Decoding PCB Layout Services Cost: A Comprehensive Guide for 2024

In our increasingly interconnected world, printed circuit boards (PCBs) are the unsung heroes powering our devices. But how much does it actually cost to transform an idea into a functional PCB? The answer isn't straightforward, with PCB layout services cost varying widely. This guide is designed to unravel the complexities, providing clear insights into the factors influencing pricing, whether you are developing a simple gadget or a complex industrial machine. We'll explore the different pricing models, typical rates, and ways to manage costs effectively, ensuring you can confidently embark on your next electronics endeavor.

Factors Influencing PCB Layout Services Cost

The cost of PCB layout services is not a fixed figure; it is a dynamic value influenced by a confluence of factors inherent to the design and the service provider. A thorough understanding of these elements is crucial for effective budgeting and project planning. This section elucidates the primary drivers of PCB layout costs, empowering informed decision-making.

- Design Complexity

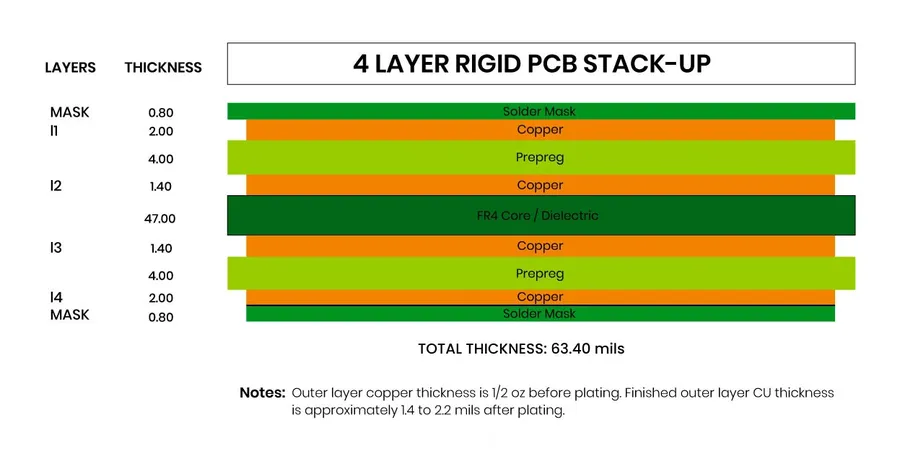

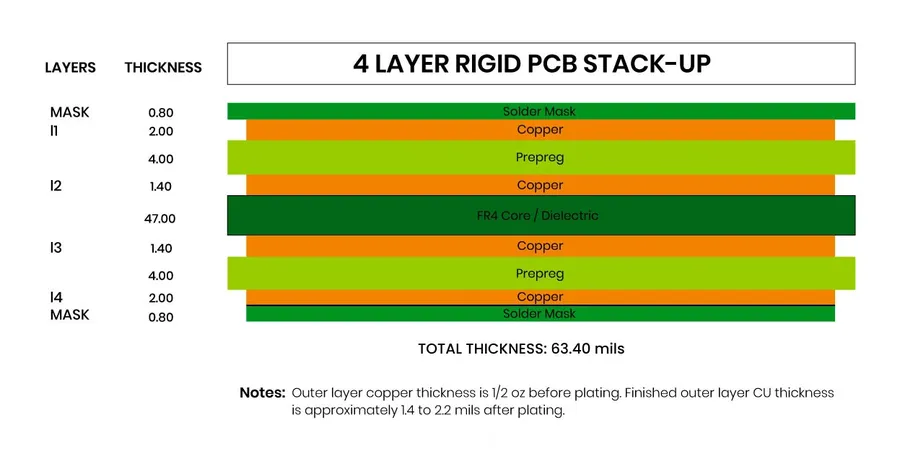

The intricacy of the circuit directly impacts layout time and, thus, cost. Factors include the number of components, the density of interconnections, and the presence of specialized circuits like RF or high-speed signaling, all of which require more expertise and effort. - Layer Count

The number of layers in a PCB significantly affects manufacturing and design complexity. Simple double-sided boards are generally the least expensive, while multi-layer boards, often with four or more layers, require more intricate routing and thus incur higher design costs. Layer count influences routing density and complexity. - Component Density

A high density of components on a board necessitates complex routing strategies, potentially demanding microvias and blind vias. This increased complexity translates to longer layout times and higher service fees. Additionally, high density challenges signal integrity and thermal management. - Component Type and Package

The types of components used, particularly surface-mount technology (SMT) components versus through-hole components, influence layout complexity. BGA (Ball Grid Array) packages, due to their high pin density, pose significant routing challenges, especially in multi-layer PCBs, which can lead to increased costs. The complexity of the component footprint also affects placement and routing time. - Signal Integrity Requirements

Designs requiring high signal integrity, such as those in high-frequency applications, demand careful impedance control, differential routing, and shielding techniques. This translates to increased layout effort, which can increase the final cost. Designs for high speed communication protocols like USB 3.0 and PCIe require careful signal integrity planning. - Designer Expertise and Experience

The skill and experience of the PCB designer greatly influence the cost of services. Experienced designers with specialized knowledge in areas like RF, high-speed, or high-density designs can typically command higher rates due to their ability to produce high-quality layouts efficiently. Conversely, less experienced designers may offer lower rates but the designs may be less reliable and may require rework.

Hourly Rates vs. Project-Based Pricing for PCB Layout

The cost of PCB layout services can be structured in two primary ways: hourly rates or project-based pricing. Understanding the nuances of each model is critical for budget management and ensuring you receive the best value for your investment. The choice between these models often depends on project scope, complexity, and your comfort level with managing the design process.

Hourly Rate Pricing: This model charges clients based on the time spent by the designer working on the PCB layout. Rates typically fluctuate based on the designer's experience, expertise, and geographical location. Experienced designers or those specializing in complex layouts command rates from $50 to $150 per hour or more. This model is beneficial for projects where the scope is not clearly defined or where frequent changes are anticipated. However, it can lead to cost overruns if the design process is not carefully managed and if scope creep occurs.

Project-Based Pricing: With project-based pricing, a fixed fee is agreed upon before the project commences. This pricing model offers greater budget predictability, as clients know the total cost upfront. Project-based pricing is preferred for well-defined projects with clear specifications and minimal anticipated changes, but changes to requirements mid-project could lead to additional cost.

| Pricing Model | Description | When to Use | Advantages | Disadvantages |

|---|---|---|---|---|

| Hourly Rate | Cost is calculated based on the number of hours spent on the project. | Projects with unclear scopes or anticipated changes. | Flexibility, Cost-effective for well-defined small projects, Transparent tracking of hours spent | Potential for cost overruns due to unforeseen complications or scope creep, Less budget predictability. |

| Project-Based | A fixed fee is agreed upon before the start of the project, regardless of time spent. | Projects with clearly defined scopes and specifications. | Predictable budget, Easier cost management, Protection from cost overruns due to scope creep | Less flexibility, Cost may be higher if project is simpler than anticipated, difficult to make changes mid-project |

Negotiating the Best Terms: When negotiating, consider your project's complexity and scope. For hourly rates, ask for an estimate of total hours required. For project-based pricing, ensure that all project requirements and deliverables are explicitly defined in the contract to avoid disputes and additional charges. It is often beneficial to obtain multiple quotes from different designers to understand the market rate and ensure you are getting a fair price. Furthermore, asking about the designers process including communication frequency and process transparency is useful to have a well managed project.

Typical PCB Layout Service Costs by Project Complexity

The cost of PCB layout services is significantly influenced by the complexity of the project. Understanding how complexity impacts pricing is crucial for effective budget management. Generally, costs can range from a few hundred dollars for simple designs to several thousand for highly complex multi-layer boards. This section will provide a breakdown to help set clear cost expectations.

| Project Complexity | Description | Estimated Cost Range |

|---|---|---|

| Simple, Single or Double-Sided PCB | Basic boards with through-hole components, few layers and minimal routing. Example: simple LED circuit. | $200 - $1000 |

| Intermediate, Multi-Layer PCB (4-6 Layers) | Boards with moderate component density, fine-pitch components, and some impedance control. Example: simple microcontroller board. | $1000 - $3000 |

| Complex, Multi-Layer PCB (8+ Layers) | High component density, advanced routing, high-speed design, and impedance matching requirements. Example: high-speed memory interface board. | $3000 - $10,000+ |

| Highly Complex, High-Density Interconnect (HDI) | Extremely dense boards with microvias, blind and buried vias, and very fine traces and spacing. Example: complex mobile or network device. | $8,000 - $20,000+ |

Geographical Impact on PCB Design Costs

The cost of PCB layout services is significantly influenced by geographic location due to variations in labor costs, market competition, and the overall economic landscape of different regions. These factors can lead to substantial price differences for similar services.

Regions with lower labor costs, such as China, often offer more cost-effective PCB layout services. Conversely, regions with higher labor costs, such as North America and Western Europe, typically have higher prices, reflecting increased operating expenses and a different pricing structure.

| Region | Typical Cost per Hour (USD) | Cost-Effectiveness | Additional Notes |

|---|---|---|---|

| China | $20 - $50 | High | Large talent pool, high competition, potentially lower quality |

| India | $25 - $60 | High | Growing talent pool, diverse skill sets, communication might be a consideration |

| Eastern Europe | $30 - $70 | Medium | Good technical skill, moderate prices, may have time zone differences |

| North America | $75 - $180+ | Low | High level of expertise, robust infrastructure, higher costs |

| Western Europe | $80 - $170+ | Low | High level of expertise, strong compliance and regulatory standards, higher costs |

It's important to note that while cost is a major factor, considering factors like communication proficiency, intellectual property protection, compliance with regulatory standards, and quality assurance is also important. Engaging with regions that are cost-effective yet provide necessary assurances of quality, communication standards, and data security is very crucial.

Finding Cost-Effective PCB Layout Solutions

Optimizing PCB layout costs without sacrificing quality is crucial for project success. This section details strategies for achieving cost-effectiveness, focusing on clear specification, smart designer selection, and Design for Manufacturability (DFM) implementation to minimize costly revisions and production delays.

- Detailed Specification Requirements

Providing a comprehensive and unambiguous set of requirements for your PCB layout is paramount. This includes specifying layer count, component types (including footprint library files), critical signal traces and impedance requirements, mechanical dimensions, required clearances, and any specific industry standards. Incomplete or unclear specifications often lead to misinterpretations by the designer, resulting in multiple iterations, increased costs, and significant delays. By doing a thorough front-end design specification, you can save significant cost and time in the long run. - Strategic Designer Selection

Choosing the right PCB layout designer is critical for balancing cost and quality. Consider designers or firms with a proven track record in similar projects and with relevant experience using the layout software specific to your requirements. Compare their past work, client testimonials, and ensure they have a full understanding of DFM principles and that they can provide clear, concise answers to your questions. Consider the following: experience, portfolio, communication, and reviews and references. By taking the time to make the right selection, you can avoid future issues and ensure cost-effective solutions. - Design for Manufacturability (DFM)

Implementing DFM principles is essential for reducing iterations and rework. This involves designing the PCB layout with manufacturing constraints in mind from the beginning. Considerations include choosing commonly available component packages, ensuring adequate spacing between components for assembly, using design rules specific to the fabrication house, and specifying reasonable tolerances for trace widths and clearances. DFM checks should be performed regularly during the design process to proactively identify and resolve any potential issues before the design is finalized. By incorporating DFM at every step, you'll save significant costs related to production errors.

Frequently Asked Questions About PCB Layout Service Costs

Understanding the costs associated with PCB layout services can be complex. This section addresses common questions to provide clarity and help you make informed decisions.

- How much should I charge for PCB design?

Charging for PCB design depends heavily on your experience, the complexity of the board, and the local market rates. Beginners might charge $30-$50 per hour, while experienced designers can command $80-$150+, or even more for specialized designs. Project-based pricing is also common, where a flat fee is determined after a thorough project assessment. - What is the typical cost to get a PCB assembled?

PCB assembly costs are influenced by several factors, such as the number of components, surface mount vs. through-hole technology, and the assembly volume. Simple boards might cost a few dollars per board, while complex assemblies could range from $50 to $200 or more per unit. Minimum order quantities (MOQs) also play a significant role in the final cost. - How much does PCB fabrication typically cost?

PCB fabrication costs depend on material, layer count, board size, and quantity. Simple, double-sided PCBs can cost as little as $5-$10 per board in small quantities, while multilayer boards or custom materials can increase this to $50-$100+, or even more. Large volume orders will have reduced per-unit costs. - How do I calculate PCB fabrication cost?

Fabrication costs are calculated based on board dimensions, number of layers, material type (FR4, Aluminum, etc.), copper thickness, and the desired quantity of boards. PCB manufacturers often provide online calculators that take these parameters to estimate prices. It's advisable to request quotes from multiple vendors to compare the overall cost and lead times. - What are the key cost drivers for PCB layout services?

The key cost drivers for PCB layout services include board complexity (number of layers, component density), turnaround time, and the designer’s experience. Complex, multilayer designs with high component densities demand more time and skill, thus costing more. Faster turnaround times often incur rush fees, while experienced designers typically command higher hourly rates. - What are the benefits of using professional PCB layout services?

Professional PCB layout services offer benefits including expertise in signal integrity, manufacturability, and reducing design iterations. Although potentially more expensive initially, experienced designers can help avoid costly errors and improve design quality. Their knowledge of Design for Manufacturability (DFM) can streamline the production process. A well designed PCB reduces iterations and ensures faster time to market. - Can I reduce my PCB layout costs without sacrificing quality?

Yes, you can reduce costs by providing detailed specifications, selecting components wisely, and optimizing the layout for DFM. Designing simpler boards can also reduce complexity and lower cost. Requesting quotes from multiple designers and fabricators will also allow you to compare prices and select a cost effective solution. Early planning and accurate designs will reduce iterations and additional costs.

Cost Comparison Table: DIY vs. Professional PCB Layout

Choosing between DIY and professional PCB layout services involves evaluating cost against expertise, time, and desired quality. A detailed comparison helps in making an informed decision, balancing budget constraints with project requirements.

| Feature | DIY PCB Layout | Professional PCB Layout |

|---|---|---|

| Initial Cost | Lower, primarily software and learning curve related costs. | Higher, includes designer's fees and project management overhead. |

| Time Investment | Significant, especially for beginners, involves learning software, debugging design issues, and manual verification. | Less, design process is faster due to the expertise of professionals and established workflows. |

| Expertise | Limited to own skill and knowledge, potential errors due to lack of experience. | High, professional designers have extensive experience and knowledge of best practices. |

| Design Quality | May vary, often lower quality due to design errors, and may require multiple design iterations | High, designs are optimized for manufacturability and performance. |

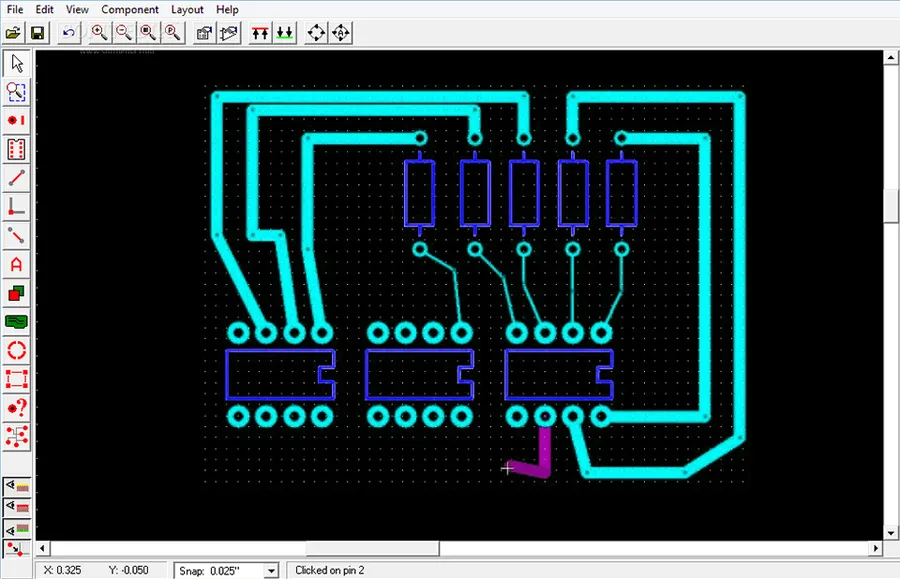

| Software | Free or low-cost software options available. | Often uses industry-standard professional software (e.g., Altium Designer, Cadence Allegro). |

| Complexity Handling | Suitable for simple, single or double layer designs. | Handles complex multi-layer, high-density designs efficiently. |

| Design For Manufacturability (DFM) | Limited, may lead to manufacturing issues. | Integrated, design is optimized for smooth manufacturing process with reduced risk of errors and extra cost. |

| Error Correction and Iteration | Time-consuming and costly if not handled properly | Efficient, quick correction of design issues. |

| Overall Project Cost | Potentially lower for simple designs, but may increase due to errors and iterations. | Higher initial cost but potentially more cost-effective for complex projects due to optimized design. |

| Risk | Higher risk of design flaws and manufacturing issues. | Lower risk due to experience and professional design practices. |

| Support | Limited, relies on online communities, tutorials and self-learning | Professional support available throughout the design process. |

Real-World Examples and Case Studies

Analyzing real-world PCB layout projects provides invaluable insights into how pricing models and design choices significantly affect overall project costs. These case studies highlight the importance of strategic decision-making throughout the design process.

Consider a project involving a simple two-layer PCB for a basic sensor module. Using a fixed-price model, the client secured a deal for $500. This option minimized costs compared to the hourly rate, which would have depended on design hours. However, this model requires detailed specification from the client and may incur additional costs if further design changes are needed. On the other hand, a complex multi-layer PCB for an advanced medical device utilized an hourly pricing model at a rate of $120. While the hourly cost was higher, the model allowed for necessary revisions during the design process, ensuring optimal performance. The project totaled $6,000 over time, with the increased price offset by the necessity of ongoing design modifications.

Another project for a four-layer PCB for an industrial controller serves as an example of the importance of design for manufacturability (DFM). Initial estimates, without DFM considerations, came in at $2,500. However, by adhering to DFM practices, such as selecting readily available components and ensuring adequate spacing between elements, the cost was reduced by 20% without compromising the quality of the board.

These examples demonstrate that the total cost of PCB layout services is not just about the price but about project management and clear design requirements. It is also essential to explore and understand the trade-offs between various pricing models and the value of adopting DFM principles to control costs effectively while ensuring project success. Each project illustrates that a well-defined and thoughtful strategy is key to managing expenses.

Navigating the cost of PCB layout services requires a blend of understanding the various pricing models, the factors that influence these costs, and finding ways to optimize expenses. Whether you opt for hourly rates, project-based fees, or a hybrid model, always factor in the complexity of your project, the designer's expertise, and geographical considerations. By combining realistic budgets with informed decisions, your PCB project will be on the path to success, with the pcb layout services cost managed efficiently. Ultimately, it's about balancing value and costs for the best outcome.

AnyPCBA

AnyPCBA