Finding the Best Cheap PCB Service: A Comprehensive Guide

In today's tech-driven world, printed circuit boards (PCBs) are the backbone of almost every electronic device. For hobbyists, students, and even professionals, finding a reliable yet cheap PCB service is crucial to bringing their projects to life without breaking the bank. This article provides a comprehensive look into the world of affordable PCB manufacturing, helping you navigate the options and make informed decisions about your PCB production needs. We'll explore various manufacturers, discuss pricing strategies, and highlight important factors to consider before placing your order, ensuring that you can access quality PCBs without overspending.

Understanding Your PCB Needs: Key Specifications

Prior to engaging with a cheap PCB service, a thorough understanding of your project's requirements is paramount. This involves defining several critical specifications that directly influence both the cost and the manufacturability of your printed circuit boards. These key considerations range from physical dimensions and layer counts to material selection and specific design constraints.

- Dimensions and Size

Accurately define the board's length, width, and thickness. These parameters affect material usage and cost. For example, oversized PCBs will cost more in materials and require specific shipping arrangements. - Layer Count

Determine the number of copper layers required (single-layer, double-layer, or multi-layer). The complexity and cost of the PCB increase with the layer count. Multi-layer PCBs are often necessary for high-density designs and complex signal routing, while simple circuits may only need one or two layers. - Material Type

Specify the substrate material, typically FR-4 (Flame Retardant 4). Other materials like aluminum-backed, high-frequency laminates (Rogers) are specialized, affecting cost and performance. FR-4 is common, cost-effective, and good for general electronics, while specialized materials offer benefits like improved thermal or electrical performance. - Copper Weight

Select the appropriate copper thickness, typically measured in ounces per square foot. Higher currents necessitate thicker copper, adding to cost. Standard PCBs use 1oz copper weight, but power electronics often need 2oz or more to handle high currents. - Surface Finish

Choose a surface finish (HASL, ENIG, etc.). Different finishes impact solderability and shelf life, and cost. HASL is a common low-cost option, while ENIG provides a superior finish for more critical applications. - Solder Mask and Silkscreen

Specify solder mask and silkscreen colors as these may impact cost and lead time. Common colors are green solder mask with white silkscreen, other colors may cost more. - Via Types and Sizes

Detail the types of vias needed (through-hole, blind, buried) and their sizes. Blind and buried vias increase cost but enable greater board density. Standard through-hole vias are the most cost-effective option for most designs. - Tolerance Levels

Specify the acceptable tolerances for critical dimensions and features. Tighter tolerances will increase the manufacturing price. General purpose PCBs have loose tolerances while RF PCBs may require tighter control. - Special Considerations

Identify any additional requirements such as impedance control, thermal management, or specific certifications. These will influence the manufacturing process, and price. For example impedance matching may be essential for high-speed designs, requiring custom stackups and trace widths.

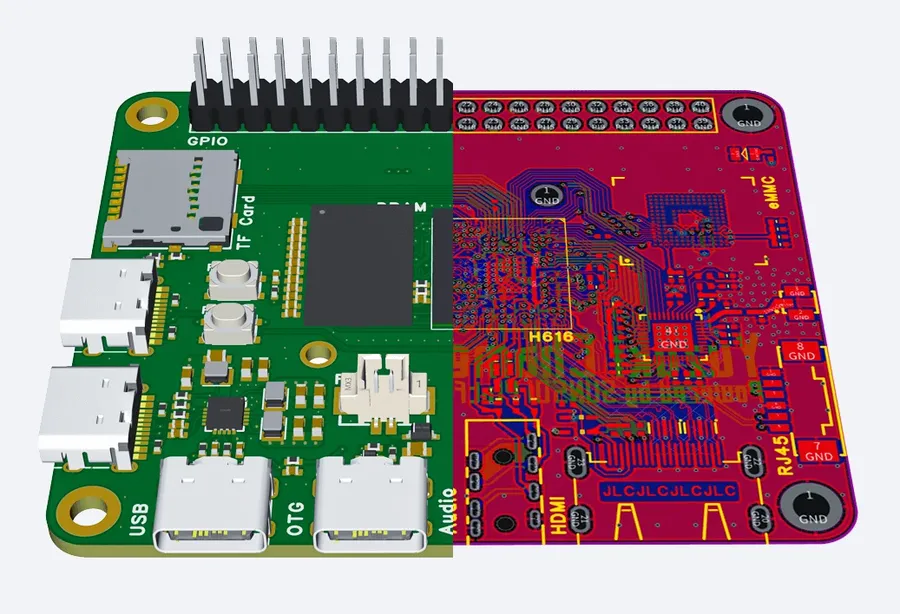

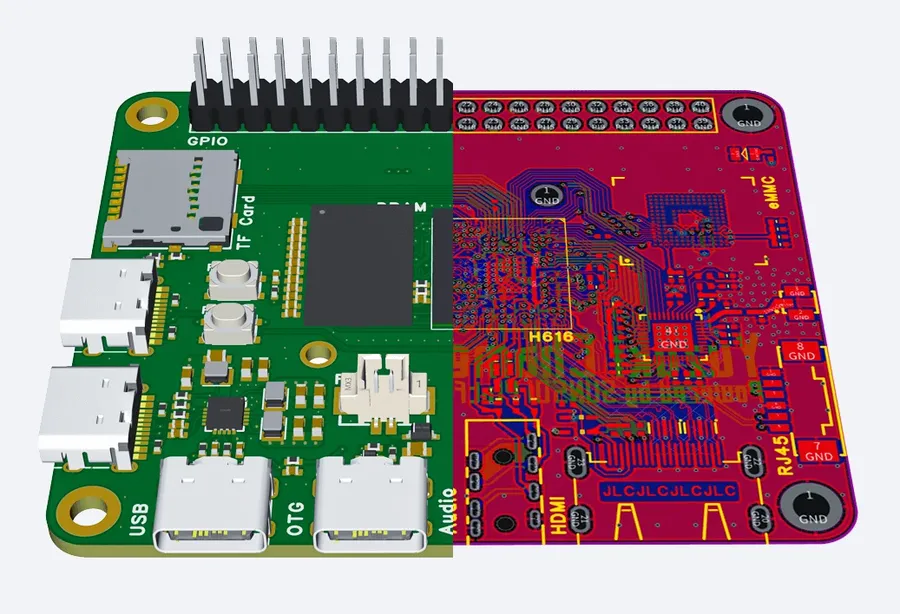

JLCPCB has established itself as a leading provider in the cheap PCB service market, particularly renowned for its cost-effectiveness and rapid turnaround times, making it a popular choice for both hobbyists and professionals needing quick prototyping or small-batch production runs. Their focus on efficient manufacturing and a user-friendly online ordering system has streamlined the PCB fabrication process.

| Feature | Description | Advantages | Limitations |

|---|---|---|---|

| Pricing | Highly competitive, especially for small quantities and standard specifications. | Affordable for prototyping and small projects; consistent pricing structure. | Costs can increase with complex designs, specialized materials, or large orders. |

| Lead Time | Fast turnaround times, with options for expedited shipping. | Quick prototyping and testing; reduced project delays. | May not be as fast for highly complex or large batch orders; shipping times can vary. |

| Quality | Offers good quality PCBs for the price, with standard manufacturing processes. | Suitable for a wide range of applications; reliable performance. | May not be suitable for highly demanding or critical applications; quality may vary with complex designs. |

| Capabilities | Supports a variety of materials, layer counts, and surface finishes. | Versatile to meet different design needs; can accommodate a range of project requirements. | More complex or specialized requirements may incur additional cost; fewer options for advanced features. |

| Ordering System | User-friendly online platform with instant quoting and order tracking. | Streamlined ordering process; easy to manage projects. | Some users may prefer a more traditional customer service experience. |

| Customer Support | Provides online support through email and chat. | Responsive and readily available to answer questions about orders. | May not provide the same level of personalized support as some other manufacturers. |

Top Cheap PCB Service Providers: A Comparative Analysis

Selecting a cost-effective PCB manufacturer requires a thorough analysis of available options, focusing on pricing, lead times, and quality control. This section presents a comparative view of leading PCB service providers, enabling informed decisions based on project needs.

| Feature | JLCPCB | PCBWay | Other Notable Manufacturers |

|---|---|---|---|

| Pricing (Small Quantity) | Highly Competitive, often the lowest | Competitive, slightly higher than JLCPCB for small orders | Varies, some may have special deals on first order |

| Pricing (Large Quantity) | Bulk discounts available, generally very affordable | Good discounts for large quantities | Varies, can be competitive depending on the manufacturer |

| Lead Time (Prototyping) | Fast, often within 2-3 days | Fast, typically 3-5 days | Varies, some might offer express services |

| Lead Time (Mass Production) | 7-10 days | 7-12 days | Varies, depends on production capabilities |

| Quality Control | Good, with automated inspection | Good, with thorough manual inspection | Varies, some offer more detailed testing |

| Special Services | SMT Assembly service available | Advanced PCB options, SMT Assembly, Stencils, and more | May include special material options, laser stencils, or unique board finishes |

| Customer Support | Responsive, but may have language barrier | Good customer service | Varies, can range from excellent to limited |

| Shipping Options | Various shipping options including economy and expedited | Various shipping options including express | Various, depending on the manufacturer |

JLCPCB: Known for affordability and rapid prototyping

JLCPCB is renowned for its highly competitive pricing, especially for small quantity orders, and rapid prototyping capabilities. They are a popular choice for hobbyists and professionals alike due to their efficient manufacturing process and automated inspection systems. While primarily focused on standard PCB manufacturing, they also offer SMT assembly services, expanding their appeal for projects requiring component placement.

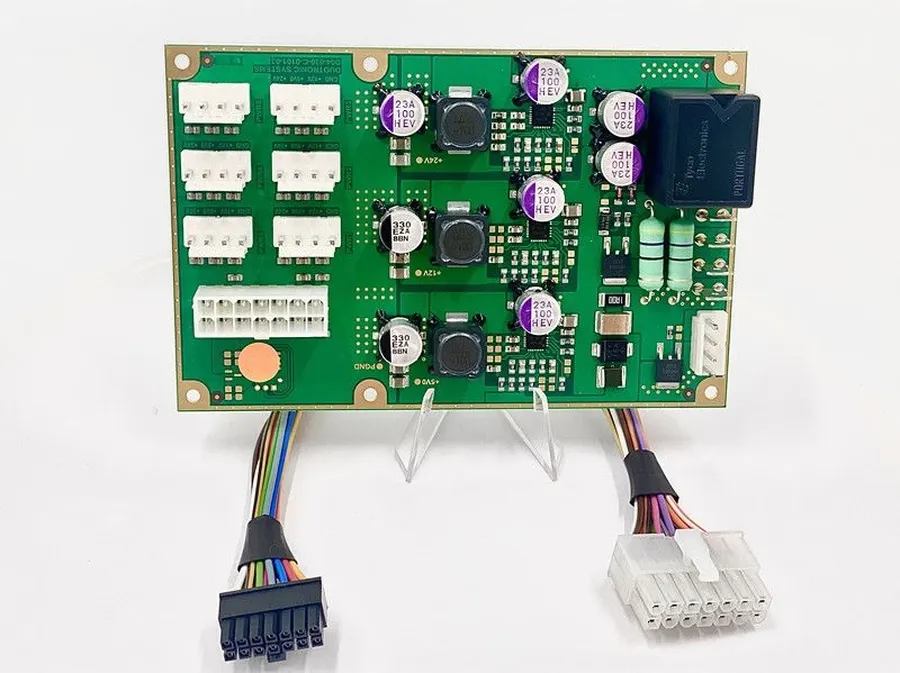

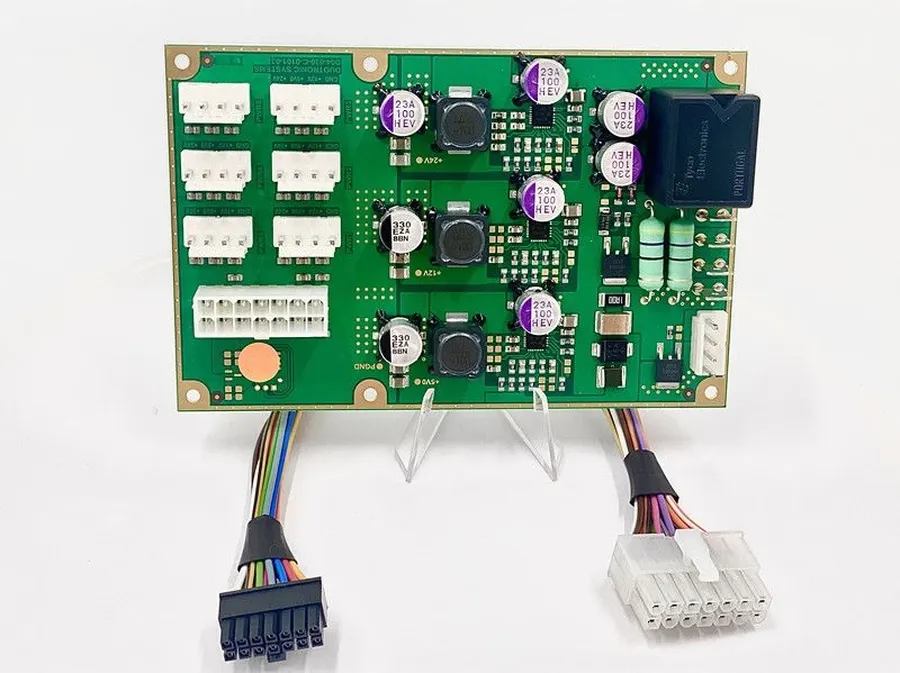

PCBWay: Offers a wide range of options and services

PCBWay distinguishes itself by offering a comprehensive suite of services, including advanced PCB options, SMT assembly, stencils, and more. While their pricing may be slightly higher than JLCPCB for small orders, they provide greater flexibility in terms of customization and specialized manufacturing. Their commitment to quality control involves thorough manual inspections alongside automated checks, ensuring a high standard of fabrication.

Other Notable Manufacturers

Beyond JLCPCB and PCBWay, several other manufacturers cater to different niches. Manufacturers like EasyEDA/JLCPCB (integrated design and fabrication), AllPCB (offering a wide range of manufacturing capabilities), and AdvancedPCB (known for specialized PCB types and higher precision) present viable alternatives depending on your specific project needs and design complexity. These manufacturers may offer unique services or materials, making them worth considering for specialized projects or those with stringent requirements.

PCBWay distinguishes itself in the cheap PCB service market by providing a broad spectrum of manufacturing options and additional services, catering to diverse needs from simple prototypes to complex, multi-layered boards. This positions them as a versatile option for both hobbyists and professional engineers who require more than just basic PCB fabrication.

The following table highlights PCBWay's core offerings, comparing them to the industry standards.

| Feature | PCBWay | Industry Average | Notes |

|---|---|---|---|

| Layer Count | Up to 32 layers | 2-4 layers (standard) | Supports complex designs. |

| Material Options | FR-4, Aluminum, Rogers, etc. | Primarily FR-4 | Wider selection for specific applications. |

| Finishes | HASL, ENIG, Immersion Silver/Tin | HASL, ENIG | More finish options for better solderability and corrosion resistance. |

| Special Services | Assembly, Stencil, 3D Printing, CNC Machining | Limited to PCB fabrication | Offers comprehensive manufacturing solutions beyond PCBs. |

| Lead Time (Prototype) | 24-48 hours for simple PCBs | 3-7 days | Fast turnaround times for urgent projects. |

| Shipping Options | DHL, FedEx, UPS, EMS, etc. | Limited to a few options | Global shipping with various speed and cost options. |

While PCBWay's diverse offerings make it an attractive choice, potential users should carefully weigh their specific project needs against the associated costs and lead times for specialized options. They offer a good balance between cost and features, with a focus on rapid prototyping and a wide variety of advanced features.

Other Notable Manufacturers

While JLCPCB and PCBWay often dominate discussions regarding budget-friendly PCB fabrication, several other manufacturers offer unique advantages or cater to specific niches. This section explores some of these alternative providers, highlighting their strengths and differentiating factors in the competitive PCB manufacturing landscape.

- EasyEDA/JLCPCB

EasyEDA is an online PCB design tool tightly integrated with JLCPCB's manufacturing services. This integration streamlines the design-to-production process, enabling users to design, order, and track their PCBs all on a single platform. This is a key advantage for users who prefer a simplified workflow and eliminates the need to use multiple softwares. Their close relationship allows them to offer quick turn around times and competitive pricing. - AllPCB

AllPCB distinguishes itself by offering a broad range of manufacturing capabilities, including advanced PCB technologies. AllPCB can be a suitable choice for projects requiring complex board designs, a wider range of material options, and they often cater to both prototype and production runs, this makes them a comprehensive service for various project stages and different demands. - Advanced Circuits

Advanced Circuits is a US-based manufacturer known for high-quality PCBs and rapid turnaround times. They are particularly suitable for projects with strict requirements or those needing local manufacturing and support. While they may not be the cheapest option, their focus on quality and speed makes them a strong contender for professional PCB manufacturing needs, and they also offer a wide range of capabilities including flexible PCBs and advanced materials. - Seeed Studio Fusion

Seeed Studio Fusion offers a blend of prototyping and low-volume manufacturing services. They are well-regarded for their user-friendly platform and support for open-source hardware. They are a good choice for designers who value prototyping and agile manufacturing practices, and they also have a selection of other electronic components which designers may find helpful.

Pricing Structures and Cost Factors

Understanding the pricing mechanisms of PCB manufacturing services is crucial for cost-effective project management. PCB service costs are not uniform and are influenced by several interconnected factors. These factors encompass order volume, design complexity, the materials utilized, and logistical considerations such as shipping.

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Order Size | The quantity of PCBs ordered in a single batch. | Generally, larger orders reduce the per-unit cost due to economies of scale. Small orders tend to have higher per-unit costs due to setup fees. |

| PCB Complexity | This includes the number of layers, trace widths, via count, hole sizes, and other design features. | More complex designs require more advanced manufacturing processes, resulting in higher costs. Designs with finer features or more layers increase production difficulty and expense. |

| Material Selection | The type of substrate material used (e.g., FR-4, aluminum, polyimide) and copper thickness. | High-performance materials or thicker copper will increase costs, but may be required for higher performance applications. FR-4 material is commonly used, and is usually the cheapest option. |

| Surface Finish | Options such as HASL, ENIG, Immersion Silver, and others. | Different surface finish have different manufacturing processes, impacting the final cost. ENIG is a more costly option, but it has superior solderability and oxidation resistance compared to HASL. |

| Shipping Costs | The cost to transport the manufactured PCBs. | Shipping costs are based on weight, distance, speed and method of delivery. Express shipping methods will cost more than standard shipping. |

| Turnaround Time | The time required to manufacture the PCBs. | Faster turnaround times, often referred to as expedited production, incur additional expenses. Standard production times are typically cheaper. |

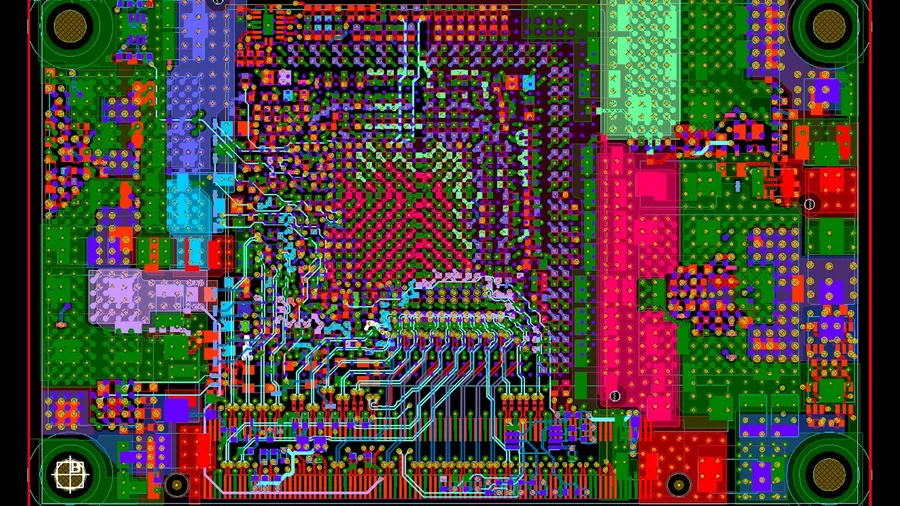

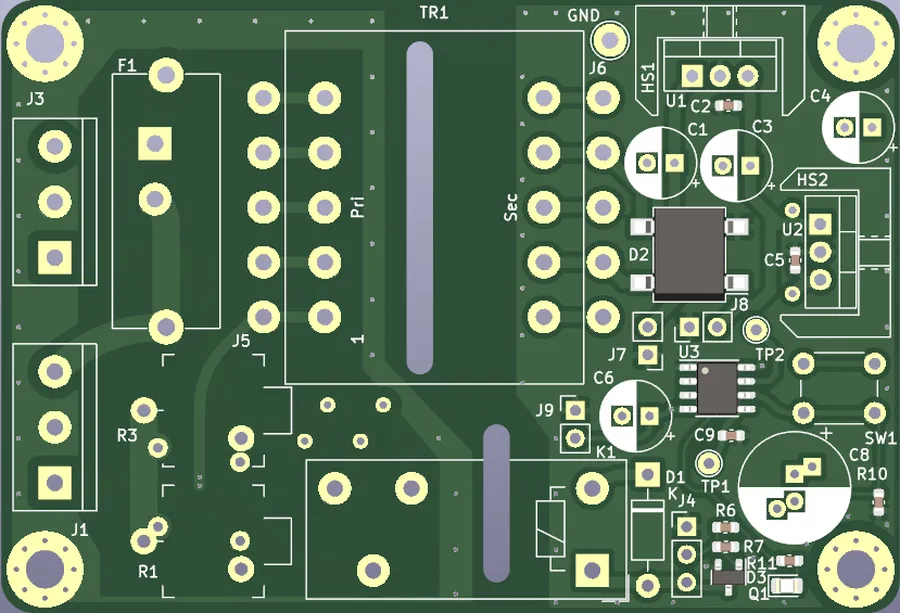

Navigating Design Software for Seamless PCB Production

Efficient PCB production hinges on the seamless integration of design software with manufacturing processes. Selecting the appropriate design software and adhering to best practices can significantly reduce errors and expedite fabrication, directly influencing both cost and production timelines of cheap PCB services.

Popular design software options like Eagle, Altium, and KiCAD offer distinct features that can impact the fabrication process. Ensuring compatibility between your design software and the chosen PCB service provider is paramount for efficient and error-free production.

| Design Software | File Format Compatibility | Ease of Use | Cost | Key Features |

|---|---|---|---|---|

| Eagle | Gerber, Drill files, BOM | Beginner-friendly, but limited free version | Paid subscriptions, free for personal use with limitations | Component library, scripting support, intuitive interface |

| Altium Designer | Gerber, ODB++, IPC-2581 | Professional-grade, steep learning curve | High cost subscription model | Advanced PCB layout, signal integrity analysis, 3D visualization |

| KiCAD | Gerber, Drill files, SVG | Open source, moderate learning curve | Free and open source | Active development, strong community support, cross-platform compatibility |

Adopting the following design practices will streamline production and reduce potential errors when using cheap PCB services:

- Gerber File Generation:

Always generate all necessary Gerber files (including copper layers, solder mask, silkscreen, drill files, and outline) in the correct format and resolution. Verify these files using a gerber viewer prior to uploading them to the PCB service provider. - Design Rule Checks (DRC):

Implement design rule checks within the software to prevent common errors such as trace widths, clearance issues, and annular ring problems. Ensure that DRC rules match the manufacturer's capabilities and requirements. - Component Libraries:

Use verified and up-to-date component libraries that align with the manufacturer's specifications, including pad dimensions and pin mappings. This ensures accurate placement and soldering during production. - BOM and Centroid File Generation:

Generate an accurate Bill of Materials (BOM) and centroid (pick and place) file, including manufacturer part numbers, component values, and coordinates. Ensure the BOM is accurate with the selected components - Layer Alignment and Stackup:

Confirm correct layer alignment and stackup, according to the manufacturer's guidelines to ensure proper connectivity and functionality of your PCB. Understanding the layers and their respective functions in multilayer PCBs is essential. - Communication with Manufacturers:

Consult manufacturer's datasheets and guidelines to ensure your design is within their production capabilities and tolerances. For more complex designs it is best practice to contact the manufacture directly for a design review prior to starting fabrication.

Frequently Asked Questions About Cheap PCB Services

Navigating the landscape of cheap PCB services can raise several questions. This section addresses the most common inquiries to provide clarity and assist you in making informed decisions regarding your PCB fabrication needs. We'll cover topics from pricing strategies to file formats, ensuring you're well-prepared for your next order.

- How can I secure the most cost-effective pricing for my PCB order?

To get the best price, consider panelizing your PCB design to maximize the board area used and order in bulk, as unit costs decrease with higher quantities. Being flexible with your production and shipping times can also open doors to lower-cost options. Consider using the manufacturer's stock material for further cost reductions. - What various shipping options are typically available, and which should I choose?

Standard shipping is usually the most economical but comes with longer delivery times. Expedited shipping options are available for faster delivery, but at a higher cost. The best option depends on your budget and time constraints. Consider the total cost of shipping when comparing service providers, not just the PCB price. - Which file formats are acceptable for submitting PCB designs to manufacturers?

Most manufacturers accept Gerber files, which are the industry standard for PCB fabrication. Ensure all necessary layers are included in your Gerber files (copper layers, solder mask, silk screen, drill files). Some also accept native design files from software like KiCad, Eagle, or Altium, but it's best to verify the specific requirements of your chosen manufacturer. - What is the typical turnaround time for PCB production and delivery?

Turnaround times can vary significantly based on the manufacturer, complexity of the design, and shipping method chosen. Basic PCBs can often be produced in 24-48 hours, with shipping adding a few days to a couple of weeks, depending on the distance and method. Consider the production time and shipping time when planning your project timeline. Always confirm the lead times directly with the manufacturer before placing your order. - Are there differences in material options that may affect the cost of my PCB?

Yes, the choice of material directly impacts the cost. FR-4 is the most common and cost-effective material. Specialized materials like aluminum substrates or high-frequency laminates will increase the price. If your design doesn’t have special requirements for thermal or signal performance, opting for standard FR-4 can keep costs low. - How does the complexity of my PCB design affect manufacturing costs?

Complexity, such as the number of layers, the size of the board, the density of components, and the fineness of the traces and spaces, will increase the manufacturing cost. Simplifying your design where possible, using larger trace widths where feasible, and reducing the number of layers can reduce costs, if your application does not require more complexity. - What should I know about panelizing my PCBs for cheaper production?

Panelization means combining multiple PCBs into one large panel to be fabricated at once. This significantly reduces per-unit costs by making more efficient use of manufacturing processes. When designing for panelization, consider the manufacturer's standard panel size, the spacing between PCBs, and include fiducial marks and tooling holes.

User Reviews and Community Insights

Understanding the real-world performance of cheap PCB services is crucial for making informed decisions. User reviews and community discussions provide invaluable insights, highlighting both the strengths and weaknesses of different manufacturers, supplementing the information provided by the companies themselves. These peer-to-peer interactions often reveal aspects such as consistency in quality, reliability of lead times, and the responsiveness of customer support, which are not always immediately apparent from the manufacturers' websites.

- Reddit:

Subreddits dedicated to electronics and PCB design, like r/PrintedCircuitBoard, are a great source of user experiences. Here, you can find threads detailing the positive and negative experiences of users with different PCB manufacturers. Pay close attention to recurring themes, such as consistent quality issues, unexpected delays, or exceptional customer service. User-submitted photos of boards can also help assess real-world production quality. - Online Forums:

Electronics forums (e.g., EEVBlog forums) often host extensive discussions about PCB manufacturers. These forums tend to have more technically savvy users who can provide detailed feedback about board performance, materials used, and adherence to manufacturing specifications. Look for discussions involving the specific manufacturer you are considering and analyse the types of problems mentioned. - Independent Review Platforms:

Check dedicated review sites that collate feedback on various services including PCB manufacturing. While these may not always be as technical as a forum, they can give a broader overview of user satisfaction and can highlight common themes across different user groups.

When analysing user feedback, consider the following points:

- Recency of Reviews:

Ensure that you are analysing recent feedback, as older reviews may not reflect the current state of a company's services, or the effect of new production technology. Ideally, focus on reviews from the last 6-12 months to get a reliable understanding of current operations. - Pattern Recognition:

Look for common themes or patterns in user feedback. A single negative review may not be conclusive, but a pattern of similar complaints, such as persistent delays or frequent manufacturing errors, should be taken seriously. Similarly, repeated praise for the same aspect of a manufacturer, such as their customer support or turnaround time, can be a good sign. - User Background and PCB Complexity:

Consider the technical background of the user and the complexity of the PCB they had manufactured when assessing their review. A complex multi-layer board from an experienced user carries more weight than simple single-layer boards from less experienced users. - Bias:

Be mindful of potential bias in reviews, especially on the manufacturer's own website. Try to focus on independent platforms and those who have an established and verified online persona.

Tips for Optimizing Your Order for Cost Savings

Optimizing your PCB order is crucial for reducing costs without compromising quality. Strategic planning regarding design, order quantities, and shipping can significantly impact your overall expenditure. This section details actionable strategies to minimize expenses when utilizing cheap PCB services.

- Panelize Your PCBs

Designing your PCBs to fit within a panel can dramatically decrease costs, as manufacturers often charge a flat rate for a panel rather than individual boards. This method is particularly effective for smaller boards and increases the efficiency of the manufacturing process. Always check panelization guidelines to ensure compatibility with the chosen manufacturer's capabilities. - Order in Bulk

The cost per PCB significantly decreases with larger order volumes. This is because the initial setup costs for manufacturing a PCB dominate over the cost of the raw materials. By ordering in bulk, you distribute this setup cost across a higher number of boards, reducing the individual board price. - Standardize your Design

Using standard components (like sizes, packages etc) can reduce costs. By sticking to industry standards, manufacturers require fewer changes in the manufacturing process which makes the overall process cheaper - Utilize Standard Materials and Processes

Opting for standard PCB materials and processes, such as FR-4 with a typical thickness, can significantly lower costs compared to more exotic materials or specialized processes. The more standard your PCB's specifications, the more efficient the production line is, and the lower your cost should be. - Be Flexible with Lead Times

Non-urgent orders can often be manufactured at a lower cost if you are flexible with production times. Many PCB services offer discounted rates for longer lead times, which can be beneficial for projects that do not have stringent deadlines. - Optimize Shipping Options

Consider the various shipping options available, from express delivery to more economical but slower methods. The optimal choice depends on your project timeline. If there is no time constraint, slower shipping will reduce cost, or ordering in bulk from the same manufacturer (to the same destination) will reduce shipping costs.

Actionable Advice: How to Select the Right Cheap PCB Service

Choosing the right cheap PCB service requires a systematic approach, balancing cost with quality, delivery speed, and support. This section provides a step-by-step guide to help you make an informed decision, ensuring your project's success without breaking the bank. Consider these factors as part of your decision making process.

- Define Your Project Requirements

Start by clearly outlining the specifications of your PCB, including dimensions, layer count, material type (e.g., FR-4, aluminum), copper thickness, surface finish, and any impedance control requirements. These parameters significantly influence the cost and the complexity of the manufacturing process. - Assess Quantity Needs

Determine the number of PCBs needed for your project, this will directly influence the cost per unit. Evaluate the trade-off between the per-board price and the total cost. If your design is likely to require multiple iterations, then consider ordering a smaller quantity of your first prototype and increasing the quantity for later revisions. - Compare Pricing Structures

Analyze the pricing models of different manufacturers. This includes not only the cost of the PCBs themselves but also any tooling fees, shipping expenses, and potential taxes or import duties. Understand if there are any volume based discounts and how it would benefit your application. - Evaluate Quality Standards

Look for manufacturers that adhere to industry standards like IPC, ISO, UL, etc. and ensure they have robust quality control processes in place. Check for information on their manufacturing and inspection processes, their equipment, and the certifications they possess. Look for customer feedback and third party evaluations to gauge their track record on quality. - Gauge Lead Time and Shipping Options

Consider how long it will take for your PCBs to be manufactured and delivered. Some manufacturers have faster lead times but often come with an increased cost. Evaluate the available shipping options, and consider if the turnaround time fits within your project timeline. If possible use a shipping option with tracking information. - Review Customer Support

Assess the customer service responsiveness, technical support availability, and the level of communication that the PCB manufacturer provides. Clear and prompt communication is crucial, especially when troubleshooting design or manufacturing issues. The responsiveness can make all the difference in production efficiency. - Check File Format Compatibility

Confirm that the PCB manufacturer supports your preferred file formats, such as Gerber, Eagle, Altium, and KiCAD. This reduces the time and effort to make modifications to be compatible with their processing systems, preventing delays and errors in the manufacturing process. Ensure your design file is complete and error free. - Review User Reviews

Look for user reviews and forum discussions to get real-world insights into the performance of various manufacturers. These reviews can give you valuable insight and help confirm their reliability and quality of service. Be wary of comments that are overly positive or negative. Look for patterns in multiple reviews to gauge the overall experience. - Start with a Small Order

If you are unsure about the PCB manufacturer, place a small test order before committing to a large production run. This allows you to evaluate the PCB quality and service and make adjustments before mass production.

Finding a cheap PCB service that meets your specific needs can be a challenge, but by understanding the various options available and considering key factors like quality, turnaround time, and cost, you can make an informed decision. Remember that while price is important, it's crucial to balance cost with quality to ensure your final product meets your expectations. By using this guide, you're well-equipped to choose the best cheap PCB service and bring your electronic projects to life efficiently and affordably. When selecting your provider for your next cheap pcb service project, consider all of these factors and make an informed decision based on your specific needs and budget.

AnyPCBA

AnyPCBA