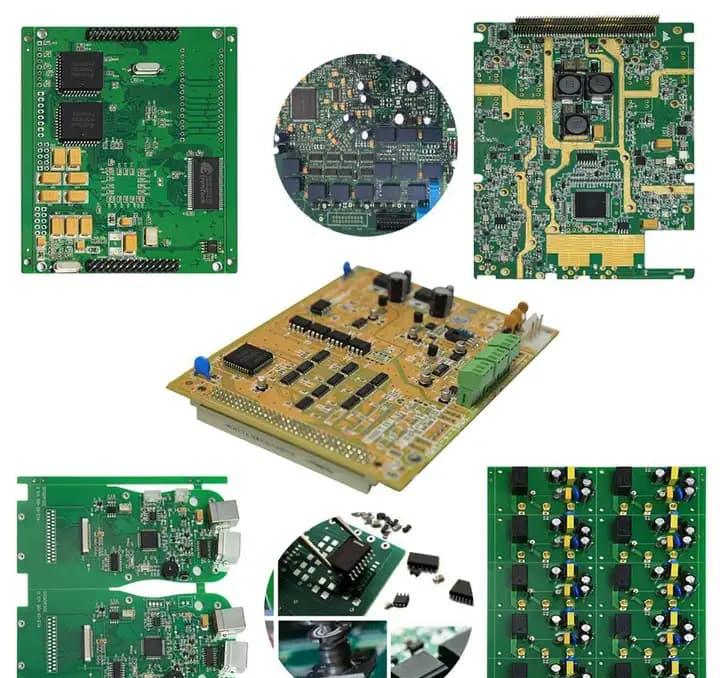

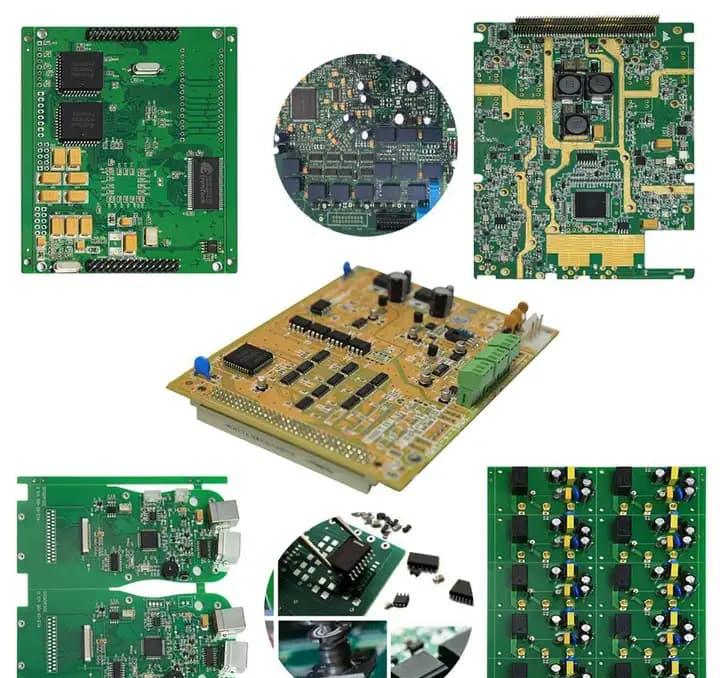

Detailed understanding of PCBA, PCBA is the abbreviation for Printed Circuit Board Assembly

•

AnyPCBA

1, PCB production

PCB (i.e., not assembled any electronic components of the bare board) production, it is mainly based on the design of the PCB file to produce, is the design file into the physical process;2. Assembling electronic components into PCBs

Assembling various electronic components onto the PCB, this process also involves assembling various pre-determined electronic components onto the PCB according to the PBCA file. According to the package specifications of various electronic components, there are mainly SMT mounting and DIP insertion of two assembly methods. SMT mounting is mainly for the soldering foot to mount the welding package of electronic components, DIP insertion is mainly for the soldering foot to insert the welding package of electronic components. the assembly of electronic components on the PCB is usually completed SMT mounting, and then complete the DIP insertion. SMT mounting is mostly done by machines and equipment through the DIP insertion. SMT mounting is more by the machine and equipment by the program set up for automatic assembly, DIP insertion is more by manual assembly, but also by the equipment by the program set up for automatic assembly, just DIP insertion of automatic assembly equipment than SMT mounting automatic assembly equipment prices are much higher. Moreover, the vast majority of circuit boards on the electronic components are from a long time ago, all the evolution of insertion to the majority of are now mainly mounted (while there are also a few inserted), or even all are mounted. Therefore, unless a circuit board with more plug-ins, and the production of large quantities, will choose to go by the automated insertion equipment to complete the insertion, otherwise, usually still by the manual completion of the insertion.3, the PCB board inspection

The purpose of the test is to ensure that the PCB material and line fully comply with the requirements of the design documents, there is no difference and disconnection; to ensure that the electronic components on the PCB correctly assembled in place, there is no leakage, installed wrong, installed the reverse, poor welding, damage to the components, etc.; to ensure that all the electronic components on the PCB can be used normally. With the development of modern technology, the detection of circuit boards, there are many by the original manual testing to the development of a lot of machines and equipment can now be automatically detected, that is, to liberate the labor force of manual testing, but also greatly improve the efficiency and accuracy of testing.4, software burning

In accordance with the requirements of the design documents, to the designated electronic components (mainly IC) burn a well-designed program, that is, to complete the software installation. To ensure that the entire circuit board can realize some specific functions.After these steps, according to the design of the board related documents, the first production of a good PCB (bare board), and then in accordance with the BOM purchased electronic components according to the board documents assembled to the PCB (bare board), after testing to ensure that the hardware part of the error-free, and then install the software program, after testing to ensure that the relevant functions can be properly realized, basically from scratch to complete a complete and usable circuit board. This whole process is the so-called PCBA, of course, in this process there are still a lot of details need to be completed, including the handling of some unexpected events.

AnyPCBA

AnyPCBA

October 21, 2024