Understanding 0 PCB Price: A Comprehensive Guide to Cost-Effective Circuit Boards

In today's tech-driven world, printed circuit boards (PCBs) are the unsung heroes, powering everything from smartphones to complex machinery. Many wonder about '0 pcb price', thinking it implies free PCBs. While not literally free, understanding the factors that drive PCB costs is key for any project. This article will explore the real costs of PCBs, offering practical advice to secure the best value.

What is a Zero PCB Board?

The term 'zero PCB board' often causes confusion, as it doesn't refer to a free printed circuit board. Instead, it typically describes general-purpose prototyping boards, such as perf boards or breadboards, which are essential tools for electronics development. These boards facilitate circuit testing and experimentation before committing to a final PCB design. Understanding the distinctions between these prototyping tools and actual PCBs is crucial to accurately assess and manage project costs.

Factors Affecting PCB Costs: Beyond the '0 PCB Price' Myth

The notion of a '0 PCB price' is a misnomer, as Printed Circuit Boards inherently involve manufacturing costs. Instead, understanding the key factors influencing PCB pricing is crucial for effective budgeting. These factors span material selection, design complexity, production volume, and turnaround time, all contributing significantly to the final cost.

| Factor | Description | Impact on Cost |

|---|---|---|

| Material | The type of material used (e.g., FR-4, aluminum, flex) directly affects cost. FR-4 is common and cost-effective, while others like aluminum or flexible materials are pricier. | High-performance materials increase cost; commodity materials lower cost. |

| Layer Count | The number of conductive layers in the PCB design. More layers increase complexity and processing steps. | More layers lead to higher costs due to increased complexity and processing time. |

| Board Size | The physical dimensions of the PCB, typically in square inches or millimeters. Larger boards require more material and processing. | Larger boards cost more due to the increased material usage and complexity. |

| Quantity | The total number of PCBs manufactured in a single order. Higher volume orders can reduce the cost per unit. | High volumes decrease unit costs because of economies of scale. |

| Lead Time | The time required for manufacturing. Rush orders demand faster turnaround and often carry a premium. | Shorter lead times increase costs; standard or longer lead times reduce costs. |

| Surface Finish | The plating and surface finish applied to the PCB, different types like ENIG, HASL, etc. having different costs. | More complex surface finishes like ENIG will increase costs over more basic options like HASL. |

| Drill Hole Size | The complexity and size of drill holes on the PCB | Micro vias and smaller drill holes can increase costs, whilst through hole components are more cost effective. |

| Minimum Trace Width & Spacing | The minimum feature sizes required by a given board design, which dictates process complexity | Finer features require a more complex manufacturing processes and therefore cost more. |

| Special Design Requirements | Any features not common in a standard PCB design, such as impedance control. | Non standard requirements increase the cost. |

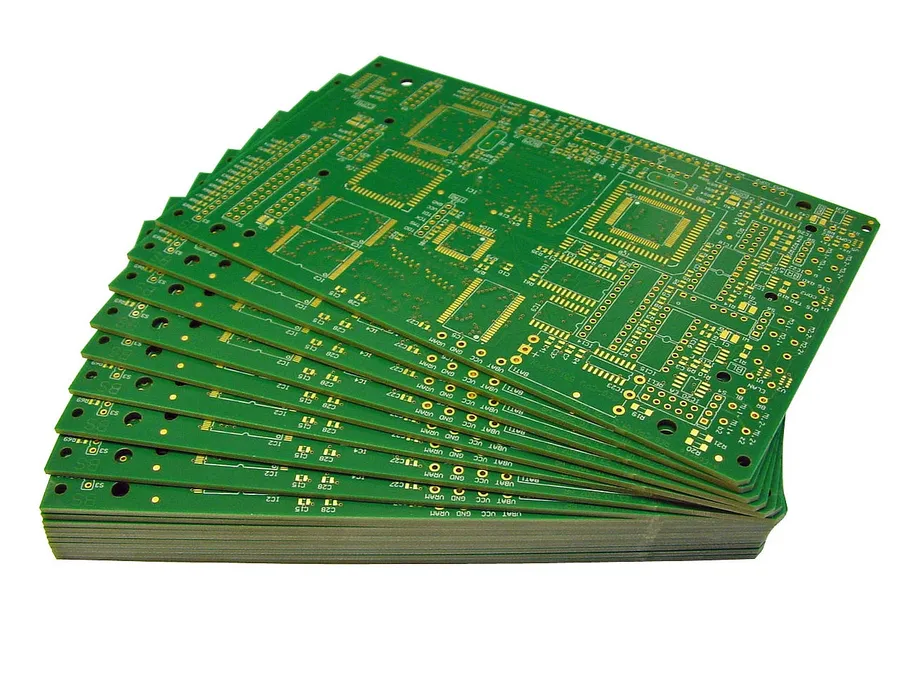

Prototype vs. Production PCB Costs

The cost of Printed Circuit Boards (PCBs) varies significantly between prototypes and mass-produced units. Understanding these differences is crucial for effective budget management in electronics projects. Prototypes, typically produced in low quantities, incur higher per-unit costs due to setup expenses and the lack of economies of scale, whereas production runs benefit from these economies, leading to lower per-unit prices.

| Feature | Prototype PCBs | Production PCBs |

|---|---|---|

| Quantity | Low (e.g., 1-10 units) | High (e.g., 100+ units) |

| Per-Unit Cost | High | Lower |

| Setup Costs | Significant | Distributed over volume |

| Lead Time | Often Faster | Can vary with volume |

| Customization | High flexibility | Less flexibility |

| Ideal For | Testing and validation | Large-scale deployment |

| Cost Drivers | Initial tooling and setup | Raw material prices, labor and efficiency |

The increased cost of prototype PCBs is attributed to initial tooling costs which include creating custom files and setting up specialized equipment for small batches. Conversely, large-scale production allows manufacturers to distribute these costs across a greater number of units, resulting in a lower price per board. While the per-unit cost of prototypes can be high, this initial expense is critical for identifying design flaws and validating functionality before committing to a full production run. This helps to avoid costly errors and revisions in mass production. The choice between prototype and production orders must be made in light of these considerations, carefully balancing the need for initial testing against cost optimization.

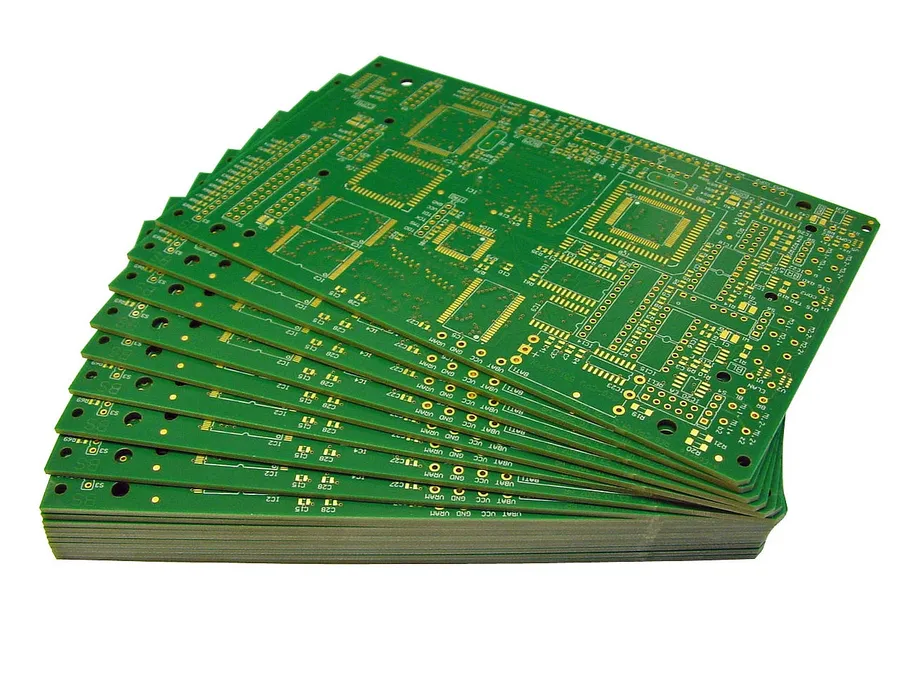

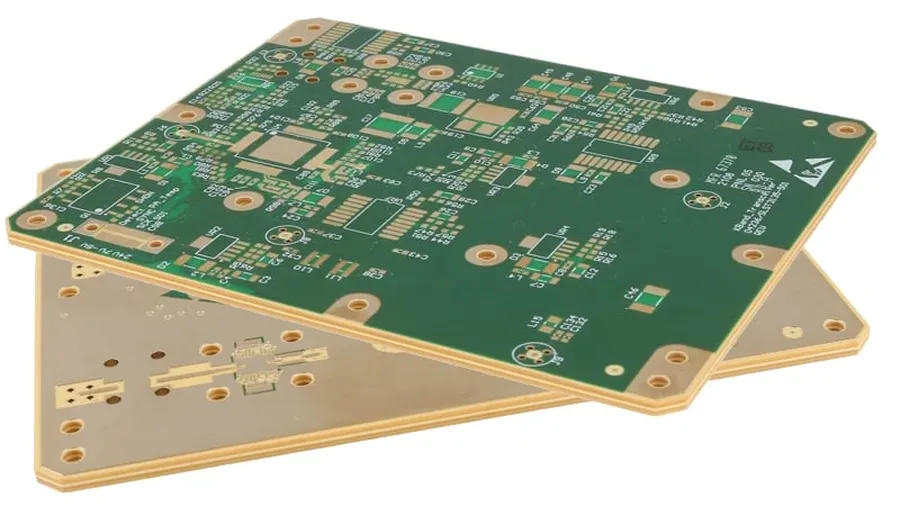

PCB Material Types and Their Impact on Price

The selection of PCB material is a critical factor influencing both the performance and cost of a printed circuit board. Different materials offer varying electrical, thermal, and mechanical properties, which directly affect the final price. Understanding these differences is essential for optimizing design choices.

| Material | Description | Typical Applications | Cost | Advantages | Disadvantages |

|---|---|---|---|---|---|

| FR-4 | Most common PCB material; fiberglass reinforced epoxy laminate | General purpose, consumer electronics, industrial control | Low to Medium | Good balance of cost, electrical and mechanical properties, ease of fabrication | Limited thermal performance, can be brittle |

| Aluminum | Metal core PCB material with aluminum base | LED lighting, power electronics, high power applications | Medium to High | Excellent heat dissipation, high durability, dimensionally stable | Higher cost, more complex fabrication process |

| Flex PCB (Polyimide) | Flexible PCB material; Polyimide based | Wearables, automotive, medical, complex interconnection | High | Flexible, lightweight, high density interconnect, good temperature range | High cost, lower mechanical strength compared to rigid boards |

| Rogers | High-performance PCB material for high-frequency applications | RF and microwave circuits, antennas, aerospace | Very High | Superior electrical performance, low loss, excellent thermal properties | Very high cost, specialized fabrication |

The cost of FR-4 PCBs is generally lower than that of aluminum or flex PCBs due to its widespread availability and ease of manufacturing. Aluminum PCBs are more costly than FR-4 due to increased material costs and complex fabrication. Flex PCBs tend to have higher cost due to intricate design requirements and the material’s inherent complexity. Rogers materials, while offering the best high frequency performance, are the most expensive.

When selecting a PCB material, designers must weigh the performance requirements against the budget. For example, for applications that generate significant heat, aluminum PCBs, despite their higher cost, offer an advantage due to their superior thermal properties. In contrast, FR-4 is more suitable for less demanding applications that are cost-sensitive, as it provides a balance between cost and performance. For applications requiring flexibility, polyimide-based flex PCBs are the optimal solution, albeit at a higher price point.

Where to Find Affordable PCBs

Sourcing affordable PCBs requires a strategic approach, considering various suppliers ranging from online marketplaces to specialized manufacturers. The key is to balance cost with quality and reliability, while understanding that the term "0 PCB price" generally refers to prototyping boards and not actual cost-free PCBs.

Online marketplaces offer a wide range of options, often with lower initial costs, while specialized manufacturers cater to specific requirements and often provide better quality and support, especially for more complex designs and larger volumes. Consider your project's needs carefully when choosing between these options.

- Online Marketplaces

Platforms like AliExpress, eBay, and Amazon host numerous PCB suppliers. These are often a good starting point for simple designs and small quantities, offering relatively low prices. However, carefully assess the quality and supplier reputation as there can be inconsistencies. - Specialized PCB Manufacturers

Companies that specialize in PCB manufacturing, like JLCPCB, PCBWay, and Seeed Studio, provide a balance between cost and quality. They offer more advanced manufacturing capabilities, material choices, and often provide better customer support. These companies usually have minimum order quantities, so keep that in mind when placing orders. - Local PCB Manufacturers

Exploring local manufacturers can sometimes offer benefits such as faster turnaround times and better communication. It might be a good option if you require higher quality or custom specifications. However, local manufacturing may come at a higher price point than international options.

While a '0 PCB price' is a misnomer when referring to fully functional PCBs, these platforms provide a competitive market where you can find options that align with different budget levels. Thorough research and consideration of lead time, shipping costs, and reviews are critical when selecting a supplier to ensure that you make an informed decision.

Comparative Analysis of PCB Suppliers

Selecting the right PCB supplier is crucial for project success, balancing cost, quality, and delivery timelines. This section provides a comparative overview to aid informed decision-making, considering factors beyond just the often-misleading '0 PCB price'.

| Supplier | Price (Prototype) | Price (Mass Production) | Lead Time (Prototype) | Lead Time (Mass Production) | Material Options | Customer Reviews |

|---|---|---|---|---|---|---|

| Company A | $50-$150 | $0.5-$5/pc | 1-2 Weeks | 2-4 Weeks | FR-4, Aluminum | Mostly Positive, Some Delivery Delays |

| Company B | $75-$200 | $0.75-$6/pc | 2-3 Weeks | 3-5 Weeks | FR-4, Flex | High Quality, Good Customer Service |

| Company C | $30-$100 | $0.3-$4/pc | 3-5 Days | 1-3 Weeks | FR-4, CEM-1 | Fast Turnaround, Quality Could Be Better |

| Company D | $100-$250 | $1-$8/pc | 1-2 Weeks | 2-6 Weeks | FR-4, High Tg, Rogers | Advanced Materials, Premium Cost |

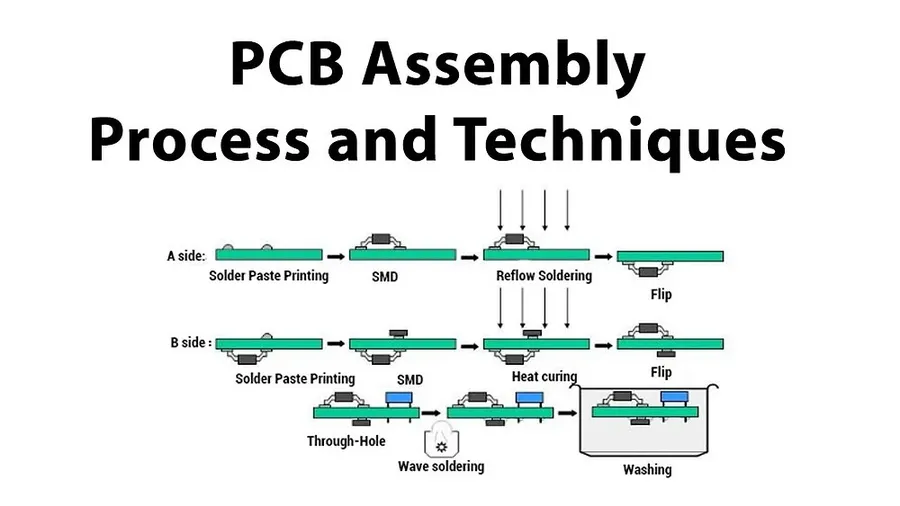

PCB Assembly and its impact on the overall cost

The process of assembling components onto a Printed Circuit Board (PCB) significantly impacts the overall cost, often exceeding the bare board cost itself. This involves placing and soldering electronic components onto the PCB, and the complexity and method used directly affect the final price.

Different assembly methods have varied cost implications:

Key factors influencing assembly costs include:

Understanding these factors allows for a more accurate budgeting of PCB projects. It's often beneficial to involve the assembly provider early in the design process to optimize for cost-effectiveness.

Frequently Asked Questions about PCB Costs

Understanding PCB costs can be complex, with many factors influencing the final price. This section addresses common questions to clarify these aspects, ensuring you are well-informed when budgeting for your electronic projects.

- How much does 1 PCB cost?

The cost of a single PCB can vary dramatically. For simple, single-layer boards, it can range from a few dollars for small prototyping boards to tens of dollars or more for custom designs. Factors such as the board's size, layer count, material, and any special requirements significantly influence the cost. It's important to note that smaller quantities often result in higher per-unit prices due to the setup and tooling costs incurred by the manufacturer. - What is a zero PCB board?

The term 'zero PCB board' is often a misnomer. It typically refers to general-purpose perfboards or prototyping boards rather than actual PCBs with zero cost. These boards are used for building and testing circuits before committing to a full custom PCB design. While they might be inexpensive to purchase as raw boards, they are distinct from manufactured PCBs. - What factors influence the overall cost of a PCB?

Several key factors influence PCB cost: Material type (FR-4, aluminum, flex), layer count (single, double, multilayer), board size and complexity, required tolerances and specifications, the quantity being ordered, and the turnaround time needed. Complex designs, tighter tolerances, and faster delivery times will generally increase the cost of the PCB. - How much should a PCB cost?

There's no single answer to this question because costs depend on various factors including PCB specifications and order volumes, the complexity of design, and the manufacturing service. Budgeting for PCBs needs to consider both per-unit costs and any additional fees like setup charges, testing and assembly. A detailed analysis of your design will help you to determine the approximate cost. - Where can I find affordable PCB options?

Affordable PCBs can be sourced from online marketplaces that aggregate multiple PCB manufacturers, specialized PCB manufacturers that offer low cost services, or even some general electronics suppliers. Comparing quotes from various sources and being flexible with lead times and material choices can help find more affordable options. - Are there differences in pricing between PCB prototypes and production runs?

Yes, there are usually significant differences in price between prototype and production PCB runs. Prototypes, typically ordered in small quantities, often incur high per-unit costs due to setup and tooling fees. Mass production runs, on the other hand, benefit from economies of scale, reducing the per-unit price. As production volumes increase, the cost per board generally decreases substantially. Planning for long-term orders helps you access these lower production costs. - How does PCB assembly impact the overall cost?

PCB assembly involves mounting components onto the manufactured board, and it is usually a significant cost factor. Assembly costs depend on factors such as the number of components, mounting type (surface mount or through-hole), the required testing, and the assembly method (automated or manual). Combining PCB fabrication and assembly at the same facility can sometimes lead to cost savings and may be considered if you have limited resources.

Tips for Reducing PCB Costs

Minimizing PCB costs requires a multi-faceted approach, focusing on design optimization, component selection, and strategic manufacturing choices. By carefully considering each stage of the PCB development process, significant cost reductions can be achieved without compromising functionality or quality.

- Optimize Board Design

Efficient use of board space and a simplified layout can reduce material consumption and manufacturing complexity. Consider a single-layer or double-layer design if feasible, and adhere to standard PCB sizes to avoid extra costs due to custom sizes. - Standard Components

Using common, readily available components instead of specialty parts can substantially lower the cost. Standard components are produced in larger quantities, resulting in lower prices and readily available supply, and avoiding supply chain shortages. - Panelization

When ordering multiple PCBs, designing them in a panel (multiple boards on a single larger sheet) allows for efficient processing by the manufacturer, thereby lowering the cost per board, especially for mass production. - Bulk Ordering

The per-unit cost of PCBs decreases significantly with larger order quantities. If the demand and storage allows it, consolidate projects to meet higher quantities. - Cost-Effective Manufacturing

Choosing a PCB manufacturer that balances quality and cost is critical. Consider offshore manufacturers to reduce production costs, but ensure they maintain high-quality standards and have a track record of reliable deliveries. - Design for manufacturability (DFM)

Incorporating DFM principles from the outset minimizes costly errors and ensures streamlined manufacturing. This includes adhering to proper spacing, using via size standards and ensuring appropriate silkscreen and solder mask clearance. - Avoid unnecessary Features

Every extra feature or process, such as controlled impedance or plated slots increases PCB cost, so avoid such features if the board’s function doesn’t need it. Evaluate your design to remove any unnecessary features.

While the term '0 pcb price' might be misleading, understanding the factors that influence PCB costs and exploring various manufacturing options, is essential to get the best value for your budget. This guide has outlined how you can make informed decisions, optimize your designs and ensure the success of your project with cost-effective PCB solutions. Remember to always compare your options and plan ahead to avoid unexpected costs. The perfect PCB, even one with a great value and not a literal 0 pcb price, is achievable with the right approach.

AnyPCBA

AnyPCBA