Understanding PCB Manufacturing Plant Cost: A Comprehensive Guide

In today's technology-driven world, printed circuit boards (PCBs) are the backbone of nearly every electronic device. From smartphones to medical equipment, PCBs are essential, making the PCB manufacturing industry a critical part of our global economy. Many entrepreneurs and engineers are considering starting their own PCB manufacturing plants. But, how much does it really cost to set up a PCB manufacturing plant? This article delves into the costs, and challenges of starting your own PCB factory, providing a comprehensive analysis to help you understand the financial implications and make informed decisions.

Initial Investment: Equipment Costs

The most substantial initial outlay for a PCB manufacturing plant is acquiring the necessary equipment. This encompasses a broad spectrum of machinery, ranging from fundamental tools to sophisticated automated systems. The associated costs vary significantly, depending on the scale of operation and the precision requirements of the manufacturing process. Core equipment categories include PCB printers, pick-and-place machines, reflow ovens, CNC machines, etching equipment, and testing & inspection instruments. These investments can range from tens of thousands to millions of dollars. For instance, the cost of pick-and-place machines alone can fluctuate from $20,000 to over $200,000, contingent upon their automation level and throughput capacity.

| Equipment Category | Description | Estimated Cost Range |

|---|---|---|

| PCB Printers | Used for applying solder paste or conductive inks onto the PCB substrate. | $5,000 - $50,000+ |

| Pick-and-Place Machines | Automatically places surface mount components onto the PCB. | $20,000 - $200,000+ |

| Reflow Ovens | Melts solder paste to form permanent connections between components and PCB. | $10,000 - $80,000+ |

| CNC Machines | Used for drilling, milling, and routing the PCB. | $15,000 - $150,000+ |

| Etching Equipment | Removes unwanted copper from the PCB to create the circuit pattern. | $8,000 - $60,000+ |

| Testing & Inspection Equipment | Includes AOI machines, ICT equipment for quality assurance and fault detection. | $10,000 - $100,000+ |

Facility and Infrastructure Costs for PCB Manufacturing Plant

Establishing a PCB manufacturing plant requires significant investment beyond just machinery; the physical facility and its infrastructure are critical components. These costs are highly variable, influenced by factors such as location, scale of operations, and specific building conditions. A well-planned facility ensures efficient production, worker safety, and compliance with environmental standards.

- Building Acquisition or Lease Costs

This includes the cost of purchasing land and a suitable building or the monthly lease payments. The size of the facility needs to be adequate for all manufacturing processes, storage, and office space. Location impacts costs significantly, with urban areas typically more expensive than rural ones. Ensure the building has the necessary structural integrity and room for future expansion. - Environmental Control Systems

PCB manufacturing requires precise environmental control to maintain quality and prevent defects. This includes HVAC (Heating, Ventilation, and Air Conditioning) systems to control temperature and humidity and specialized air filtration systems to manage dust and other airborne particulates. The cost of these systems depends on the size and complexity of the facility, as well as specific requirements of the processes. - Utility Infrastructure

Essential utilities, including electrical power supply, water supply, and compressed air systems, must be established. The cost of this infrastructure involves ensuring sufficient power capacity for machinery, clean water for various processes, and compressed air for pneumatic tools and equipment. Proper planning will prevent bottlenecks in the production and operation. - Storage Solutions

Adequate storage space is needed for raw materials, finished products, chemicals, and other supplies. This may include specialized storage units such as climate-controlled storage, and storage racks. Effective storage ensures easy access and management to raw material and finished goods which will reduce time and increase overall efficiency. - Security Systems

Security systems are necessary to protect the facility, equipment, and materials from theft, vandalism, and other risks. This may include security cameras, access control systems, and alarm systems. These measures safeguard assets and ensure the production flow by minimizing interruptions. - Waste Disposal Systems

PCB manufacturing generates hazardous waste, which must be managed and disposed of in compliance with environmental regulations. The cost will include the installation of treatment facilities and the disposal of the waste by approved processes. Compliance and proper waste management can avoid the penalty and fines imposed by the EPA.

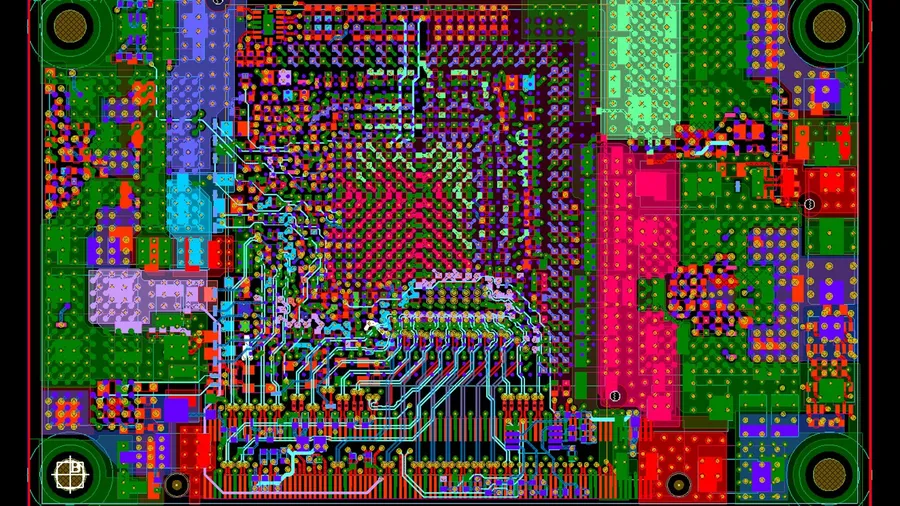

Software and Design Costs

The operation of a modern PCB manufacturing plant is heavily reliant on specialized software for design, layout, testing, and production control. These software tools are crucial for ensuring precision, efficiency, and quality throughout the manufacturing process. The expenses associated with acquiring and maintaining these software systems represent a notable portion of the overall operational costs.

| Software Category | Description | Cost Range | Key Features |

|---|---|---|---|

| CAD (Computer-Aided Design) | Used for designing and laying out PCB circuits and components. | $1,000 - $10,000+ per license | Schematic capture, PCB layout, component library management, 3D visualization. |

| CAM (Computer-Aided Manufacturing) | Translates design data into instructions for manufacturing equipment. | $2,000 - $15,000+ per license | Gerber file generation, drilling data, routing instructions, panelization, design rule checking (DRC). |

| ERP (Enterprise Resource Planning) | Manages various aspects of the manufacturing process, including inventory, production planning, and cost tracking. | $5,000 - $50,000+ per system | Production scheduling, material requirements planning (MRP), inventory control, financial management, quality control. |

| Simulation and Analysis Software | Used for simulating the performance of the design in real-world conditions, allowing manufacturers to optimize the design before it goes to production | $1,000 - $10,000+ per license | Signal Integrity analysis, thermal analysis, electromagnetic compatibility (EMC) analysis, stress analysis. |

The cost of software can fluctuate considerably based on the selected features, the scale of production, and the licensing model (e.g., perpetual vs. subscription). While basic software suites may start at around $5,000 to $20,000, comprehensive solutions that cater to high-volume manufacturing can reach substantially higher investment levels. Additionally, it's essential to budget for ongoing maintenance and upgrades to ensure the software remains current and compatible with evolving technological advancements.

Operational Costs: Raw Materials

Raw material costs represent a substantial portion of the ongoing expenses in PCB manufacturing. These costs are subject to market volatility and supply chain dynamics, necessitating careful management and strategic sourcing. The primary materials include copper-clad laminates (CCL), prepreg, various chemicals used in etching and plating processes, solder mask, and other consumables.

| Raw Material | Description | Cost Drivers | Impact on Overall Cost |

|---|---|---|---|

| Copper-Clad Laminates (CCL) | Base material for PCBs consisting of copper foil bonded to a substrate. | Copper prices, substrate type (e.g., FR-4, CEM), thickness. | Significant, directly related to the amount of copper and type of substrate used. |

| Prepreg | Partially cured fiberglass or other fabric, used in multilayer PCB manufacturing to bond different layers. | Resin type, thickness, fabric material. | Moderate, important for multilayer boards. |

| Etching and Plating Chemicals | Chemicals used for etching away unwanted copper and for plating vias and through-holes. | Chemical type, concentration, supplier. | Moderate, but consistent usage makes them significant over time. |

| Solder Mask | A protective layer applied to the PCB to prevent solder bridges and protect traces. | Type of ink (e.g., epoxy, UV-curable), application method. | Relatively low, but essential. |

| Consumables | Various materials such as drilling bits, cleaning solutions, and packaging materials. | Material type, quality, supplier. | Low individually, but collectively significant due to volume. |

Effective management of these raw materials is critical for maintaining profitability. Strategies such as establishing reliable, potentially multiple, supply sources, implementing just-in-time inventory management, and monitoring market fluctuations in material costs can mitigate risks associated with price volatility and supply shortages.

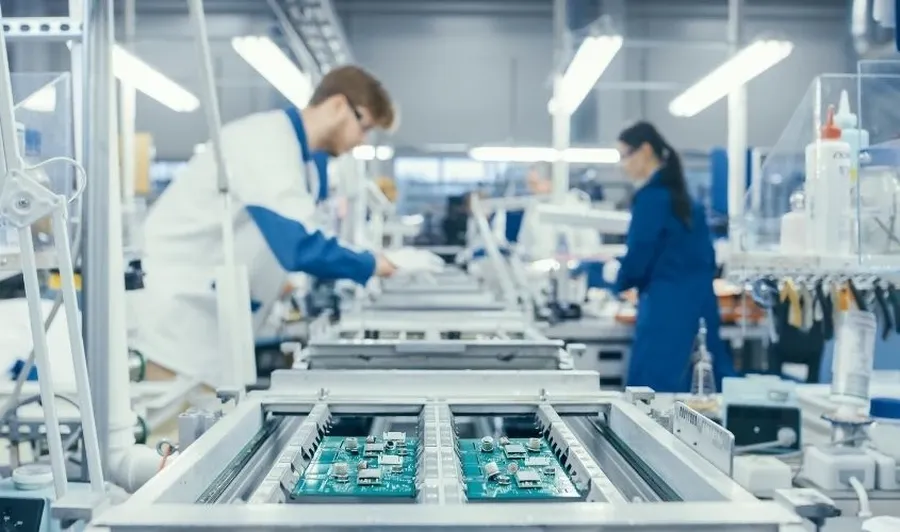

Operational Costs: Labor and Training

The operational efficiency of a PCB manufacturing plant heavily relies on the expertise of its workforce. This encompasses not only the initial recruitment of skilled personnel but also the continuous investment in their training and development. Labor costs, including wages, salaries, and benefits, form a substantial part of the overall operational expenses.

A breakdown of labor categories and their associated roles is necessary for a comprehensive understanding of the cost structure:

- Engineers

Responsible for process design, optimization, and troubleshooting. Their roles also extend to research and development, ensuring the implementation of advanced techniques for improved productivity and cost efficiency. - Technicians

Involved in equipment setup, maintenance, and repair. They are crucial for ensuring the smooth operation of manufacturing machinery and minimizing downtime. These individuals also handle component selection, material handling, and verification of system functionalities. - Machine Operators

Tasked with the daily operation of machinery, ensuring production is performed according to established quality standards. Their role is crucial for managing production output and maintaining a steady pace of work. - Quality Control Personnel

Responsible for inspecting the quality of materials, components and finished product. This guarantees the final PCBs adhere to stringent quality standards, preventing defects that can be costly and compromise the reputation of a manufacturer. - Administrative Staff

Manage non-manufacturing related functions such as inventory control, accounting, purchasing and management. Their work guarantees operational efficiency through the efficient handling of all administrative duties.

Training, both initial and ongoing, is a critical factor in reducing operational expenses through increased proficiency and reduced material waste. A well-structured training program, emphasizing industry standards and best practices, helps to maximize staff efficiency, improve product quality, and minimize the chances of defects, all contributing to lower overall costs. Furthermore, continuous learning is essential for keeping pace with advancements in technology and production methodologies in the industry.

| Cost Factor | Description | Cost Considerations |

|---|---|---|

| Wages & Salaries | Compensation for all personnel categories. | Dependent on experience, skill, location, and market conditions; often the largest portion of labor costs. |

| Benefits | Health insurance, retirement plans, paid leave, etc. | Vary based on company policy and local laws. Contributes significantly to labor overhead. |

| Initial Training | Onboarding and basic skills development. | Includes costs for trainers, training materials, and time away from production; usually a short-term expense. |

| Ongoing Training | Continuous education and upskilling programs. | Essential for adapting to new technologies, quality improvements, and maintaining a skilled workforce. |

Operational Costs: Utilities and Maintenance

Sustaining a PCB manufacturing plant necessitates a reliable supply of utilities and a proactive maintenance program. These factors are not just operational necessities but significantly impact long-term cost management and plant efficiency. Consistent utilities support uninterrupted production, while diligent maintenance minimizes downtime and expensive repairs, contributing to overall cost savings and productivity.

| Category | Description | Cost Factors | Mitigation Strategies |

|---|---|---|---|

| Electricity | Powering machinery, lighting, environmental controls | Consumption rate, peak demand charges, energy source | Energy-efficient equipment, renewable energy options, load balancing |

| Water | Cooling, cleaning, chemical processing | Consumption rate, water treatment needs, regulatory compliance | Water recycling systems, leak detection, efficient water usage techniques |

| Compressed Air | Operating pneumatic equipment, cleaning | Consumption, compressor efficiency, maintenance | Regular maintenance, efficient piping, leak detection and repair |

| Maintenance | Regular upkeep and repair of machinery and infrastructure | Frequency, parts cost, labor cost | Preventive maintenance programs, skilled technicians, spare parts inventory |

Frequently Asked Questions About PCB Manufacturing Plant Costs

This section addresses common inquiries regarding the costs associated with establishing and operating a PCB manufacturing plant. We'll cover the expenses related to manufacturing individual PCBs, typical profit margins, calculation methods for fabrication costs, and steps to become a PCB manufacturer. The answers are designed to be concise, substantial, and authoritative, providing practical insights.

- How much does it cost to get a PCB manufactured?

The cost to manufacture a PCB varies widely based on several factors, including the complexity of the design, the materials used, the quantity ordered, and the manufacturer's pricing. Simple single-layer boards in small quantities can be relatively inexpensive, while complex multi-layer boards with fine pitch components and high volume production runs will significantly increase costs. Expect a cost range from a few dollars for simple prototypes to hundreds or thousands of dollars for complex, high-volume production runs. For accurate estimates, provide detailed specifications to multiple manufacturers for competitive quotes. - What is the typical profit margin in PCB manufacturing?

The profit margin in PCB manufacturing is not uniform, it depends on numerous factors such as manufacturing scale, process efficiency, technology level, customer type, and the regional market. While some high-volume manufacturers may operate on margins of around 10-15%, those with specialized boards or smaller volumes can achieve margins of 20% or more. The business model directly affects profit margin: specialized high-tech PCBs can generate higher margins compared to mass production of basic PCBs. It's a competitive industry, so operational efficiency and cost control are key to profitability. - How do I calculate PCB fabrication cost?

PCB fabrication cost calculation involves several components: material costs (CCL, prepreg, solder mask, etc.), manufacturing costs (etching, drilling, plating, etc.), tooling costs (if applicable), and testing costs. Some manufacturers may also include overhead and administrative costs in their price. A cost-per-panel approach is common, where costs are allocated based on the number of panels used. Many manufacturers use software that accounts for all these parameters to generate precise quotes. When comparing quotes, ask for a detailed breakdown to understand how they arrived at their price and to compare costs effectively. - How to become a PCB manufacturer?

Becoming a PCB manufacturer requires a significant investment in equipment, facilities, and skilled personnel. Key steps include: developing a detailed business plan that includes market research, funding strategies, and operational plans. Securing appropriate funding for equipment purchase, facility setup and operating costs. Acquire the needed machinery and software. Obtain all necessary licenses and permits. Build a team of skilled personnel, including engineers, technicians, and quality control staff. Establish relationships with material suppliers and customers. Adhere to environmental regulations and implement a continuous quality improvement system. It’s essential to understand both manufacturing processes and business operations to succeed in this market. - What are the primary factors influencing PCB manufacturing cost?

The primary factors influencing PCB manufacturing costs include material costs (such as copper-clad laminates, prepreg), design complexity (number of layers, trace width, vias, etc.), the number of boards ordered, technology requirements (high density interconnects or special finishes), and manufacturing facility location (labor costs, environmental regulations). Material and design complexity are the main drivers. High-volume orders typically result in lower per-unit costs due to economies of scale, while specialized features add more cost. - How does the type of PCB affect manufacturing cost?

The type of PCB significantly affects manufacturing costs. Single-layer PCBs are the least expensive, while double-layer PCBs are moderately priced. Multi-layer PCBs, especially those with fine traces, vias, and advanced materials, increase manufacturing costs substantially. Flexible PCBs and rigid-flex PCBs are often more expensive due to their specialized manufacturing processes. High-frequency PCBs also demand special materials and precise tolerances, impacting costs. A simpler design reduces costs, and it’s important to match the PCB type with the intended application for cost-effectiveness. - What are the common pitfalls when starting a PCB manufacturing plant?

Common pitfalls when starting a PCB manufacturing plant include underestimating initial investment costs, not properly accounting for operational expenses, insufficient market research, improper equipment selection, lack of qualified personnel, inadequate quality control processes, and failure to comply with environmental regulations. Ignoring these factors can lead to budget overruns, production delays, and low product quality. Proper due diligence, detailed planning, and a solid understanding of the industry are critical to avoid these pitfalls. It is wise to consider a phased approach starting with a limited scale.

Cost-Saving Strategies for PCB Manufacturing

Implementing effective cost-saving strategies is paramount for the financial viability and competitiveness of a PCB manufacturing plant. These strategies encompass optimizing material usage, investing in efficient equipment, streamlining process flows, negotiating favorable supplier terms, and embracing sustainable manufacturing practices. A holistic approach to cost reduction can lead to significant savings and improved profitability.

- Optimizing Material Usage

Reducing material waste through careful design and layout, employing efficient cutting techniques, and implementing robust inventory management practices can result in significant cost savings. For example, panelization strategies can reduce the amount of waste generated in the fabrication process. - Investing in Efficient Equipment

Upgrading to energy-efficient and high-throughput machinery can lower operational costs and improve output rates. Automated systems may require higher initial investment but can lead to substantial long-term cost savings due to reduced labor costs and increased production efficiency. - Improving Process Flows

Analyzing and optimizing the manufacturing process can help identify and eliminate bottlenecks, reduce lead times, and minimize defects. Employing lean manufacturing principles and standardizing processes can help optimize material flow and improve overall efficiency. - Negotiating with Suppliers

Securing favorable contracts with material suppliers and forging long-term partnerships can lead to price reductions and more stable supply chains. Bulk purchasing of materials when market conditions are favorable can also lower costs. Establishing relationships with multiple suppliers can provide a hedge against supply disruptions and fluctuations in price. - Adopting Sustainable Manufacturing Practices

Implementing environmentally friendly practices, such as water recycling, waste reduction, and responsible disposal of hazardous materials, can not only reduce environmental impact but also lower costs associated with waste management and environmental penalties. Reducing energy consumption can also yield significant cost savings.

| Strategy | Description | Cost Reduction Impact |

|---|---|---|

| Material Optimization | Efficient layout, nesting, inventory control | Significant reduction in material wastage. |

| Efficient Equipment | Automated, high-throughput machinery | Lower labor costs, higher production volume. |

| Process Improvement | Lean processes, defect reduction | Reduced lead times, lower defect rates. |

| Supplier Negotiation | Long-term contracts, bulk purchasing | Lower material costs, stable supply. |

| Sustainable Practices | Recycling, waste reduction, energy efficiency | Lower waste management, energy expenses. |

Breakdown of Costs for Different Scales

Understanding the cost variations across different scales of PCB manufacturing is crucial for strategic planning and investment. This section provides a breakdown of cost estimations for small-scale prototyping facilities, medium-sized production lines, and large-scale mass production plants. The economies of scale significantly impact the initial investment and operational expenditures. Each scale has unique requirements regarding machinery, infrastructure, and staffing, directly affecting overall costs.

| Cost Factor | Small-Scale Prototyping | Medium-Scale Production | Large-Scale Mass Production |

|---|---|---|---|

| Initial Equipment Investment | $50,000 - $200,000 | $200,000 - $1,000,000 | $1,000,000 + |

| Facility and Infrastructure Costs | $20,000 - $100,000 | $100,000 - $500,000 | $500,000 + |

| Software and Design Costs | $5,000 - $10,000 | $10,000 - $30,000 | $30,000 + |

| Annual Raw Material Costs | $20,000 - $100,000 | $100,000 - $1,000,000 | $1,000,000 + |

| Annual Labor and Training Costs | $30,000 - $150,000 | $150,000 - $1,000,000 | $1,000,000 + |

| Annual Utilities and Maintenance | $10,000 - $50,000 | $50,000 - $300,000 | $300,000 + |

| Typical Production Volume | 100 - 1,000 boards/month | 1,000 - 10,000 boards/month | 10,000+ boards/month |

Note: These are approximate ranges. Actual costs may vary significantly based on specific requirements, equipment choices, location, and market conditions. Below is a more detailed look at each category.

- Small-Scale Prototyping Facilities:

Primarily focused on research, development, and low-volume production. Equipment includes basic PCB printers, a manual pick-and-place machine, a small reflow oven, and basic etching equipment. The focus is on flexibility and quick turnaround, not necessarily high throughput. Labor is often composed of a small team of skilled technicians and engineers. These facilities allow companies to test their designs and validate their manufacturing processes before investing in large scale production. - Medium-Scale Production Lines:

This level balances production capacity with some degree of flexibility. These plants often have multiple automated pick-and-place machines, larger reflow ovens, and semi-automated etching and plating equipment. They often have more robust testing equipment. The workforce is larger and includes specialized operators, quality control teams, and more administrative support. Production volumes are higher, catering to more demanding requirements, while remaining cost-effective - Large-Scale Mass Production Plants:

Optimized for high-volume, consistent output. These plants have fully automated production lines featuring high-speed pick-and-place machines, large reflow ovens, automated etching and plating lines and extensive testing and inspection systems. They often require dedicated logistics, supply chain management, and extensive quality control systems, with a large workforce across all functions. The goal here is maximum efficiency and lowest cost per unit through economies of scale.

Starting a PCB manufacturing plant involves significant investment and careful planning. Understanding the various cost components is crucial for success. From initial equipment purchases to ongoing operational expenses, each aspect requires meticulous consideration. While the initial costs can be substantial, the potential for profitability in the growing electronics market makes it a worthwhile venture. This comprehensive guide helps you understand the complexities involved and make informed decisions, helping to manage the PCB manufacturing plant cost effectively and achieve success in this competitive industry. Keeping track of costs and adapting to market dynamics will be paramount to ensure your PCB manufacturing business thrives in the coming years.

AnyPCBA

AnyPCBA