Powering Innovation: Understanding PCB Power Company

In today's rapidly evolving world of electronics, printed circuit boards (PCBs) are the backbone of nearly every device we use. The PCB Power Company stands as a pivotal player in this landscape, powering innovation across industries with its comprehensive manufacturing and design services. This article delves into the core of PCB Power, exploring its offerings, global impact, and its commitment to delivering quality PCBs that drive technological advancement. Understanding their role is crucial for anyone involved in electronics design and manufacturing.

What is PCB Power Company?

PCB Power Company is a prominent entity in the printed circuit board (PCB) manufacturing sector, specializing in the production of high-quality PCBs and related services. Their core mission is to provide robust, reliable, and cost-effective PCB solutions to a global clientele, supporting innovation across various industries. The company has evolved to become a key player by delivering comprehensive services ranging from PCB fabrication to assembly, catering to diverse project needs with a commitment to quality and technological advancement.

Comprehensive PCB Manufacturing Services

PCB Power offers a comprehensive suite of PCB manufacturing services, addressing the diverse needs of the electronics industry. Their capabilities span from initial design support to the mass production of printed circuit boards, encompassing fabrication, component sourcing, assembly, and layout services.

These services ensure that clients receive end-to-end solutions, streamlining the manufacturing process and reducing time-to-market. The focus is on delivering high-quality PCBs that meet stringent performance requirements across various applications.

| Service | Description | Key Features |

|---|---|---|

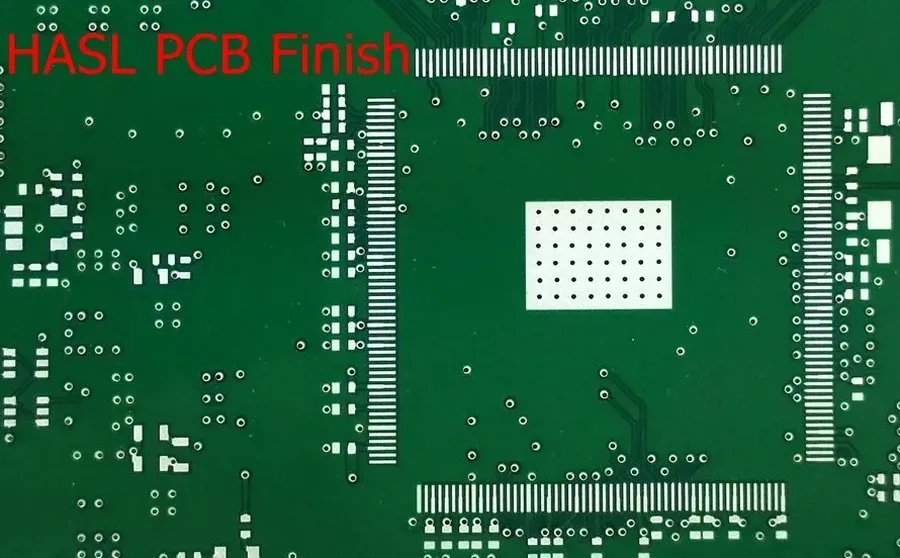

| PCB Fabrication | Manufacturing of bare PCBs based on design specifications. | Supports single-layer, multi-layer, and flex PCBs; High precision manufacturing; Wide range of materials; various surface finishes. |

| Component Sourcing | Procurement of electronic components required for PCB assembly. | Extensive network of suppliers; Ensures availability of high-quality components; Competitive pricing. |

| PCB Assembly | Mounting of electronic components onto fabricated PCBs. | Surface mount technology (SMT) and through-hole assembly; Automated assembly lines; High throughput and accuracy; Testing and inspection. |

| PCB Layout | Designing and optimization of the PCB layout for efficient electrical performance. | Expertise in signal integrity analysis; Design for manufacturability (DFM); Collaboration with clients; Optimization for performance |

The range of PCB types manufactured by PCB Power is extensive, including single-layer PCBs for basic applications, multi-layer PCBs for complex designs requiring high density and performance, and flexible PCBs for applications requiring bending and fitting into irregular spaces. These flexible PCBs are ideal for aerospace, automotive, and medical industries. Their expertise and advanced capabilities in each of these areas are crucial for product innovation and reliability.

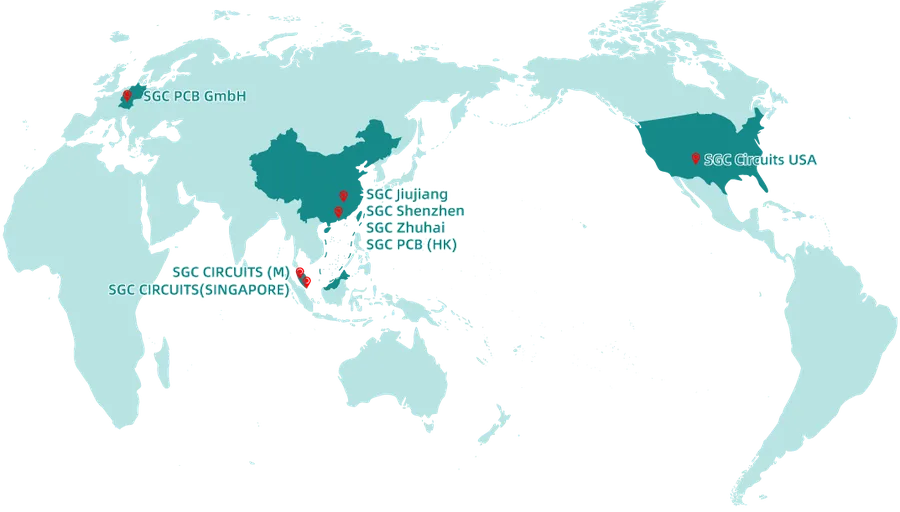

Global Reach: Locations and Impact

PCB Power's global presence is a cornerstone of its ability to deliver robust manufacturing solutions and high-fidelity PCB designs to a diverse clientele. With strategic locations in key regions such as India and the USA, PCB Power ensures efficient production, logistics, and support for its customers across different time zones and markets.

The company's footprint is not just about geographical distribution; it's about the impact it creates within the local electronics industries. Through its facilities, PCB Power fosters technological advancements and provides employment opportunities within the regions it operates.

| Region | Significance | Impact |

|---|---|---|

| India | Serves as a major manufacturing hub for both domestic and international markets. | Contributes to the local electronics ecosystem, provides job opportunities, and supports the growing demand for high-quality PCBs. |

| USA | Provides close proximity and support for US-based companies, ensuring faster turnaround and streamlined communication. | Facilitates advanced technology adoption and provides tailored solutions to the North American market. |

Industries Served by PCB Power

PCB Power's versatile manufacturing capabilities support a wide spectrum of industries, each with unique demands for printed circuit boards. Their expertise ensures that diverse sector requirements are not only met but exceeded, facilitating technological advancements across multiple domains.

| Industry | Specific Needs | PCB Power's Solutions |

|---|---|---|

| Aerospace | High reliability, extreme temperature tolerance, low weight | Robust PCBs with advanced materials, stringent quality control, compliance with aerospace standards (e.g., AS9100) |

| Industrial | Durability, resistance to harsh environments, high current carrying capacity | Heavy copper PCBs, ruggedized designs, extended operational temperature ranges |

| Consumer Electronics | Cost-effectiveness, miniaturization, high-volume production | Multilayer PCBs, advanced surface mount technology, optimized manufacturing processes for scale |

| Medical Devices | Precision, reliability, biocompatibility, adherence to strict regulatory requirements | High-density interconnect (HDI) PCBs, biocompatible materials, stringent validation processes |

| Automotive | High reliability in harsh conditions, vibration resistance, compliance with automotive standards | Automotive grade PCBs with rigorous testing, high-temperature materials, quality adherence to IATF 16949 |

| Telecommunications | High-speed signal integrity, low signal loss, advanced RF capabilities | RF PCBs, impedance-controlled designs, high-frequency materials |

| Renewable Energy | High power handling, durability, extended operational lifespan | Heavy copper PCBs, high-temperature stability, customized power circuit designs |

PCB Power's Technological Capabilities

PCB Power leverages advanced technologies and robust manufacturing processes to deliver high-quality, cost-effective printed circuit boards. Their technological capabilities are built upon a foundation of agility, ensuring rapid response to customer needs and evolving industry demands.

Key aspects of their technological approach include:

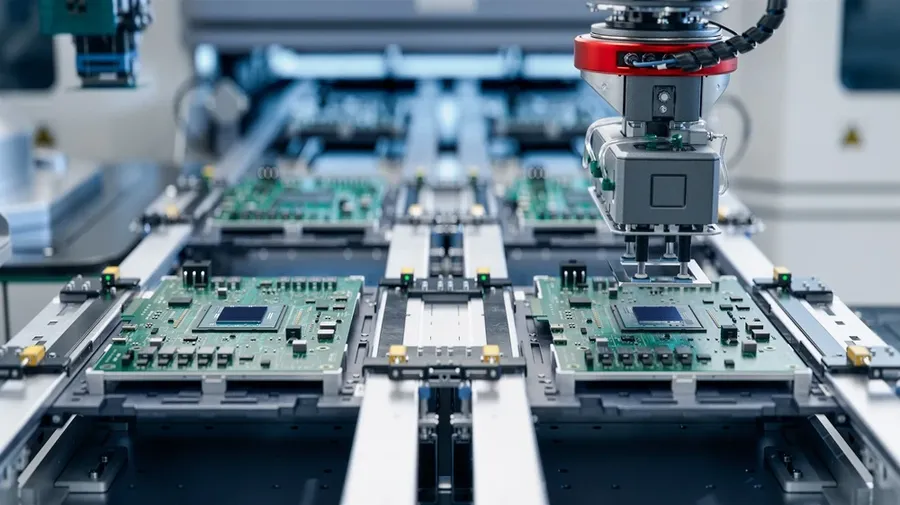

- Advanced Manufacturing Equipment

PCB Power employs state-of-the-art machinery for precise fabrication, including automated pick-and-place machines for component assembly, laser direct imaging (LDI) systems for high-resolution patterning, and automated optical inspection (AOI) systems to ensure defect-free production. These technologies minimize human error and maximize throughput. - Surface Mount Technology (SMT)

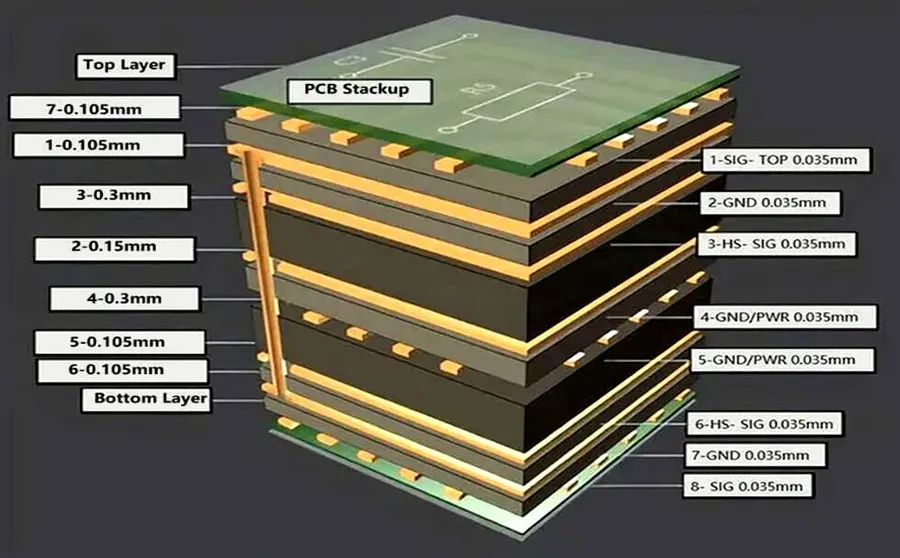

The use of SMT allows for the efficient placement of components directly onto the surface of the PCB, facilitating higher circuit densities and better electrical performance. This technique is critical for manufacturing modern, compact electronic devices. - Multi-Layer PCB Fabrication

PCB Power's expertise extends to multi-layer PCB fabrication, utilizing controlled impedance processes for high-speed signal transmission. This includes precise layer registration and lamination to ensure signal integrity and reliability. - Automated Processes

Automation is paramount in PCB Power's approach, reducing lead times and production costs. From design rule checking (DRC) to automated testing, various stages are optimized for efficiency and reliability. - Material Selection

A wide array of materials are available for PCB fabrication, ranging from FR-4 for standard applications to high-frequency laminates such as Rogers or Teflon for more specialized needs. Careful material selection is crucial to achieve specific design and performance requirements. - Cost-Effective Manufacturing

By integrating advanced technology and efficient production methods, PCB Power strives to deliver cost-effective PCB solutions without compromising quality. This is achieved through process optimization, material management, and lean manufacturing principles.

| Technology | Description | Benefit |

|---|---|---|

| Laser Direct Imaging (LDI) | Uses laser to directly create patterns on PCB | High precision, fine lines, reduced cost |

| Automated Optical Inspection (AOI) | Automated inspection for PCB defects | Improved quality, reduced error |

| Surface Mount Technology (SMT) | Mounting components directly onto PCB | Higher density, better electrical performance |

| Multi-Layer PCB Technology | Fabricating PCBs with multiple layers | Complex circuits, high functionality |

PCB Design and Layout Expertise

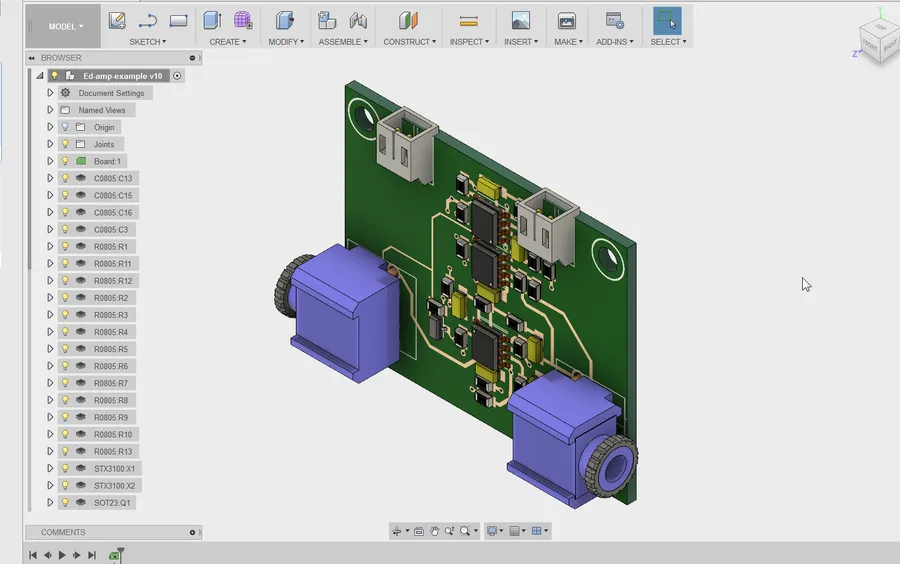

PCB Power provides comprehensive PCB design and layout services, guiding clients from initial concept through to a finished, manufacturable product. Their expertise encompasses schematic capture, PCB layout, and prototyping, streamlining the development process. By leveraging their experienced team, customers can expect optimized designs that adhere to industry standards and best practices, reducing time-to-market and ensuring high performance.

PCB Power's design and layout services cater to various needs, from simple single-layer boards to complex multi-layer and flex PCBs. Their team is adept at navigating the challenges associated with high-density and high-speed designs, and ensures optimal signal integrity and thermal management. By utilizing cutting-edge software and processes, they offer designs that are both robust and cost-effective.

Furthermore, PCB Power offers online design tools and an intuitive ordering process, simplifying the transition from design to production. Clients can upload their design files, receive instant quotes, and track their orders through each stage of the process. This online platform allows for efficient communication between the client and PCB Power's engineering team, accelerating the design cycle and ensuring accuracy.

Quality Assurance and ITAR Compliance at PCB Power

PCB Power prioritizes rigorous quality assurance and adherence to industry standards, ensuring the reliability and performance of every printed circuit board (PCB) they manufacture. Their commitment to quality is manifested through comprehensive testing, meticulous inspection processes, and compliance with stringent international regulations, particularly ITAR.

A robust quality management system is foundational to their operations. This system encompasses several key aspects:

- Incoming Material Inspection

All raw materials undergo thorough checks upon arrival to ensure they meet specified quality standards. This includes verifying material type, thickness, and other critical properties. - In-Process Quality Control

Continuous monitoring and testing during the PCB manufacturing process ensure that each stage meets stringent quality parameters. This includes dimensional checks, lamination quality assessments, and electrical testing at various points. - Final Quality Inspection

Prior to shipment, every PCB is subjected to a comprehensive final inspection. This process includes visual checks for defects, electrical testing to ensure functionality, and dimensional verification to guarantee accurate specifications. - Testing Protocols

PCB Power employs various testing methods, such as electrical continuity testing, impedance testing, and functional testing, to confirm that the PCBs meet the design specifications and performance requirements.

ITAR compliance is of paramount importance for PCB Power, particularly when dealing with clients in the aerospace, defense, and related sectors.

- ITAR (International Traffic in Arms Regulations) Compliance

PCB Power adheres strictly to ITAR regulations, ensuring that all manufacturing processes and data handling meet the necessary requirements for controlled goods. This involves maintaining secure facilities, implementing access control, and training employees on ITAR procedures. - Data Security

The handling and storage of sensitive data, especially regarding ITAR-controlled products, are done with utmost security. PCB Power uses secure systems and protocols to protect sensitive information from unauthorized access. - Traceability

All processes are traceable from material origin to final product, aiding quality control and compliance audits, which further demonstrates their commitment to security and regulation.

PCB Power's dedication to quality assurance and ITAR compliance makes them a reliable partner for industries requiring high-performance and highly regulated PCBs. They ensure that all manufactured products meet stringent quality and compliance standards.

Frequently Asked Questions About PCB Power Company

This section addresses common inquiries regarding PCB Power Company, offering clear, concise answers to enhance understanding of their operations and capabilities in the PCB manufacturing sector.

- Who is the owner of PCB Power Company?

While specific ownership details can vary, it's important to refer to the company's official website or corporate filings for the most accurate and up-to-date information on its ownership structure. Typically, such information is available in the 'About Us' or 'Investor Relations' section. - What role do PCBs play in power supplies?

In power supplies, PCBs act as the foundation for all electronic components, providing a structured and interconnected platform for the circuits to operate. They offer both electrical and mechanical support for all components, ensuring efficient power transmission and stability. The layout of the PCB directly influences thermal performance and the overall reliability of the power supply. - What makes PCB Power a reliable PCB manufacturing company?

Reliability in PCB manufacturing stems from stringent quality control, adherence to industry standards, and the use of advanced technologies. PCB Power, like other reputable companies, ensures reliability through rigorous testing, ITAR compliance (if applicable), and transparent processes. Key factors include precision manufacturing, high-quality materials, and consistent performance. - What does PCB stand for?

PCB stands for Printed Circuit Board. It is a non-conductive board with conductive pathways (traces) printed or etched onto its surface. These pathways connect various electronic components, allowing them to communicate and function together. It is the physical structure on which most electronic devices are built. - What are PCB Power's key capabilities in PCB manufacturing?

PCB Power offers a comprehensive suite of services encompassing PCB design, fabrication, assembly, and testing. Key capabilities include producing single-layer, multi-layer, and flexible PCBs, component sourcing, layout services, and online ordering platforms, which help streamline the process from concept to finished product. Their advanced technologies and scalable infrastructure are pivotal to serving diverse industries with specialized needs. - Does PCB Power offer online PCB ordering services?

Yes, PCB Power provides online ordering services, allowing customers to easily submit designs, receive quotes, and track the production of their PCBs. These platforms are designed to be user-friendly, providing efficient and transparent communication and management of orders, thereby simplifying the process from design to delivery. - What types of industries benefit from PCB Power's services?

PCB Power caters to a wide range of industries, including but not limited to, aerospace, industrial, consumer electronics, and medical devices. Each industry has unique needs regarding PCB specifications (complexity, reliability, and size). PCB Power has the capability to provide solutions that meet the strict requirements for high-fidelity, robust performance in these critical fields.

Choosing the Right PCB Manufacturer: Why PCB Power Stands Out

Selecting the appropriate PCB manufacturer is crucial for the success of any electronics project. While several companies exist in the market, including JLCPCB and PCBWay, PCB Power distinguishes itself through a combination of factors including robust manufacturing processes, comprehensive service offerings, and a commitment to quality. This section will analyze these differentiators, demonstrating why PCB Power is often the preferred choice.

| Feature | PCB Power | JLCPCB | PCBWay |

|---|---|---|---|

| Service Range | Comprehensive: Fabrication, Assembly, Component Sourcing, Layout | Primarily Fabrication | Fabrication & Assembly |

| Manufacturing Capabilities | Advanced: Multi-layer, Flex, Rigid-Flex | Standard: Multi-layer | Standard: Multi-layer |

| Quality Assurance | Stringent ITAR Compliance, Multi-Point Checks | General Quality Checks | General Quality Checks |

| Global Support | Multiple Facilities across India and the USA | Primarily China-based | Primarily China-based |

| Turnaround Time | Flexible, with options for expedited service | Variable, dependent on complexity | Variable, dependent on complexity |

| Customization | High degree of customization in design and manufacturing | Limited customization options | Limited customization options |

| Cost | Competitive pricing with value-added services | Budget focused | Budget focused |

PCB Power's Unique Selling Propositions (USPs) include its comprehensive service offering. Unlike some competitors focusing primarily on fabrication, PCB Power provides end-to-end solutions, from design and layout to component sourcing and assembly. This integrated approach streamlines the process for clients and reduces the risk of incompatibilities between different stages of production. Furthermore, their commitment to quality, particularly through ITAR compliance and rigorous multi-point checks, ensures that the final PCBs are reliable and perform as expected, which is especially critical for high-stakes applications. Lastly, their global facilities provide both flexibility and robust manufacturing solutions, with responsive customer support in multiple regions.

The PCB Power Company is a critical force in the electronics manufacturing sector, powering innovations across a wide range of industries. Their global presence, comprehensive services, and commitment to quality make them a leading partner for companies seeking high-fidelity and robust PCB solutions. As technology continues to evolve, the PCB Power Company remains at the forefront, driving the industry forward with its dedication to delivering top-notch PCBs that push the boundaries of what's possible. The company's integrated approach and agile manufacturing process ensures that from design to production, customers are supported with the highest standards of service and expertise.

AnyPCBA

AnyPCBA