The Ultimate Guide to PCB SMT: Technology, Process & Applications

In today's technology-driven world, almost every electronic device we use, from smartphones to medical equipment, relies on Printed Circuit Boards (PCBs). Surface Mount Technology (SMT) is the revolutionary method that allows for the precise and efficient assembly of these complex circuits. This article will demystify PCB SMT, exploring the core processes, key equipment, applications and impact, providing a comprehensive understanding for both professionals and enthusiasts.

Understanding Surface Mount Technology (SMT)

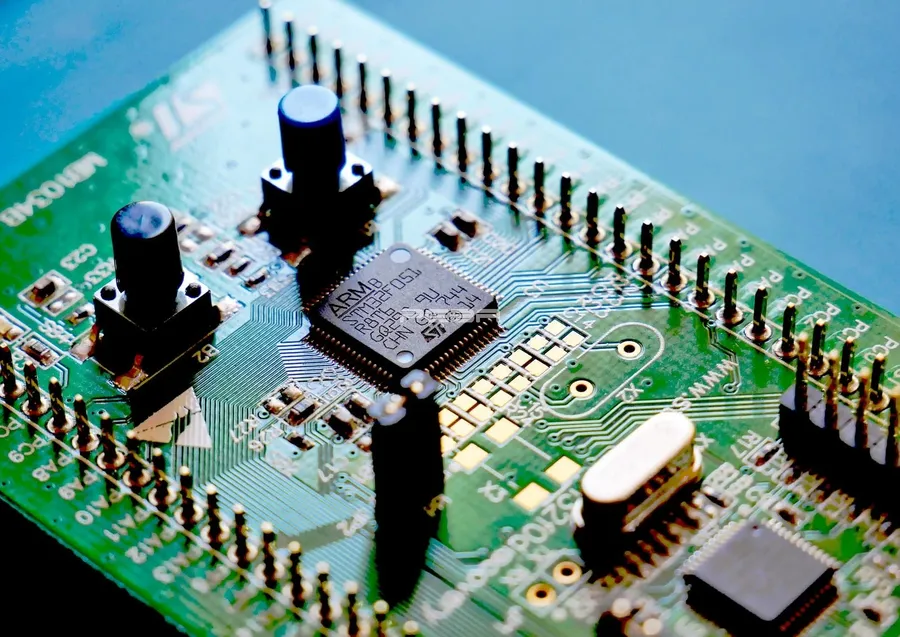

Surface Mount Technology (SMT) is a method of assembling electronic circuits where components are mounted directly onto the surface of a printed circuit board (PCB), contrasting with through-hole technology, which involves inserting component leads through drilled holes. SMT facilitates miniaturization and higher component density, essential for modern electronic devices. This approach significantly enhances performance and reduces the physical footprint of electronic assemblies.

- Core Principle of SMT

The core principle of SMT is the direct mounting of components onto the PCB surface using solder paste rather than inserting leads through holes. This allows for higher component densities and greater automation. - Miniaturization

SMT enables the production of smaller and lighter electronic devices due to its ability to utilize smaller surface mount components (SMD) and reduces the board space required. - Performance Enhancements

The smaller size and shorter lead lengths of SMT components lead to improved electrical performance, reducing signal interference and improving high-frequency characteristics. This also results in reduced parasitic inductance and capacitance. - Automated Assembly

SMT processes are highly automated, allowing for faster production and higher volumes compared to through-hole technology, thus significantly reducing labor costs and production time. - Improved Reliability

SMT can provide greater stability and reliability in high vibration and high-temperature environments, due to the stronger solder joints resulting from reflow soldering processes.

| Feature | SMT | Through-Hole |

|---|---|---|

| Component Size | Smaller | Larger |

| Component Mounting | Surface | Through Holes |

| Component Density | Higher | Lower |

| Assembly Process | Automated | Manual or Semi-Automated |

| Production Volume | High | Low to Medium |

| Cost | Lower for high volume | Higher for high volume |

| Electrical Performance | Better | Lower |

| Applications | Most consumer electronics | High-power, low-volume |

The SMT Assembly Process: Step-by-Step

The Surface Mount Technology (SMT) assembly process is a precise and multi-stage operation crucial for the reliable production of modern electronic devices. It involves a series of carefully orchestrated steps, each demanding meticulous attention to ensure high-quality, durable printed circuit boards (PCBs). The process encompasses stencil printing, component placement, reflow soldering, inspection, and testing.

- Step 1: Solder Paste Stencil Printing

Solder paste, a mixture of solder alloy and flux, is applied onto the PCB pads using a stencil. This stencil acts as a template, ensuring that solder paste is accurately deposited only in the required locations for component attachment. Precise alignment and consistent paste thickness are paramount at this stage to prevent soldering defects. - Step 2: Component Placement

Surface mount components (SMDs), including resistors, capacitors, and integrated circuits, are carefully placed onto the PCB, aligning with the solder paste deposits. Automated pick-and-place machines are employed to achieve the required speed and accuracy. These machines utilize vacuum nozzles to pick components from reels or trays and accurately position them onto the board. - Step 3: Reflow Soldering

The PCB, with components now placed, is subjected to a reflow soldering process. This involves a precisely controlled heating and cooling cycle. The solder paste melts, creating a reliable electrical and mechanical connection between the components and the PCB pads. The reflow profile, i.e., temperature versus time, must be carefully managed to prevent thermal stress on components and achieve optimal soldering results. - Step 4: Inspection

Following reflow soldering, each PCB undergoes thorough inspection to identify any defects such as misplaced components, insufficient or excessive solder, or solder bridges. Inspection methods include visual inspection, automated optical inspection (AOI), and X-ray inspection to ensure quality and reliability. This step aims to identify and correct any defects before further processing. - Step 5: Testing

The final stage involves functional and electrical testing of assembled PCBs. This testing verifies the circuit's performance against design specifications. Tests may involve in-circuit testing (ICT), functional testing, and other custom test protocols. Testing ensures the board performs to its intended design parameters before deployment in electronic devices.

Key Equipment in SMT Assembly

The SMT assembly process relies on specialized equipment to achieve the precision and reliability required for modern electronics. These machines work in concert to accurately deposit solder paste, place components, and fuse them to the PCB, ultimately creating functional electronic circuits. The sophistication of this equipment allows for high-speed, high-volume production while maintaining rigorous quality standards.

| Equipment | Function | Key Features | Advancements |

|---|---|---|---|

| Stencil Printer | Applies solder paste to the PCB through a stencil. | Precise alignment, consistent paste deposition, automated cleaning systems. | Automated vision systems, programmable paste parameters, advanced stencil materials. |

| Pick-and-Place Machine | Accurately places SMD components onto the PCB. | High placement speed, accurate component centering, multiple component handling capabilities. | Advanced vision systems for component recognition, real-time placement correction, adaptive feeder technology. |

| Reflow Oven | Melts solder paste to create a permanent connection between components and PCB. | Precise temperature control, multiple heating zones, conveyor belt transport. | Advanced convection systems, vacuum reflow, integrated temperature profiling. |

| Inspection System (AOI/X-Ray) | Verifies solder joint quality and component placement. | High-resolution imaging, fast defect detection, automated reporting. | 3D AOI, x-ray laminography, AI-powered defect analysis. |

SMT Components: Types and Characteristics

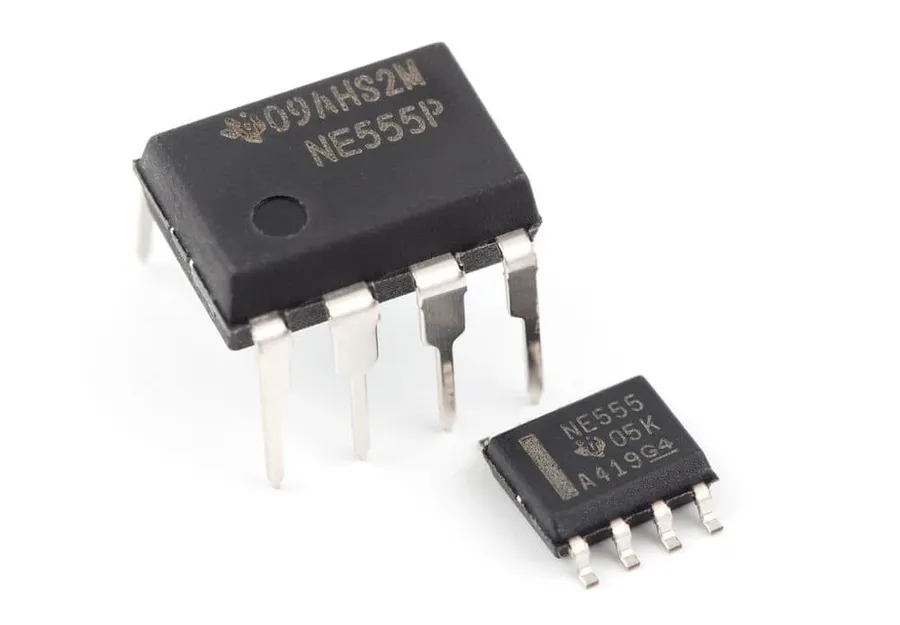

Surface Mount Technology (SMT) relies on a diverse range of components, each with specific characteristics and applications. These Surface Mount Devices (SMDs), including resistors, capacitors, inductors, and integrated circuits, are designed for direct mounting onto the surface of a Printed Circuit Board (PCB), in contrast to through-hole components which require leads to pass through drilled holes. This section delves into the types of these components, their packages, and the critical aspects of material selection and reliability in SMT assembly.

| Component Type | Description | Package Types | Material Considerations | Common Applications |

|---|---|---|---|---|

| Resistors | Components that impede the flow of electrical current. | 0402, 0603, 0805, 1206, 2512, etc. | Thick film, Thin film, Metal film. Temperature coefficient of resistance (TCR). | Current limiting, Voltage division, Signal conditioning. |

| Capacitors | Components that store electrical energy in an electric field. | 0402, 0603, 0805, 1206, Tantalum, Ceramic, Electrolytic. | Ceramic (Class 1, Class 2), Tantalum, Electrolytic. Capacitance tolerance, ESR (Equivalent Series Resistance). | Filtering, Decoupling, Energy storage. |

| Inductors | Components that store energy in a magnetic field. | 0402, 0603, 0805, 1206, Wirewound, Multilayer. | Ferrite, Ceramic core. Inductance, Q factor. | Filtering, Signal tuning, Impedance matching. |

| Integrated Circuits (ICs) | Complex components incorporating multiple electronic circuits on a single substrate. | SOIC, QFN, BGA, TSSOP, QFP. | Silicon, packaging materials. Power dissipation, Thermal resistance. | Microcontrollers, Logic gates, Memory, Amplifiers. |

Material selection for SMDs is critical for performance and reliability. Resistor materials like thick film and thin film impact precision and stability. Capacitor materials, such as ceramic and tantalum, are chosen for specific frequency and temperature characteristics. For inductors, core materials like ferrite affect inductance and losses. Furthermore, the package type significantly influences the component's thermal management and ease of handling during SMT assembly.

SMT vs. Through-Hole Technology: A Detailed Comparison

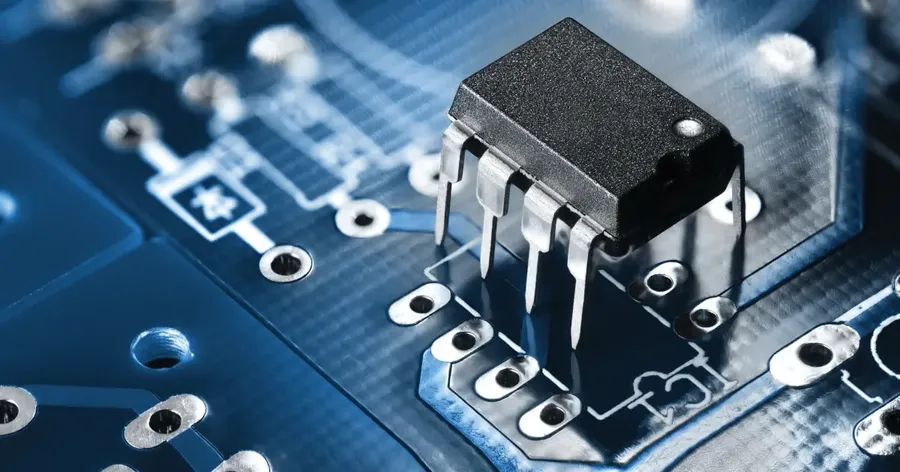

Surface Mount Technology (SMT) and Through-Hole Technology represent the two primary methods of mounting electronic components onto printed circuit boards (PCBs). Understanding their differences is crucial for selecting the optimal approach based on application requirements, cost considerations, and performance demands. This section provides a direct comparison to aid in informed decision-making for both designers and manufacturers.

| Feature | SMT (Surface Mount Technology) | Through-Hole Technology |

|---|---|---|

| Component Mounting | Components are mounted directly onto the surface of the PCB. | Components are inserted through holes in the PCB and soldered on the opposite side. |

| Component Size | Smaller components with finer pitch and higher density are used. | Larger components with leads that pass through the PCB. |

| Assembly Process | Automated, high-speed assembly using pick-and-place machines and reflow soldering. | Often requires manual placement of components followed by wave soldering. |

| Component Density | Higher component density achievable, allowing for smaller and more compact designs. | Lower component density due to space occupied by through-hole leads. |

| Cost | Generally lower assembly cost due to automation and higher yield. | Higher assembly cost due to manual labor and lower yields. |

| Performance | Superior high-frequency performance and reduced parasitic inductance. | Suitable for larger components that require stronger mechanical connections. |

| Reliability | Reliability depends on proper soldering and is generally reliable when properly executed. | Stronger mechanical bond due to the component leads passing through the PCB, more robust in harsh environments. |

| Applications | Widely used in modern electronics, including consumer devices, computers, and automotive systems. | Common in applications requiring stronger mechanical connections, prototyping, or when through-hole components are specifically required. |

SMT in Different Industries: Applications and Impact

Surface Mount Technology (SMT) has become a cornerstone of modern electronics manufacturing, enabling the creation of compact, high-performance devices across a multitude of industries. Its versatility and efficiency have made it indispensable in applications ranging from everyday consumer gadgets to advanced aerospace systems.

- Consumer Electronics

The consumer electronics sector heavily relies on SMT for the production of smartphones, laptops, tablets, smartwatches, and other portable devices. The small size and high component density achievable with SMT are crucial for creating compact, feature-rich products that meet consumer demand for smaller, lighter gadgets. - Automotive

SMT plays a critical role in the automotive industry, powering a wide range of applications such as engine control units (ECUs), infotainment systems, advanced driver-assistance systems (ADAS), and electric vehicle (EV) components. The durability and reliability of SMT assemblies are vital in harsh automotive environments, ensuring the safety and performance of vehicles. - Aerospace

In aerospace, SMT is essential for creating the complex and highly reliable electronic systems used in aircraft, satellites, and space exploration vehicles. The lightweight nature of SMT components and their ability to withstand extreme conditions make them ideal for demanding aerospace applications. SMT also supports high-density packaging required in compact avionics. - Medical Devices

SMT is fundamental to the production of medical devices, from diagnostic equipment to therapeutic instruments and implantable devices. The precision and reliability of SMT are paramount in medical applications, ensuring the accurate and safe operation of life-critical systems, SMT's small footprint allows for miniaturization of medical devices and improves patient comfort. - Telecommunications

The telecommunications industry uses SMT extensively in networking equipment, communication satellites, and base stations, and mobile phone infrastructure. SMT enables high-speed data transmission by allowing faster signal routing and improved signal integrity in communication devices. - Industrial Automation

SMT is instrumental in industrial automation systems, such as programmable logic controllers (PLCs), industrial robots, sensors, and control systems. SMT's ruggedness and reliability ensure that these systems function reliably in harsh industrial environments. - Military and Defense

The military and defense sector utilizes SMT in various applications, from communication systems to weapon control systems, and surveillance and targeting equipment. SMT enables the creation of robust and compact devices that perform reliably under challenging conditions.

The adoption of SMT continues to grow, driven by the demand for smaller, more efficient, and highly reliable electronic devices across all industries. Its widespread use demonstrates its importance in modern manufacturing and its profound impact on technological advancements.

Frequently Asked Questions about PCB SMT

This section addresses common questions surrounding Surface Mount Technology (SMT) in Printed Circuit Board (PCB) assembly. We aim to clarify the core concepts, differences between related terms, and practical considerations to ensure a comprehensive understanding of SMT processes and applications.

- What exactly is SMT in PCB Assembly?

SMT, or Surface Mount Technology, is a method of assembling electronic circuits where components are mounted directly onto the surface of a printed circuit board (PCB). This contrasts with through-hole technology, where components have leads that are inserted into holes in the board. SMT enables higher circuit densities, reduced board size, and often improved automated assembly. - What does SMT stand for?

SMT stands for Surface Mount Technology. This term is widely used in the electronics manufacturing industry to refer to the process of mounting components directly onto the surface of a printed circuit board, rather than inserting leads through holes in the board. - What are the primary differences between SMT and SMD?

SMT (Surface Mount Technology) refers to the process of assembling electronic components on the PCB surface, whereas SMD (Surface Mount Device) refers to the electronic components themselves that are designed to be mounted using SMT. Therefore, SMD is a component, and SMT is the assembly method that utilizes those components. - What are the typical categories of SMT components?

SMT components are diverse and include various package types. Common categories are passive components like resistors and capacitors (often packaged as 0402, 0603, 0805, etc., indicating their size), inductors, and active components like integrated circuits (ICs) in packages such as SOIC, QFP, QFN, BGA, and others. These packages are selected based on their functionality, size, and thermal requirements. - How does SMT differ from through-hole technology in terms of assembly and application?

Through-hole technology involves inserting component leads through holes in the PCB and soldering them on the opposite side, which can provide stronger mechanical connections. SMT, on the other hand, is better for high-density designs, smaller board sizes, and efficient automated assembly, making it suitable for mass production of complex electronics. Through-hole is often preferred for larger, more robust components or situations where mechanical strength is essential. - What is the standard process of SMT assembly?

The SMT assembly process typically includes applying solder paste to the PCB using a stencil, placing surface mount components onto the solder paste using automated pick-and-place machines, reflow soldering to melt the solder and create connections, and then inspecting the final assembly for quality and function. - What are common challenges in the SMT process and how are they addressed?

Common challenges in SMT include solder bridging, tombstoning, component misalignment, and insufficient solder. These are often addressed by precise stencil design, correct component placement using pick-and-place machines, and carefully controlled reflow profiles and temperatures. In addition, automated optical inspection (AOI) systems can help identify and resolve defects before they progress into final products.

Future Trends in SMT

The landscape of Surface Mount Technology (SMT) is in constant evolution, driven by the relentless pursuit of miniaturization, enhanced performance, and increased efficiency. Emerging trends point towards significant advancements in materials, processes, and automation, shaping the future of electronics manufacturing.

- Miniaturization and High-Density Packaging:

The demand for smaller and more powerful electronic devices is pushing the limits of component size and packaging density. We are seeing advancements in fine-pitch components, 3D packaging, and system-in-package (SiP) technologies that integrate multiple functionalities into a single device. These trends enable the creation of compact and feature-rich products. - Advanced Materials:

New materials are being developed with enhanced thermal and electrical properties, improved durability, and better resistance to environmental factors. This includes innovations in substrate materials, solder pastes, and component encapsulation that are driving performance and reliability. For example, research into materials with lower dielectric constants allows for higher signal speeds and lower losses, crucial for high-frequency applications. - Increased Automation and Robotics:

Automation is becoming integral to SMT assembly with robotic systems taking over more complex and delicate tasks. The integration of AI-powered machine vision systems is enhancing pick-and-place accuracy, defect detection, and real-time process optimization. The increased automation reduces manual errors and improves production throughput, driving cost-efficiency. - Sustainability and Eco-Friendly Processes:

The electronic industry is focusing on sustainability, leading to research in eco-friendly materials and processes. Lead-free soldering, water-based flux, and closed-loop recycling are becoming standard. Additionally, energy-efficient manufacturing techniques and reduced material waste are being adopted. These changes seek to minimize the environmental impact of electronic manufacturing, moving the industry towards a more sustainable model. - Improved Precision and Reliability:

Demands are continuously increasing for more reliable devices, pushing for SMT techniques that focus on quality control and long-term performance, as the complexity and use case of SMT rises. Improvements in inspection technologies such as X-ray inspection and automated optical inspection (AOI) are enhancing defect detection. Research into robust component design and assembly processes also contribute to enhanced overall product reliability.

In conclusion, Surface Mount Technology (SMT) has revolutionized PCB assembly, enabling smaller, faster, and more reliable electronic devices. By understanding the SMT process, its components, and the key equipment involved, both professionals and enthusiasts can appreciate its profound impact on modern technology. With continued advancements, SMT remains at the forefront of innovation in electronics manufacturing and PCB SMT will be integral to shaping our future. This overview provides a solid foundation for engaging more complex concepts and applications of SMT.

AnyPCBA

AnyPCBA