Speedy PCB Assembly Pty Ltd: Your Partner in Fast and Reliable PCB Solutions

In today's fast-paced world of electronics, time is of the essence. Speedy PCB Assembly Pty Ltd understands this need, offering rapid and reliable PCB assembly services. From initial design to final product, we provide the expertise and resources you need to bring your electronic innovations to life. This article explores the comprehensive services offered by Speedy PCB Assembly, ensuring your projects are completed efficiently and to the highest standards. By connecting the rapid evolution of technology with everyday needs, we aim to provide a clear and insightful overview of what Speedy PCB Assembly can offer.

Understanding Speedy PCB Assembly Pty Ltd's Core Services

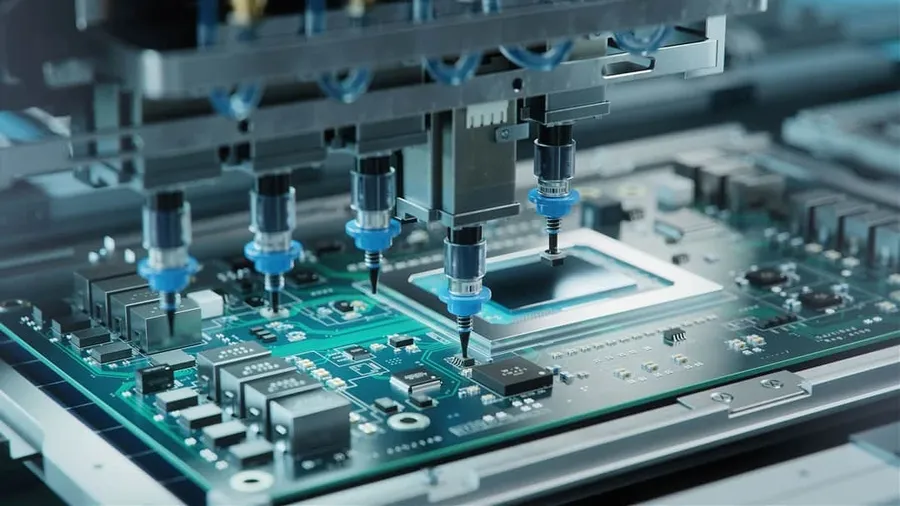

Speedy PCB Assembly Pty Ltd specializes in providing comprehensive printed circuit board (PCB) assembly services, encompassing a range of technologies to meet diverse manufacturing requirements. Their core services include Surface Mount Technology (SMT) assembly, through-hole assembly, and mixed technology assembly, each designed to ensure precision and reliability in electronic product manufacturing.

- Surface Mount Technology (SMT) Assembly:

SMT involves mounting electronic components directly onto the surface of a PCB. This method is ideal for high-density designs and is essential for miniaturized electronic devices. Speedy PCB utilizes automated SMT lines for efficient and precise component placement. - Through-Hole Assembly:

Through-hole assembly involves inserting component leads through holes in the PCB and soldering them on the opposite side. This method is commonly used for larger components and applications requiring robust mechanical connections. Speedy PCB offers both automated and manual through-hole assembly services. - Mixed Technology Assembly:

Mixed technology assembly combines both SMT and through-hole components on the same PCB. This approach is often necessary to achieve specific design goals where both surface mount and through-hole components are required for different functions or design constraints. Speedy PCB is equipped to handle such complex assemblies.

The Benefits of Choosing Speedy PCB Assembly

Speedy PCB Assembly Pty Ltd provides significant advantages for clients seeking efficient and reliable PCB assembly services. These benefits stem from their commitment to fast turnaround times, competitive pricing strategies, and a dedication to maintaining high-quality standards throughout the assembly process. Choosing Speedy PCB Assembly means partnering with a company that prioritizes speed, cost-effectiveness, and quality.

- Rapid Turnaround Times

Speedy PCB Assembly is structured to minimize lead times, offering expedited services for urgent projects without compromising quality. This capability is critical for time-sensitive product launches and prototype development. - Cost-Effective Solutions

The company’s efficient processes and streamlined operations allow for competitive pricing, making high-quality PCB assembly accessible to a broad range of clients, from startups to large corporations. They strategically manage costs without sacrificing the integrity of their services. - Uncompromising Quality Standards

Speedy PCB Assembly adheres to stringent quality control procedures, utilizing advanced testing and inspection protocols. Their focus on quality ensures that each assembled board meets exact specifications and performs reliably, resulting in consistent product performance and reducing the risk of costly failures. - Flexible and Scalable Services

Whether the project involves a small batch of prototypes or large-scale production, Speedy PCB Assembly offers flexible services that can adapt to diverse project needs. Their infrastructure can readily handle fluctuating demand, providing consistent services across varied project scopes and volumes.

| Benefit | Description | Impact on Clients |

|---|---|---|

| Quick Turnaround | Reduced lead times for PCB assembly. | Faster time-to-market, improved project timelines. |

| Competitive Pricing | Cost-effective PCB assembly services. | Lower project costs, budget-friendly for all clients. |

| High-Quality Standards | Rigorous quality control and testing procedures. | Reliable and durable PCBs, minimizing failures. |

| Flexible Scalability | Adapts to various project scopes. | Suits both prototype and large production volumes. |

Detailed Look at PCB Manufacturing Capabilities

Speedy PCB Assembly Pty Ltd demonstrates advanced capabilities in PCB manufacturing, offering a diverse range of printed circuit boards to meet varied design requirements. Their expertise encompasses the production of single-sided, double-sided, and multilayer PCBs, utilizing a variety of materials and precise dimensions.

| PCB Type | Description | Typical Applications | Material Options | Dimension Range |

|---|---|---|---|---|

| Single-Sided PCB | A basic PCB with components on one side only. | Simple electronics, basic devices | FR-4, CEM-1 | Up to 300mm x 300mm |

| Double-Sided PCB | PCB with components on both sides, connected by vias. | Standard electronics, industrial controls | FR-4, CEM-3 | Up to 400mm x 400mm |

| Multilayer PCB | PCB with three or more layers, increasing circuit density and complexity. | Complex systems, advanced technology | FR-4, High Tg FR-4 | Up to 500mm x 500mm |

The materials used in PCB manufacturing are crucial to the functionality and longevity of the boards. Speedy PCB Assembly Pty Ltd uses industry standard materials such as FR-4, which is a flame-retardant material widely used in electronics due to its good balance of cost and performance. For applications requiring higher performance, they also offer higher Tg FR-4 materials capable of withstanding higher operating temperatures.

Speedy PCB Assembly's Complete Product Assembly Services

Speedy PCB Assembly offers comprehensive product assembly services, managing the entire process from component procurement to the final, functional product. This includes electronic assembly, electrical integration, rigorous testing, and software or firmware programming, ensuring a streamlined and efficient manufacturing experience for clients.

| Service Category | Description | Key Activities |

|---|---|---|

| Electronic Assembly | The physical mounting of electronic components onto PCBs. | Surface Mount Technology (SMT), Through-Hole Technology (THT), and mixed technology assembly; component placement and soldering. |

| Electrical Integration | Connecting and wiring various electrical components and sub-assemblies. | Wiring harnesses, cable assembly, and interconnection of assembled PCBAs. |

| Functional Testing | Comprehensive testing to verify the correct operation of the assembled product. | In-circuit testing (ICT), functional testing, and environmental stress testing. |

| Programming & Firmware Loading | Loading software and firmware onto microcontrollers and other programmable devices. | Flashing firmware to integrated circuits and verifying software functionality. |

Location and Contact Information for Speedy PCB Assembly Pty Ltd

Speedy PCB Assembly Pty Ltd is strategically located in Derrimut, Victoria, providing accessible and efficient service to clients. This section details their precise address and vital contact information, ensuring seamless communication for all inquiries and project discussions.

Below are the essential contact details for Speedy PCB Assembly:

- Physical Address:

Derrimut, Victoria, Australia (Specific street address available upon direct inquiry for security purposes) - Contact Number:

Please contact us through the form provided on our website, as we do not list our direct phone numbers for public view. - Email:

Inquiries can be directed to our dedicated email address: sales@speedypcb.com.au - Website:

Visit our official website at www.speedypcb.com.au for comprehensive information.

Quality Assurance and Testing Procedures at Speedy PCB Assembly

Speedy PCB Assembly Pty Ltd implements rigorous quality assurance and testing procedures to ensure that all manufactured printed circuit boards (PCBs) meet the highest standards of quality and reliability. These processes are critical to identifying and rectifying any defects before the products reach the customer, thereby guaranteeing optimal performance and longevity.

The quality assurance framework at Speedy PCB Assembly is multi-faceted, encompassing several stages of production. These stages include but are not limited to:

- Incoming Material Inspection

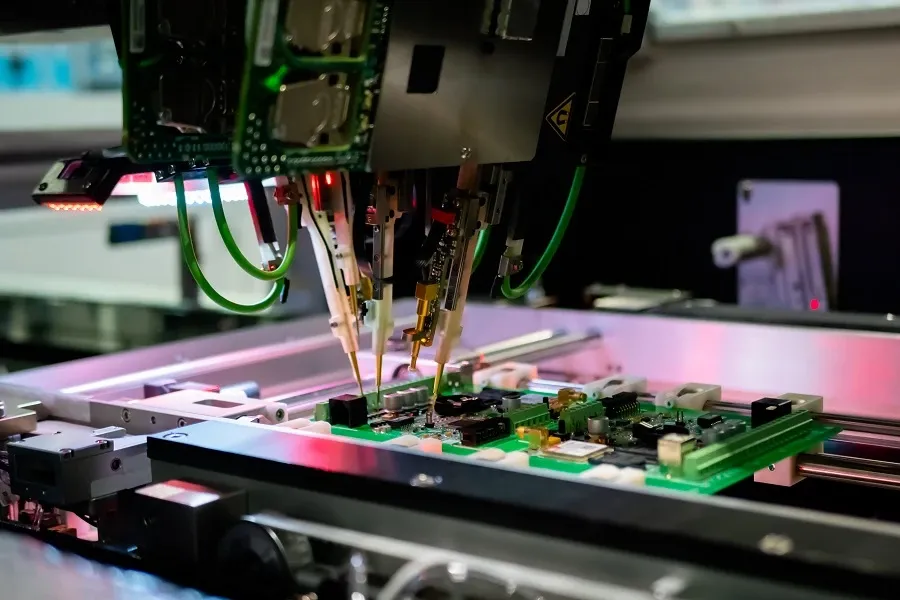

All raw materials, including PCB laminates, components, and solder pastes, undergo thorough inspection upon arrival. This ensures that only compliant and high-quality materials are used in the manufacturing process. - Automated Optical Inspection (AOI)

Following component placement and soldering, AOI machines inspect each board for defects such as misplaced components, solder bridges, and insufficient solder. This automated approach provides a highly accurate and rapid detection of potential issues. - X-Ray Inspection

For more complex assemblies and BGAs (Ball Grid Arrays), X-ray inspection is used to visualize solder joints beneath components, ensuring they meet specifications. - Functional Testing

Each PCB undergoes functional testing to verify its operation under simulated conditions. This may include checking voltage levels, signal integrity, and other parameters specific to the PCB's design. Customized test jigs and software can be designed to meet the specific needs of the product. - In-Circuit Testing (ICT)

ICT verifies the electrical connections and circuit values of the assembled PCB and detects shorts, opens, and component errors before the functional testing step. - Final Visual Inspection

A final manual inspection by experienced technicians is performed on each completed board to detect any visible defects that may have been missed by previous testing methods.

By integrating these comprehensive quality control measures, Speedy PCB Assembly ensures that every product meets the highest standards of quality and reliability, thereby providing its customers with trustworthy PCB solutions.

Customer Support and Communication at Speedy PCB Assembly

Effective communication is paramount at Speedy PCB Assembly Pty Ltd, ensuring a seamless experience for clients throughout their project. From initial consultation to post-project support, they prioritize clear and consistent dialogue to align with client needs and expectations.

- Initial Consultation and Project Scoping

Speedy PCB Assembly initiates each project with a thorough consultation to fully understand the client's requirements, specifications, and goals. This phase involves detailed discussions about the PCB design, materials, functionality, and timeline, ensuring all project parameters are clearly defined. - Regular Project Updates

Clients receive consistent updates throughout the assembly process, detailing progress against key milestones. These updates, typically provided via phone, email, or project management portal, keep clients informed, allowing for early identification and resolution of any potential issues. - Dedicated Project Management

Every client is assigned a dedicated project manager who acts as a central point of contact, streamlining communication and ensuring a cohesive and efficient project workflow. This approach ensures that clients have a go-to resource for questions and guidance throughout the assembly process. - Responsive Communication Channels

Speedy PCB Assembly employs various communication channels to provide clients the flexibility of reaching out for support. This includes phone, email, or an online support system, offering prompt response to client inquiries and concerns. - Post-Project Support and Feedback

Speedy PCB Assembly remains engaged with clients after project completion, offering technical support, addressing inquiries, and gathering feedback to continuously improve their services. They are committed to ensuring complete client satisfaction and building long-term partnerships.

Frequently Asked Questions About Speedy PCB Assembly Services

This section addresses common queries potential clients have about Speedy PCB Assembly Pty Ltd, providing essential details on lead times, pricing, accepted file formats, and other crucial information to facilitate a smooth and informed engagement.

- What are the typical lead times for PCB assembly at Speedy PCB Assembly?

Lead times vary depending on the complexity and volume of the order. However, Speedy PCB Assembly prides itself on its quick turnaround times. For standard SMT assembly orders, lead times are typically between 3 to 7 business days. Complex or large orders may require more time, and we recommend contacting us directly for an accurate estimate. - How does Speedy PCB Assembly determine pricing for PCB assembly services?

Pricing is primarily determined by the complexity of the PCB design, the number of components, the type of components (SMT, through-hole, mixed), the assembly method, order volume, and any special testing requirements. A detailed quote will be provided after reviewing your Bill of Materials (BOM) and PCB design files. We strive to provide competitive pricing while maintaining high standards of quality and reliability. - What file formats are accepted for PCB designs and Bill of Materials (BOM)?

For PCB design files, we commonly accept Gerber files (RS-274X), ODB++, and Eagle BRD files. For the Bill of Materials (BOM), CSV or Excel files with detailed component information such as part numbers, manufacturers, and quantities are preferred. It's crucial that BOMs are clear and precise to avoid delays in procurement and assembly. - Does Speedy PCB Assembly offer testing services after the PCB assembly process?

Yes, we offer comprehensive testing services that are essential to ensure the quality and functionality of the assembled PCBs. We provide various testing options, including visual inspection, automated optical inspection (AOI), in-circuit testing (ICT), and functional testing, based on your specific requirements and can customize test plans accordingly. These procedures ensure the final product meets design specifications before delivery. - Can Speedy PCB Assembly manage the procurement of components, or should I provide them?

Speedy PCB Assembly offers a full turnkey solution, which includes component procurement. However, you also have the option to supply the components if preferred. In either case, we recommend a discussion with our team to optimize the process based on your needs. We conduct rigorous checks on all procured parts, making sure they meet stringent quality parameters. - What kind of customer support can I expect during my PCB assembly project?

At Speedy PCB Assembly, we prioritize smooth communication throughout your project. You can expect dedicated support from our team from the initial consultation to post-project support. We keep clients informed with regular progress updates, ensuring that you always know the status of your order. Our aim is to ensure complete client satisfaction and will address any queries or issues promptly. - What quality assurance measures are in place at Speedy PCB Assembly?

Speedy PCB Assembly adheres to strict quality assurance protocols to ensure each board meets the highest quality and reliability standards. These measures include thorough inspections at various stages of the assembly process, from component verification to final product testing. We utilize advanced equipment and follow established quality control practices to guarantee the performance and longevity of the assembled PCBs.

Speedy PCB Assembly Pty Ltd stands out as a reliable partner for all your PCB assembly needs, offering not just speed, but also high-quality and comprehensive services. By combining cutting-edge technology with a focus on customer satisfaction, they ensure that your projects are completed efficiently and to the highest standards. Contact Speedy PCB Assembly Pty Ltd today to explore how they can bring your electronic designs to life with expertise and precision.

AnyPCBA

AnyPCBA