Top PCB Assembly Companies: Choosing the Right Partner in 2024

In our technologically advanced world, printed circuit boards (PCBs) are the backbone of virtually every electronic device. From the smart phone in your pocket to the advanced medical equipment in hospitals, reliable PCB assembly is critical. This article explores the top PCB assembly companies, examining the criteria for selection and what makes them leaders in the field. We'll delve into the nuances of choosing the right manufacturing partner, ensuring your products are built with precision and quality, highlighting [top pcb assembly companies] in the global market.

Key Considerations When Selecting a PCB Assembly Partner

Selecting the right PCB assembly partner is a critical decision that directly impacts the success of your electronic product. This choice hinges on a comprehensive understanding of your project's unique requirements, encompassing budget constraints, lead time expectations, stringent quality benchmarks, and the inherent complexity of your PCB design. A thorough evaluation of these parameters will pave the way for a successful collaboration.

- Budgetary Constraints

Establish a clear budget early in the selection process. This includes not only the cost per unit, but also non-recurring engineering (NRE) costs, tooling charges, and potential expenses related to design for manufacturability (DFM) modifications. - Lead Time Requirements

Assess your project's timeline and choose a PCB assembler with turnaround times that align with your market launch plans. Determine if you need quick-turn prototyping, standard production runs, or a combination of both. - Quality Expectations

Define your quality standards upfront and look for assemblers with robust quality management systems (QMS). Certifications like ISO 9001 and IPC standards compliance are indicators of a company's commitment to quality. - PCB Design Complexity

Consider the specific requirements of your PCB design such as number of layers, component density, micro-vias, or BGA assemblies. Ensure that your potential partner has the necessary equipment, expertise and process capabilities to handle the complexity of your PCB. - Technology and Equipment

Evaluate the technology and equipment used by the PCB assembler including the surface mount technology (SMT) lines, through-hole assembly equipment, automated optical inspection (AOI) systems, and X-ray inspection capabilities. Up-to-date equipment contributes to precision and reliability. - Material Sourcing

Inquire about their material sourcing processes and the quality of materials they use. Traceability and transparency are vital for ensuring the use of compliant and genuine components. - Communication and Project Management

Assess their project management approach and customer support availability. Effective communication ensures a smooth workflow and prompt issue resolution throughout the assembly process. - Engineering Support

Evaluate their level of DFM expertise. An experienced partner can identify design flaws, optimize for production, and reduce potential risks and costs.

Top PCB Assembly Companies in the USA

The United States hosts several leading PCB assembly companies, each with distinct strengths and specialties. These firms are pivotal in supporting the nation's electronics manufacturing sector, offering services from prototype development to high-volume production. Understanding their capabilities is essential for any project requiring PCB assembly.

| Company | Expertise | Certifications | Geographic Coverage | Market Standing |

|---|---|---|---|---|

| TTM Technologies | High-technology PCBs, complex designs, rigid-flex circuits | ISO 9001, AS9100, ISO 13485 | Multiple facilities across North America | One of the largest PCB manufacturers globally, strong presence in aerospace and defense sectors |

| Sanmina | End-to-end manufacturing, global supply chain management, diverse industry solutions | ISO 9001, ISO 13485, TL 9000 | Extensive global footprint with significant U.S. operations | A major player in electronic manufacturing services with large-scale production capabilities |

| Jabil | Design, manufacturing, and supply chain management solutions, broad industry experience | ISO 9001, ISO 13485, AS9100 | Global reach, with numerous facilities in the U.S. | Recognized for its comprehensive manufacturing capabilities and technology solutions |

| Benchmark Electronics | Specialized in complex and high-reliability PCB assemblies, including medical and aerospace | ISO 9001, ISO 13485, AS9100 | Strategic locations across the U.S. with specialized manufacturing capabilities | Known for its focus on high-quality, regulated industries |

| APCT | Specializes in quick-turn, high-reliability, and complex printed circuit boards, advanced technologies | ISO 9001, AS9100, ITAR Compliant | Multiple facilities throughout the U.S. | Strong reputation for rapid prototyping and high-mix, low-volume production |

These companies not only vary in their service offerings but also in their approach to manufacturing. TTM Technologies is known for its advanced technological capabilities, Sanmina excels in end-to-end solutions, and Jabil is recognized for its comprehensive industry experience. When evaluating the 'Top PCB Assembly Companies in the USA', it is essential to consider which company aligns best with specific project requirements in terms of technology, volume, and industry standards. Each company is certified by internationally recognized bodies. This is the reason why they are considered top-tier PCB assembly companies in the US.

Global Leaders in PCB Assembly: Expanding Beyond the USA

While the United States houses several prominent PCB assembly companies, the global market presents a diverse landscape of manufacturers offering unique advantages. This section explores leading PCB assembly firms in Europe and Asia, highlighting their strengths in technology, cost-effectiveness, and regional market expertise, providing a broader perspective for selecting a suitable partner.

| Company | Region | Key Strengths | Typical Industries Served |

|---|---|---|---|

| AT&S | Europe (Austria) | High-end interconnect solutions, advanced HDI PCBs, embedded components. | Automotive, industrial, medical, and mobile devices |

| PCBONLINE | Asia (China) | Comprehensive services from prototyping to mass production, cost-competitive solutions, strong supply chain. | Consumer electronics, telecommunications, automotive, and industrial controls |

| Sumitomo Electric | Asia (Japan) | Advanced materials, high-frequency PCBs, rigid-flex circuit boards | Aerospace, automotive, medical, and telecommunications. |

| Compeq Manufacturing | Asia (Taiwan) | High-volume production, advanced technologies for mobile and computing devices. | Mobile devices, computing, and networking equipment |

| Unimicron | Asia (Taiwan) | HDI PCBs, IC substrates, comprehensive manufacturing capabilities | Mobile devices, computing, and networking equipment |

The global distribution of PCB assembly companies often leads to different specializations and advantages. For example, European companies like AT&S tend to excel in high-reliability applications and advanced technologies such as HDI boards and embedded components. In contrast, Asian manufacturers often provide highly cost-effective solutions and high-volume production capabilities. Selecting an international partner involves careful consideration of these nuanced differences to align with the specific demands of your project.

Specialization in PCB Assembly Services

The PCB assembly industry is highly diverse, with companies offering a range of specialized services to meet varied project needs. Selecting a PCB assembly partner requires understanding these specializations to ensure the chosen company aligns with your specific production volume, complexity, and turnaround time requirements. Key areas of specialization include high-volume manufacturing, quick-turn prototyping, and complex assembly for multi-layered boards.

| Specialization | Description | Typical Applications | Advantages | Considerations |

|---|---|---|---|---|

| High-Volume Production | Focuses on manufacturing large quantities of PCBs efficiently. | Consumer electronics, automotive components, mass-market devices. | Economies of scale, lower per-unit cost, optimized processes. | May have longer lead times for initial setup; less flexible for design changes. |

| Quick-Turn Prototypes | Specializes in rapidly producing small batches of PCBs for testing and validation. | R&D projects, proof-of-concept designs, new product development. | Fast turnaround time, allows for quick iteration, cost-effective for small runs. | May have higher per-unit cost; less optimized for mass production. |

| Complex Multi-Layer Assembly | Handles intricate PCB designs with many layers and advanced features. | Aerospace, medical devices, high-performance computing, telecom. | Capable of handling high-density interconnects, advanced component placements, and complex routing. | Requires specialized equipment and expertise; may be more expensive with longer lead times. |

| Mixed Technology Assembly | Combines Surface Mount Technology (SMT) and Through-Hole Technology (THT) on a single board. | Industrial controls, power electronics, legacy systems | Offers versatility and compatibility with a wide range of components. | Requires expertise in both SMT and THT processes; may have a higher assembly time. |

| Flex PCB Assembly | Specializes in manufacturing flexible printed circuits for applications requiring bending or folding. | Wearable devices, automotive electronics, flexible displays. | Enables compact designs, dynamic bending applications, and high reliability. | Requires specialized equipment and handling techniques; can be more expensive and have a longer turnaround. |

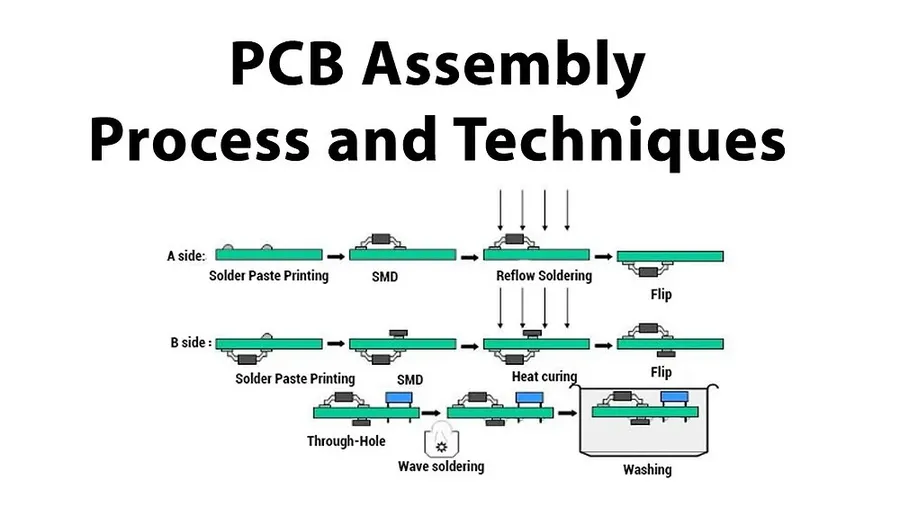

Analyzing the PCB Assembly Process: From Design to Final Product

Understanding the PCB assembly process is crucial for evaluating the capabilities of potential manufacturing partners. This process, which transforms a bare printed circuit board into a functional electronic assembly, involves several key stages, each demanding precision and expertise. From design specifications to the final product, a meticulous approach ensures optimal performance and reliability.

Here's a breakdown of the critical steps:

- PCB Design and Preparation:

This initial phase involves creating the PCB layout based on the electronic schematic. It's where the components' positions and routing of the electrical pathways are defined. Careful consideration is given to factors like signal integrity, thermal management, and manufacturability. The PCB design files, often in formats like Gerber or ODB++, are then prepared for manufacturing. - Solder Paste Application:

For surface mount technology (SMT) components, solder paste is precisely applied onto the PCB pads using a stencil. This process deposits the right amount of solder in the correct locations, which is essential for a reliable solder joint. - Component Placement:

Automated pick-and-place machines carefully position surface mount components onto the solder paste. This step requires high accuracy and speed to handle a variety of component sizes, from tiny passives to large integrated circuits. For through-hole components, manual or semi-automated placement may be required. - Reflow Soldering:

The PCB with placed components is passed through a reflow oven, where the solder paste melts and creates a permanent electrical and mechanical connection between the components and the board. This process involves a precisely controlled temperature profile to ensure all solder joints are formed correctly without damaging the components or the PCB. - Through-Hole Soldering:

For through-hole components, soldering is done after SMT reflow. This can be achieved through wave soldering, which is a bulk soldering process ideal for boards with many through-hole components, or manual soldering for more complex or low-volume assemblies. - Inspection and Testing:

After soldering, the PCBs undergo visual inspection and functional testing. Automated Optical Inspection (AOI) systems check for solder defects, component misalignments, and other manufacturing errors. Functional testing verifies that the PCB performs according to its design specifications, typically with an in-circuit test (ICT) or flying probe test. Further testing may include burn-in and environmental testing. - Cleaning and Final Assembly:

The assembled boards are cleaned to remove any solder flux residue. Final steps might include adding any additional components or parts, and finally, packaging the boards for shipment.

The assembly process can vary based on the complexity of the board, the types of components used, and the specific capabilities of the assembly partner. Understanding this flow will enable you to ask informed questions and ensure your chosen partner aligns with your project requirements.

Quality Assurance and Certifications in PCB Assembly

Rigorous quality assurance and adherence to industry certifications are paramount in PCB assembly, directly influencing the reliability and performance of the final product. Leading PCB assembly companies employ stringent quality control measures and pursue certifications to demonstrate their commitment to excellence.

These certifications are not merely badges of honor; they represent a commitment to maintaining high standards in all aspects of PCB assembly, from material sourcing to the final product inspection. A robust quality management system reduces defects, enhances product longevity, and ultimately lowers overall costs by minimizing rework and recalls.

| Certification | Description | Importance |

|---|---|---|

| ISO 9001 | International standard for quality management systems. | Ensures consistent processes and continuous improvement in manufacturing. |

| ISO 13485 | Specific to quality management systems for medical devices. | Mandatory for PCB assemblies used in medical applications, ensuring safety and efficacy. |

| AS9100 | Quality management system standard for the aerospace industry. | Ensures the reliability of PCB assemblies for critical aerospace applications. |

| IPC Standards | A set of industry standards for PCB design and manufacturing. | Specifies best practices for all stages of PCB manufacturing. |

| UL Certification | Indicates product safety and compliance with Underwriters Laboratories standards. | Ensures electrical safety of the PCB assemblies. |

In addition to certifications, leading companies also implement comprehensive quality control measures throughout the assembly process, including:

- Incoming Material Inspection

Verifying the quality and authenticity of all incoming components and raw materials. - In-Process Quality Checks

Regular inspections and testing during various stages of the assembly process to identify and rectify any issues promptly. - Automated Optical Inspection (AOI)

Using automated vision systems to detect defects such as missing components, solder shorts, and other assembly errors. - X-Ray Inspection

Examining solder joints and internal layers of the PCB for hidden defects. - Functional Testing

Verifying the functionality of the assembled PCB through electrical testing to ensure it meets the specified design requirements.

Frequently Asked Questions About Top PCB Assembly Companies

Navigating the landscape of PCB assembly can raise several questions. This section addresses common inquiries to provide clarity and assist in selecting the most suitable PCB assembly partner. We will cover key aspects, from identifying top manufacturers to understanding selection criteria.

- Who is considered the best PCB manufacturer?

The 'best' PCB manufacturer is subjective and depends on specific project needs. Factors like the type of PCB (e.g., single-layer, multi-layer, flexible), required volume (prototype, low-volume, high-volume), budget constraints, and lead time expectations all play a critical role. Some manufacturers excel in high-complexity PCBs, while others focus on cost-effective, high-volume solutions. Instead of searching for a singular 'best' company, prioritize identifying a provider that aligns with your project requirements. - Which company's PCB is the best?

Determining the 'best' PCB from a specific company is difficult as quality can vary even within a single manufacturer's product line. Instead of focusing on a single company, evaluate potential partners based on their track record, certifications (ISO, UL, etc.), manufacturing capabilities, and client feedback. Requesting samples and prototypes for testing is crucial to verifying the quality and reliability of their PCBs for your application. - Who is the largest PCB manufacturer in the world?

The title of the 'largest PCB manufacturer' varies depending on market metrics and time periods. Currently, companies like AT&S, TTM Technologies, and others often vie for this distinction, with their rankings often based on revenue, production capacity, and geographic reach. The largest manufacturer may not always be the best fit for your particular needs, so prioritize your specific requirements during the selection process. - Who is the largest manufacturer of PCBs in North America?

Several companies vie for the position of largest PCB manufacturer in North America. TTM Technologies and Sanmina are significant players with extensive operations in the region. Their size does not inherently qualify them as the best choice for every application. Evaluate manufacturers based on project alignment, technical expertise, and value offered for your specific needs rather than relying solely on size. - What criteria should I use to select the right PCB assembly company?

Choosing a PCB assembly partner involves a multi-faceted evaluation. Key criteria should include the company’s certifications, such as ISO 9001 or AS9100; the range of their assembly capabilities (SMT, through-hole, mixed technology); their expertise with your specific board complexity; the availability of design for manufacturability (DFM) reviews; their production capacity to scale up as needed; their quality control processes; and their ability to provide responsive customer service. Cost is obviously a factor, but it should not overshadow quality and reliability. Seek a balance between all criteria for an optimal partnership. - How important is geographical location when choosing a PCB Assembly company?

Geographical location of a PCB assembly company can impact several key areas. Closer proximity can reduce shipping times and costs, facilitate easier communication for collaboration and issue resolution, and better align with local industry compliance regulations. However, opting solely for local providers might limit access to specialized capabilities and competitive pricing available with international companies. Weigh the benefits of local services against global providers' strengths based on project priorities. - What are some common mistakes to avoid when selecting a PCB assembly partner?

Common mistakes include focusing solely on cost without considering quality, not verifying certifications and quality control processes, failing to thoroughly understand the company's assembly capabilities, neglecting the need for DFM reviews, and ignoring the company's customer service responsiveness. Rushing the selection process can lead to cost overruns, product delays, and ultimately, unsatisfactory results. Conduct detailed due diligence before making your selection.

Cost Analysis and Budget Planning for PCB Assembly

Understanding the cost drivers in PCB assembly is paramount for effective budget planning. This section explores the key factors that influence pricing, allowing you to optimize expenditures and ensure your project aligns with financial constraints while partnering with top PCB assembly companies.

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Material Costs | The type of substrate material (FR-4, Rogers, etc.), copper thickness, and surface finish (ENIG, HASL, etc.). | Higher-performance materials and specialized finishes increase costs. |

| Volume | The quantity of PCBs to be assembled. | Larger volumes typically result in lower per-unit costs due to economies of scale. |

| Assembly Complexity | The number of layers, component density, type of components (SMT, through-hole), and the complexity of the assembly process. | Higher complexity boards and fine-pitch components require more advanced equipment and expertise, increasing costs. |

| Testing Requirements | The level of testing required (AOI, ICT, functional testing). | More extensive testing protocols result in increased costs. |

| Turnaround Time | The required time for PCB assembly. | Quicker turnarounds often incur higher fees due to expedited production and logistics |

| Geographic Location | The location of the assembly company and the related shipping costs. | Offshore options may offer lower assembly costs but can be impacted by shipping and potential import duties. |

When planning your PCB assembly budget, consider the following strategic approaches to minimize cost:

- Design Optimization

Simplify your PCB design where possible. Reducing the number of layers, component count, and complex routing will reduce both material and assembly costs. - Component Selection

Choose components that are readily available and competitively priced. Consider alternative components that meet functional requirements without unnecessary expense. - Volume Planning

Accurately forecast your production volume to take advantage of bulk discounts from PCB assembly companies. When possible, consider batch production runs to reduce costs. Consider your projected volume over time to help determine if a long term manufacturing agreement makes sense. - Lead Time Management

Allow sufficient lead time for the assembly process to avoid expedited charges. Proper planning can reduce costs related to fast turn prototypes. - Strategic Partnerships

Select a PCB assembly company that offers transparent pricing and cost-effective solutions. Negotiate favorable terms, especially for recurring projects. Consider partnering with a manufacturing company that is vertically integrated for cost and time advantages.

Future Trends and Innovations in PCB Assembly

The printed circuit board (PCB) assembly industry is in constant evolution, driven by the demand for smaller, more efficient, and increasingly complex electronic devices. Several key trends are shaping the future of PCB assembly, requiring companies to adapt and innovate to remain competitive. These trends span from miniaturization and advanced materials to sustainable practices and intelligent automation.

These innovations are not just about technological advancements; they also represent a shift in how PCB assembly companies operate, emphasizing agility, sustainability, and deep technological expertise. Partnering with a company at the forefront of these innovations ensures access to cutting-edge solutions and long-term competitiveness.

| Trend | Description | Impact on PCB Assembly |

|---|---|---|

| Miniaturization | The ongoing reduction in the size of electronic components and devices. | Requires higher precision assembly processes and advanced technologies like micro-SMT and chip-scale packaging. |

| Flexible PCBs | The use of flexible substrates for PCBs, allowing for more dynamic and adaptable designs. | Demands specialized assembly equipment and techniques to handle the flexibility of the substrates while maintaining electrical and mechanical integrity. |

| Advanced Materials | The integration of new materials with enhanced electrical, thermal, and mechanical properties. | Calls for new assembly techniques that are compatible with these novel materials, along with different handling and soldering protocols. |

| Sustainable Practices | The increasing emphasis on eco-friendly production methods and materials. | Drives a move towards lead-free soldering, water-based cleaning solutions, and materials with lower environmental impacts. |

| Intelligent Automation | The incorporation of artificial intelligence (AI) and robotics in assembly processes. | Enables increased production efficiency, reduced errors, and better data analytics for improved process control. |

Choosing the right PCB assembly partner is crucial for the success of your electronics projects. By understanding the various factors discussed, including the capabilities of [top pcb assembly companies], from global leaders to specialized manufacturers, you can make an informed decision. The future of PCB assembly is bright, with continued innovation driving efficiency and performance. Keep abreast of these trends to ensure your products remain competitive in the dynamic electronics market and leverage the strengths of top companies in the field for superior results.

AnyPCBA

AnyPCBA