Decoding JLCPCB Assembly Prices: A Comprehensive Guide

In today's fast-paced electronics world, JLCPCB has become a go-to for many when it comes to PCB manufacturing and assembly. But just like understanding the intricacies of a new computer, figuring out the [jlcpcb assembly price] can sometimes feel like deciphering a complex code. This article breaks down those complexities, giving you a clear picture of all the costs involved, from the initial setup to the final per-joint assembly fees. We'll also delve into extra charges, coupons, and practical tips to help you optimize your budget and make informed decisions, ensuring your project stays on track and within budget.

Core Components of JLCPCB Assembly Pricing

JLCPCB's assembly pricing is determined by a combination of fixed and variable costs, primarily comprising setup fees, stencil costs, and per-joint assembly costs, alongside minimum component quantity requirements. Understanding these core elements is crucial for accurately estimating the overall expenditure for your PCB assembly project.

The pricing structure is designed to accommodate various order volumes, complexities, and component requirements. Each of these core components plays a significant role in determining the final price. Therefore, being well-informed about each part of the pricing is a prerequisite to optimizing your PCB design for cost-effectiveness.

JLCPCB Setup Fees Explained

JLCPCB's setup fees are a foundational element of their assembly pricing structure, representing the initial costs incurred to prepare for the manufacturing process. These fees are applied per order and are designed to cover the expenses associated with preparing the assembly line, setting up the pick-and-place machines, and handling the initial programming for the specific PCB design. Understanding these fees is crucial for accurately estimating the overall cost of your PCB assembly project.

| Assembly Type | Setup Fee (Approximate) | Description |

|---|---|---|

| Single-Sided SMT Assembly | Variable (typically lower) | Setup fee for placing components on one side of the PCB. The cost is typically lower because of the reduced number of processes |

| Double-Sided SMT Assembly | Variable (typically higher) | Setup fee for placing components on both sides of the PCB. The cost is usually higher because of the complex setup and multi-pass assembly |

These setup fees are incurred irrespective of the quantity of PCBs you order within the same run. Therefore, it is generally more cost-effective to order a larger batch of PCBs in one go, which distributes these fixed costs over more units and reduces the per-board price. The specific cost varies, and it is essential to check the latest JLCPCB quotation to get an accurate value. Factors impacting the precise amount include the complexity of the assembly, the number of unique components, and current market conditions.

While these setup fees cannot be eliminated, careful planning can help mitigate their impact. Ordering larger quantities of PCBs, optimizing the design to reduce the number of unique parts, and taking advantage of JLCPCB's offers and discounts can help in reducing the overall project cost. For example, sticking to their basic parts library where possible can be beneficial in reducing the overall component costs, thus diminishing the influence of setup fees on the overall quote.

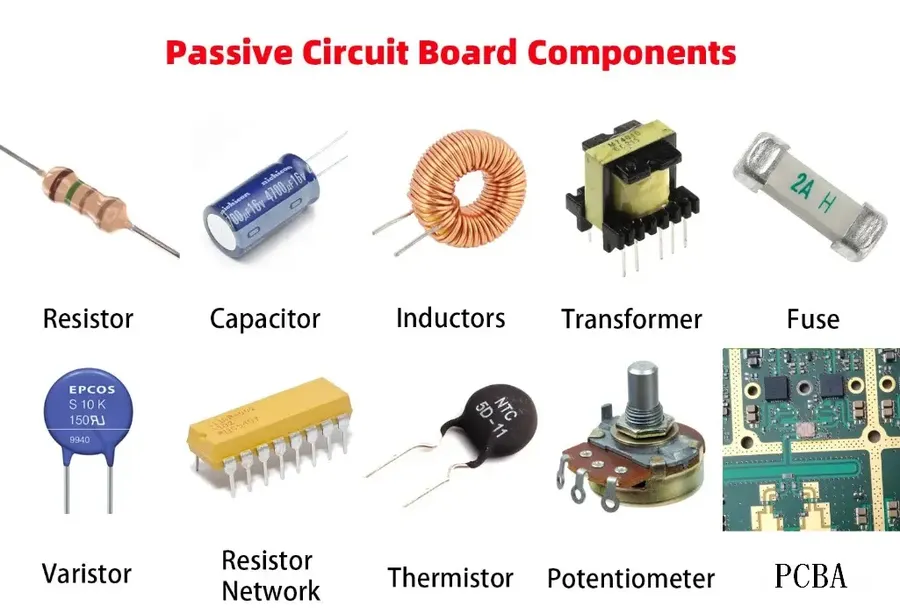

Per-Joint SMT Assembly Costs

The per-joint SMT (Surface Mount Technology) assembly cost is a fundamental component of JLCPCB's pricing model, directly reflecting the number of solder connections required on your printed circuit board. This cost is incurred for each soldered connection, also referred to as a 'joint,' which is essential for securing surface mount components to the PCB. Understanding this cost is crucial for accurately estimating the overall assembly expense.

The per-joint cost is not fixed and can vary based on factors such as the type of component and complexity of the solder process. It is important to note that this cost applies to every pad on the component that needs to be soldered to the board. For example, an SOIC-8 package with 8 pins will incur 8 joint costs, whereas a 0402 resistor with 2 pads will incur 2 joint costs.

To illustrate the impact of per-joint costs, consider the following example: If JLCPCB charges $0.0015 per joint and your PCB has 1000 joints, the total per-joint assembly cost would be $1.50. A more complex board with 5000 joints would result in a cost of $7.50. These costs directly contribute to the final price of your assembled PCB. Therefore, it is critical to consider the number of solder joints when designing and selecting components to optimize your budget.

| Component Type | Number of Pins/Pads | Per-Joint Cost (Example) | Total Cost (Example) |

|---|---|---|---|

| Resistor (0402) | 2 | $0.0015 | $0.003 |

| Capacitor (0805) | 2 | $0.0015 | $0.003 |

| SOIC-8 | 8 | $0.0015 | $0.012 |

| QFP-64 | 64 | $0.0015 | $0.096 |

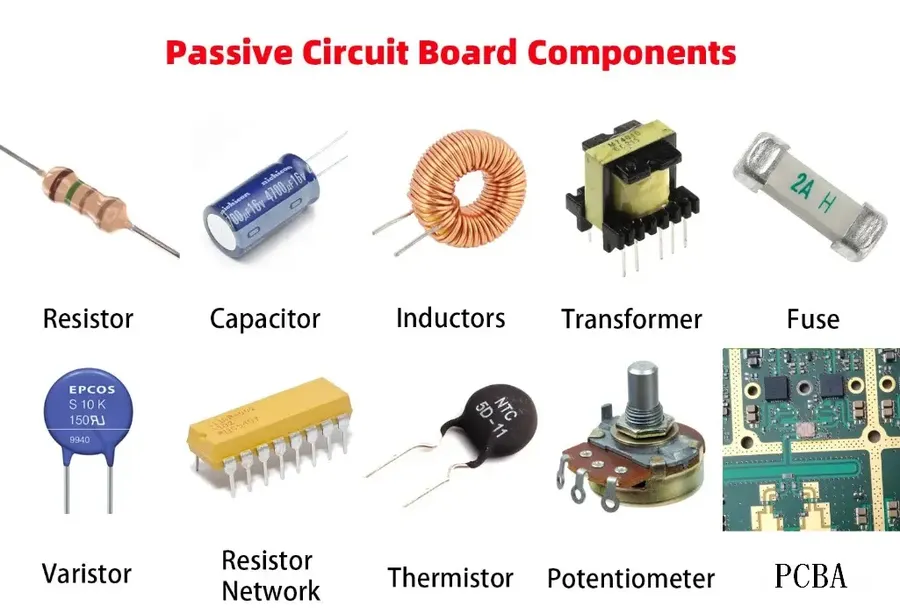

Stencil Costs: What You Need to Know

Stencils are crucial in the PCB assembly process, serving as a template to apply solder paste accurately onto the PCB pads before component placement. Understanding stencil costs is essential for accurate budgeting of your JLCPCB assembly project. This section details the importance of stencils and their cost implications.

The stencil facilitates the consistent application of solder paste to the correct locations and with the right amount for optimal soldering, ensuring reliable electrical connections. The cost associated with a stencil includes the material, manufacturing and if needed, a custom design which depends on the intricacy of the PCB.

At JLCPCB, stencils are available in several options including framed and frameless stencils, with the pricing dependent on the type of stencil and its size. Generally, framed stencils, which are pre-mounted on a frame, cost more than frameless stencils. Consider the requirements of your project when selecting the stencil option.

It’s important to know that the cost of the stencil is usually a one-time cost for a specific PCB design. If you order the same design in the future you can often reuse the same stencil, further driving down the cost of future assembly runs. This can be advantageous for larger production runs and iterative design processes. Furthermore, JLCPCB provides various stencil options, including stainless steel and chemical-etched stencils which can impact the overall cost.

The stencil, typically made from a thin sheet of stainless steel, contains precise openings that align with the solder pads on your PCB. Solder paste is applied through these openings, ensuring that the correct amount of paste is deposited on each pad, enabling efficient reflow soldering process. Stencils ensure accurate paste placement, preventing issues such as solder bridging and insufficient solder joints. Using a stencil ensures the reliable and consistent performance of the final assembled circuit board.

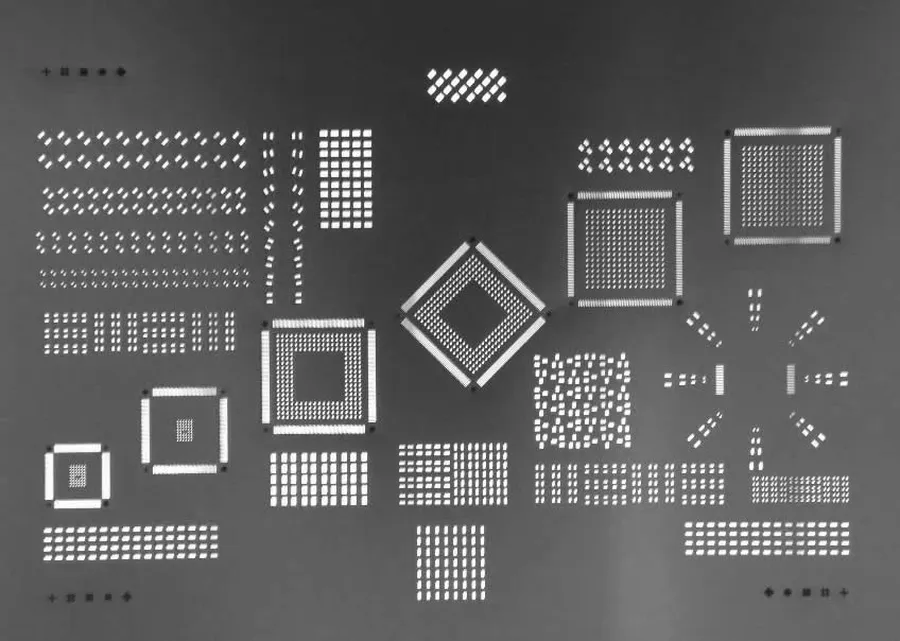

Minimum Component Costs and Quantity Considerations

JLCPCB's assembly service operates with a minimum component quantity policy that directly impacts the overall cost. This policy ensures efficient handling of parts during the assembly process. Even if your design requires fewer components, you will be charged for the minimum quantity defined by JLCPCB for each specific part. Understanding this mechanism is crucial for accurate cost estimation and efficient design practices.

The underlying principle is that, due to the automated pick-and-place machinery, parts are loaded onto feeder reels. To ensure smooth operation and account for setup and material handling losses, JLCPCB requires you to purchase a minimum quantity of each component, which is usually much more than one. This minimum is usually 10 for standard parts and can vary depending on availability and the type of component. Here's a more detailed breakdown:

- Minimum Purchase Quantity

Each component has a specific minimum purchase quantity. For instance, if a resistor has a minimum order of 15 units, you will be charged for 15 even if your board only uses 5. The cost of these 15 will be factored into your total assembly price. It is also noteworthy that some parts have a minimum quantity of 1 and that the minimum purchase quantity can be impacted by the availability of the parts - Impact on Component Cost

When the purchase quantity of a component exceeds the required number of components by your design, the cost per unit is determined by the total units purchased. JLCPCB does not provide credit or reimbursement for any surplus. For this reason it's critical to select part quantities that are within the required range. - Parts with a minimum order quantity of 1

While many components come with a minimum order quantity, it should be noted that some parts have a minimum quantity of 1.

| Scenario | Components Required | Minimum Purchase Quantity | Cost Calculation |

|---|---|---|---|

| Resistor (0603) | 5 | 15 | Cost of 15 resistors |

| Capacitor (0805) | 10 | 15 | Cost of 15 capacitors |

| IC Chip | 1 | 1 | Cost of 1 IC chip |

It is best to always check the minimum quantity for a part on the JLCPCB parts library before designing the board as it can have a major impact on costs. Careful planning and part selection is critical to optimizing the cost of PCB assembly when using JLCPCB.

Handling Extra Charges: When Do They Apply?

While JLCPCB strives for cost-effectiveness, certain situations may incur additional charges beyond the base assembly price. These extra costs typically arise from factors that increase the complexity or resources required for assembly, impacting the final JLCPCB assembly price. Understanding these circumstances is crucial for accurate budgeting and cost management.

- Larger Board Dimensions

Boards exceeding JLCPCB's standard size limits may be subject to extra charges. This is due to the increased material usage, handling complexity, and machine time required for larger PCBs. The specific dimensions that trigger these charges are detailed on their website; it's important to verify these limits before placing your order. - Sample Orders and Small Batches

Assembling very small quantities, particularly sample orders, often comes with higher per-unit costs. This is because setup costs are distributed over a smaller number of units. Although this may appear more expensive, it is necessary for prototyping and initial testing. - Non-Standard Component Packaging

Components supplied in non-standard packaging formats may incur extra charges. These formats often require additional time for handling and preparation, thus affecting overall assembly costs. It's advised to verify supported packaging formats to avoid extra costs. - Component Sourcing

If you choose to have JLCPCB source components not included in their basic component library, this could result in additional sourcing fees. These fees reflect the time and resources JLCPCB invests in procuring these specialized parts. - Insufficient Documentation

Submitting incomplete or unclear Bill of Materials (BOM) or Gerber files can cause delays and may result in extra charges, especially if JLCPCB’s engineers must intervene to correct these issues, which may require significant time. Therefore, it's important to always double-check all documents before submitting them. - Special Processes or Requirements

Any special processes or additional requirements that fall outside standard assembly procedures may lead to added costs. Examples include very intricate placement needs, extra cleaning, special soldering profiles and requirements beyond their common process capabilities.

Coupons, Discounts, and Free Assembly: How to Save Money on JLCPCB Assembly

JLCPCB offers various promotional opportunities to reduce assembly costs, including monthly coupons, free assembly for certain PCB types, and special discounts. These initiatives can significantly lower the overall price, making it crucial for customers to stay informed about these opportunities.

- Monthly Coupons

JLCPCB frequently provides monthly coupons that can be applied during checkout. These coupons may offer a percentage discount or a fixed amount off the total order. It's recommended to check their website regularly for updated coupons and terms. - Free Assembly for 1-6 Layer PCBs

JLCPCB often provides free assembly services for standard 1 to 6-layer PCB designs, which means you don’t have to pay the per-joint cost for components. This is a significant cost saving if your project fits within these parameters, however, standard set-up fees still apply. Verify this at checkout as this is not always offered. - Special Discounts

JLCPCB runs special promotional campaigns throughout the year, offering discounts on various services, including PCB assembly. Keep an eye on their promotions page or newsletter to seize opportunities when they arise. - Volume Discounts

For larger orders or frequent customers, JLCPCB sometimes offer volume discounts which can reduce overall costs. It’s best to speak to customer support if you have ongoing or larger needs.

Frequently Asked Questions About JLCPCB Assembly Pricing

Navigating the complexities of JLCPCB assembly pricing can be challenging. This section addresses common questions to clarify the cost structure and processes involved in their PCB assembly service.

- How much does JLCPCB charge for assembly?

JLCPCB's assembly costs are variable, comprising setup fees, stencil costs, and per-joint assembly charges. The total cost is contingent on the complexity of the PCB, number of components, and order volume. It is essential to use their online quote system for an accurate estimate based on your specific design. This tool will provide a detailed breakdown of costs, including both parts and labor. - What is the JLCPCB engineer fee and when does it apply?

The 'engineer fee' at JLCPCB is a charge for the work involved in reviewing your design and preparing it for assembly. This is not a fixed fee. While there isn’t a explicitly labeled ‘engineer fee’ in the standard costing, this is accounted for within the Setup Fee. Therefore, the setup fee could be viewed as encompassing the ‘engineer fee’. This is charged only once per design within the same order, usually when you have a design that requires manual checks or specific adjustments. - How much does it cost to get a PCB assembled at JLCPCB?

The total cost for PCB assembly at JLCPCB depends on several factors: the number of components, the complexity of your board, the order quantity, and any special requirements. A small, simple board with few components might cost only a few dollars to assemble, whereas a complex design with hundreds of components can range from a few tens to hundreds of dollars. It's important to use their online quotation tool to get a precise cost estimate. - How long does the JLCPCB assembly take?

The JLCPCB assembly time varies depending on the complexity and volume of the order. Simple assemblies may only take a few days, while more intricate projects or larger quantities may extend the lead time. Generally, the assembly process includes order processing, component sourcing, stencil creation, assembly, and quality checks. JLCPCB provides estimated lead times for each stage in their ordering process. - Are there any minimum component purchase requirements for assembly?

Yes, JLCPCB often requires purchasing components in minimum quantities, sometimes even if the total needed is less. For instance, you might need to buy 15 units of a resistor, even if only 10 are required for the board. This policy is implemented to manage their inventory and to reduce waste from cut tape. The online ordering system clearly shows minimum quantities, which are factored into the final cost. - Can I use my own components for JLCPCB assembly?

Yes, JLCPCB allows for the use of customer-supplied components. However, there is an additional handling fee associated with this. You are responsible for ensuring all supplied components meet their requirements, are properly packaged, and arrive on time. It is critical that you carefully pack and label all components, and comply with all of their terms and conditions for this service. - How are stencil costs handled in the assembly process?

A stencil is essential for applying solder paste onto a PCB before components are placed. JLCPCB charges a one-time fee for each unique stencil design. The stencil cost varies depending on size, material, and technology (e.g., laser-cut stencils). This cost is separate from the assembly cost and is usually calculated per order, not per piece.

JLCPCB Assembly vs. Competitors: A Quick Comparison

Choosing a PCB assembly service requires careful consideration of pricing, capabilities, and turnaround time. This section compares JLCPCB's assembly service with other popular providers like PCBWay, focusing on key differences in cost structures and service offerings.

| Feature | JLCPCB | PCBWay |

|---|---|---|

| Setup Fee (Single-sided) | Variable, often lower for basic assembly | Typically higher, especially for complex designs |

| Setup Fee (Double-sided) | Variable, more expensive then Single-sided | Typically higher, especially for complex designs |

| Per-Joint SMT Assembly Cost | Competitive pricing, varies by component | Slightly higher, may offer quantity-based discounts |

| Stencil Cost | Separate cost, can be reusable | Included in setup fee or a separate cost |

| Minimum Order Quantity | Flexible MOQs, but may have minimums for certain parts | May impose strict MOQs |

| Component Sourcing | Extensive parts library with basic parts | Broader part selection, more advanced options |

| Turnaround Time | Generally fast, but depends on complexity | Variable, may be longer for complex jobs |

| Assembly Capabilities | Good for standard SMT and through-hole assembly | Supports advanced assembly processes and complex boards |

| Promotions & Discounts | Frequent coupons and special offers | May offer project-based discounts |

Key distinctions arise in the handling of setup fees and component availability. JLCPCB frequently offers more budget-friendly options for simple projects, while PCBWay presents a broader range of component choices and specialized assembly services, which often entail higher costs. The decision between these platforms should consider the complexity of the project, budget, and component requirements. Consider exploring reviews, forums like Reddit, or detailed pricing models to refine your choice, ensuring you meet both your quality standards and your budget. In summary, JLCPCB often provides a cost-effective solution for standard PCB assembly, while PCBWay caters more to complex or specialized projects that may require a wider array of component options or more advanced assembly processes, with a premium on cost.

Understanding [jlcpcb assembly price] requires careful consideration of various factors like setup fees, per-joint costs, and potential extra charges. By understanding these elements and leveraging discounts and coupons, you can optimize your spending on PCB assembly. JLCPCB provides a range of services that can cater to different budget levels, from hobbyists to large businesses. As technology evolves, we can expect even more advancements and cost optimizations in PCB assembly, which will further reduce costs and enable even more creative and groundbreaking designs.

AnyPCBA

AnyPCBA