Understanding PCBs: From Electronic Components to Environmental Concerns

The acronym 'PCB' can refer to two very different things: the backbone of modern electronics - the printed circuit board, and a group of toxic, man-made chemicals known as polychlorinated biphenyls. While one is essential for technology, the other is a significant environmental concern. This article will delve into both aspects, unraveling their significance and implications, bridging the gap between the tiny circuit boards powering our gadgets and the environmental toxins that have left a global footprint. This understanding is crucial in today's interconnected world.

What is a Printed Circuit Board (PCB)?

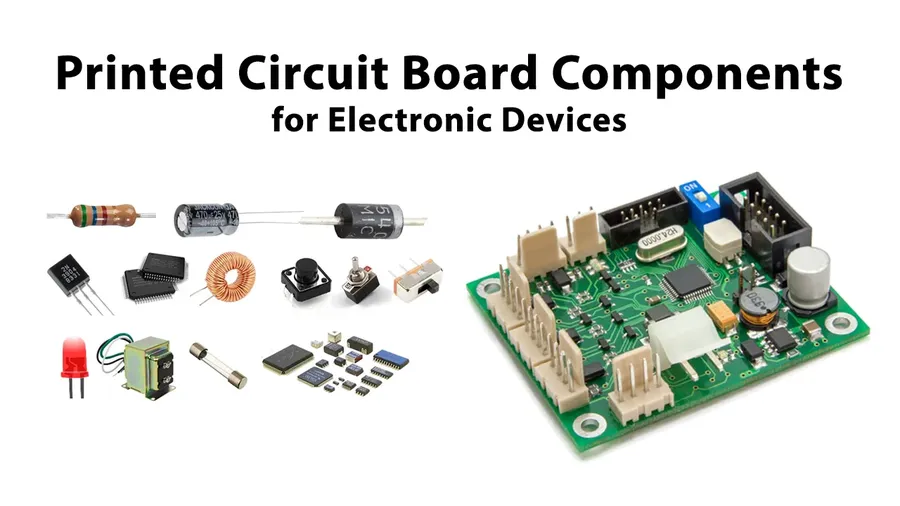

A Printed Circuit Board (PCB) serves as the foundational building block for nearly all modern electronic devices. Functionally, it's a robust platform that provides both structural support and the electrical pathways necessary for electronic components to interact. PCBs enable the organized connection of various components, ensuring a functioning circuit according to the intended design.

Key structural elements of a PCB include the substrate, copper traces, and vias. The substrate, typically made of fiberglass or composite materials, provides the rigid base. Copper traces, which are thin layers of copper, act as conductive pathways, enabling the flow of electrical current, while vias are plated holes connecting traces on different layers.

Together, these components form a sophisticated network allowing electricity to flow between different parts of the circuit, and enable engineers to design compact and complex electronic systems.

The Role of PCBs in Electronics

Printed circuit boards (PCBs) are fundamental to the functionality of modern electronics, serving as both the structural foundation and the electrical pathway for components within a device. Their role extends beyond simple connections; they are critical for miniaturization, efficient power distribution, and ensuring reliable operation of devices from simple consumer electronics to sophisticated industrial equipment.

- Structural Support

PCBs provide a stable base for mounting electronic components. This physical support is essential for maintaining the arrangement of components, which is crucial for proper function. - Electrical Interconnection

Copper traces etched onto the board form conductive pathways that connect various electronic components. These traces replace traditional wiring methods, reducing size and complexity, while improving reliability. - Miniaturization

PCBs enable the dense packing of components in electronic devices, which has driven the trend of miniaturization. This high density allows for more complex functionality in smaller, more portable devices. - Efficient Power Distribution

The layered structure of PCBs enables a more efficient power distribution by managing voltage and current requirements for various components. The copper planes act as both power and ground layers, minimizing losses. - Reliability and Repeatability

The manufacturing process ensures a high level of consistency, making each PCB very similar to the previous one, contributing to the reliability of electronics in mass production environments, unlike manual wiring.

How PCBs are Designed and Manufactured

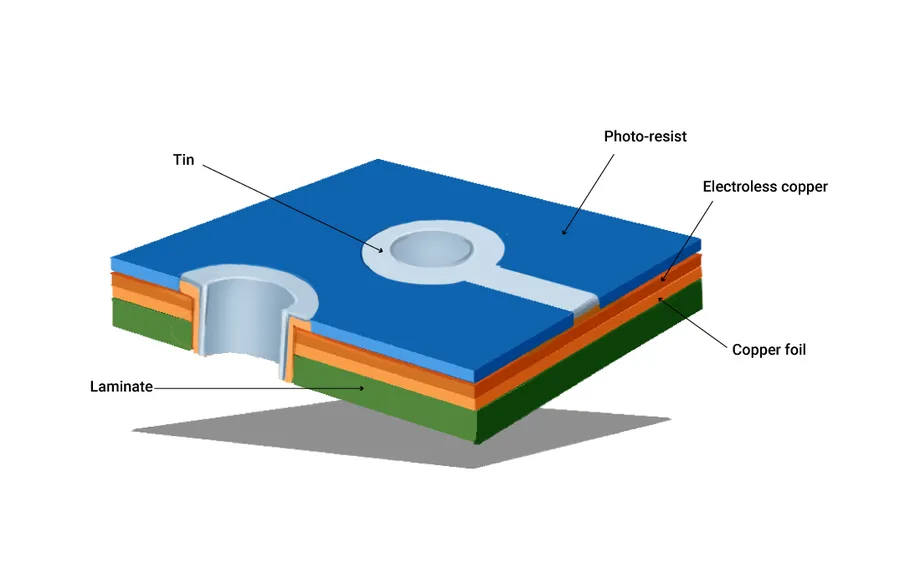

The creation of a Printed Circuit Board (PCB) is a multi-stage process involving intricate design and precise manufacturing techniques. This process transforms a conceptual electronic circuit into a physical, functional board.

The process starts with circuit design, moves into physical board layout and fabrication, and concludes with component assembly. Different types of PCBs, such as single-sided, double-sided, and multilayer boards, are produced using similar steps but with varying complexities.

The design phase utilizes Computer-Aided Design (CAD) software. Engineers use this to layout the circuit, defining the conductive traces, component placement, and other features. The CAD output is the blueprint for the physical board.

Manufacturing involves several key steps. The substrate, typically a non-conductive material like fiberglass or ceramic, is prepared. Copper is then applied to this substrate, often through a process called lamination. The design created in CAD is then transferred to the copper through etching. Etching removes unwanted copper, leaving behind the traces. Drilling creates holes for component insertion and vias, which are connections between layers. Plating is used to enhance conductivity of vias and to provide solderable surfaces. After the circuit is formed, components are then soldered onto the board.

| PCB Type | Description | Typical Applications |

|---|---|---|

| Single-sided | Components and circuits on one side. | Simple electronics, basic lighting. |

| Double-sided | Components and circuits on both sides. | Moderate complexity electronics, basic consumer electronics |

| Multilayer | Multiple layers of circuits sandwiched together. | Complex electronics, high-density circuits, advanced computing. |

What are Polychlorinated Biphenyls (PCBs)?

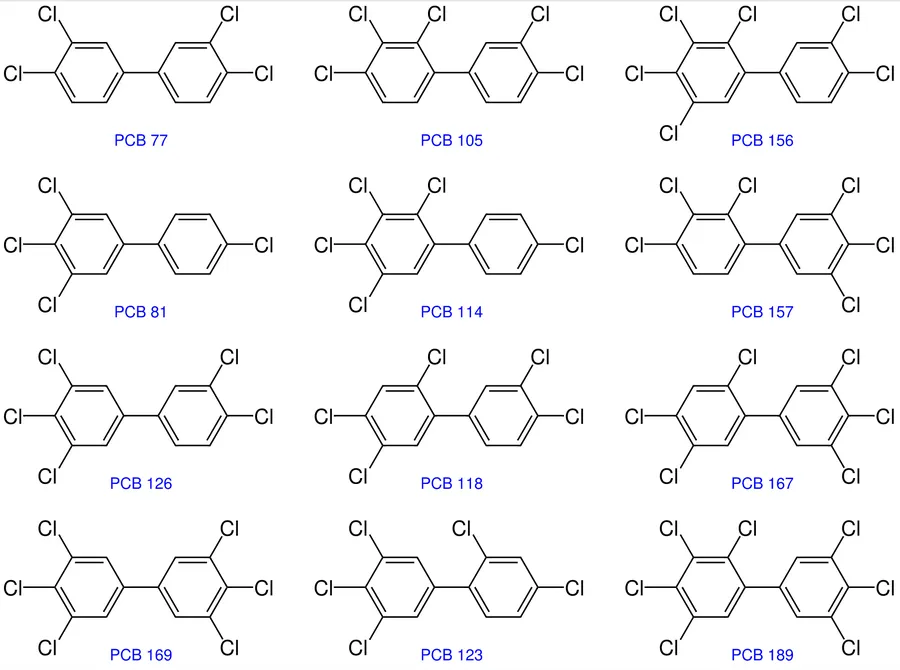

Polychlorinated biphenyls (PCBs) are a class of synthetic organic chemicals, characterized by a structure where chlorine atoms are attached to a biphenyl molecule. These compounds, once widely utilized for their insulating and non-flammable properties, are now recognized as persistent environmental pollutants with significant health risks. Their chemical stability, which initially made them valuable, also makes them extremely resistant to degradation in the environment.

Before their widespread ban, PCBs were primarily used as dielectric and coolant fluids in electrical equipment, such as transformers and capacitors, and in various industrial applications like hydraulic fluids, plasticizers, and adhesives. The presence of multiple chlorine atoms on the biphenyl structure leads to a wide variety of PCB congeners, each with slightly different chemical and toxicological properties. The properties that made PCBs desirable, such as their high thermal stability and electrical insulation capabilities, also contribute to their environmental persistence and bioaccumulation.

The inherent stability of PCBs stems from their chemical structure and the strong carbon-chlorine bonds. This stability, while useful in their industrial applications, also renders them highly resistant to environmental degradation processes. Consequently, PCBs can persist in the environment for extended periods and accumulate in living organisms, which leads to concerns about their long-term impact on ecosystems and human health.

The Health and Environmental Impacts of PCBs

Polychlorinated biphenyls (PCBs), despite their useful industrial properties, pose significant risks to human health and the environment. These compounds are persistent organic pollutants that can accumulate in living organisms and ecosystems, leading to long-term adverse effects.

The adverse health effects associated with PCB exposure are varied and can include:

- Carcinogenesis

PCBs have been classified as probable human carcinogens, with studies linking exposure to an increased risk of certain types of cancers, including liver cancer and non-Hodgkin's lymphoma. - Developmental Issues

Exposure to PCBs, particularly during pregnancy and early childhood, can lead to developmental problems, including cognitive deficits, behavioral issues, and delayed physical development. Studies have shown that prenatal exposure is particularly harmful. - Immune System Disruption

PCBs can compromise the immune system, making individuals more susceptible to infections and autoimmune diseases. The compounds can disrupt the normal function of immune cells. - Endocrine Disruption

PCBs are known endocrine disruptors, meaning they can interfere with the body's hormonal system. This disruption can lead to a range of health issues, including reproductive problems and thyroid dysfunction. - Other Health Effects

Other health problems linked to PCB exposure include skin and eye irritation, liver damage, and neurological effects.

The environmental impact of PCBs is equally concerning, characterized by:

- Persistence

PCBs are highly persistent in the environment and do not easily degrade, leading to long-term contamination of soil, water, and air. - Bioaccumulation

These compounds bioaccumulate, meaning they build up in the tissues of living organisms over time. This process is particularly harmful in the food chain, where higher trophic levels (e.g., predatory fish, birds of prey, humans) can accumulate high concentrations of PCBs. - Ecosystem Disruption

The presence of PCBs in the environment disrupts ecosystems, impacting the health and survival of various wildlife species. It also reduces biodiversity. - Water Contamination

PCBs contaminate water bodies, affecting aquatic life and potentially making drinking water sources unsafe. They can also accumulate in sediments, acting as a long-term source of pollution.

The bioaccumulation of PCBs in the food chain is a major concern, as it can lead to human exposure through the consumption of contaminated fish, meat, and dairy products. Effective mitigation and regulatory measures are essential to reduce and control the widespread presence of PCBs and protect both human and environmental well-being.

PCB Regulations and Management

The regulation and management of Polychlorinated Biphenyls (PCBs) are critical due to their persistent and toxic nature. International and national efforts have been established to control their production, use, and disposal, as well as to remediate contaminated sites. These actions aim to safeguard human health and the environment from the detrimental effects of PCBs.

- International Regulations

The Stockholm Convention on Persistent Organic Pollutants (POPs) is a key international treaty that prohibits or restricts the production and use of PCBs. It mandates the elimination of PCB stockpiles and equipment containing PCBs, as well as the remediation of contaminated areas. - National Regulations

Many countries have implemented specific national laws and regulations to align with or extend beyond the requirements of the Stockholm Convention. These regulations often include strict controls on the import, export, manufacture, and use of PCBs. They also establish guidelines for the safe handling, storage, and disposal of PCBs and PCB-containing waste. - PCB Disposal and Destruction

Environmentally sound disposal methods for PCBs are essential. High-temperature incineration is a common method, but other technologies like chemical dechlorination or bioremediation are also used. Proper disposal prevents the release of PCBs into the environment. Regulations also require companies to label and manage PCB wastes. - Remediation of PCB Contaminated Sites

Many sites, previously used for industrial activities, are contaminated with PCBs. Remediation efforts are needed to clean up these sites. Strategies include excavation and removal, in-situ treatment, or containment methods to prevent PCBs from spreading into soil, water and air. Risk assessment is also required before any remediation work starts. - Monitoring and Surveillance

Continuous monitoring programs are in place to track PCB levels in the environment (water, soil, and air) and in biological samples. These programs are essential for assessing the effectiveness of regulations and control measures, and identifying new areas of concern. - Public Awareness

Raising awareness about the dangers of PCBs is vital for preventing exposure and ensuring public cooperation in management programs. This includes disseminating information about potential sources of PCB contamination, the symptoms of PCB exposure, and actions people can take to reduce their risks.

Frequently Asked Questions About PCBs

This section addresses common questions regarding PCBs, clarifying the distinction between printed circuit boards and polychlorinated biphenyls. Understanding this difference is crucial due to their drastically different nature and implications.

- What does PCB stand for?

PCB can stand for two entirely different things: Printed Circuit Board and Polychlorinated Biphenyls. Context is essential to determine the intended meaning. Printed Circuit Boards are fundamental components in electronics, serving as a platform for mounting and connecting electronic components. Polychlorinated Biphenyls, on the other hand, are a group of synthetic organic chemicals that were once widely used but are now banned due to their harmful effects. - What are PCBs (Polychlorinated Biphenyls) and why are they harmful?

Polychlorinated Biphenyls (PCBs) are a class of persistent organic pollutants. Their chemical stability and fire-resistant properties led to their extensive use in electrical equipment, hydraulic fluids, and other industrial applications. However, PCBs are highly toxic, environmentally persistent, and can accumulate in living organisms, causing a range of health issues, including cancer, developmental problems, and immune system dysfunction. Their persistence and bioaccumulation make them particularly dangerous. - What are the health symptoms of PCB (Polychlorinated Biphenyls) exposure?

Exposure to PCBs can lead to various health problems. The symptoms can include skin irritations like chloracne, liver damage, thyroid disruption, neurological problems, and developmental issues in children. Long-term exposure is also linked to an increased risk of cancer. The severity and type of symptoms often depend on the level and duration of exposure. - How can I identify PCBs (Polychlorinated Biphenyls)?

Identifying PCBs can be challenging as they are not readily visible in most contexts. Historically, PCBs were used in products like transformers, capacitors, and some older building materials (such as caulk). If you suspect PCBs may be present, such as in old electrical equipment or in pre-1979 building materials, testing by qualified professionals is needed. It's best to assume potentially contaminated materials may contain PCBs and consult with experts before handling them. - What is the difference between PCBs as circuit boards and as a chemical compound?

The term 'PCB' is used in two distinct contexts, causing much confusion. 'Printed Circuit Board' refers to the physical board used in electronic devices to connect electronic components, facilitating the flow of electricity. These boards are composed of non-toxic materials, like fiberglass and copper. Conversely, 'Polychlorinated Biphenyls' refers to a class of toxic chemical compounds that are now banned or heavily regulated due to their harmful effects on human and environmental health. They are entirely different in purpose, chemical composition, and hazard levels. - Are PCBs (Polychlorinated Biphenyls) still present in the environment?

Although the production of PCBs has been banned in most countries, they are still present in the environment due to their persistence. These chemicals can be found in soil, water, sediment, and air. They also bioaccumulate in the food chain, meaning that they become more concentrated in organisms higher up the chain, posing a long-term risk to both humans and wildlife.

Table: Comparing PCB (Printed Circuit Boards) vs. PCBs (Polychlorinated Biphenyls)

This section provides a comparative analysis highlighting the fundamental differences between PCBs as Printed Circuit Boards, essential components in electronics, and PCBs as Polychlorinated Biphenyls, hazardous chemical compounds. Understanding these distinctions is crucial, as the acronym 'PCB' refers to two completely different entities with vastly different implications.

| Feature | PCB (Printed Circuit Board) | PCB (Polychlorinated Biphenyl) |

|---|---|---|

| Definition | A structural base and electrical connection platform for electronic components. | A class of persistent organic pollutants, synthetic chemical compounds. |

| Primary Use | Foundation of electronic devices, facilitating electrical connections. | Formerly used as industrial fluids for electrical equipment, heat transfer, and hydraulic fluids; now mostly banned. |

| Composition | Typically made of fiberglass or composite substrate, copper traces, and other conductive materials. | Composed of chlorinated biphenyl molecules, with varying numbers of chlorine atoms. |

| Function | Supports and connects electronic components to form a functional circuit. | Formerly used for their dielectric and thermal properties, now known for their environmental persistence and toxicity. |

| Environmental Impact | Minimal environmental impact when properly disposed of or recycled. | Highly toxic, persistent pollutants; cause significant environmental contamination and bioaccumulation in the food chain. |

| Health Impact | Not toxic, though improper handling of manufacturing processes may carry risks. | Highly toxic; linked to cancer, developmental issues, immune system dysfunction and other health problems. |

| Regulation | Subject to manufacturing and recycling guidelines. | Strictly regulated, with bans in place across many countries and regions due to their toxicity. |

| Disposal | Recycled or disposed of according to e-waste regulations. | Requires special disposal processes, often involving high-temperature incineration. |

| Safety Considerations | Safe in intended use and handling of electronic devices. | Extremely hazardous and require careful handling and containment; poses risks at even low concentrations. |

Understanding the dual nature of the term 'PCB' is crucial for both technological and environmental awareness. Printed circuit boards are indispensable components of our modern technological world, while polychlorinated biphenyls represent a significant environmental and health concern that requires ongoing attention and management. By being informed about both aspects of PCBs, we can make better choices and contribute to a more sustainable and healthier future, whether it's designing safer electronics or advocating for stricter environmental policies.

AnyPCBA

AnyPCBA