Decoding Printed Circuit Assembly Price: A Comprehensive Guide

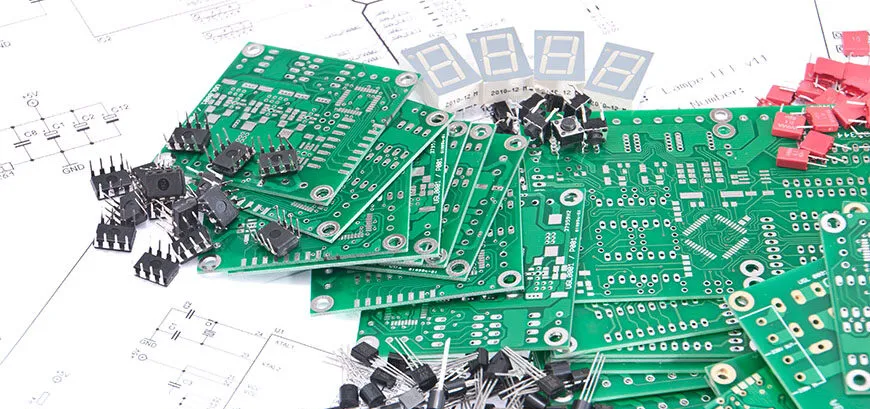

In today's technology-driven world, printed circuit assemblies (PCAs) are the backbone of countless electronic devices. The printed circuit assembly price directly impacts product cost and profitability, making cost optimization crucial. This guide explores the intricacies of PCA pricing, offering insights into cost drivers and effective strategies for managing your budget. Understanding the nuances of PCB assembly is crucial for both hobbyists and large manufacturers.

Key Factors Influencing Printed Circuit Assembly Price

The price of a printed circuit assembly (PCA), also known as a printed circuit board assembly (PCBA), is determined by a confluence of factors. Material costs, design complexity, and labor expenses are primary drivers, but manufacturing processes, turnaround time, and order quantity also significantly influence the final price. Understanding these key factors is crucial for accurate cost estimation and effective budget management when procuring PCBAs.

| Factor | Description | Impact on Price |

|---|---|---|

| Material Costs | Cost of PCB substrate, components (resistors, capacitors, ICs), and surface finishes. | Directly proportional. Higher grade materials and specialized components increase the price. |

| Design Complexity | Number of layers, component density, use of vias, fine-pitch components, and specialized features. | Positive correlation. More complex designs require advanced manufacturing techniques, resulting in higher costs. |

| Labor Costs | Expenses associated with assembly processes, including manual labor and automated equipment operation. | Variable. Influenced by location of production and the level of automation. |

| Manufacturing Processes | Selection of SMT, through-hole assembly, wave soldering, reflow soldering, etc. | Process selection and setup contribute significantly to the overall cost. |

| Turnaround Time | Lead time requirements (e.g., standard vs. expedited). | Inverse relationship. Faster turnarounds require prioritization and usually incur higher charges. |

| Quantity | Number of PCBA units ordered. | Inverse relationship. High-volume orders benefit from economies of scale, reducing the per-unit price. |

Material Costs and Their Impact on PCB Assembly Price

The selection of materials for Printed Circuit Board Assembly (PCBA) is a critical factor that significantly influences the final price. Material costs encompass the PCB substrate, electronic components, and surface finishes. Each choice has a direct bearing on the manufacturing process and, consequently, the overall expense. Optimizing material selection is crucial for achieving cost-effective PCBA without compromising quality or performance.

| Material Category | Material Options | Cost Impact | Considerations |

|---|---|---|---|

| PCB Substrate | FR-4, Aluminum, Flexible materials (e.g., polyimide) | FR-4 is cost-effective, aluminum adds to cost, flexible materials are premium | Application environment, thermal requirements, flexibility needs |

| Electronic Components | Standard passives (resistors, capacitors), ICs, connectors, specialized parts | Standard parts are lower cost, ICs and specialized parts contribute significantly to cost | Functionality, availability, lifecycle management |

| Surface Finishes | HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), Immersion Tin/Silver | HASL is generally the least expensive, ENIG provides better solderability but is more costly, Immersion Tin/Silver are mid-range | Environmental exposure, solderability, shelf life |

For example, FR-4 is the most common and affordable substrate, suitable for many standard applications. However, for high-frequency or high-temperature applications, materials like Rogers or ceramic may be necessary, significantly increasing material costs. Similarly, the choice between standard passives and specialized integrated circuits will affect the budget dramatically. The final material costs will also be greatly influenced by market forces, including raw material availability, supply chain issues, and the cost of manufacturing processes.

The Role of Design Complexity in PCBA Costs

The design complexity of a Printed Circuit Board Assembly (PCBA) is a pivotal factor influencing its final cost. Intricate designs necessitate more sophisticated manufacturing processes, precise component placement, and potentially specialized equipment, all of which contribute to increased expenses. Understanding these complexities is essential for effective cost management.

- Multilayer PCBs

PCBs with multiple layers (more than two) significantly raise production costs due to the intricate manufacturing required for layer alignment, interconnection, and lamination. Each additional layer adds complexity to the manufacturing process, demanding higher precision and more sophisticated equipment. - Component Density

The density of components on a PCB plays a substantial role in cost. Higher densities demand more meticulous pick-and-place processes, finer soldering techniques, and may require advanced inspection methods. This increase in precision and effort results in higher costs. - Fine Pitch Components

Components with very small pin pitches (distance between pins) require higher precision during placement and soldering. Such processes often require specialized equipment and higher skill levels, impacting the overall assembly price. Fine-pitch components also increase the risk of manufacturing defects, requiring more thorough testing and rework. - Specialized Features

Unique features such as blind vias, buried vias, impedance control, and microvias require advanced manufacturing techniques. These features improve the performance of the PCB but also substantially increase manufacturing cost due to the extra processes involved. - Complex Routing

Intricate trace routing, particularly in high-speed designs, may necessitate additional layers or advanced fabrication techniques. More complex routing not only increases the cost of the PCB board itself but also the time and effort required to assemble the board with components.

Labor Costs and Their Effect on Printed Circuit Assembly Price

Labor costs are a significant component of the overall printed circuit assembly (PCBA) price, influenced by the level of automation and the geographical location of the assembly facility. The balance between manual labor and automation directly affects production efficiency and cost.

The impact of labor costs on PCBA pricing is multifaceted, encompassing not just wages but also the expertise required for complex assembly tasks. Regions with lower labor costs may offer more competitive prices, but this advantage must be weighed against factors like potential differences in quality and technological capabilities. This section delves into these nuances to provide a clearer understanding of how labor costs shape PCBA pricing.

| Factor | Manual Assembly | Automated Assembly |

|---|---|---|

| Initial Investment | Lower | Higher |

| Labor Costs | Higher | Lower per unit |

| Production Speed | Slower | Faster |

| Accuracy | Subject to human error | Higher precision |

| Flexibility | Higher flexibility for complex designs | Limited flexibility |

| Scalability | Less scalable | Highly scalable |

The geographic location of the assembly facility plays a pivotal role due to varying labor rates and standards. Regions with lower labor costs might reduce PCBA prices, but this should be balanced against potential drawbacks in quality control, turnaround times, and the availability of skilled personnel. Conversely, regions with higher labor costs may provide higher quality and a faster turnaround, however this can result in a greater overall expense.

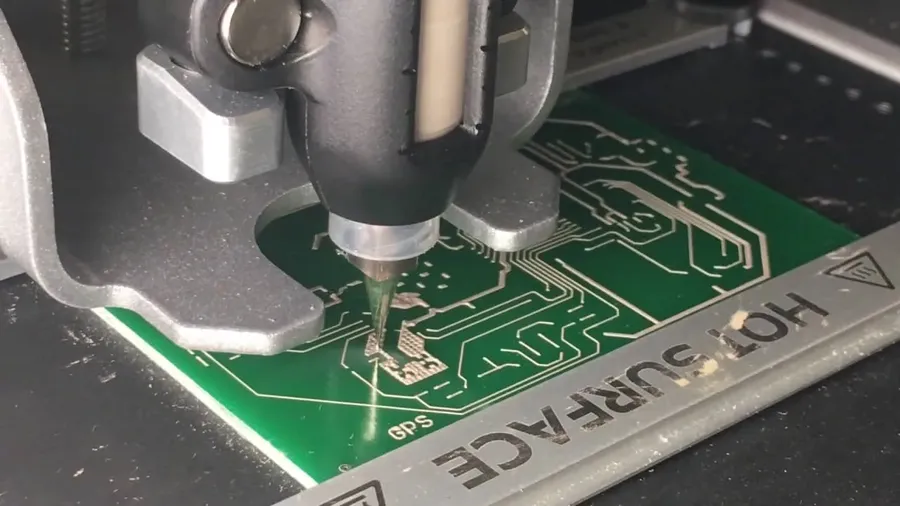

Manufacturing Processes and Their Influence on PCB Assembly Price

The selection of manufacturing processes significantly impacts the final printed circuit assembly (PCA) price. Different techniques, such as Surface Mount Technology (SMT) and Through-Hole Technology (THT), each with unique cost structures, are employed depending on design requirements and component types. Understanding these differences is crucial for cost-effective PCA production.

| Manufacturing Process | Description | Cost Implications | Suitable Applications |

|---|---|---|---|

| Surface Mount Technology (SMT) | Components are mounted directly onto the surface of the PCB. Automated processes are typically employed. | Generally lower labor costs due to automation, but requires more precise equipment and higher initial setup costs. Suitable for smaller, high-density boards. | High-volume production, small components, surface mount devices (SMDs) |

| Through-Hole Technology (THT) | Components have leads that are inserted into holes on the PCB and soldered on the opposite side. Often requires manual labor for insertion and soldering. | Higher labor costs due to manual processes but more robust connections. Suitable for larger, heavier components or components with high mechanical stress. | Larger components, connectors, components requiring high mechanical strength |

| Mixed Assembly (SMT and THT) | Combines both SMT and THT on the same PCB to leverage the benefits of each. | Moderate to high cost due to additional steps. Offers flexibility but requires skilled technicians. | Boards with a mix of small SMDs and larger THT components |

The choice between SMT and THT, or a combination, is not merely a technical decision but a significant cost driver. Factors such as the complexity of the design, the types of components used, and the required production volume dictate the most appropriate process and associated costs.

Turnaround Time and Its Impact on PCB Assembly Price

Expedited manufacturing and assembly timelines significantly influence the final printed circuit assembly (PCBA) price. The urgency of a project directly correlates with increased costs, as manufacturers must often prioritize these orders, disrupting standard production schedules and potentially incurring additional expenses. Understanding this relationship is crucial for effective cost management.

The impact of turnaround time on PCBA pricing stems from several factors. Shorter lead times may require manufacturers to allocate resources away from other projects, leading to overtime pay for staff and potentially higher costs for expedited shipping of components and raw materials. Additionally, rush orders typically involve higher per-unit costs due to the disruption of planned production flow and the need for quick response from all departments involved.

Conversely, allowing ample time for PCB assembly can lead to cost savings. Manufacturers can optimize their production schedules, procure materials more efficiently, and avoid premium prices for expedited services. This approach also reduces the likelihood of errors due to rushed processes, potentially saving on rework costs. Therefore, the trade-off between turnaround time and assembly cost should always be considered.

| Turnaround Time | Impact on Price | Potential Trade-offs |

|---|---|---|

| Standard Lead Time | Lower Cost | Longer wait times |

| Expedited Lead Time | Higher Cost | Faster delivery, but increased risk of errors and rework. |

| Same-Day or Next-Day Rush | Significantly Higher Cost | Extremely rapid delivery, but can lead to significant costs and very low flexibility for design changes. |

Quantity and Its Impact on Printed Circuit Assembly Price

The quantity of printed circuit assemblies (PCBs) ordered directly influences the per-unit cost due to economies of scale. Larger production runs typically result in lower individual prices, a principle rooted in the distribution of fixed costs across a greater number of units.

This effect is not merely a linear reduction. Instead, the cost reduction curve tends to flatten out at higher production volumes. Initial price drops per unit are most significant when moving from prototype to low-volume production. As quantities continue to increase, the rate of price reduction decreases as well, due to diminishing returns.

| Production Quantity | Per-Unit Price Trend | Cost Drivers |

|---|---|---|

| Prototype (1-10 units) | Highest | Setup costs, manual processes |

| Low-Volume (10-100 units) | High | Some automation, component setup |

| Medium-Volume (100-1000 units) | Medium | Increased automation, bulk component purchasing |

| High-Volume (1000+ units) | Lowest | Maximized automation, volume discounts |

Several factors contribute to this phenomenon. With larger orders, manufacturers can optimize their production lines and reduce setup times. Bulk purchasing of components often yields significant cost savings which are then passed on to the customer. Further, automation is more cost effective with higher quantities, minimizing the labor costs per unit. However, warehousing, potential obsolescence of components, and risk of design changes are factors that a manufacturer must consider when quoting for larger quantities.

Frequently Asked Questions About Printed Circuit Assembly Price

Understanding the costs associated with printed circuit assembly (PCA) can be complex, as numerous factors influence the final price. This section addresses common questions to provide clarity on PCA pricing.

- How much does it generally cost to assemble a PCB?

The cost to assemble a PCB varies widely depending on complexity, volume, materials, and labor. It can range from a few dollars for simple, low-volume boards to hundreds or even thousands of dollars for complex, high-density assemblies. A precise estimate requires a detailed analysis of your specific design and production needs. - How can I estimate PCB assembly costs effectively?

Estimating PCB assembly costs involves considering multiple parameters. Start by detailing your bill of materials (BOM) and design complexity, accounting for surface mount (SMT) or through-hole components. Then, factor in manufacturing processes like SMT, wave soldering, and manual assembly, as well as labor costs, and quantity. Using an online PCB assembly cost calculator can provide a rough estimate, but direct quotes from assembly houses are recommended for accuracy. - What should a PCB cost, considering material and assembly?

The total cost of a PCB includes the price of the bare board and the assembly cost. The bare board price is influenced by the number of layers, materials used, and manufacturing tolerances. Assembly costs depend on factors like component count and type, the method of assembly used, and any additional services such as testing. The final price will be determined by the sum of these individual costs. - What is the typical cost of a printed circuit board?

The cost of a printed circuit board (PCB) without assembly depends on its complexity, size, and material composition. Simple, single-layer boards can cost as little as a few dollars, while complex, multilayer boards using advanced materials can cost significantly more, sometimes exceeding hundreds of dollars. Material selection, copper weight, and board finish directly impact the price of the bare PCB. - Are there specific factors that significantly increase PCB assembly costs?

Yes, several factors can significantly increase costs. These include high component density, small component packages (like 0201 or 01005), the use of specialized or hard-to-source components, multilayer boards with complex via structures, and stringent quality control requirements. Additionally, expedited turnaround times or small production runs typically incur higher costs per unit. - Does the number of assembled boards affect the per-unit cost?

Absolutely. PCB assembly often benefits from economies of scale. Larger production runs generally result in a lower per-unit cost, as fixed costs like setup charges are distributed over more boards. Conversely, small quantities or prototype builds tend to have a higher per-unit cost due to increased setup time and lower material discounts. - How can design choices affect the overall cost of a PCBA?

Design choices have a profound impact on the final PCBA cost. Using standard, readily available components, optimizing for manufacturability, designing for simpler assembly processes, and minimizing the number of unique components all contribute to cost reduction. Avoiding overly dense layouts, and incorporating Design for Manufacturing (DFM) principles early in the design phase will result in reduced manufacturing costs.

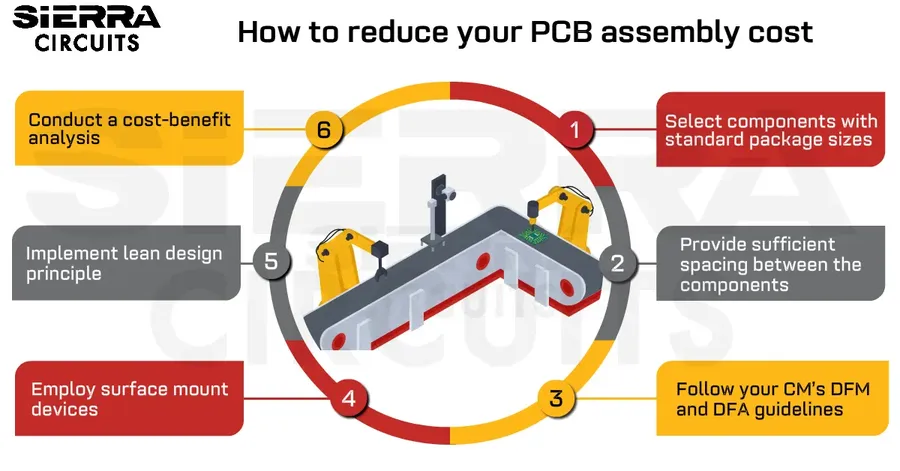

Strategies for Reducing Printed Circuit Assembly Price

Optimizing the cost of printed circuit assembly (PCBA) requires a multifaceted approach, focusing on design efficiency, component selection, and strategic vendor relationships. Implementing these strategies can significantly reduce the overall PCBA price without compromising quality or functionality.

- Efficient PCB Design

Simplifying your PCB design can lead to substantial cost savings. Consider using fewer layers, standard component footprints, and minimizing the board size. A well-optimized layout reduces manufacturing complexity and material usage, lowering overall costs. - Component Selection

Choosing readily available and cost-effective components is crucial. Opt for standard components and avoid using proprietary or obsolete parts, which can be expensive and difficult to source. Consider alternative components with similar functionality but lower prices. - Optimize Panelization

Panelizing multiple PCBs onto a single manufacturing panel can significantly reduce the cost per unit, especially for smaller board sizes. Proper panelization reduces material waste and manufacturing costs. - DFM Analysis

Conducting Design for Manufacturing (DFM) analysis is essential. This step ensures that the PCB design is optimized for assembly, reducing manufacturing issues and costs. Addressing any potential manufacturing challenges during the design phase can prevent costly rework and delays. - Strategic Vendor Selection and Negotiation

Establishing relationships with multiple vendors allows for competitive bidding and better pricing. Consider requesting quotes from different suppliers and negotiate the terms of service. Leverage long term contracts and volume orders for additional cost reductions. Open communication with your manufacturer can also lead to process efficiencies and reduced overall cost. - Testing Strategy

Implementing a smart test strategy is also important. Performing in circuit tests(ICT) or flying probe tests early in the production cycle can identify defects early on, preventing the expense of dealing with faulty assembled boards at the final product level. Properly defining testing specifications in advance will lead to a more efficient testing process.

Navigating the complexities of printed circuit assembly price requires a thorough understanding of the factors involved. By meticulously planning, optimizing your designs, and carefully selecting your manufacturing partner, you can significantly reduce costs. Keep in mind that focusing on value over price alone is key to achieving the optimal balance between cost and performance for your product. Ultimately, a well-informed approach to managing the printed circuit assembly price ensures both economic efficiency and reliable final product performance.

AnyPCBA

AnyPCBA