Effortless PCB Board Order Online: A Comprehensive Guide

In today's fast-paced tech world, ordering a custom PCB board online has become essential for innovation and development. From hobbyists to professional engineers, the ability to quickly procure high-quality printed circuit boards is key to success. This article will guide you through the process of ordering PCBs online, exploring different manufacturers and options to help streamline your next project. We will also cover how to optimize your search for the perfect [pcb board order online] solutions.

Understanding Your PCB Needs

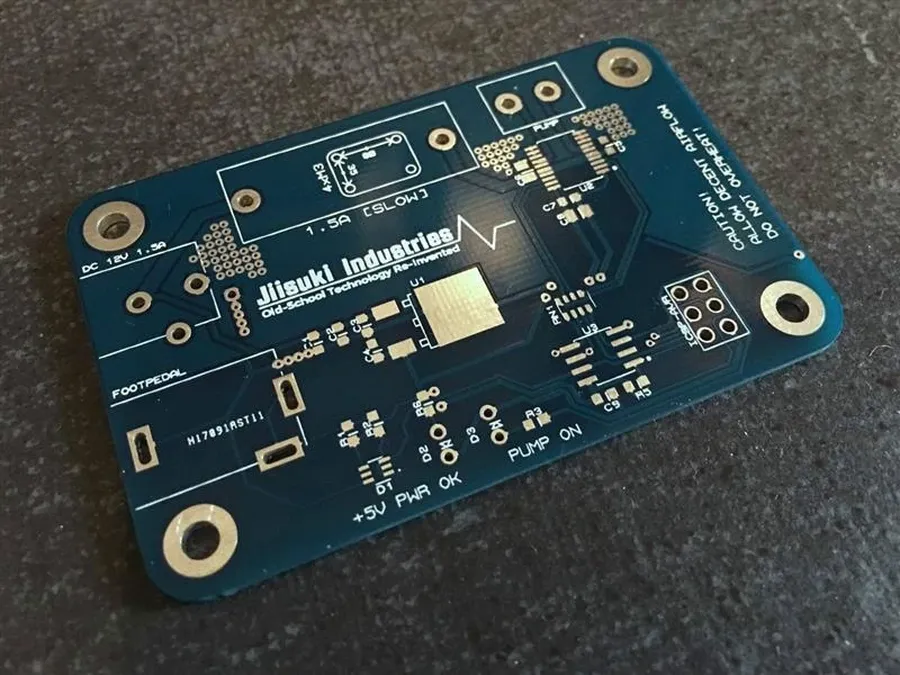

Prior to initiating a PCB board order online, a thorough understanding of your project's specific requirements is paramount. This includes defining the precise dimensions, the number of conductive layers, the type of substrate material, and the acceptable fabrication tolerances. These parameters are crucial for selecting the appropriate manufacturer and ensuring the final product meets the necessary operational specifications.

- Board Dimensions

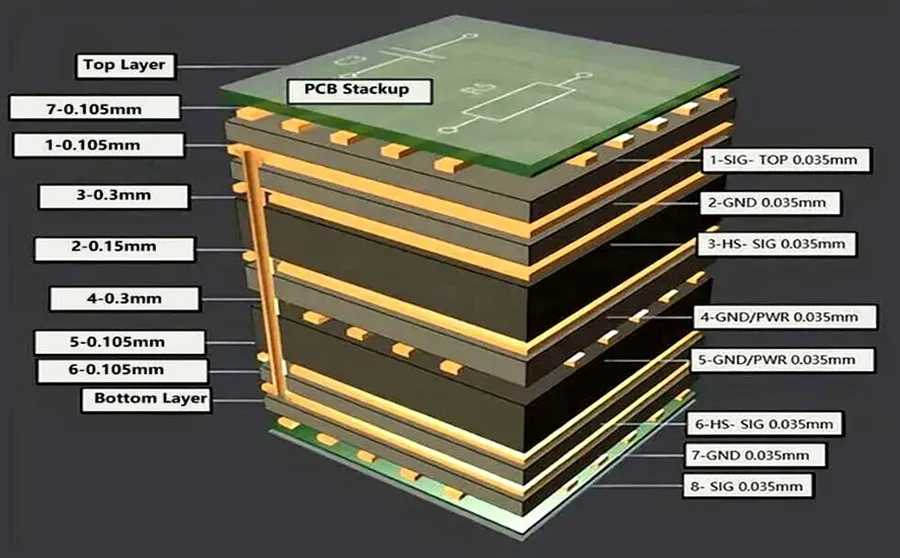

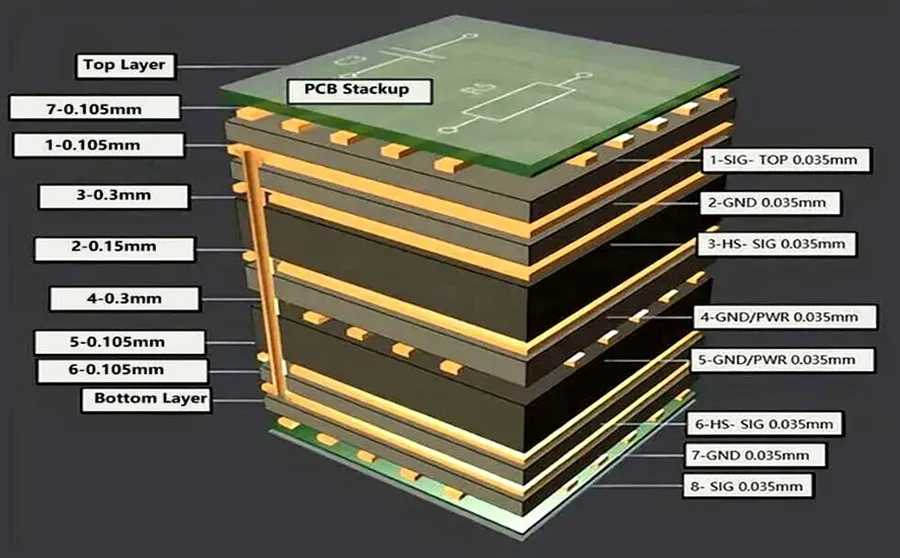

Specify the length and width of the PCB in millimeters or inches. These dimensions are critical for fitting the board into your enclosure and integrating it with other components. - Number of Layers

Determine the number of conductive layers (e.g., single-layer, double-layer, or multi-layer) required for your circuit complexity. The layer count directly impacts trace routing and signal integrity. - Substrate Material

Choose the appropriate base material for your PCB, such as FR-4, aluminum, or polyimide. FR-4 is the most common material due to its balance of cost and performance, however, specialized applications may demand other materials. - Copper Thickness

Define the copper thickness for traces and pads which is measured in ounces per square foot. The copper weight influences the current carrying capacity of the traces, and must be selected based on power requirements - Required Tolerances

Specify acceptable variations in dimensions, feature sizes, and material properties, which directly impact the manufacturability and reliability of the PCB. Tighter tolerances generally increase costs but are necessary for high precision applications. - Via Types and Sizes

Specify the types of vias, such as through-hole, blind, or buried vias, as well as their diameter and plating requirements, which is critical for layer interconnections. - Surface Finish

Select the appropriate surface finish for the pads such as HASL, ENIG, or Immersion Tin. Each has it's own advantages, cost, and application requirements.

Choosing the Right PCB Manufacturer

Selecting the appropriate PCB manufacturer is crucial for a successful project. This decision directly impacts the cost, timeline, and quality of your final product. Evaluating potential manufacturers based on their specific capabilities, pricing, and customer feedback is essential for a streamlined and effective online PCB board order.

- Manufacturer Options

Several manufacturers specialize in online PCB orders, including PCBWay, JLCPCB, DigiKey, and PCB Unlimited. Each has distinct strengths, so researching them is paramount to finding the best fit for your needs. - Pricing

Cost is a critical factor. Compare pricing structures, including base costs, per-unit pricing, and potential tooling fees. Understand how quantity impacts overall cost, as many manufacturers offer bulk discounts. - Lead Time

Project timelines are influenced by the manufacturer's production and delivery times. Some offer faster 'express' or 'rapid' services, but these options often come at a higher price. Evaluate your project's time sensitivity and choose accordingly. - Quality

The quality of PCB manufacturing is non-negotiable for functionality and reliability. Check for independent certifications or test reports demonstrating their adherence to industry standards, such as IPC standards. - Reviews and Testimonials

User reviews and testimonials provide insights into the manufacturer's reliability and customer service. Look for consistent feedback from multiple sources to gauge the overall experience, noting both positive and negative recurring comments. - Specialization

Manufacturers might have specializations, for example, prototypes, small-batch, or high-volume production. Evaluate whether a manufacturer's specialization aligns with your project's production needs. Some might also offer special services like flex boards, or specific material handling.

Key Factors When Ordering PCBs Online

Ordering printed circuit boards (PCBs) online requires careful consideration of several key factors to ensure a smooth and successful process. These factors directly impact the manufacturability, cost, and delivery timeline of your PCBs, influencing your overall experience.

- Gerber File Compatibility

Ensuring your Gerber files are compatible with the manufacturer's specifications is critical. Gerber files are the standard format for PCB manufacturing data and include information about layers, drill holes, and component placement. Incompatibility can lead to production delays or errors. Always double-check the required file format and naming conventions before submitting your order. - Minimum Order Quantity (MOQ)

PCB manufacturers often have a minimum order quantity. This number can vary significantly, with some focusing on prototypes and low-volume production while others are geared toward high-volume orders. Confirming the MOQ is crucial for budget planning and project feasibility, particularly for smaller projects or startups, and may affect your choice of manufacturer. - Accepted Payment Methods

Online PCB manufacturers provide various payment options, including PayPal, major credit cards, and bank transfers. Understanding and confirming which methods the manufacturer accepts ensures you can pay promptly. This can also affect your financial workflow if your company has specific payment policies. - Shipping Options and Lead Time

The available shipping methods and the overall lead time (manufacturing plus shipping) are critical for project planning. Factors that influence shipping options include shipping distance, shipping provider, service level, and board complexity. Lead time for manufacturing of your PCB is usually available in the manufacturer's quotation system, but don't forget to add the transit time for accurate planning.

Comparing PCB Manufacturers: A Quick Table

Selecting the right PCB manufacturer is crucial for a successful project. This table offers a concise comparison of several leading manufacturers, highlighting key factors to aid your decision-making process for your PCB board order online. It is essential to note that 'Varies' for minimum order quantity and lead time means these aspects are highly dependent on the specific board design and order specifications.

| Manufacturer | Minimum Order | Lead Time | Payment Options | Specializations |

|---|---|---|---|---|

| PCBWay | Varies | Fast | PayPal, TT, Credit Card | Prototype, small batches |

| JLCPCB | Varies | Fast | PayPal, Credit Card | Prototypes, assembly |

| DigiKey | Varies | Varies | Credit Card | Custom PCB build |

| PCB Unlimited | Varies | Rapid Turn | Online Quoting | Prototype & low volume assembly |

Streamlining Your PCB Order Process Online

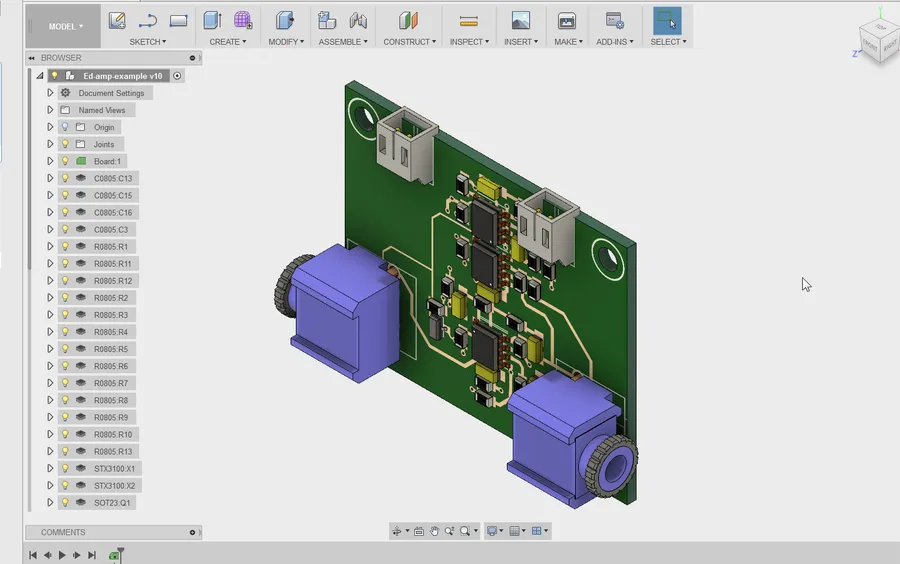

The efficiency of your PCB board order online hinges on understanding and leveraging streamlined ordering systems. Instant online quoting and ordering have revolutionized the process, shifting away from tedious manual exchanges to a more immediate and transparent approach. Central to this is the Gerber file, the standard in PCB manufacturing, that acts as a digital blueprint for your design.

Here’s how to optimize the online ordering of your PCB boards:

- Instant Online Quoting Systems

Many PCB manufacturers offer instant online quoting tools. These systems allow you to input your design specifications—board dimensions, layer count, material type, etc.—and receive an immediate cost estimate. This feature removes the uncertainty and wait time associated with manual quote requests, allowing for faster decision making and project planning. The accuracy of these quotes, however, is directly related to the accuracy of your input. - Gerber File Upload

The cornerstone of the online ordering process is uploading your Gerber files. These files are a set of manufacturing data that includes all necessary information to fabricate your PCB accurately. Ensure that your files are meticulously prepared to prevent production delays or incorrect boards. A complete set typically includes copper layers, solder mask, silkscreen, and drill files. It's recommended to check with your manufacturer for their specific file requirements to ensure a smooth transition from design to production. - Comparing Offers

After receiving initial quotes, carefully assess each offer. Price is important, but it's also critical to consider lead time, material quality, available customization options, and the manufacturer’s reputation for precision and adherence to specifications. The lowest price doesn't always translate to the best value, especially if the product is below the needed specifications. The goal is to find a balance of cost-effectiveness and high-quality manufacturing. - Key benefits of streamlined ordering systems

Streamlined systems save time and money by automating the quoting and order process and reduce the risk of errors with clear and direct communication. With the ability to compare offers and transparent pricing, it is a far more efficient approach to PCB ordering.

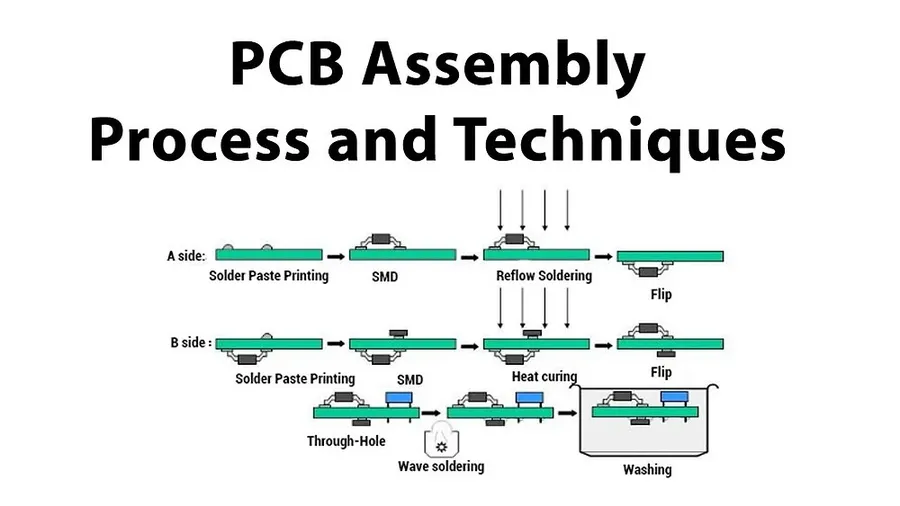

Understanding PCB Assembly Services

PCB assembly services provide an option to receive your printed circuit boards with all components soldered and ready for use, thus streamlining the product development process. This section explores the range of available assembly services, including SMD stencils, to help you determine if a fully assembled board aligns with your needs when placing a PCB board order online.

- Full Turnkey Assembly

The manufacturer handles everything from component sourcing to PCB assembly and testing. This is ideal for projects where you lack the time or resources for in-house assembly. - Partial Assembly

You may choose to have the manufacturer assemble only specific components, typically surface mount devices (SMD). You then complete the assembly with through-hole parts. - Consignment Assembly

In this model, you provide all the components, and the manufacturer assembles them onto your PCB. This option allows greater control over part selection. - SMD Stencil Services

SMD stencils facilitate the application of solder paste onto surface mount pads for accurate component placement. You may order a stencil along with your board or utilize the PCB manufacturer's services.

The selection of the appropriate assembly method hinges on several key factors, including project complexity, required quantities, time constraints, and in-house capability. A detailed consideration of these factors ensures optimal allocation of both resources and budget.

| Assembly Type | Component Sourcing | Assembly Process | Best Suited For |

|---|---|---|---|

| Full Turnkey | Manufacturer | Complete Assembly | Projects with tight timelines or limited resources |

| Partial Assembly | Mixed Responsibility | Partial SMT Assembly | Projects that require a specific assembly approach |

| Consignment | Client Provided | Manufacturer assembles components | Projects where there is a desire to have complete control over part selection |

Frequently Asked Questions About PCB Board Orders Online

Ordering PCBs online can be a straightforward process, but it's natural to have questions. This section addresses some of the most common concerns to help you confidently place your PCB board order online.

- How do I choose a reliable PCB manufacturer online?

Selecting a reliable PCB manufacturer involves considering several factors. Start by evaluating their production capabilities to match your project's complexity (e.g., layer count, materials, tolerances). Check for certifications that demonstrate quality adherence. Customer reviews and testimonials provide insights into their reliability and service quality. Finally, a responsive customer support team is critical for addressing any issues that may arise during the order process. Verify the manufacturer's capability to fulfill your desired specifications, that their customer service is able to address any of your inquiries, and check to see if they are a reputable company through reviews. - What's the best payment option for ordering PCBs online?

The 'best' payment option varies depending on individual circumstances and preferences. Credit cards offer convenience and purchase protection, which can be valuable for first-time orders or for transactions with new manufacturers. PayPal provides an extra layer of security by not directly sharing your financial information with the seller, in addition to purchase protection similar to credit cards. Bank transfers are sometimes favored for large volume or international orders. Always ensure the payment method you select is secure and offers sufficient recourse if needed. Ensure that the payment processor has a high level of security and is reputable. - How do I ensure quality control when ordering PCBs online?

Quality control starts with the manufacturer's capabilities and processes. Look for manufacturers that adhere to industry standards such as IPC. Request samples or prototypes before placing a large order to evaluate the quality firsthand. Ensure that the manufacturer provides clear documentation of their processes, materials, and specifications. Reviewing manufacturer feedback and testimonials can help determine the level of care taken with quality control. Also, double-check your designs before submitting to reduce the potential for error. - What file format should I use when ordering my PCB online?

The industry-standard file format for ordering PCBs is the Gerber file format. This includes not only the Gerber files themselves, but also Excellon drill files, and any necessary documentation to ensure that the manufacturer understands your design parameters. Ensure that the files you upload are compatible and accurate to reduce the potential for issues with your online order. It is always a good idea to review your files before uploading them to ensure there are no discrepancies. - What is the typical lead time for online PCB orders?

Lead times for online PCB orders vary based on several factors, including the manufacturer’s current workload, the complexity of your design, and shipping distance. Standard prototypes can be produced as fast as 24-48 hours, with full assembly requiring 1-2 weeks. Always confirm the lead time before placing an order, especially if your project has tight deadlines, and use any rapid turn options, if necessary. Keep an open line of communication with your manufacturer so that there is no confusion regarding potential lead times. - Are there minimum order quantities when ordering PCBs online?

Yes, most online PCB manufacturers have minimum order quantities (MOQ), although these can vary significantly. Some manufacturers focus on low-volume prototyping and may not have a strict MOQ, while others who target large volume orders might. Check with manufacturers to see what their order requirements are. These minimums might vary based on board complexity, and whether or not the boards require assembly. - What should I do if there's an issue with my delivered PCBs?

If you encounter issues with your delivered PCBs, contact the manufacturer's customer support as soon as possible with the details of the problems. Most reputable manufacturers have return or replacement policies if the error was on their end. Be prepared to provide detailed information about the problem and use clear communication to ensure that you reach an agreement with your PCB manufacturer regarding the potential issue. Keeping detailed and accurate records can be crucial in resolving disputes.

Tips for a Smooth Online PCB Board Order

Ensuring a smooth online PCB board order involves meticulous preparation and attention to detail. By verifying your design files and leveraging available tools, you can minimize errors and achieve optimal results for your PCB fabrication needs.

- Double-Check Your Gerber Files

Before uploading, meticulously review your Gerber files for accuracy. Ensure all layers are correctly aligned, drill holes are properly specified, and all necessary design details are included. Use a Gerber viewer software to visualize the final board and catch potential errors before production. This is critical to avoid costly manufacturing mistakes. - Utilize Online Quoting Tools

Take full advantage of the instant quoting tools provided by PCB manufacturers. These tools allow you to get real-time pricing based on your board specifications, and often provide options to customize your order based on your specific needs. This proactive approach lets you compare different offerings and find the most cost-effective solutions. - Explore PCB Design Resources

Familiarize yourself with online design guides and CAD tools. Many manufacturers provide tutorials and resources to assist you in optimizing your design for manufacturing (DFM). Additionally, consider using professional PCB design software to ensure accurate and reliable Gerber file generation. This enhances the quality and precision of your PCB, minimizing potential issues in the fabrication process. - Review Manufacturer's Specifications

Thoroughly understand the design rules and capabilities of your chosen PCB manufacturer. These typically include minimum trace widths and spacing, via sizes, and board dimensions. Adhering to these guidelines ensures your design is manufacturable and meets the required performance standards. Failure to follow these guidelines could result in delays and added costs. - Consider Panelization Options

If you are ordering multiple boards, explore the panelization options offered by the manufacturer. Panelization can reduce the cost per board, especially for small-batch runs. Familiarize yourself with the necessary parameters and guidelines to ensure correct panelization. - Communicate Effectively with the Manufacturer

If you encounter any issues or have questions, engage directly with the manufacturer’s support team. Clear communication can help resolve problems quickly, avoid misinterpretations and ensure a smoother order process.

Ordering a PCB board online is now a straightforward and accessible process, but it requires careful consideration of your project's needs and the right selection of a PCB manufacturer. By leveraging the information discussed in this article and focusing on your project needs, you will be able to streamline your [pcb board order online] process. Remember to evaluate all options based on quality, lead time, and cost. This enables you to focus on innovation and bring new and exciting electronic ideas to life.

AnyPCBA

AnyPCBA