Decoding PCBWay Assembly Cost: A Comprehensive Guide

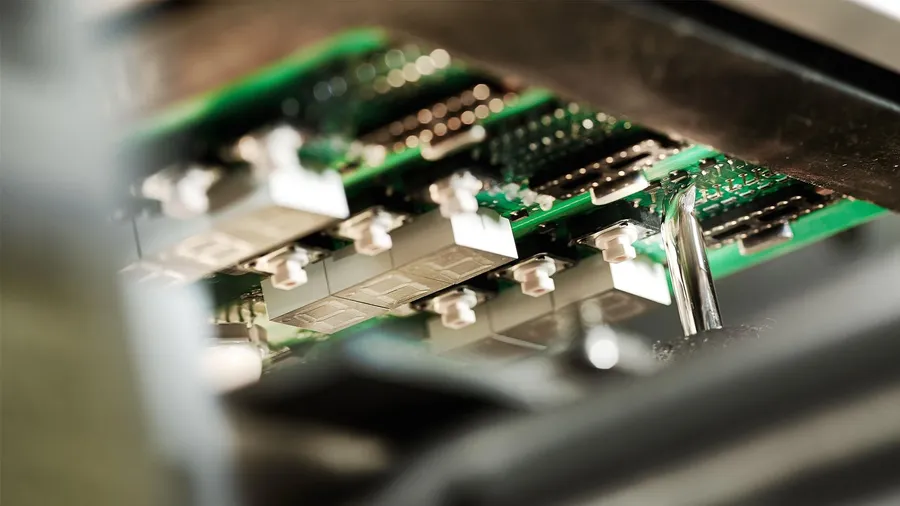

In today's interconnected world, printed circuit boards (PCBs) are the backbone of countless electronic devices. From smartphones to complex industrial machinery, PCBs enable functionality. PCBWay stands as a popular choice for both PCB fabrication and assembly. But what impacts the PCBWay assembly cost? Whether you are a seasoned engineer or a hobbyist, understanding the cost drivers can save you money and time. This guide will walk you through everything you need to know to get the best PCB assembly cost at PCBWay and answer all the questions you might have.

Key Factors Influencing PCBWay Assembly Cost

The final cost of PCB assembly at PCBWay is a multifaceted calculation influenced by several key factors. Understanding these elements is crucial for effective budgeting and cost management in your electronics projects. These factors range from the fundamental type of assembly to the intricacies of component sourcing and board complexity.

- Assembly Type

The method of component placement significantly impacts cost. Surface Mount Technology (SMT), through-hole, or mixed assemblies each have unique processes and pricing implications. SMT is generally less expensive for smaller components, while through-hole may incur higher costs due to manual insertion and wave soldering. Mixed assembly may be more expensive because of the combined SMT and through-hole assembly processes. - Component Count

The sheer number of components directly correlates with assembly time and material usage. Each component requires precise placement, potentially involving automated or manual processes. Thus, a higher component count typically translates to a higher overall assembly cost. - Board Complexity

The intricacy of the PCB design, including the number of layers, component density, and use of special materials, also impacts cost. A design with many layers will cost more because of the manufacturing process and the time involved. High component density can also drive up costs due to more complex assembly. Certain materials or requirements may incur additional expenses. - Component Sourcing Options

How components are procured—whether through PCBWay’s turnkey service or by consignment—influences the overall project cost. Turnkey involves PCBWay handling the purchasing and sourcing of all components, which has a higher initial cost but reduces the burden on the user. Consignment, where the customer provides all the components, can lower costs, but requires more involvement from the user and can introduce schedule risks if parts are not delivered in time or are incorrect.

Understanding the Base Assembly Fees

PCBWay's assembly service includes base fees that form the initial cost component, and it's vital to understand how these are structured, as these costs can vary based on several factors, primarily the quantity of boards being assembled and the complexity of the board.

The base assembly fee is typically a fixed cost for each order, regardless of the number of components. It is charged to cover setup costs for the assembly process, including machine programming and stencil preparation. This fee is essentially an overhead cost that PCBWay incurs for every assembly job.

While the base fee may be a fixed cost per order, it can scale based on factors such as the number of boards in each production run, with high volume orders often experiencing lower per-unit base fees, reflecting economies of scale.

| Order Quantity | Base Fee (Example) | Per-Unit Base Fee (Example) |

|---|---|---|

| 1-5 Boards | $50 | $10 - $50 |

| 6-20 Boards | $75 | $3.75 - $12.5 |

| 21-50 Boards | $100 | $2 - $4.76 |

| 50+ Boards | $150 | $3 or less |

It's important to note that the example base fees listed above are for illustrative purposes only and do not reflect real pricing from PCBWay. It is critical to consult their website directly for the most up-to-date and accurate costs. Base assembly fees can also be dependent on current market factors, so it is wise to receive a quote from PCBWay prior to production.

Component Sourcing and Its Impact on Cost

After the cost of PCB fabrication, component sourcing typically represents the most substantial expense in PCB assembly. PCBWay provides various options for component procurement, but it is essential to understand their associated markups to manage costs effectively. Strategic component selection can significantly influence the overall project budget.

- PCBWay's Component Sourcing Options

PCBWay offers both a full turnkey option, where they source all parts, and a consignment option, where you supply the components. Each option has its implications on cost, lead time, and project management. - Markup on Components

When PCBWay sources components for you, they will apply a markup to cover their procurement costs, handling, and risk. These markups can vary based on component type, availability, and quantity. Understanding these markups is important for cost estimation. - The Importance of Strategic Component Selection

Choosing components wisely can have a substantial impact on your overall assembly costs. Opting for standard, readily available components, rather than specialized or hard-to-source parts, can reduce procurement costs and lead times. - Impact of Component Availability

Component shortages and market fluctuations can directly affect sourcing costs. Being flexible with your designs can help to avoid using components with long lead times, and reduce costs.

| Factor | Impact on Cost | Mitigation Strategies |

|---|---|---|

| Component Type | High cost for specialized or low-volume components. | Choose standard, readily available parts. |

| Sourcing Method | Turnkey assembly has higher costs due to component markup. | Consider consignment assembly with careful planning. |

| Component Availability | Parts shortages increase prices and can delay projects. | Plan and check component availability in advance. Consider using alternative components that are functionally equivalent and readily available. |

| Order Volume | Low-volume orders increase the per-unit cost of components. | Order components in optimal quantities to reduce individual unit costs. |

Turnkey vs. Consignment Assembly at PCBWay

PCBWay provides two primary assembly options: turnkey and consignment. Selecting the appropriate method is essential for balancing budget and project management needs. Understanding the nuances of each approach is crucial for making an informed decision.

| Feature | Turnkey Assembly | Consignment Assembly |

|---|---|---|

| Component Sourcing | PCBWay sources all components | Customer provides all components |

| Cost | Higher due to component sourcing and handling | Lower assembly cost; customer bears component cost |

| Lead Time | Potentially faster overall lead time, all components sourced in one place | Lead time depends on customer providing components on-time |

| Responsibility | PCBWay handles component procurement and inventory management | Customer is responsible for component procurement, quality, on-time delivery, and inventory management |

| Suitability | Ideal for projects needing quick turnaround, large quantities, or where internal component sourcing is a challenge | Ideal for projects with tight budgets, specialized components, and strict control over component selection, lower labor costs |

Turnkey assembly at PCBWay entails them handling all aspects of the assembly process, including parts procurement and assembly. This approach streamlines the production process by having the manufacturer manage the component supply chain. Conversely, consignment assembly involves the customer providing all the necessary components to PCBWay for assembly. The cost benefits of consignment assembly must be balanced against the added workload of acquiring and managing parts on the customer's end. Selection between turnkey and consignment depends on the priorities of the project, balancing cost, speed, and the need for component control.

Detailed Breakdown of Component Costs

Understanding the intricacies of component costs is crucial for effective budget management in PCB assembly. PCBWay, like other assembly services, calculates these costs based on several factors, including component type, quantity, and sourcing.

| Component Type | Cost Drivers | Cost Variation Factors | Potential Additional Fees |

|---|---|---|---|

| Resistors and Capacitors | Size (e.g., 0603, 0805), Tolerance, Quantity | Standard vs. Precision, Brand, Availability | Markup for Non-standard Values or Tolerances |

| Integrated Circuits (ICs) | Complexity, Package Type (e.g., SOIC, QFP, BGA), Functionality | Market demand, Lead Time, Availability | Programming or Testing Fees, Special Handling |

| Diodes and Transistors | Power Rating, Voltage, Current, Package Type | Specific part availability, Lead time | Markup for Non-standard specifications |

| Connectors and Headers | Pin Count, Type (e.g., SMT, Through-hole), Material | Availability of Specific connectors, Plating Material | Markup for unusual connectors |

| Specialty Components (e.g., sensors) | Specific function, integration complexity | Market availability, lead time | Markup for niche components |

Beyond the component cost itself, PCBWay may apply additional charges. These can include a markup on the purchased components, handling fees, and potentially extra fees for specialized components. Furthermore, components with specific requirements, like precise tolerance or high power ratings, may have an increased cost due to sourcing challenges or the necessity for specialized testing and handling. It's essential to note that components that are sourced and stocked at PCBWay will be generally more cost-effective than components that need to be specifically sourced and purchased for a low quantity order.

The Impact of Board Complexity on PCBWay Assembly Cost

The complexity of a PCB design exerts a considerable influence on the final assembly cost at PCBWay. Factors such as the number of layers, component density, and the utilization of specialized materials all contribute to variations in cost. Complex designs may necessitate more sophisticated assembly processes, potentially increasing component sourcing expenses due to difficulty in obtaining certain components. This section details how these design parameters affect the overall assembly cost.

| Complexity Factor | Impact on Assembly Cost | Additional Considerations |

|---|---|---|

| Number of Layers | Increased cost due to more complex fabrication and assembly processes. | Multi-layer boards require more precise alignment and handling. |

| Component Density | Higher density leads to increased placement complexity and potential need for specialized equipment. | Fine-pitch components increase placement difficulty. |

| Specialized Materials | Specialized materials such as High-Tg or Rogers materials, may have higher material costs and require specific assembly processes, increasing cost. | Availability of these materials can affect lead time. |

| Fine Pitch Components | Components with fine pitch lead to the need for more complex assembly processes and increase the chance for rework. | Component cost may be increased due to difficulty in sourcing. |

| Board Size | Larger board sizes can increase the cost of fabrication and the assembly processes. | Larger boards may require custom reflow oven pallets. |

In summary, designers should weigh the benefits of a complex PCB design against the increased assembly costs. Simplifying the design where possible, optimizing for standard components, and choosing readily available materials can lead to significant savings.

Frequently Asked Questions About PCBWay Assembly Cost

Understanding the costs associated with PCB assembly at PCBWay can be complex. This section addresses common questions to provide clarity and help you make informed decisions.

- How much does it typically cost to get a PCB assembled at PCBWay?

The cost of PCB assembly at PCBWay varies significantly depending on several factors. These include the type of assembly (SMT, through-hole, mixed), the number of components, the complexity of the board design (number of layers, component density), component sourcing (turnkey or consignment), and the order quantity. It's not possible to give a single definitive cost, however, a simple 1-2 layer board with basic SMT assembly and a quantity of 5, may have an assembly cost in the $10-50 range. A more complex board can easily cost hundreds of dollars to assemble due to increased labor and component costs. - How can I calculate my PCB assembly cost at PCBWay?

PCBWay provides an online quote tool where you can upload your BOM (Bill of Materials) and Gerber files. The tool will analyze your design and provide an estimated cost, including fabrication and assembly. This tool will give you a breakdown of costs. This can help in understanding how each element influences pricing. It's important to carefully review the quote to understand the different cost elements such as component costs, assembly fees and shipping costs. Pay particular attention to any applicable setup or NRE (Non-Recurring Engineering) charges. - Does PCBWay offer PCB assembly services?

Yes, PCBWay provides comprehensive PCB assembly services. They support both turnkey assembly, where they source all the components, and consignment assembly, where you provide the components. PCBWay offers SMT (Surface Mount Technology), through-hole, and mixed assembly options. The website also has many resources detailing its assembly capabilities, including maximum board size and components. PCBWay’s website is the best place to confirm specific capabilities. - Why can PCB assembly be so expensive?

PCB assembly can be expensive due to several factors. These include the labor involved in setting up the assembly lines, the cost of the components themselves, the complexity of the board, the precision required for placing components accurately, and quality control processes. Additionally, factors such as the cost of tooling, especially for complex boards, can impact cost. Furthermore, if you choose a turnkey solution, then PCBWay also adds in the sourcing of the components and any associated markups. Low order quantities also increase cost due to setup and NRE charges being spread across less units. - What are the differences between turnkey and consignment assembly at PCBWay and which is more cost effective?

Turnkey assembly means PCBWay will source all the necessary parts for your PCB assembly. This has the advantage of being faster to get your boards in hand and offloading the responsibility for correct parts, and ensuring they are there on time, to PCBWay. Consignment assembly means you provide the parts to PCBWay, This can be a good option for more advanced designs or if you already have parts. Turnkey assembly often carries higher upfront costs due to material sourcing, but may save you time and hassle. Consignment assembly may reduce assembly fees, however, you are responsible for the parts arriving on time. If you choose consignment assembly you will need to provide an accurate and complete BOM to PCBWay. - What is the impact of component type on assembly cost at PCBWay?

The cost of components directly impacts the overall assembly cost. Resistors and capacitors are generally inexpensive. Complex ICs (Integrated Circuits), especially those with limited availability, can be very costly. Special components like connectors or sensors may also impact price due to availability and material type. The PCBWay system will source the best priced parts available at the time you place your order. It's best to optimize your BOM to use cost effective and readily available components whenever possible.

Tips for Reducing PCBWay Assembly Cost

Reducing PCB assembly costs at PCBWay requires a strategic approach, focusing on design optimization, component selection, and efficient ordering practices. Implementing these tips can lead to significant savings without compromising the quality and functionality of your electronic product.

- Optimize Component Footprints

Utilize standard component footprints whenever possible. This reduces the complexity of the assembly process and the potential for errors, often resulting in lower costs. - Standardize Component Selection

Opt for commonly available and cost-effective components. The price of components can vary significantly based on availability and demand. Using standard components lowers sourcing costs and lead times. - Optimize the Bill of Materials (BOM)

Carefully review your BOM to ensure you are using cost-effective equivalents where possible. Consider using components with lower tolerances where the application allows to save money without impacting functionality. - Design for Manufacturability (DFM)

Adhering to DFM principles can simplify assembly, reduce error rates, and avoid costly rework. These include appropriate component spacing, pad sizes, and trace widths. - Panelize your Designs

If applicable, panelize your PCB designs to increase efficiency in assembly. Panelization allows for multiple PCBs to be processed simultaneously, thereby reducing per-unit costs. - Thorough Design Testing

Invest time in prototyping and testing your design thoroughly before assembly. This minimizes the need for multiple iterations and costly rework during the production phase. - Plan for Volume Ordering

When possible, plan your projects for volume ordering. As with many manufacturers, larger orders often qualify for significant discounts, resulting in lower per-unit assembly costs.

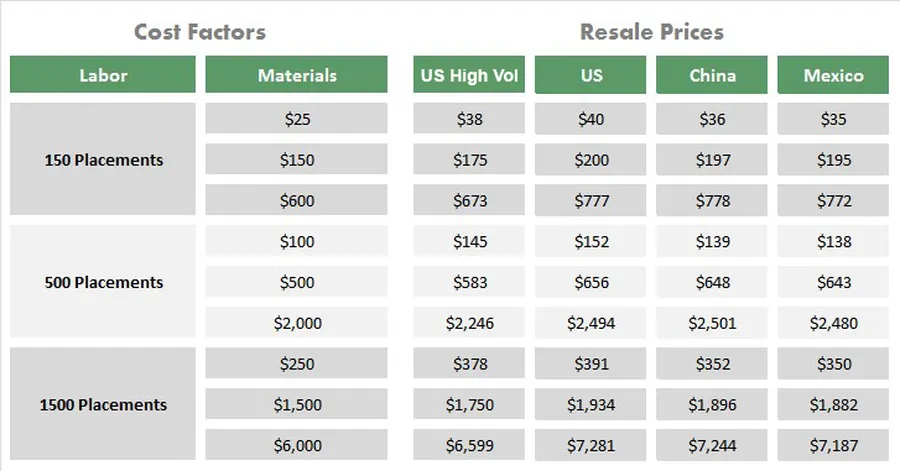

PCBWay vs. Competitors: Pricing Comparison

When selecting a PCB assembly service, a thorough cost-benefit analysis is essential, extending beyond just the unit price. This section compares PCBWay with key competitors like JLCPCB, focusing on pricing, lead time, and quality, to aid in making a well-informed decision.

| Feature | PCBWay | JLCPCB | Other Potential Competitors |

|---|---|---|---|

| Assembly Pricing (Small Batch) | Competitive, varies with complexity and components | Often lower for standard components, higher for specialty | Varies widely, requires individual quotes |

| Assembly Pricing (Large Batch) | Negotiable for volume orders, potential discounts available | Volume discounts often less aggressive than others | Significant bulk discounts available from several |

| Lead Time (Assembly) | Standard lead time can vary, expedited services available for a premium | Generally fast, but can vary with complexity | Highly variable; depends on location and load |

| Component Sourcing | Extensive library, potential for markups | Good selection, but sourcing constraints on uncommon components | Some have strong partnerships and can source at lower cost |

| Assembly Quality | Generally good, reports of occasional issues that are often resolved | Generally good, but may vary | Quality often depends on the individual assembly house |

| Turnkey Options | Available, streamlining the assembly process | Available, but may have limited component options | Varies; some offer full turnkey and some consignment |

| Consignment Options | Available for cost savings | Available, requires meticulous preparation of parts | Available, terms and procedures vary greatly |

| Customer Service | Responsive, but there are reports of varying issue resolution times | Strong reputation for customer support | Variable customer support, can be a differentiator |

The above table provides a comparative overview, however, each project has different specific needs. It is paramount that one understands their requirements before making a choice. PCBWay offers a reliable service, and while they are more costly than JLCPCB, it is important to balance the total cost with quality and responsiveness.

Understanding PCBWay assembly cost involves navigating various interconnected factors, from the base assembly fees to component sourcing and design complexity. By carefully considering all these elements, you can optimize your budget and achieve cost-effective, high-quality PCB assembly with PCBWay. Keep in mind that pcbway assembly costs are variable based on the components, quantities, and time required. Always get a quote first before making a decision. With detailed understanding of these drivers, you can make the best decisions for your project’s budget and goals.

AnyPCBA

AnyPCBA