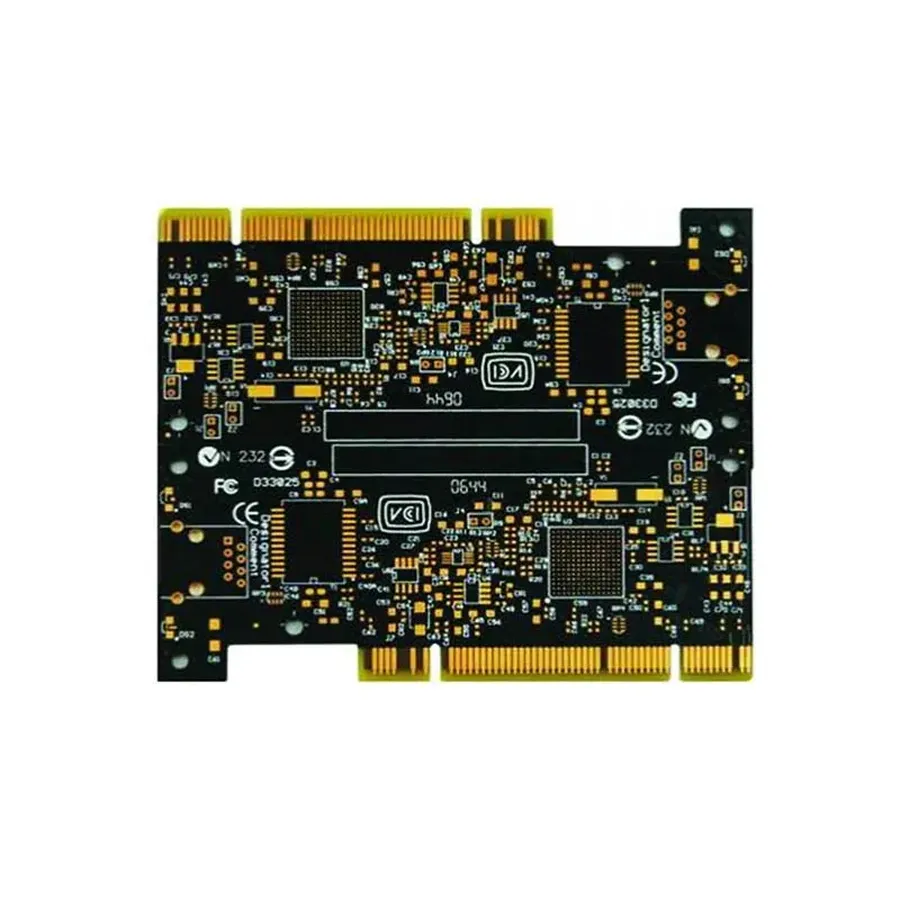

In today's technology-driven world, custom printed circuit boards (PCBs) are the unsung heroes powering everything from smartphones to medical devices. But what does it really cost to bring your custom PCB design to life? This article breaks down the cost of custom PCB fabrication, exploring the key factors that influence pricing, offering actionable advice to manage expenses, and ensuring you get the most bang for your buck. Whether you're a hobbyist or a seasoned engineer, understanding the nuances of custom PCB costs is crucial for project success, and we will help you navigate this complex landscape.

Key Factors Influencing Custom PCB Costs

The cost of custom Printed Circuit Boards (PCBs) is not fixed; it's a complex equation influenced by several interconnected factors. Understanding these variables is crucial for effective budget planning and cost optimization in your electronics projects. This section delves into the core elements that drive custom PCB pricing, offering insights into how each factor contributes to the overall cost.

| Factor | Description | Cost Impact |

|---|---|---|

| Board Size | The physical dimensions of the PCB. Larger boards require more material and processing time. | Directly proportional to cost. Larger size = higher cost. |

| Layer Count | The number of conductive layers within the PCB. More layers increase complexity and manufacturing steps. | Significant impact. More layers = higher cost. |

| Material Selection | The type of substrate used (e.g., FR-4, Aluminum, Rogers). Different materials have varying costs and performance characteristics. | Varies widely. High-performance materials are more costly. |

| Surface Finish | The coating applied to the PCB's exposed copper (e.g., HASL, ENIG, OSP). Different finishes offer varying levels of protection and solderability. | Affects cost and performance. ENIG is typically more expensive than HASL. |

| Quantity | The number of PCBs ordered. Larger production runs generally result in lower per-unit costs. | Inversely proportional. Higher volume = lower per-unit cost. |

| Complexity of Design | The density of traces and components, and use of advanced features | Higher complexity often increases costs as it demands more precision and testing |

A Deep Dive into PCB Layer Count and Pricing

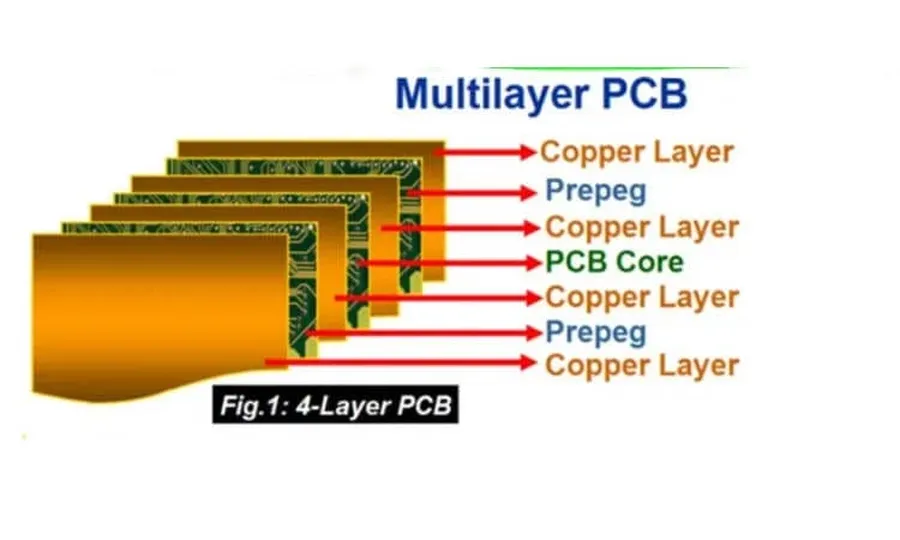

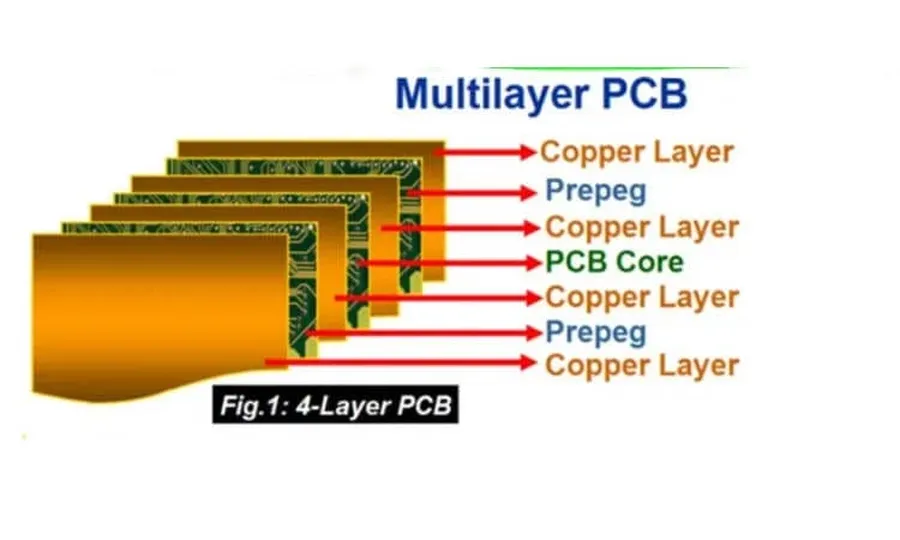

The number of layers in a printed circuit board (PCB) is a primary determinant of its cost, reflecting the complexity of fabrication and the materials required. As the layer count increases, so do manufacturing costs, impacting the final price significantly. Understanding the cost implications of single-layer, double-layer, and multi-layer PCBs is crucial for effective budget management.

| PCB Layer Count | Complexity | Typical Applications | Approximate Cost (Relative) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Single-Layer | Simplest | Basic electronic devices, LED lighting, simple sensors | Lowest | Lowest cost, Simple design and manufacturing | Limited functionality, higher signal interference |

| Double-Layer | Moderate | Consumer electronics, power supplies, simple controllers | Medium | Increased routing flexibility, reduced size compared to single-layer | Limited density compared to multi-layer, higher cost than single-layer |

| Multi-Layer (4+ Layers) | High | Complex electronics, computing devices, high-speed data applications | Highest | High component density, Improved signal integrity and impedance control | Highest cost, complex design and manufacturing |

The transition from single to double-layer PCBs introduces the ability to route traces on both sides of the board, significantly enhancing design flexibility and reducing board size for comparable circuit complexity. However, this increase in functionality comes with a cost. Multi-layer PCBs, defined as those with four or more layers, further escalate costs due to the need for more complex pressing, lamination, and drilling processes, along with the additional material expenses.

When selecting the appropriate layer count, consider not only the immediate cost but also the long-term implications for performance and reliability. Balancing cost with functionality is key, and choosing a minimal layer count required to meet the design specifications can offer substantial cost savings.

Material Selection: How Does it Affect the Price?

The choice of material for a Printed Circuit Board (PCB) significantly impacts its cost, performance, and application suitability. Selecting the appropriate material involves balancing electrical, mechanical, thermal, and cost considerations. This section will explore common PCB materials and their associated cost implications.

| Material | Description | Typical Applications | Cost Relative to FR-4 | Key Advantages | Key Disadvantages |

|---|---|---|---|---|---|

| FR-4 | Fiberglass epoxy laminate, the most common PCB material. | Most general-purpose PCBs, consumer electronics, etc. | Base cost (reference) | Cost-effective, good electrical properties, widely available. | Moderate thermal performance, not ideal for high-speed applications. |

| Aluminum | Metal core PCB using aluminum as a base material | LED lighting, power electronics, high-temperature applications. | Higher | Excellent thermal conductivity, good heat dissipation, robust. | Higher cost, limited flexibility, increased weight |

| Rogers | High-performance ceramic-filled PTFE based materials. | High-frequency applications, RF/microwave circuits, telecommunications. | Significantly Higher | Excellent high-frequency performance, low signal loss, stable dielectric constant. | Very high cost, requires specialized processing, not suitable for general use. |

| Polyimide | Flexible substrate materials known for high-temperature resistance. | Flexible PCBs, aerospace, automotive, high-reliability applications. | Higher | Excellent thermal stability, flexibility, chemical resistance. | Higher cost, may require specialized processing. |

| CEM-1/CEM-3 | Composite material using paper and fiberglass core | Single and double-sided PCBs, lower-cost consumer electronics. | Lower | More cost-effective than FR-4 in certain applications, good mechanical properties. | Less thermal resistance and not suitable for all application scenarios |

When selecting a PCB material, it is crucial to consider not just the immediate cost, but also its impact on the long-term reliability and performance of the final product. For instance, choosing a more expensive material with better thermal characteristics can reduce the need for additional heat management solutions and improve overall product longevity. Conversely, over-specifying material for an application with modest performance requirements can unnecessarily inflate costs.

Surface Finishes and Their Impact on Cost

The surface finish of a Printed Circuit Board (PCB) is a critical aspect influencing its cost and performance. It serves to protect the underlying copper circuitry from oxidation and ensures solderability. The choice of finish depends on application requirements, reliability needs, and budget constraints. Different finishes exhibit varying characteristics in terms of cost, solderability, shelf life, and environmental impact, necessitating a careful evaluation.

| Surface Finish | Cost | Solderability | Shelf Life | Application Notes |

|---|---|---|---|---|

| HASL (Hot Air Solder Leveling) | Low | Good | Moderate | Cost-effective, suitable for most standard applications, can have uneven surface. |

| ENIG (Electroless Nickel Immersion Gold) | High | Excellent | Excellent | Superior solderability, good for fine pitch components and wire bonding, more expensive. |

| OSP (Organic Solderability Preservative) | Low | Good | Short | Cost-effective, flat surface good for SMT, short shelf life, requires careful handling. |

| Immersion Tin | Moderate | Good | Moderate | Good for fine pitch SMT, can be susceptible to whisker growth over time. |

| Immersion Silver | Moderate | Good | Moderate | Good for fine pitch SMT, can tarnish over time, requires specific handling. |

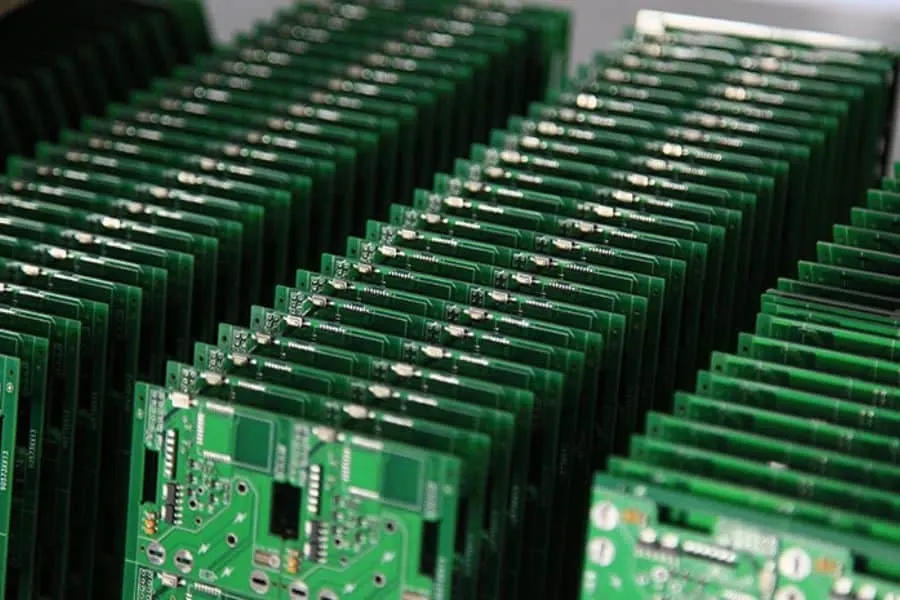

Quantity Matters: The Price per Unit Breakdown

The unit cost of custom PCBs is significantly affected by the order volume. Understanding this relationship is crucial for optimizing your budget, as the price per PCB decreases as the quantity increases. This principle applies across different stages, from prototypes to large-scale production.

Initial setup costs, including tooling and programming, are a major component of PCB fabrication expenses. These costs are relatively fixed and are spread across the number of units produced. Therefore, larger production runs can effectively reduce the per-unit cost, leading to significant savings.

| Order Quantity | Cost per PCB (Approximate) | Total Cost (Approximate) |

|---|---|---|

| 1-5 (Prototypes) | $50 - $200+ | $50 - $1000+ |

| 10-50 (Small Batch) | $15 - $50 | $150 - $2500 |

| 100-500 (Medium Batch) | $5 - $15 | $500 - $7500 |

| 1000+ (Large Scale) | $1 - $5 | $1000+ |

It is imperative to determine your actual demand before making an order. Overestimating production needs will lead to surplus stock, whereas underestimating will result in additional setup costs and delays. A balanced approach to order quantities, along with accurate demand forecasting, is essential for cost management and timely production.

Prototyping vs. Production Costs: Understanding the Differences

Understanding the cost variations between PCB prototyping and full-scale production is crucial for effective project budgeting. Prototyping involves creating a small number of boards to test and validate a design, whereas production focuses on manufacturing larger quantities. Each phase incurs distinct expenses related to tooling, testing, and quality control.

| Cost Factor | Prototyping | Production |

|---|---|---|

| Tooling Costs | Lower, may include setup fees for small batch | Higher, includes dedicated tooling for mass manufacturing |

| Unit Price | Higher per unit, due to small batch production. | Lower per unit, benefit from economies of scale. |

| Testing Costs | Basic functional testing, manual checks likely. | Rigorous testing, automated tests for quality assurance. |

| Quality Control | Individual inspections possible. | Systematic process, includes statistical process control. |

| Setup Time | Faster, emphasis on speed of iteration. | Slower, requires more thorough planning and tooling. |

| Design Changes | More easily implemented and less expensive. | More difficult and expensive to implement at large scale |

Prototype costs are influenced by the need for flexibility and rapid iterations and typically involve a higher per-unit price due to lower volumes and manual adjustments. In contrast, production costs benefit from economies of scale, reducing unit price but requiring higher initial tooling investments and more stringent quality checks. Therefore, accurate budgeting must consider these differing cost structures to plan effectively from design to manufacturing.

Frequently Asked Questions About Custom PCB Cost

Understanding the costs associated with custom PCBs is crucial for effective project planning. This section addresses the most common questions regarding PCB pricing, providing clarity and actionable insights.

- Why are custom PCBs often perceived as expensive?

Custom PCBs involve a range of processes including design, fabrication, and potentially assembly, each contributing to the overall cost. Factors like specialized materials, unique layer configurations, precise surface finishes, and the complexity of the design significantly impact the final price. Unlike mass-produced electronics, each custom PCB is tailored to a specific application, reducing economies of scale. - How can I accurately estimate the cost of PCB fabrication?

Estimating PCB costs requires considering several key variables: the board's area, the number of layers, material type (e.g., FR-4, Rogers), selected surface finish (e.g., HASL, ENIG), solder mask requirements, and the order quantity. Many PCB manufacturers offer online calculators where you can input these parameters to obtain a quote. However, always get a formal quotation for a thorough assessment, as specialized designs might need manual calculation. - What is the typical cost range for a single custom PCB?

The cost of a single custom PCB can vary greatly depending on the factors mentioned above. For a simple two-layer board with standard materials and finish, the cost may range from tens to hundreds of dollars for a single prototype. Complex multi-layer boards can reach thousands of dollars for just one board. The price per unit dramatically decreases with volume due to amortization of initial setup costs. - Does the complexity of the PCB design affect the cost?

Absolutely. Complex designs requiring finer traces, smaller vias, non-standard shapes, or intricate routing increase the manufacturing difficulty and, consequently, the cost. Design complexity often translates to higher manufacturing time and yields, impacting the final price. Optimizing your design and using standard components can significantly reduce costs. - How does the choice of PCB material influence the price?

The material selected for your PCB directly impacts the cost. FR-4 is the most common and cost-effective material. However, high-frequency applications may require materials like Rogers, which have better electrical properties and higher price points. Aluminum substrates, while great for heat dissipation, also incur higher costs than FR-4. Choosing the correct material balance between performance and budget is crucial. - What are the key cost drivers for surface finishes?

The choice of surface finish can significantly impact both cost and performance. HASL is generally the most economical option, while ENIG (Electroless Nickel Immersion Gold) is more expensive but provides better solderability and corrosion resistance. OSP (Organic Solderability Preservative) offers a cost-effective alternative for less demanding applications. Select the finish that is best suited to your application. - Is there a significant difference between prototype and production costs?

Yes, there's a substantial cost difference between prototypes and production runs. Prototypes typically carry higher per-unit costs because of setup expenses for tooling, programming, and low yield rates. As production volume increases, these initial costs are spread across more units, leading to lower per-unit costs. Production also benefits from optimized processes, contributing to overall cost reduction.

Cost-Saving Tips for Your Custom PCB Project

Reducing the cost of custom PCBs requires a strategic approach encompassing design optimization, material selection, and manufacturing choices. By implementing these actionable strategies, you can significantly lower your project expenses without compromising quality or performance.

- Optimize PCB Design

Streamline your PCB layout by minimizing the board size, using fewer vias, and reducing the number of layers whenever possible. A more compact and straightforward design typically translates to lower fabrication costs. - Standardize Components

Opt for readily available, standardized components. Custom or rare components often carry a premium, increasing the overall cost. Sourcing common parts simplifies the assembly process and saves money. - Choose the Right Manufacturer

Thoroughly research and compare different PCB manufacturers. Some manufacturers may offer lower prices for specific quantities, board sizes, or material types. Selecting a manufacturer that specializes in your project's needs will yield significant savings. Consider offshore options for large-scale production but factor in shipping time and communication differences. - Consider Alternative Materials

While FR-4 is the most common material, alternative materials like CEM-1 or lower-grade FR-4 may suffice for less demanding applications and significantly reduce costs. Evaluate your project requirements carefully to determine if a more cost-effective material is a viable choice without compromising performance. For example, switching from high-end dielectrics to standard FR4 can be a very effective cost saving measure. - Panelize Your Design

For larger quantities, panelizing your design allows the manufacturer to produce multiple boards at once, which reduces the per-unit cost by utilizing the manufacturing panel size more efficiently. Combine smaller PCBs into a larger array to minimize waste and save on production time. - Avoid Complex Finishes

Opt for the most basic, functional surface finish if possible. ENIG (Electroless Nickel Immersion Gold) is a high quality but expensive finish. HASL (Hot Air Solder Leveling) is a reliable and much more affordable alternative for many applications. - Avoid Tight Tolerances

Tighter tolerances during the PCB design and manufacturing process increase costs. Relax the tolerances where possible to simplify the fabrication process and reduce the overall expense. Consider if your project really needs the most precise etching and drilling parameters. - Careful DFM (Design for Manufacturing) Review

Perform a comprehensive DFM check early in the design process. This helps identify potential manufacturing problems before production and avoids costly rework or redesigns. This step can ensure the PCB can be made efficiently.

By meticulously implementing these cost-saving strategies, you can optimize your custom PCB project, making it more affordable and achieving the desired outcome.

Comparing PCB Manufacturers: Pricing and Services

Selecting the right PCB manufacturer is crucial for balancing cost, quality, and lead time. This section provides a comparative overview of major PCB manufacturers, highlighting their pricing structures, service offerings, and turnaround times, specifically addressing the [cost of custom pcb] to help you make an informed decision.

| Manufacturer | Base Price (USD) | Lead Time (Days) | Capabilities | Specialization | Notes |

|---|---|---|---|---|---|

| JLCPCB | $2- $5 for 10 boards | 3-7 | Prototyping, small-batch production, multi-layer PCBs | Rapid prototyping, low cost | Extremely competitive on price and quick turnarounds, ideal for prototype runs and small batches. |

| PCBWay | $5 - $10 for 10 boards | 5-10 | Prototyping, medium-batch production, advanced materials | Flexible PCBs, advanced materials | Offers a broader range of materials and technologies, well-suited for medium production and specialized requirements. |

| AllPCB | $8 - $12 for 10 boards | 7-12 | Medium-batch production, multi-layer PCBs, assembly services | Assembly services, moderate cost | Emphasis on one-stop solutions with integrated PCB fabrication and assembly. |

| Advanced Circuits | $10 - $20 for 10 boards | 5-10 | Rapid turn PCBs, large batch capabilities, ITAR Compliance | High-Reliability, Quick Turn | A reputable, reliable provider for high-quality PCBs, with a strong focus on rapid turn and complex designs. |

| Sierra Circuits | $20- $50 for 10 boards | 7-15 | High-complexity, multi-layer PCBs, Rigid-Flex | Advanced technology, high-complexity designs | Specializes in complex PCB designs requiring a high level of expertise |

Note that the 'Base Price' figures are an approximation for a standard double-layer PCB prototype and can vary based on board size, complexity and material selection. Lead times represent estimates and may be affected by the manufacturer’s workload and additional services selected. It is recommended to obtain a quote based on specific project requirements.

Navigating the landscape of custom PCB costs can be challenging, but armed with the right information, you can make informed decisions that align with your project goals and budget. By understanding the factors influencing custom PCB costs, from board materials to order quantity, and employing cost-saving strategies, you can maximize the value of your investment, ensuring the final product is both high-quality and cost-effective. The cost of custom pcb varies significantly based on your needs, so proper planning is essential to success.

AnyPCBA

AnyPCBA