Get Your Instant PCB Quote: A Comprehensive Guide to Cost-Effective PCB Manufacturing

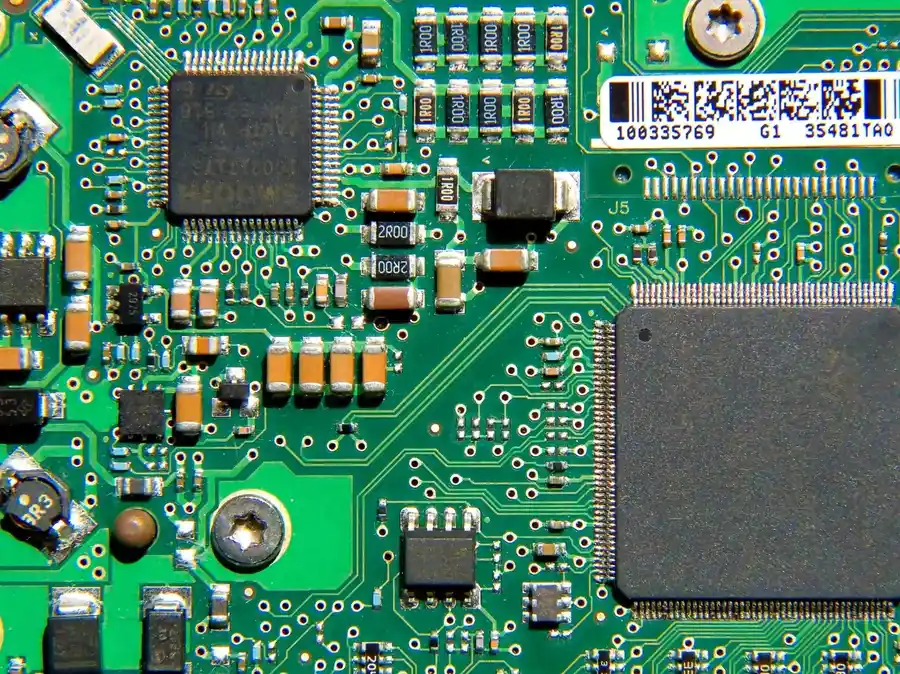

Printed circuit boards (PCBs), the silent heroes of modern electronics, are the bedrock of almost every electronic device we use daily. From the smartphone in your pocket to the complex industrial machines, PCBs enable functionality. Securing a timely and cost-effective PCB quote is vital for any project's success. This article delves into the world of PCB quotes, revealing how to navigate the process, understand pricing factors, and unlock the most competitive deals. We'll explore the landscape of online PCB quote systems and provide actionable insights to get the most value from your PCB manufacturing needs.

Understanding the Core Components of a PCB Quote

A Printed Circuit Board (PCB) quote is fundamentally determined by several key factors that reflect the complexity and material requirements of the board. Understanding these elements is crucial for accurately estimating the final manufacturing cost. These factors include the type of material used, the physical dimensions of the board, the number of layers, the surface finish, and the solder mask color. Each of these parameters plays a significant role in the overall pricing.

| Component | Description | Cost Impact |

|---|---|---|

| Material Type | Refers to the substrate material (e.g., FR-4, Aluminum, Rogers) used to construct the PCB. FR-4 is standard, while others offer unique properties. | Higher performance materials increase the cost. |

| Dimensions | The length and width of the PCB, influencing the amount of material needed. | Larger boards use more material, increasing the cost. |

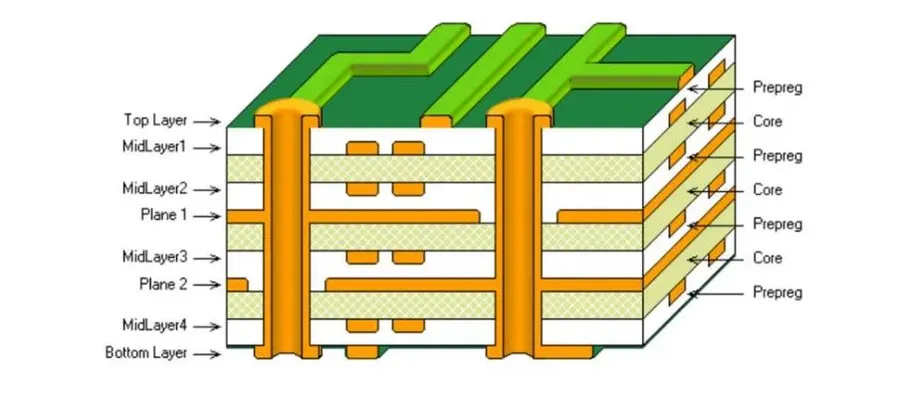

| Layer Count | The number of conductive layers in the PCB, allowing for complex circuit designs. | More layers mean more complex fabrication, resulting in a higher cost. |

| Surface Finish | The coating applied to exposed copper to improve solderability and prevent oxidation (e.g., HASL, ENIG, Immersion Tin). | Different finishes have varying costs, with ENIG generally being more expensive than HASL. |

| Solder Mask Color | The protective layer that covers the conductive layers. Green is the standard, but other colors are available. | Standard colors are cost effective, while specialty colors may incur extra charges. |

The Role of Online PCB Quote Calculators

Online PCB quote calculators have revolutionized the procurement process for printed circuit boards, offering a streamlined and efficient method for obtaining instant cost estimates. These systems provide a convenient alternative to traditional quoting methods, allowing users to rapidly assess the financial implications of their design choices.

At the heart of these online tools is a robust engine that considers a multitude of parameters to generate an accurate quote. Users input their design specifications, such as board dimensions, layer count, material type, and surface finish, and the system instantly calculates the corresponding cost. This capability allows for immediate evaluation of different design scenarios, facilitating rapid iteration and cost optimization.

The major advantages of using online PCB quote calculators are speed and convenience. Obtaining quotes through traditional means involves a lengthy process, including contacting vendors, submitting files, and waiting for a response, which can take days or weeks. Online calculators eliminate these delays, providing real-time estimates within minutes. This expedites the design and prototyping process, allowing engineers to move quickly from conceptualization to manufacturing.

Key features of most online PCB quote calculators include:

- Real-Time Cost Estimates

Instantaneous pricing based on user-defined parameters, eliminating delays in the quoting process. - Parameter Customization

Ability to specify a wide range of design parameters, including board dimensions, layer count, material, and surface finish. - Multi-Platform Accessibility

Accessible via web browsers on different devices, ensuring ease of use across various operating systems and screen sizes. - File Upload Options

Capability to directly upload Gerber files, simplifying the data transfer process for accurate quotes. - Comparative Analysis

Option to compare costs with varied design parameters, allowing assessment of the financial implications of different design choices.

Factors Influencing PCB Manufacturing Costs

Understanding the factors that drive Printed Circuit Board (PCB) manufacturing costs is crucial for effective budgeting and project management. These factors encompass material choices, design complexity, manufacturing processes, and order specifications. Effectively balancing these elements is key to optimizing cost without sacrificing quality or performance.

| Factor | Cost Impact | Description |

|---|---|---|

| Quantity | Economies of Scale | Larger production runs typically reduce the per-unit cost due to amortized setup and tooling costs. Small quantities often incur higher per-board costs. |

| Lead Time | Premium for Speed | Expedited lead times typically incur a higher cost due to the need for quicker processing and dedicated resources. Standard lead times are generally more cost-effective. |

| Board Complexity | Direct Correlation | Features such as a high layer count, small vias, fine-pitch components, and complex routing directly increase the fabrication complexity, and thus the cost. |

| Material Type | Variable Impact | The choice of substrate material (e.g., FR-4, aluminum, polyimide) significantly affects cost, with advanced materials generally being more expensive. Material thickness also contributes to the overall cost. |

| Surface Finish | Variable Cost | Different surface finishes, such as HASL, ENIG, and Immersion Silver, vary in cost and suitability for different applications. ENIG, for example, is typically more expensive than HASL. |

| Solder Mask Color | Minor Impact | While typically a minor cost factor, custom or less common solder mask colors can sometimes lead to increased costs compared to standard green. |

| Special Processes | Increased Cost | Specialized requirements like blind or buried vias, controlled impedance, and specific testing add to the cost due to the more advanced processes involved. |

| Panelization | Cost Saving Opportunity | Panelizing a design, where multiple boards are manufactured on one panel, can reduce costs if done properly to maximize panel usage and minimize material waste. |

Comparing PCB Manufacturers and Their Offerings

Selecting the right PCB manufacturer is crucial for balancing cost, quality, and turnaround time. This section provides a comparative analysis of various manufacturers, their pricing structures, specializations, and customer feedback, to aid in making informed decisions.

| Manufacturer | Pricing Model | Specialization | Lead Time | Customer Reviews (Avg Rating/5) | Pros | Cons |

|---|---|---|---|---|---|---|

| JLCPCB | Competitive, tiered pricing based on volume and complexity | Low-cost prototypes and small to medium production runs | Fast (24 hrs for some prototypes, 3-7 days production) | 4.6 | Low cost, fast turnaround, online ordering | Limited material options, less customization |

| PCBWay | Moderate pricing, bulk discounts available | Complex PCB designs, multi-layer PCBs, and SMT assembly | 3-5 days for prototyping, 7-15 days for production | 4.7 | Good quality, wide range of services, SMT assembly | Can be slightly more expensive than JLCPCB |

| Allpcb | Competitive, instant quotes | Quick turn prototyping, low to medium volume production | 24 hours-7 days | 4.5 | Affordable, fast, good customer service | Limited advanced options |

| Eurocircuits | Higher pricing, focused on high-quality | High-reliability boards, high-layer count, and advanced materials | Moderate to longer (5-10 days for prototyping, 10-20 days production) | 4.8 | Excellent quality, comprehensive testing options, good for complex designs | Higher cost, longer lead times |

| Advanced Circuits | Moderate to high, focused on rapid turnaround | Quick turn prototypes, complex boards for Aerospace and defense | Fast (24 hrs for some prototypes, 5-10 days production) | 4.7 | Very fast, domestic manufacturing, good for complex boards | More expensive than overseas options |

Tips for Optimizing Your PCB Design for Cost-Effectiveness

Optimizing your PCB design is crucial for minimizing manufacturing costs without compromising quality. Strategic design choices can significantly impact the final price, making it essential for designers to understand and implement cost-effective practices.

- Layer Stackup Optimization

Minimize the number of layers if possible. Each additional layer increases manufacturing complexity and cost. Consider a 2-layer or 4-layer board for simpler designs to reduce expenses. Proper planning of the layer stack up ensures impedance control and signal integrity but may add complexity, so a careful balance needs to be struck based on application needs. - Panelization

Panelize your PCBs, which means arranging multiple copies of your board on a single panel. This is especially cost effective for mass production and assembly. Manufacturers can fabricate and assemble multiple boards simultaneously, reducing cost. Consider using standard panel sizes to avoid incurring additional setup fees. - Material Selection

Choose standard materials like FR-4 for most applications. Advanced materials like Rogers can increase the cost considerably. Assess the actual needs of your design, and if standard materials meet the required performance criteria, opt for them to reduce material costs. Be aware that choosing alternative materials might have implications on manufacturing processes and thus cost. - Component Selection

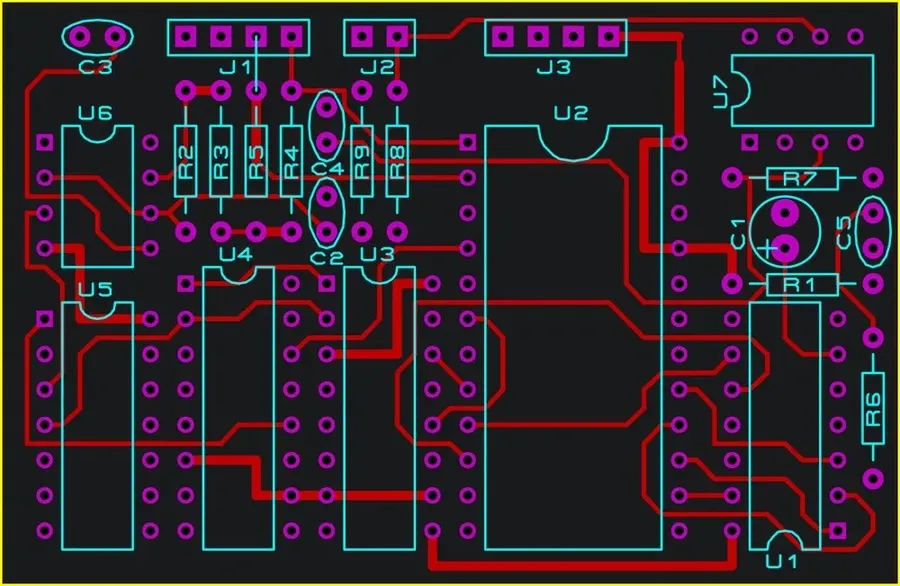

Utilize standard components rather than custom or rare parts whenever possible, as these are typically more readily available and cost-effective. Standard components also often come in larger production runs, which contributes to lower per-unit prices. Avoiding hard-to-source components will also reduce procurement times and potential delays in your production cycle. - Via Optimization

Minimize the number of vias used in your design. Using blind or buried vias will increase cost. Using standard through-hole vias wherever possible will reduce complexity and cost. Careful routing will reduce unnecessary vias. - Trace Width and Spacing

Use standard trace widths and spacing if possible. These are easier to manufacture and will avoid additional costs. Minimum trace widths and spacing often require higher fabrication accuracy and could drive costs up. Consult your manufacturer's capabilities and standards to achieve a balance between density and cost.

Beyond the Quote: Considerations for PCB Manufacturing

While obtaining a PCB quote is a crucial first step, a holistic view of PCB manufacturing extends beyond just the price tag. Factors like turnaround time, quality control measures, availability of assembly services, and shipping logistics significantly impact the overall project outcome. Choosing a PCB manufacturer involves evaluating these critical non-price factors to ensure a successful and reliable final product.

Turnaround time is crucial, especially for time-sensitive projects. It's important to verify the manufacturer's stated lead times for both fabrication and assembly. Quality control is another key aspect. Manufacturers should have stringent testing protocols and quality control measures in place to ensure the boards meet the required specifications. Moreover, if assembly services are needed, choosing a manufacturer that offers a comprehensive solution for both PCB fabrication and assembly can simplify the process and potentially reduce costs. Finally, evaluating the shipping options and costs is vital, as shipping can significantly impact the overall project budget.

The benefits of using a one-stop shop are numerous. It consolidates the manufacturing process, simplifies communication, reduces potential errors caused by transferring designs between different entities, and often leads to better coordination. A single point of contact for both fabrication and assembly streamlines the process, ensuring better project management and ultimately reducing project time and costs. Further, verifying the manufacturer's qualifications through certifications, customer reviews, and sample quality checks, especially in initial orders, contributes significantly to the project's long-term success.

| Factor | Description | Impact |

|---|---|---|

| Turnaround Time | Time from order placement to delivery. | Project timeline, overall project cost (due to delays). |

| Quality Control | Testing and inspection protocols during manufacturing. | Product reliability, performance, and longevity. |

| Assembly Services | Availability of SMT and other assembly options. | Simplified production, reduced costs through streamlining. |

| Shipping and Logistics | Shipping options, time, and costs. | Overall project cost, delivery time, handling impact. |

| One-Stop Shop | Combined fabrication and assembly services. | Simplified workflow, project management, coordination and time. |

Frequently Asked Questions About PCB Quotes

This section addresses common queries related to obtaining PCB quotes, providing concise answers to assist users in understanding the process and making informed decisions about their PCB manufacturing needs.

- What is the typical turnaround time for a PCB quote and subsequent fabrication?

Turnaround times vary significantly based on the complexity of the board, the manufacturer's workload, and the shipping method chosen. Simple, standard PCBs can often be quoted instantly, with fabrication completed within a few days. Complex designs, or those requiring special materials and processes, may require several days or weeks for both quoting and manufacturing. - How does the quantity of PCBs affect the overall cost?

The relationship between quantity and cost is not linear. While increasing the number of PCBs reduces the unit cost due to economies of scale (spreading tooling, setup, and overhead costs), the cost doesn't simply halve if you double the quantity. Larger quantities typically offer better per-unit cost savings, particularly for larger production runs. - Can I obtain a quote for both PCB fabrication and assembly?

Yes, many PCB manufacturers offer integrated services for both fabrication and assembly. Obtaining a combined quote can be more efficient and cost-effective than sourcing these services separately. This bundled approach often includes component sourcing, PCB assembly, and quality control, simplifying the process for customers. - What file formats are typically required to obtain a PCB quote?

The industry-standard file formats required for quoting are Gerber files (.GBR), which describe the PCB layers, pads, and vias, along with an Excellon drill file (.DRL) detailing the hole sizes and locations. A bill of materials (BOM) in CSV or Excel format, listing all the components required for assembly, is necessary for a combined fabrication and assembly quote. Often, a pick-and-place file (.TXT, .CSV) is also needed for assembly quotes. - How can I verify the quality and reliability of a PCB manufacturer before committing to a quote?

Verify the PCB manufacturer's certifications (e.g., ISO 9001), read customer reviews and testimonials, check sample boards and compare their quality to your requirements. Request detailed specifications of materials used and the manufacturing processes they employ to ensure the pcb meets your expectations. Evaluate the manufacturer’s quality control process. A reputable manufacturer will readily provide this information and can share a sample for validation. - What is the impact of surface finish choices (e.g., HASL, ENIG) on the PCB quote?

Different surface finishes provide varying levels of solderability, resistance to oxidation, and cost. HASL (Hot Air Solder Leveling) is generally the most cost-effective, but ENIG (Electroless Nickel Immersion Gold) offers better solderability and reliability, often with a higher price tag. Other options include OSP (Organic Solderability Preservative) which can provide a balance of cost and performance. Select a surface finish that meets both the functional needs and the cost targets of your project. - Are there additional costs associated with prototype runs versus mass production?

Yes, prototype runs often incur higher per-unit costs due to setup expenses and smaller volumes. Mass production benefits from economies of scale, lowering the individual board price. Some manufacturers may have specific programs for prototype runs that can be optimized for cost, so you should always verify this with the manufacturer.

Emerging Trends in PCB Quoting and Manufacturing

The PCB industry is constantly evolving, with emerging trends in both quoting and manufacturing processes. These trends are driven by technological advancements, market demands, and a growing focus on sustainability. Understanding these trends is crucial for businesses looking to optimize costs, improve efficiency, and stay competitive.

- Automation in PCB Manufacturing

Increased automation through robotics and AI is streamlining PCB production. This reduces human error, shortens lead times, and enhances precision, ultimately lowering costs and improving quality. Smart factories with automated processes are becoming the standard, and are being integrated into online quote systems to provide more accurate cost estimates. - Advanced Materials

The utilization of new materials with enhanced performance characteristics is gaining momentum, providing enhanced thermal performance, greater flexibility, and reduced weight. Advanced ceramics, bio-resins, and flexible substrates are among the materials revolutionizing PCB design and manufacturing, and also impacting the quoting process. These materials are used for specialized applications, and can contribute to both higher cost and improved functionality. - Eco-Friendly Processes

Sustainability is becoming a vital consideration in PCB manufacturing. The industry is transitioning towards eco-friendly materials, such as lead-free solder and bio-based resins, reducing the use of harmful chemicals, and implementing water treatment and energy-saving processes. As environmental regulations become more stringent, these processes are increasingly influencing quoting and manufacturing practices. The use of environmentally friendly material can increase the upfront material costs of the PCB. - AI and Machine Learning in Quoting

Artificial intelligence and machine learning algorithms are being adopted in online quoting systems to provide more accurate and instant price estimations by analyzing complex design parameters and market trends. AI-powered tools can predict the cost of manufacturing based on the specifications and help to optimize both design and material selection to reduce cost. This allows real-time pricing adjustments based on market fluctuation. - Digital Twins

Digital twin technology is being employed to simulate the entire PCB manufacturing process. Digital twins help optimize manufacturing workflows, reduce waste, and improve quality, which is ultimately reflected in the quoting process. This simulation can reduce the overall cost of PCB manufacturing by enabling design optimization before physical production begins. - On-Demand Manufacturing

On-demand manufacturing and prototyping services are making PCB fabrication more accessible to smaller companies and individual inventors. This allows for the rapid prototyping of designs and fast turnaround times for small-quantity production runs. This approach is particularly beneficial for complex designs that require testing before mass production, and is reflected in faster quoting processes.

Securing a good PCB quote is an essential part of any electronic design and manufacturing process. Understanding the cost drivers, leveraging online tools, and optimizing design choices allows for informed decisions. Just as the complexity of the electronic world is built upon the foundation of the PCB, so must your project be built upon a sound understanding of how to secure the best pcb quote, and manufacture those core components. By utilizing the insights provided here, you're well-equipped to get the best possible outcome for your project, and effectively navigate the world of PCB manufacturing. In the evolving world of technology, keeping informed will only elevate your work.

AnyPCBA

AnyPCBA