Get Instant Online PCB Quotes: A Comprehensive Guide

In today's fast-paced world of electronics, getting a quick and reliable online PCB quote is crucial for project success. Just as advancements in social science shape our interactions, technology like printed circuit boards (PCBs) forms the backbone of modern electronics. This article guides you through the process of obtaining an online PCB quote, ensuring you select the best option for your needs and budget, ultimately streamlining your journey from design to physical product. Discover the ease and affordability of obtaining an [online pcb quote] for your next project.

Understanding Online PCB Quote Systems

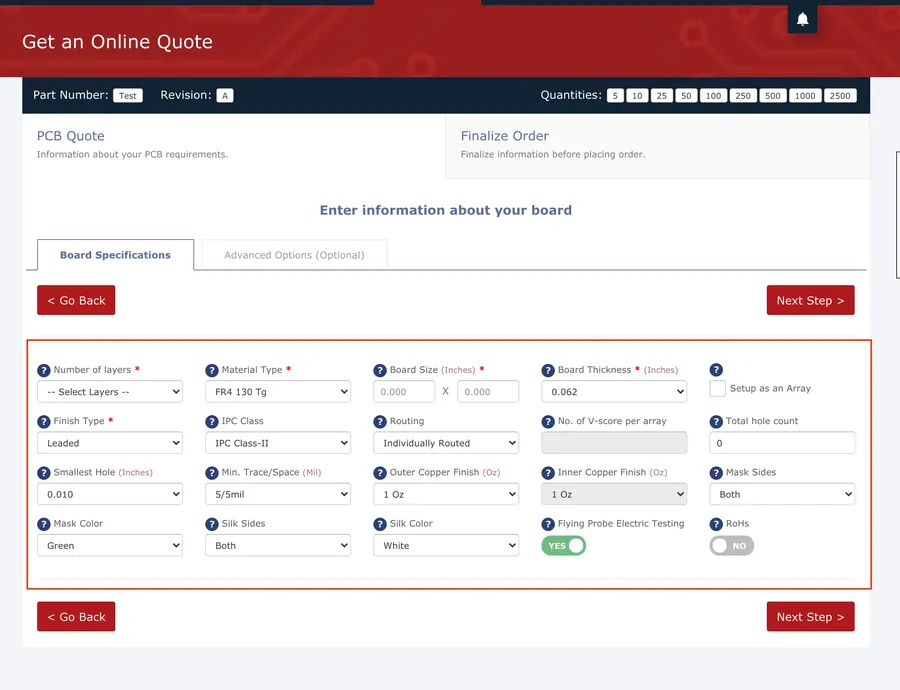

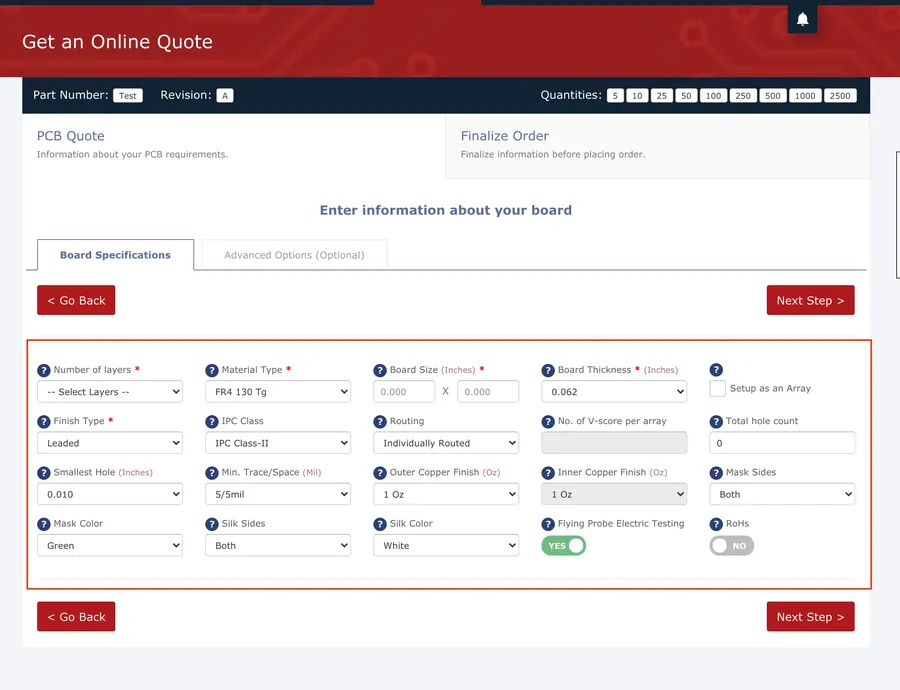

Online PCB quote systems provide an automated and rapid alternative to traditional, manual quoting processes. These systems allow users to upload their design specifications, and in return, receive an immediate estimate for the fabrication of their printed circuit boards. This efficiency stems from algorithms that calculate costs based on user-defined parameters, dramatically reducing the time and effort required for price discovery compared to traditional methods which involve manual review by the manufacturer.

The core functionality of these online systems revolves around a structured input process, typically requiring the following parameters:

- PCB Dimensions:

Length and width of the board in millimeters or inches. - Number of Layers:

Single, double, or multi-layered PCB. - Material Type:

Such as FR-4, aluminum, polyimide, etc. - PCB Thickness:

The overall thickness of the board. - Copper Weight:

Copper thickness, often specified in ounces per square foot. - Surface Finish:

Options such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), etc. - Solder Mask Color:

Typically green, but other colors available. - Silkscreen Color:

Color for text and markings. - Quantity:

Number of PCBs required. - Lead Time:

The time you require your boards in (typically in days).

The advantage of using online PCB quote systems includes the rapid generation of cost estimations, greater transparency in pricing, and the ability to compare prices from multiple manufacturers easily. This level of efficiency is especially helpful for prototyping and small to medium production runs where the cost is often a major consideration. However, it is imperative that users supply accurate design specifications, as errors can lead to inaccurate quotes and potential production issues.

Key Factors Affecting PCB Quote Prices

Understanding the drivers behind PCB fabrication costs is crucial for obtaining accurate online quotes. Several key factors significantly influence the final price, and awareness of these variables can help optimize your design and reduce expenses. The following breakdown details these crucial cost determinants.

| Factor | Description | Impact on Cost |

|---|---|---|

| Board Size | The overall dimensions of the PCB. | Larger boards require more material and processing, leading to higher costs. Price generally scales with area. |

| Layer Count | The number of conductive layers in the PCB. | More layers increase complexity, material usage, and fabrication time, significantly raising the price. Double-layer boards are usually the most cost-effective. |

| Material Type | The base material (e.g., FR-4, Aluminum, Rogers) used for the PCB. | Different materials have varying costs, with FR-4 being the most common and cost-effective. High-performance materials increase the price. Material choice depends on the desired electrical and thermal properties of the PCB. |

| Surface Finish | The type of plating or finish on the copper traces (e.g., HASL, ENIG, Immersion Tin). | ENIG (Electroless Nickel Immersion Gold) offers excellent solderability and corrosion resistance, is more expensive than HASL (Hot Air Solder Leveling) which is generally the most economical option. |

| Lead Time | The time required to fabricate and deliver the PCBs. | Faster turnarounds, typically through expedited manufacturing, lead to higher costs. Standard lead times are more economical. |

| Hole Count and Size | The number and size of drill holes on the board. | Higher count and smaller hole sizes require more precise drilling processes, which increases manufacturing costs. |

| Minimum Trace Width and Spacing | The smallest width of the copper traces and the spacing between them. | Tighter tolerances demand more advanced manufacturing processes, thus increasing costs. The standard design rules should be used to keep costs to a minimum. |

| Solder Mask Color | The color of the protective layer on the PCB. | Standard colors like green are generally the least expensive. Special colors or custom colors can increase the costs. |

| Silkscreen | The markings and text on the PCB. | Additional text, complex marking, or multiple silkscreen layers can increase costs. |

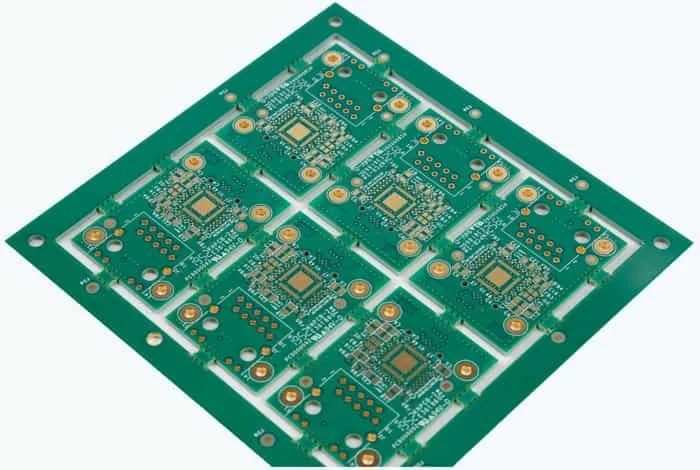

| Panelization | The process of combining multiple PCBs into a single panel for manufacturing. | Panelization is generally cost-effective for higher volume production. If you design your own panel, be sure to follow the manufacturers guidelines, as non-standard panel sizes can increase the quote. |

Comparing Top Online PCB Quote Providers

Selecting the right PCB manufacturer is crucial for both cost-effectiveness and quality. This section examines several leading online PCB quote providers, offering a comparative analysis of their unique strengths, weaknesses, and features to guide your decision-making when seeking an online PCB quote.

| Provider | Strengths | Weaknesses | Key Features |

|---|---|---|---|

| PCBWay | Wide range of services, including PCB prototyping and assembly, excellent customer support, good reputation for quality. | May have slightly higher prices for complex designs. | Real-time online quote system, online order tracking, comprehensive manufacturing capabilities. |

| JLCPCB | Extremely cost-effective, especially for prototype quantities, fast turnaround times. | Limited material options, less customization flexibility than some competitors, basic quality level. | Very low-cost PCB service, efficient online ordering and quoting platform, offers assembly services. |

| AllPCB | Offers a variety of fabrication options, supports complex designs, has a user-friendly online platform. | Customer support may be slower, prices can be higher for very large orders. | Instant quoting, design for manufacturability (DFM) check, good for mid-range production runs. |

| Seeed Studio Fusion PCB | Good for small-scale prototyping and open-source projects, offers an integrated ecosystem. | Less cost-effective for large-scale production, limited options for advanced features. | Integration with Seeed Studio's other services, good for DIY and educational projects, fast prototyping options. |

The Importance of Gerber Files for Accurate Quotes

Gerber files are the cornerstone of precise online PCB quotes. These files, a standardized format in the PCB manufacturing industry, provide a comprehensive blueprint of your board design, allowing manufacturers to accurately assess the complexity and cost involved in fabrication. Without proper Gerber files, obtaining an accurate quote is extremely challenging, often resulting in delays, cost overruns, or even manufacturing errors.

Gerber files are essentially a set of vector-based files, each representing a layer of your PCB, including copper traces, solder mask, silkscreen, and drill locations. These files tell the fabrication equipment exactly where to etch, plate, drill, and print on your board. The importance of these files for online quotes stems from the fact that they eliminate ambiguity and ensure that the manufacturer understands your design intent completely and accurately. This leads to a more precise quote, and it also allows the manufacturer to identify potential manufacturability issues before production begins. Using only a schematic diagram or a simple description of your PCB design is insufficient, because these cannot contain all the data needed for a precise manufacturing quote.

- What information is contained in Gerber files?

Gerber files contain detailed information about each layer of a PCB, including copper traces, pads, vias, solder mask, and silkscreen. They specify the shape, size, and location of each element, as well as drill locations and board outline. All these elements are crucial to producing your boards. - Why are Gerber files necessary for accurate quotes?

Without Gerber files, manufacturers rely on estimates and assumptions, which often lead to inaccurate quotes. These files ensure that the quote is based on the actual design complexity and material requirements, reducing the chances of unexpected charges or manufacturing problems. - How to Generate Gerber Files?

Gerber files are typically generated by PCB design software such as Altium Designer, Eagle, KiCad, or OrCAD, which often has one-click export options for generating all the required Gerber files. - Essential Gerber Files:

The essential Gerber files include copper layers, solder mask layers, silkscreen layers, and drill files. All the files must be accurately generated with no misalignments or missing layers. - How do Gerber files work with online quoting platforms?

Online quoting platforms automatically parse Gerber files to determine the necessary parameters for an accurate cost estimation. These platforms use the files to automatically calculate board size, layer count, drill holes, material, and other important parameters of your PCB which is used to determine the fabrication costs of your board. - What are common issues with Gerber files?

Common issues include missing files, incorrect file extensions, incomplete or outdated Gerber versions, or errors in the design file itself. Make sure you've used the correct settings in your PCB design software before generating your final files.

Navigating PCB Manufacturing Options: Prototype vs. Production

Understanding the distinction between prototype and production runs is crucial when seeking an online PCB quote, as these significantly impact cost, lead time, and manufacturing approach. Prototypes are small-batch runs aimed at testing and validating a design, while production runs involve larger volumes for finalized products. Choosing the appropriate run type is essential for cost-effectiveness and efficiency.

| Feature | Prototype Runs | Production Runs |

|---|---|---|

| Purpose | Design validation and testing | Mass production of finalized designs |

| Quantity | Small quantities, typically 1-100 boards | Large quantities, often hundreds to thousands or more |

| Cost per board | Higher due to setup and low volume | Lower due to economies of scale |

| Lead Time | Shorter, often within a few days or weeks | Longer, typically several weeks or months |

| Manufacturing Process | May utilize less automated processes | Employs highly automated, optimized processes |

| Design Flexibility | Allows for design changes before mass production | Requires finalized design with minimal changes |

| Ideal For | Initial design development, functional testing, and iterations | Final product manufacturing for market release |

For projects in the early stages of development, a prototype run is recommended. This allows for design verification and adjustments before committing to mass production. Once the design is finalized, transitioning to a production run helps reduce the cost per board due to the economies of scale associated with larger volumes. When requesting an online PCB quote, carefully specify the quantity and type of run required to ensure you receive an accurate and appropriate estimate.

Frequently Asked Questions About Online PCB Quotes

This section addresses common inquiries regarding online PCB quotes, providing clarity on aspects such as lead times, payment methods, shipping expenses, and the precision of online calculators. The aim is to equip users with the information needed to minimize errors and secure the most favorable deals.

- What is the typical turnaround time for an online PCB order?

Turnaround times vary depending on the complexity of your design, the manufacturer's current workload, and the shipping method selected. Standard lead times for simple boards can be as short as 24 hours, while more complex designs or larger orders may require several days or weeks. Always check the manufacturer's stated lead time when placing your order. - What payment methods are generally accepted for online PCB quotes?

Most online PCB manufacturers accept major credit cards (Visa, MasterCard, American Express), PayPal, and wire transfers. Some may also offer alternative payment methods like company checks for larger orders. Review each manufacturer's payment options to determine what best suits your needs. - How are shipping costs calculated for online PCB orders?

Shipping costs are typically determined by the weight and dimensions of your package, the shipping destination, and the shipping service selected (e.g., express, standard). Some manufacturers may offer flat-rate shipping based on order value or volume. These factors ensure transparency in your final cost calculation. - How accurate are online PCB quote calculators?

Online PCB quote calculators are generally accurate for standard designs and specifications. However, it is essential to be precise with your specifications, as subtle variations can impact cost. Always double-check the input parameters before finalizing your order. For complex designs, it's best practice to review and verify quotes manually with customer support representatives. - Are there any hidden costs to be aware of when using online PCB quote services?

While most reputable services provide transparent pricing, be vigilant for potential additional costs such as tooling fees for non-standard board shapes, expedited shipping charges, and value-added tax (VAT). Confirm the total cost with your manufacturer’s representative before finalizing your order. - How can I minimize errors when requesting an online PCB quote?

The most common errors in online quotes originate from inaccurate parameter input or incorrect interpretation of technical specifications. Ensure your Gerber files are prepared according to the manufacturer’s requirements and that your board’s dimensions, layer count, material type, and other parameters are double-checked. This helps prevent miscommunication and minimizes any potential costly mistakes. - What should I do if I need assistance with my online PCB quote?

Most online PCB manufacturers offer customer support via email, chat, or phone. Do not hesitate to reach out to them for help, as they are experts in resolving technical and pricing issues. Clearly explain your requirements and be ready to provide your design files and specifications for a complete understanding.

Tips for Getting the Best Online PCB Quote

Securing an optimal online PCB quote necessitates meticulous preparation and a clear understanding of your project's needs. By focusing on accuracy and completeness when compiling your specifications and files, you can significantly reduce costs and avoid delays. The following tips will guide you through the process, ensuring you receive the most favorable quote for your PCB fabrication.

- Precise Gerber Files

Ensure your Gerber files are generated correctly, adhere to industry standards (RS-274X format preferred), and include all necessary layers (copper, solder mask, silkscreen, drill data, board outline). Double-check for any errors or omissions before uploading. - Detailed Specifications

Provide clear and complete specifications, including board dimensions, layer count, material type (FR-4 is common, but alternatives exist), copper thickness, surface finish (e.g., ENIG, HASL), solder mask color, silkscreen requirements, and any impedance control needs. Avoid ambiguity for accurate pricing. - Panelization Considerations

If you need panelized PCBs, explicitly specify the array size, panel layout, and any required fiducials or tooling holes. Panelization can affect pricing, so accurately represent your needs to avoid surprises. - Accurate Quantity

Clearly state the required number of PCBs. Prices typically decrease with larger quantities, so ensure you request the correct amount. Confirm whether the quote is for a single panel or the total quantity of boards in the panel. - Lead Time Requirements

Specify your desired lead time (the time it takes to manufacture the PCBs). Expedited lead times typically incur higher costs, so planning ahead can optimize your budget. - Check for Special Requirements

If your PCB requires special features, such as blind or buried vias, controlled impedance traces, or specific material stack-ups, make sure to document these clearly. These features may impact costs and need to be accurately reflected in your quote. - Leverage Online Tools and Calculators

Use online calculators and tools provided by manufacturers to get preliminary estimates and compare prices across providers. However, be aware that these might not be as accurate as a finalized quote based on Gerber files. Cross-verify your data and do not solely rely on estimations.

Beyond Price: Evaluating PCB Manufacturer Reliability

While securing a competitive online PCB quote is essential, the true value of a PCB manufacturer extends beyond just the price. Reliability, encompassing factors like reputation, quality control, customer feedback, and support, significantly influences the overall success of your project. A low quote from an unreliable manufacturer can lead to costly delays, defective boards, and ultimately, project failure.

This section explores these crucial non-price related aspects to help you make informed decisions when selecting a PCB fabrication partner.

- Manufacturer Reputation

A manufacturer's reputation, built over years of service, reflects their reliability and commitment to quality. Look for established companies with a proven track record. - Quality Control Processes

Robust quality control is paramount in ensuring that the final PCBs meet the required specifications. Inquire about their testing procedures and certifications. - Customer Reviews and Testimonials

Online reviews provide genuine insights into the experiences of other customers. Pay close attention to patterns of satisfaction or dissatisfaction. - Technical Support and Communication

Effective and responsive technical support can be invaluable, particularly when complex technical issues arise. Assess the manufacturer's communication protocols, such as their responsiveness and willingness to help. - Certifications and Standards

Manufacturers that adhere to industry standards and hold certifications (e.g., ISO 9001, UL) demonstrate their dedication to maintaining quality and regulatory compliance. - Manufacturing Capabilities and Capacity

Ensure that the manufacturer has the necessary facilities and resources to handle your project’s specific requirements and can scale production to your needs.

Obtaining an online PCB quote has revolutionized the way electronic projects are approached. It streamlines the initial stages, allowing for quick iterations and informed decision-making. By understanding the factors that affect cost, diligently preparing your project files, and choosing a reputable manufacturer through an [online pcb quote] process, you can ensure your projects come to life efficiently and cost-effectively. As technology continues to evolve, these processes will only become more seamless, further accelerating innovation in the electronics landscape. Start your journey today with a simple online PCB quote.

AnyPCBA

AnyPCBA