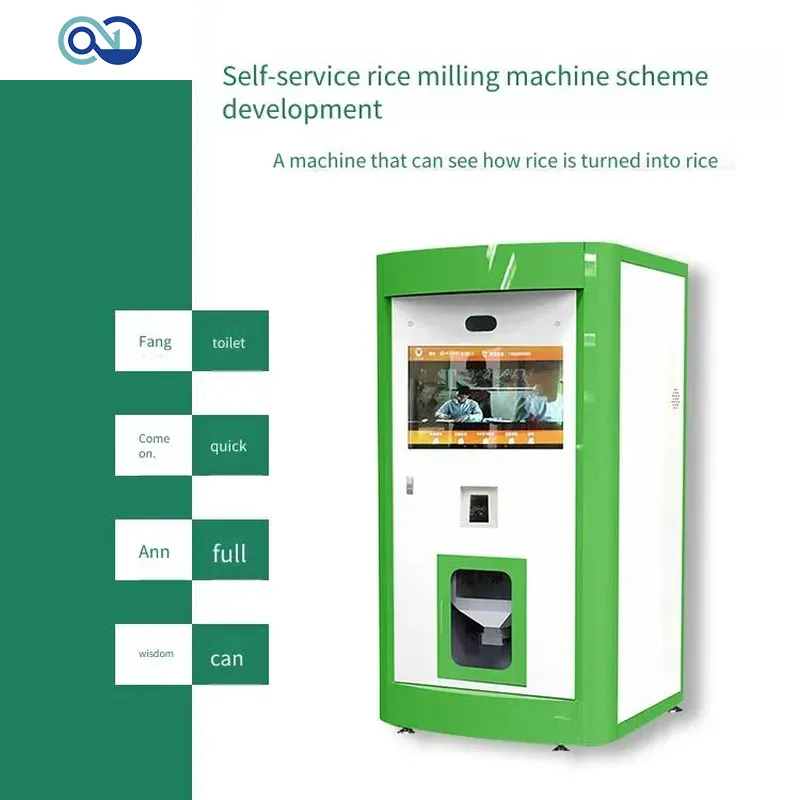

Smart Shared Rice Milling Machine Solution

In an era where technology is transforming every sector, agriculture stands poised for a significant leap forward. The traditional methods of rice milling, often inefficient and inaccessible to small-scale farmers, are ripe for innovation. Imagine a system that empowers communities with on-demand, high-efficiency rice processing, reducing waste and increasing profitability. This vision is now a reality through the Smart Shared Rice Milling Machine Solution. At Zero One Solution Limited, we've leveraged our decade of expertise in rapid PCB prototyping and one-stop manufacturing to design and implement the critical electronic backbone of this transformative agricultural technology. This article will delve into how our advanced PCB solutions are making shared, smart rice milling machines not just possible, but highly effective and scalable, ushering in a new era of agricultural productivity and economic empowerment.

The Evolution of Rice Milling: From Traditional to Smart Shared Systems

The journey of rice milling has undergone a significant transformation, evolving from rudimentary manual processes to sophisticated, technology-driven solutions. Recognizing the pressing need for modern, efficient, and accessible rice processing methods in today's agricultural sector, the Smart Shared Rice Milling Machine Solution emerges as a pivotal innovation. This evolution addresses critical challenges related to efficiency, accessibility, and sustainability in rice production.

Historically, rice milling was a labor-intensive task, often performed manually or with the aid of simple machinery. Traditional methods were characterized by low efficiency, high grain loss, and significant physical exertion. These systems were also geographically limited, making it difficult for smallholder farmers in remote areas to access milling services.

The advent of mechanized rice mills marked a significant step forward, increasing processing speed and reducing physical labor. However, these early mills were often expensive to operate and maintain, posing a barrier for many small-scale farmers. Furthermore, the centralized nature of these milling facilities often resulted in transportation costs and post-harvest losses, diminishing the overall profitability for farmers.

Today, the Smart Shared Rice Milling Machine Solution represents a paradigm shift in rice processing. By leveraging advancements in automation, IoT, and cloud computing, these systems offer a decentralized, efficient, and data-driven approach to rice milling. This innovative solution not only reduces post-harvest losses and improves grain quality but also empowers local communities by providing affordable and accessible milling services. The shift towards smart shared systems addresses the limitations of traditional methods and paves the way for a more sustainable and equitable rice production ecosystem.

Understanding the Smart Shared Rice Milling Machine Solution

The Smart Shared Rice Milling Machine Solution represents a paradigm shift in agricultural technology, offering a modern approach to rice processing that addresses the limitations of traditional methods. This solution integrates advanced technology with a shared access model, aiming to provide efficient, cost-effective, and accessible rice milling services to farmers and communities. At its core, it's about leveraging technology to enhance productivity, reduce waste, and empower agricultural communities.

- What are the core components of a Smart Shared Rice Milling Machine?

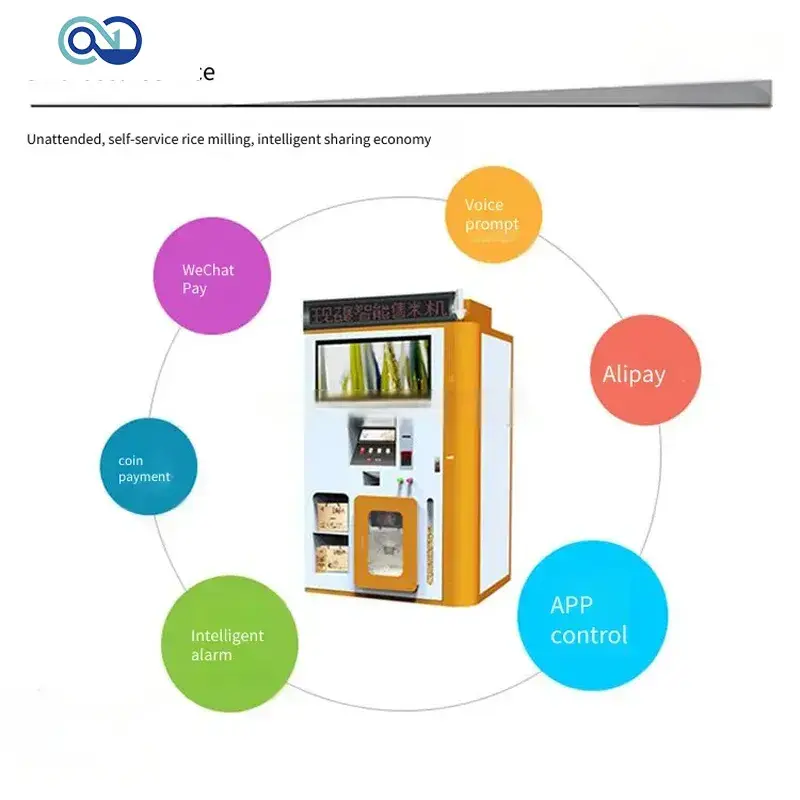

The core components typically include a high-efficiency rice milling unit, an IoT-enabled control system for remote monitoring and operation, a user-friendly interface for easy access, and a robust data analytics platform for optimizing performance. Also, a payment gateway for shared access usage fees and durable housing to protect the internal components from external environmental factors. - How does the Smart Shared Rice Milling Machine operate?

The machine operates on a shared access model, allowing multiple farmers or community members to use the facility on a pay-per-use basis. The IoT system enables users to schedule milling sessions, monitor the milling process remotely, and receive notifications upon completion. This ensures optimal machine utilization and reduces downtime. - What are the key benefits for farmers using this solution?

Farmers benefit from reduced post-harvest losses due to timely milling, lower operational costs compared to owning individual milling machines, access to advanced milling technology, and increased income potential by offering higher quality rice to the market. The sharing aspect also promotes community collaboration and resource optimization. - How does this solution contribute to community development?

By providing accessible and affordable rice milling services, the solution fosters economic empowerment within the community. It creates opportunities for local entrepreneurship, reduces the burden on farmers, and improves the overall quality of life. Furthermore, the shared model encourages community engagement and strengthens social bonds. - What makes this solution 'smart'?

The 'smart' aspect comes from the integration of IoT technology, which enables remote monitoring, data analytics, and automated operation. This allows for predictive maintenance, optimized milling parameters, and efficient resource management, leading to higher productivity and reduced waste. The machine is also 'smart' due to its payment system, enabling the machine owner to easily collect money. - Can the Smart Shared Rice Milling Machine be used in remote areas?

Yes, the solution is particularly beneficial for remote areas where access to milling facilities is limited. The shared model makes it economically viable for communities to access advanced milling technology, regardless of their location. Also, because of the potential for remote monitoring, a technician does not have to be physically present at all times.

Key Technologies Powering Smart Rice Milling: IoT and Automation

The Smart Shared Rice Milling Machine's intelligence stems from the synergistic integration of Internet of Things (IoT) and automation technologies. These technologies enable remote monitoring, predictive maintenance, and optimized processing, transforming traditional rice milling into a data-driven, efficient operation. By leveraging real-time data and automated processes, the smart milling machine minimizes waste, reduces downtime, and ensures consistent quality, thereby maximizing benefits for farmers and communities.

- What specific IoT sensors are used in a Smart Shared Rice Milling Machine?

Smart Shared Rice Milling Machines utilize a range of IoT sensors to monitor various parameters. These include sensors for measuring grain moisture levels, temperature sensors to prevent overheating, vibration sensors to detect mechanical issues, and load cells to optimize milling pressure. Data from these sensors is transmitted to a central system for real-time analysis and decision-making. - How does automation improve the rice milling process?

Automation enhances rice milling by precisely controlling each stage of the process. Automated systems manage grain feeding, husk removal, polishing, and sorting, ensuring consistency and minimizing human error. This leads to higher yields, reduced grain damage, and improved overall efficiency compared to manual methods. - What are the benefits of remote monitoring for rice milling operations?

Remote monitoring provides operators with real-time insights into the milling machine's performance, allowing them to identify and address issues proactively. This capability reduces downtime, optimizes energy consumption, and enables data-driven decisions regarding maintenance and process adjustments, ultimately lowering operational costs and improving productivity. - How does predictive maintenance work in a smart rice milling context?

Predictive maintenance uses sensor data and machine learning algorithms to forecast potential equipment failures. By analyzing patterns in vibration, temperature, and performance data, the system can predict when maintenance is needed, preventing unexpected breakdowns and extending the lifespan of the milling machine. This minimizes disruptions and lowers maintenance costs. - What data security measures are in place to protect the IoT-enabled rice milling system?

Data security is paramount in IoT-enabled rice milling systems. Measures include secure data transmission protocols (e.g., encryption), access controls to limit unauthorized access, regular security audits, and robust firewalls. These safeguards ensure the integrity and confidentiality of sensitive data related to milling operations. - Can the Smart Shared Rice Milling Machine be integrated with other agricultural technologies?

Yes, the Smart Shared Rice Milling Machine can be integrated with various agricultural technologies, such as farm management systems, weather monitoring services, and supply chain platforms. This integration enables a holistic approach to agriculture, optimizing resource utilization, improving crop yields, and streamlining the entire value chain from farm to consumer. - How does IoT and automation contribute to sustainable rice milling practices?

IoT and automation promote sustainable rice milling by optimizing resource consumption and reducing waste. Precise control of the milling process minimizes grain loss, while efficient energy management lowers the carbon footprint. Remote monitoring enables proactive maintenance, extending equipment life and reducing the need for frequent replacements, contributing to a more environmentally friendly operation.

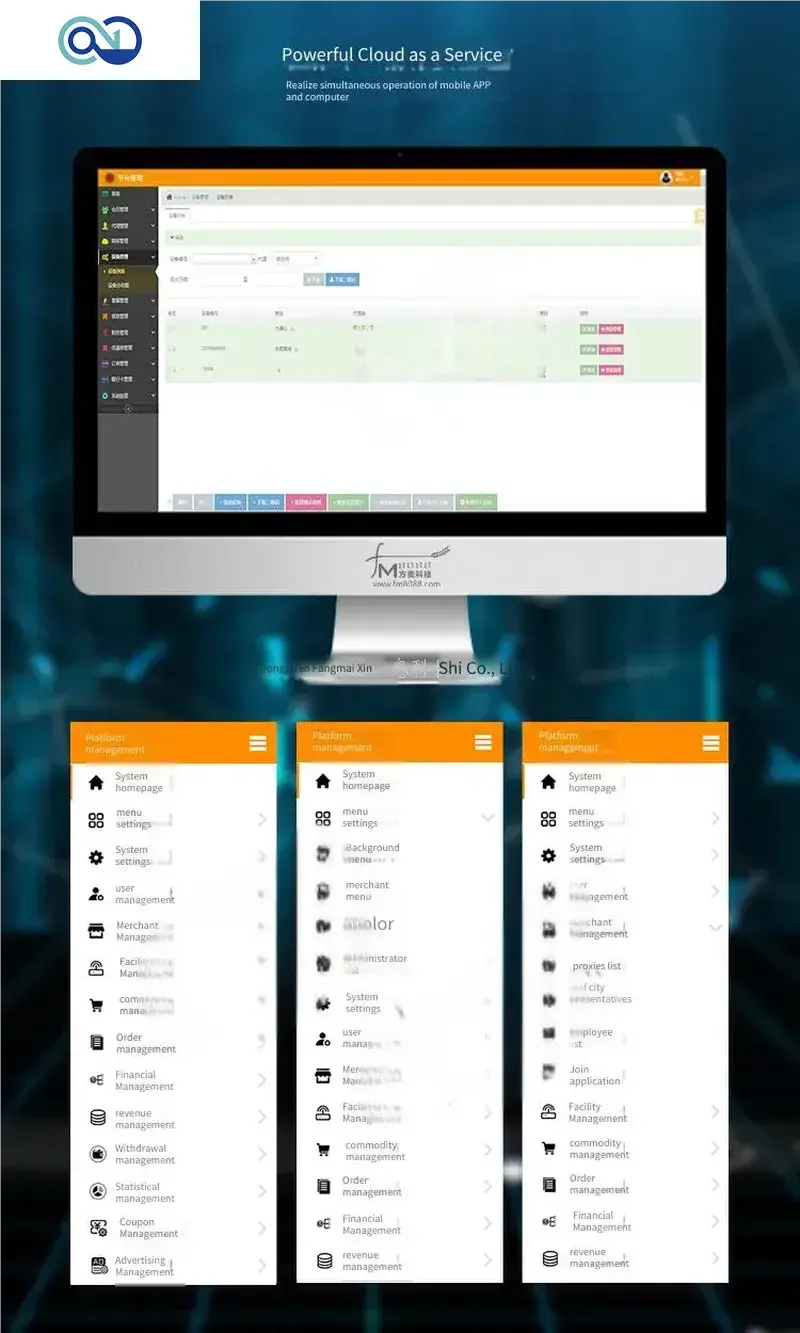

The Critical Role of PCB Solutions in Smart Agriculture

In the realm of smart agriculture, the Smart Shared Rice Milling Machine stands as a testament to technological advancement. At the heart of this innovation lies the Printed Circuit Board (PCB), serving as the central nervous system that orchestrates the machine's complex functions. PCBs are not merely components; they are the indispensable foundation upon which the reliability, performance, and connectivity of these smart machines are built. Custom PCB designs ensure that the Smart Shared Rice Milling Machine operates with optimal efficiency and precision, adapting to the unique demands of agricultural environments.

- Ensuring Reliability in Harsh Environments

Agricultural settings are often characterized by dust, moisture, and temperature variations. PCBs designed for smart rice milling machines must be robust enough to withstand these conditions. This is achieved through: * **Conformal Coatings:** Applying protective layers that shield the PCB from moisture and corrosion. * **High-Quality Materials:** Selecting materials that resist thermal stress and mechanical wear. * **Stringent Testing:** Conducting thorough testing to ensure PCBs function flawlessly under extreme conditions. - Optimizing Performance for Efficient Milling

The performance of a smart rice milling machine hinges on the efficiency of its PCB. Key considerations include: * **Signal Integrity:** Designing PCBs to minimize signal loss and interference, ensuring accurate data transmission between sensors, processors, and actuators. * **Power Management:** Implementing efficient power distribution to reduce energy consumption and prevent overheating. * **Component Placement:** Strategically placing components to optimize thermal management and minimize electromagnetic interference. - Enhancing Connectivity for Seamless Integration

Connectivity is crucial for remote monitoring, data analysis, and predictive maintenance. PCB design facilitates this through: * **Wireless Communication Modules:** Integrating Wi-Fi, Bluetooth, or cellular modules for seamless data transfer to cloud platforms. * **Sensor Integration:** Incorporating interfaces for various sensors that monitor grain quality, machine performance, and environmental conditions. * **Remote Control Capabilities:** Enabling remote control and diagnostics through secure communication protocols. - Custom PCB Design for Smart Rice Milling

Why is custom PCB design so important? Because it allows for: * **Tailored Solutions:** Creating PCBs that are specifically designed for the unique requirements of smart rice milling machines. * **Optimized Layout:** Arranging components to maximize performance and minimize space. * **Cost Efficiency:** Reducing material waste and improving manufacturing yields. - The Future of PCBs in Smart Agriculture

The role of PCBs in smart agriculture is set to expand with advancements in: * **Flexible PCBs:** Adapting to curved surfaces and irregular shapes, allowing for more innovative designs. * **Biodegradable Materials:** Reducing the environmental impact of electronic waste. * **AI-Powered Design:** Using artificial intelligence to optimize PCB layouts and improve performance.

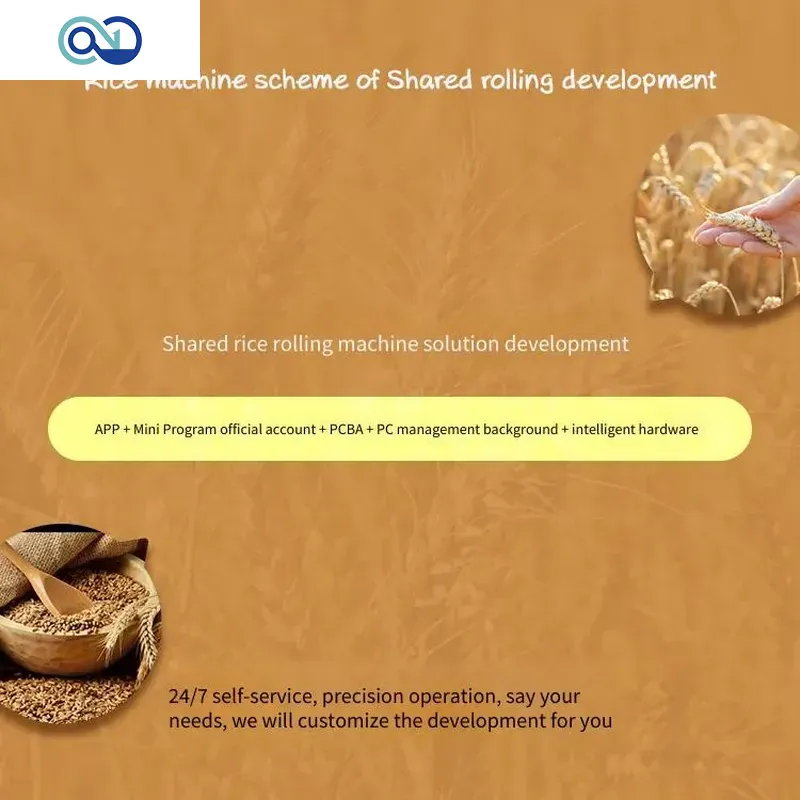

Zero One Solution Limited's Expertise in Enabling Smart Shared Rice Milling

Zero One Solution Limited stands at the forefront of enabling the Smart Shared Rice Milling Machine revolution. Our expertise spans rapid prototyping, PCB design, manufacturing, and assembly, all crucial for the seamless development and deployment of these innovative solutions. We transform concepts into reality, ensuring that each Smart Shared Rice Milling Machine operates with peak efficiency and reliability.

Here’s a closer look at our key capabilities:

- Rapid Prototyping

We accelerate innovation with our rapid prototyping services, enabling quick iterations and validations of design concepts for the Smart Shared Rice Milling Machine. This ensures faster time-to-market and optimized performance. - PCB Design

Our expert PCB design team crafts high-performance, reliable circuit boards tailored to the specific needs of smart rice milling machines. We focus on optimizing signal integrity, power distribution, and thermal management. - Manufacturing

With state-of-the-art manufacturing facilities, we produce PCBs with exceptional quality and precision. Our manufacturing processes adhere to stringent quality control standards, ensuring the durability and longevity of the smart rice milling machines. - Assembly

We provide comprehensive PCB assembly services, integrating components seamlessly and efficiently. Our assembly processes are optimized for high-volume production while maintaining the highest levels of accuracy and reliability.

Our commitment extends beyond just providing services; we are dedicated to empowering our clients in the agricultural sector with cutting-edge technology. By partnering with Zero One Solution Limited, you gain access to a wealth of expertise and a collaborative approach that ensures your Smart Shared Rice Milling Machine project is a resounding success. From initial design to final assembly, we are your trusted partner in bringing innovation to the field.

Benefits and Impact of the Smart Shared Rice Milling Machine Solution

The Smart Shared Rice Milling Machine Solution delivers a transformative array of benefits, from dramatically increasing efficiency and minimizing post-harvest losses to empowering farmers economically and fostering environmental sustainability. This innovative system reshapes traditional rice processing, making it more accessible, affordable, and eco-friendly.

- Increased Efficiency

Smart rice milling machines process rice faster and with greater precision than traditional methods. Automation and IoT technologies ensure optimal milling parameters, reducing processing time and maximizing output. - Reduced Post-Harvest Losses

By providing localized milling solutions, the Smart Shared Rice Milling Machine minimizes transportation and storage needs, significantly decreasing post-harvest losses due to spoilage and pest infestation. Real-time monitoring and data analytics further aid in identifying and addressing potential issues promptly. - Economic Empowerment for Farmers

This solution empowers farmers by enabling them to process their rice locally, adding value to their crops and increasing their income. The shared model also reduces the financial burden of owning and maintaining individual milling equipment, making advanced technology accessible to smaller-scale farmers. - Environmental Sustainability

Smart Shared Rice Milling Machines promote environmental sustainability through several avenues. They minimize transportation-related emissions, reduce waste by optimizing the milling process, and can be powered by renewable energy sources, contributing to a smaller carbon footprint. - Improved Rice Quality and Nutrition

Precision milling ensures that rice is processed to the highest quality standards, preserving its nutritional value. This leads to better food security and improved health outcomes for communities that rely on rice as a staple food. - Enhanced Community Access

The 'shared' aspect of the solution means that communities can collectively benefit from access to advanced rice milling technology. This promotes social equity and ensures that even remote or underserved areas can enjoy the benefits of efficient and sustainable rice processing.

Challenges and Future Outlook for Smart Shared Rice Milling

The Smart Shared Rice Milling Machine Solution represents a significant leap forward in agricultural technology, but its widespread adoption faces several challenges. Overcoming these hurdles is crucial to realizing the full potential of this innovation and ensuring its positive impact on farming communities and the environment. Looking ahead, the integration of these smart systems with broader agricultural ecosystems holds immense promise for the future of rice production.

- Adoption Barriers in Smart Shared Rice Milling Solutions

One of the primary challenges is the initial investment cost, which can be a significant barrier for small-scale farmers. Additionally, the need for reliable internet connectivity in rural areas and the digital literacy of farmers are critical factors influencing adoption rates. Overcoming these barriers requires innovative financing models, infrastructure development, and comprehensive training programs. - Maintenance and Technical Support

Ensuring the longevity and efficient operation of Smart Shared Rice Milling Machines requires robust maintenance and readily available technical support. This includes establishing local service networks, training technicians, and providing access to spare parts. Remote diagnostics and predictive maintenance, enabled by IoT technology, can also play a key role in minimizing downtime and optimizing performance. - Data Security and Privacy Concerns

As Smart Shared Rice Milling Machines rely on data collection and analysis, addressing data security and privacy concerns is paramount. Implementing robust cybersecurity measures, ensuring data transparency, and adhering to ethical data handling practices are essential to building trust and fostering user confidence. - Integration with Agricultural Ecosystems

The future of Smart Shared Rice Milling lies in its integration with broader agricultural ecosystems. This includes connecting with other smart farming technologies, such as precision irrigation systems and crop monitoring sensors, to create a holistic, data-driven approach to rice production. Furthermore, integrating with supply chain management systems can optimize distribution and reduce post-harvest losses. - Policy and Regulatory Frameworks

Supportive policy and regulatory frameworks are essential to fostering the adoption and growth of Smart Shared Rice Milling. This includes government incentives, subsidies, and regulations that promote sustainable agricultural practices and encourage technological innovation. Clear guidelines on data privacy, safety standards, and environmental regulations are also crucial. - Scalability and Adaptability

Ensuring the scalability and adaptability of Smart Shared Rice Milling Solutions to diverse farming environments and community needs is crucial for widespread adoption. This includes developing modular designs, customizable software platforms, and flexible business models that can be tailored to specific local contexts. - Future Innovations

The future holds exciting possibilities for further innovation in Smart Shared Rice Milling. This includes the development of AI-powered optimization algorithms, integration with renewable energy sources, and the use of advanced materials to improve efficiency and reduce environmental impact. Continuous research and development are essential to unlocking the full potential of this technology and shaping the future of rice production.

FAQs about the Smart Shared Rice Milling Machine Solution

This section addresses frequently asked questions to provide quick insights into the Smart Shared Rice Milling Machine Solution. We aim to clarify the technology, its implementation, and its benefits for all interested parties, including farmers, investors, and community stakeholders.

- What is a Smart Shared Rice Milling Machine Solution?

It's an innovative approach to rice milling that utilizes IoT and automation technologies to create efficient, accessible, and remotely managed rice milling services. The solution is designed to reduce post-harvest losses, enhance grain quality, and empower local farming communities by providing affordable milling options. - How does the Smart Shared Rice Milling Machine improve efficiency?

By leveraging real-time data analytics and automation, the machine optimizes the milling process, minimizing waste and energy consumption. Remote monitoring capabilities allow for proactive maintenance, reducing downtime and ensuring consistent performance. Furthermore, the 'shared' aspect maximizes utilization, serving multiple farmers and communities. - What are the key benefits for farmers?

Farmers benefit from reduced milling costs, increased grain quality leading to better market prices, minimized post-harvest losses, and convenient access to milling services. The smart features also provide data-driven insights into their yield and milling performance, enabling informed decision-making for future harvests. - What role do PCBs play in the Smart Shared Rice Milling Machine?

Printed Circuit Boards (PCBs) are the 'brains' of the smart milling machine, controlling its various functions from motor operation to data processing and connectivity. Custom PCB designs ensure the reliability, performance, and seamless communication necessary for the machine's smart features to function effectively. - How does Zero One Solution Limited contribute to this solution?

Zero One Solution Limited offers comprehensive PCB solutions, including rapid prototyping, design, manufacturing, and assembly. This expertise is crucial in developing the robust and reliable PCBs needed for the Smart Shared Rice Milling Machine to operate efficiently and withstand the harsh environmental conditions often found in agricultural settings. - Is the Smart Shared Rice Milling Machine environmentally friendly?

Yes, the solution promotes environmental sustainability by reducing post-harvest losses, which minimizes waste. Optimized energy consumption through smart automation further lowers the carbon footprint. The shared model also reduces the need for individual farmers to invest in their own milling equipment, cutting down on resource consumption. - What is the future outlook for smart shared rice milling?

The future is promising, with potential for integration into broader agricultural ecosystems, including smart farming platforms that provide comprehensive data and support to farmers. Further advancements in IoT and automation will continue to enhance the efficiency and accessibility of smart shared rice milling, driving sustainable agricultural practices and economic empowerment in rural communities.

The Smart Shared Rice Milling Machine Solution represents a significant leap forward in agricultural technology, perfectly aligning with the principles of efficiency, accessibility, and sustainability. By integrating advanced IoT, precise control, and robust connectivity, this solution empowers farmers and communities to achieve higher yields, reduce waste, and participate more effectively in the agricultural value chain. At Zero One Solution Limited, we are incredibly proud to be at the forefront of this innovation. Our rapid prototyping, design, and manufacturing expertise in PCB solutions are the silent powerhouses enabling these smart machines to operate flawlessly. We invite you to explore how our specialized PCB services can catalyze your next groundbreaking project, much like we've done for the Smart Shared Rice Milling Machine Solution. Contact Zero One Solution Limited today to turn your innovative concepts into tangible, market-ready products, and let's build the future, together.

AnyPCBA

AnyPCBA