Understanding PCB Layout Price: Factors, Costs, and How to Save

The intricate dance of electronics often begins with a carefully crafted PCB (Printed Circuit Board) layout. But how much does this crucial step cost? Like a perfectly designed city plan guides its growth, the pcb layout price determines the trajectory of your electronics project. This article will delve into the real factors influencing PCB layout prices and arm you with strategies to optimize your budget without sacrificing quality. We'll explore the intricacies of cost estimation, from basic single-layer boards to complex multi-layer designs, drawing on real-world experiences to help you understand the financial side of your hardware endeavors. Through simple terms, we bridge the gap between technical complexity and financial transparency.

Key Factors Influencing PCB Layout Price

The cost of PCB (Printed Circuit Board) layout is not a fixed value; it's determined by a combination of several interrelated factors. Understanding these key drivers is crucial for effective budgeting and cost management in electronic product development. These primary factors include board complexity, layer count, component density, and routing difficulty.

Board complexity significantly impacts price. A simple single-sided board with few components will cost considerably less than a multi-layer board with high-density components and complex signal routing. The intricacy of the design translates directly into the time and effort required for layout, which affects costs.

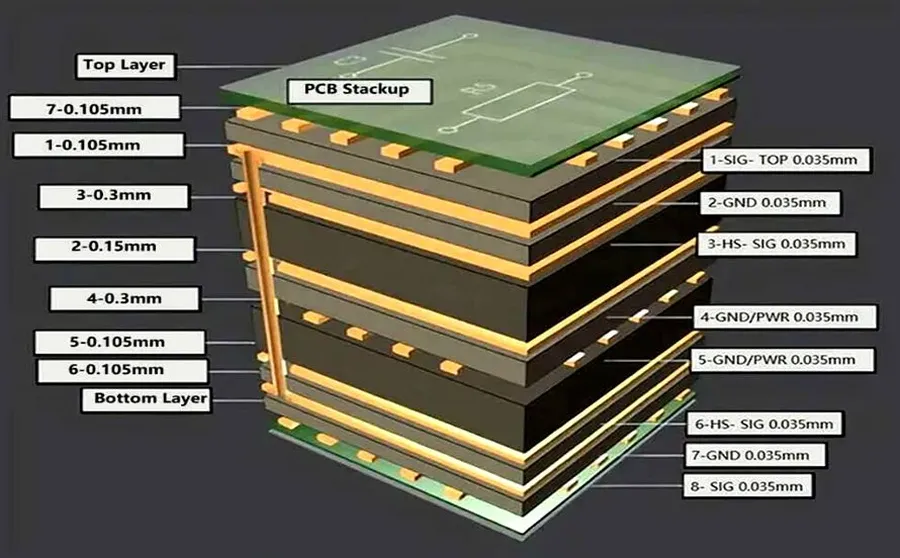

The number of layers required for a PCB directly affects the manufacturing complexity and the cost. Single-layer PCBs are the least expensive, followed by double-layer boards and then multi-layer boards, which are necessary for more complex designs. Each layer requires additional processing and materials, driving up costs.

Component density refers to the number of components packed onto a board. Higher component density increases the complexity of the layout and routing process, leading to higher costs. Smaller components with tighter spacing also necessitate more precise placement and routing, further influencing price.

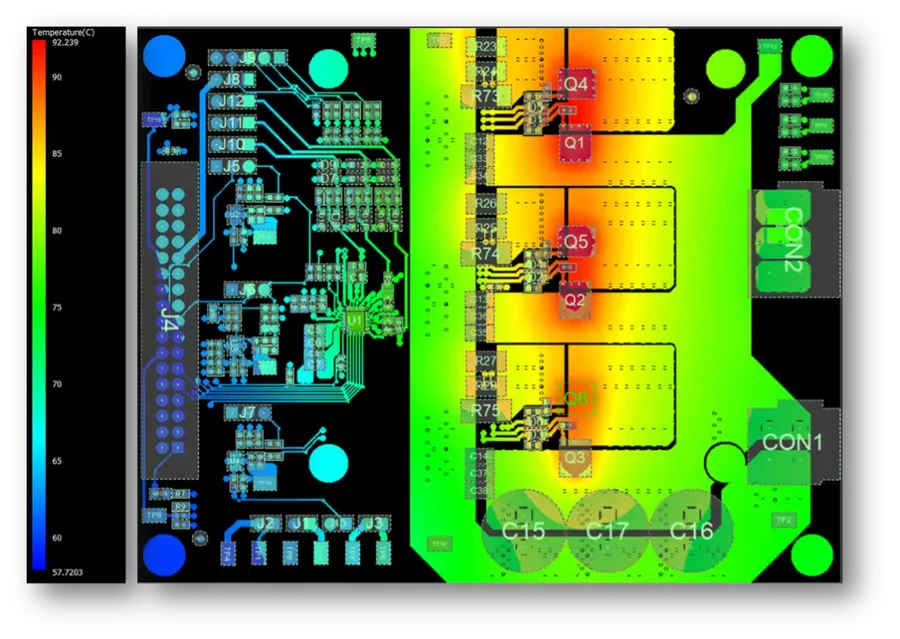

Routing difficulty is another critical factor. Complex signal paths, high-speed signals, and differential pairs demand careful and precise routing to ensure signal integrity. This level of precision requires more time and expertise and therefore increases cost.

| Factor | Impact on Price | Description |

|---|---|---|

| Board Complexity | High | Intricacy of the design (e.g., digital, analog, mixed-signal) |

| Layer Count | Medium to High | Number of conductive layers (single, double, multi-layer) |

| Component Density | Medium to High | Number of components and their proximity on the board |

| Routing Difficulty | Medium to High | Complexity of signal paths (high-speed signals, differential pairs) |

Hourly Rates vs. Fixed Project Costs: What to Expect

When procuring PCB layout services, understanding the different pricing models is crucial for effective budget management. Two primary models exist: hourly rates and fixed project costs, each with distinct implications for cost predictability and project management.

| Pricing Model | Description | Advantages | Disadvantages | Best Use Case |

|---|---|---|---|---|

| Hourly Rates | Designers charge for each hour spent on the project. | Flexibility to accommodate changes and revisions; potentially lower cost for simple projects. | Uncertainty in final cost; can escalate quickly with scope creep or inefficiencies. | Projects with unclear scope, where changes are highly probable. |

| Fixed Project Costs | A set price is agreed upon before the project begins. | Predictable budget; easier financial planning; cost containment. | Less flexibility for changes; may result in higher costs for unforeseen changes; can be inflexible. | Projects with clear and well-defined specifications. |

Choosing between hourly rates and fixed project costs requires careful consideration of the project’s nature. For projects with well-defined specifications, a fixed price offers budget certainty, while hourly rates are suitable for complex projects where design requirements are likely to change. Always get a detailed estimate, whether it's fixed or hourly, to understand the scope and costs before you start.

Typical PCB Layout Price Ranges: A Comprehensive Overview

Understanding the typical cost spectrum for PCB layout services is crucial for effective project budgeting. PCB layout prices vary significantly based on the board's complexity, ranging from simple single-layer boards to intricate multi-layer designs with high component density. This section provides a breakdown of these price ranges to help you anticipate costs accurately.

| PCB Complexity | Description | Typical Price Range (USD) | Notes |

|---|---|---|---|

| Simple Single-Layer | Basic boards with components on one side, minimal routing. | $50 - $200 | Suitable for very basic circuits. |

| Standard Double-Layer | Components and traces on both sides, moderate routing. | $150 - $500 | Most common for general purpose electronics. |

| Multi-Layer (4-6 Layers) | Increased layer count for more complex routing and power distribution. | $400 - $1,500 | Suitable for more complex circuitry, higher density designs. |

| Multi-Layer (8+ Layers) | Complex boards with high layer count, dense components, fine-pitch. | $1,200 - $5,000+ | Common in advanced electronics, high-speed applications, and RF circuits. |

| High-Density Interconnect (HDI) | Advanced boards with microvias and blind vias, high pin count devices. | $3,000+ | Typically used in highly advanced electronics where space is at a premium. |

These price ranges are estimates and can be affected by various factors, including the designer's experience, software used, and specific project requirements. For instance, a single-layer board with a simple circuit might fall at the lower end, while a multi-layer board with complex routing and high component density can reach the upper end or even exceed it. The price can also be affected by the turn around time. Expedited turnaround time will increase the price significantly. It's advisable to seek detailed quotes based on your specific needs to get an accurate cost estimate for your PCB layout project. Understanding these ranges, however, will give you a solid starting point when planning the budget for your PCB project.

Software and Tooling Costs Impact on PCB Layout Pricing

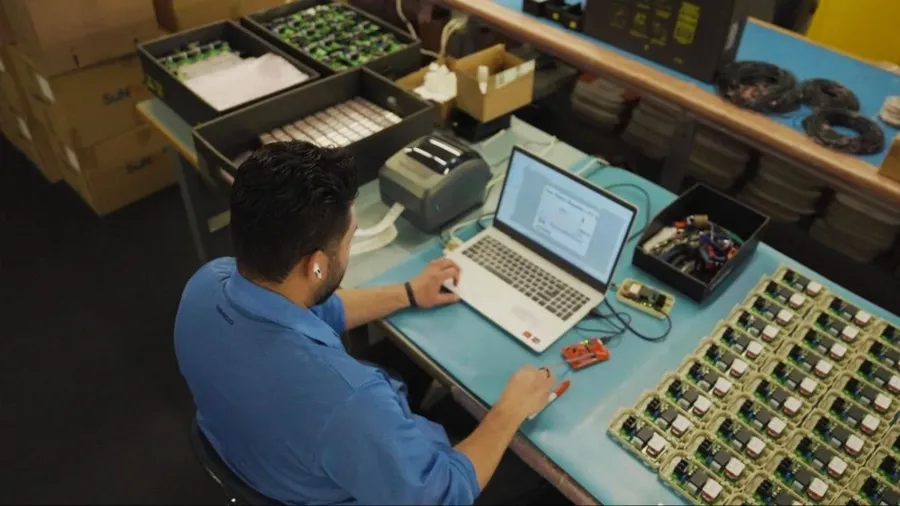

The selection of Electronic Design Automation (EDA) software significantly influences PCB layout pricing. The cost of these tools, along with the specific features they offer, directly affects the overall expense of PCB design projects. Understanding these factors is crucial for cost-effective PCB design.

Different EDA software packages come with varying licensing costs and feature sets. High-end software often includes advanced simulation capabilities and robust design rule checking, but at a premium price. Conversely, more affordable or free options, while sometimes lacking in advanced features, can effectively meet the needs of many projects.

| EDA Software | Licensing Model | Typical Cost Range | Key Features | Suitability |

|---|---|---|---|---|

| Altium Designer | Subscription | $7,000 - $10,000+/year | Advanced Routing, Signal Integrity Analysis, 3D Visualization | Complex, high-performance designs |

| Cadence Allegro | Perpetual/Subscription | $10,000 - $20,000+/year | Advanced Simulation, Large Team Collaboration, High-Speed Design | High-complexity, enterprise projects |

| Mentor Graphics Xpedition | Perpetual/Subscription | $15,000 - $30,000+/year | High-Speed Design, Advanced Simulation, Large Team Collaboration | Very high complexity, enterprise projects |

| PADS Professional | Perpetual/Subscription | $5,000 - $10,000+/year | Mid-range designs, good balance of features and cost | Mid to high complexity projects |

| Eagle (Autodesk) | Subscription | $100 - $500+/year | User-friendly interface, cloud-based, suitable for small teams and startups | Small to medium complexity projects |

| KiCad | Open Source (Free) | $0 | Free and open source with a large user community, good for hobbyist and small projects | Simple to medium complexity projects |

The choice of EDA software should align with project requirements and budget. KiCad, for example, is an excellent choice for budget-conscious projects, while Altium or Cadence might be necessary for highly complex designs with signal integrity requirements. The cost of the software is not the only consideration, the time required for a designer to complete a task with the chosen software should be factored into project cost.

Geographic Location and Its Effect on PCB Design Costs

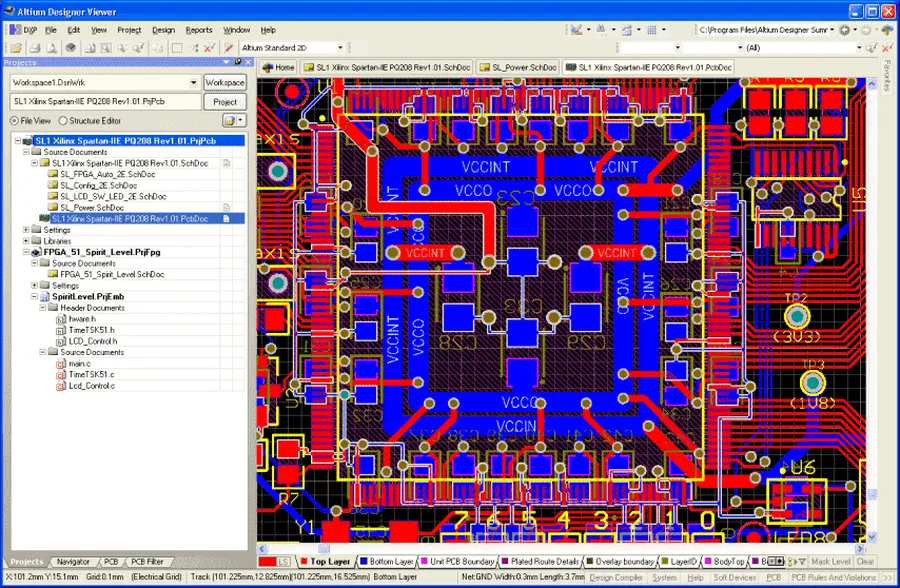

The geographic location of PCB design services significantly impacts pricing due to variations in labor costs, infrastructure, and operational overhead. Understanding these geographical influences is crucial for optimizing your budget when outsourcing PCB layout projects. This section explores the cost differences between North America/Europe and Asia, and discusses strategies to leverage global markets for cost efficiency.

| Region | Typical Hourly Rate for PCB Design | Key Cost Drivers | Overall Cost Implications |

|---|---|---|---|

| North America/Europe | $75 - $150+ | Higher labor costs, advanced infrastructure, higher operating costs. | Generally higher overall PCB layout prices. |

| Asia (e.g., China, India) | $20 - $70 | Lower labor costs, competitive market, established supply chains. | Significantly lower overall PCB layout prices. |

The cost differential arises primarily from discrepancies in labor costs. Regions like North America and Europe, with higher wages and stringent labor regulations, naturally command higher service fees. Conversely, Asian countries, with their larger labor pools and lower living expenses, offer more cost-effective solutions. Furthermore, established manufacturing hubs in Asia benefit from economies of scale and well-developed supply chains, further reducing costs. However, it is essential to consider other factors, including communication, quality control, and intellectual property protection, when deciding to work with an offshore provider.

To optimize costs, you can employ several strategies that leverage global market dynamics. Carefully vet potential partners in different regions based on their experience, certifications, and past projects. Engage in transparent communication to avoid misunderstandings and ensure your requirements are thoroughly understood. Additionally, consider splitting your project by performing the initial design work locally and then send the layout out to an overseas vendor for the detailed layout and manufacturing stages. This hybrid approach helps balance cost efficiency with quality assurance.

Strategies to Reduce PCB Layout Price without Sacrificing Quality

Reducing PCB layout costs without compromising quality requires a strategic approach that focuses on efficient design practices and informed decision-making throughout the design process. By carefully considering various design choices and communication strategies, significant cost savings can be achieved without sacrificing the functional integrity of the PCB.

- Optimize Component Placement

Strategic component placement can minimize routing complexity and board size, leading to lower manufacturing costs. Grouping related components together and minimizing long traces contributes to a more efficient and cost-effective layout. - Simplify Board Complexity

Reducing the number of layers and simplifying the board's overall structure can dramatically reduce fabrication costs. Consider if all features are necessary for the project and if there are ways to consolidate functionality. - Effective Communication

Clearly and precisely communicate all project requirements, including functional specifications, design constraints, and performance expectations, to the PCB designer. Minimizing ambiguity reduces costly errors and design revisions. - Standardization

Use standardized components and footprints whenever possible. This simplifies procurement, reduces component costs, and speeds up the design and manufacturing processes. - Minimize Vias

Excessive vias can increase manufacturing costs. Optimize the layer stack-up and routing strategy to minimize the number of vias required. - Panelization Strategy

When multiple PCBs are required, consider panelizing the design. This method allows multiple boards to be manufactured on a single panel, reducing manufacturing cost per board. - Design for Manufacturability (DFM)

Adhere to DFM guidelines, such as proper trace widths, pad sizes, and clearances, to minimize potential fabrication problems. Adhering to DFM early in the design process reduces the likelihood of costly rework and production delays. - Early Cost Estimation

Seek early cost estimates and feedback from PCB manufacturers to make informed design choices. Knowing cost implications early allows for adjustments that reduce overall project costs.

Frequently Asked Questions About PCB Layout Costs

Understanding the costs associated with PCB layout can be complex, as numerous factors influence the final price. This section addresses common queries regarding PCB layout costs, providing clarity and guidance for those seeking to budget their projects effectively.

- How much do PCB layout services typically cost?

The cost of PCB layout services varies widely based on factors such as board complexity, layer count, component density, and the designer's experience. Simple single-layer boards might cost a few hundred dollars, while complex multi-layer boards can range into the thousands. It's essential to obtain quotes based on the specific details of your design. - What is the price range for a PCB prototype?

PCB prototypes typically command a higher per-unit cost compared to production runs. For simple designs, a single prototype could cost from $50 to $200. However, for more complex prototypes with specialized materials and processes, prices can range from $200 to $1000 or more. The cost is influenced by factors such as minimum order quantities, turn-around time, and technology involved. - How much should a PCB design cost, generally?

A standard PCB design project can range significantly in price. Simple single-sided boards could cost less than $500, while intricate multi-layer designs might cost upwards of $1000. The complexity of the design, the time required for layout, and the designer’s hourly rate are crucial factors in the overall cost. To obtain a more precise estimate, it's important to get quotes from multiple providers. - What factors influence the cost of PCB assembly?

PCB assembly costs are affected by several factors including the number of components, the complexity of the assembly process (e.g., surface mount vs. through-hole), the type of components used, and the required testing. The price per board generally decreases with larger production runs, reflecting the economies of scale. Sourcing components and labor costs can also contribute to the overall expense. - Can the cost of PCB layout be reduced without affecting the quality?

Yes, several techniques can lower PCB layout costs without compromising quality. This includes optimizing component placement to reduce trace lengths, using standard board sizes where possible, simplifying routing paths, and carefully reviewing design rules to prevent potential issues during manufacturing. Choosing cost-effective materials and standard parts can further reduce costs. Effective communication with the designer and clear design specifications can prevent costly revisions and minimize project time. - How does the number of PCB layers affect the price?

The number of PCB layers has a direct impact on cost. Single-layer boards are the least expensive, followed by double-layer boards. Multi-layer boards, with four or more layers, are more costly because of the complexity in manufacturing. The increased cost is due to extra processes needed for laminating and interconnecting layers, and the more complex drilling needed. - Is it more cost-effective to use hourly rates or fixed project costs?

Choosing between hourly rates and fixed project costs depends on the specific project. Hourly rates might be better for projects where the scope is hard to define initially and revisions are anticipated. On the other hand, fixed project costs offer more budget predictability but require a clear scope of work at the outset. Fixed costs can potentially offer more value, especially for well-defined and familiar project types. Reviewing the designers previous work and their estimation process is crucial in this decision process.

The Impact of PCB Complexity on Layout Cost

The complexity of a Printed Circuit Board (PCB) design significantly impacts its layout cost. This complexity is largely defined by the number of layers, with single-layer, double-layer, and multi-layer boards each presenting unique challenges and corresponding costs. Understanding these differences is crucial for effective budget planning and design optimization.

| PCB Type | Complexity | Typical Cost per Square Inch (USD) | Typical Applications |

|---|---|---|---|

| Single-Layer | Lowest | $0.05 - $0.15 | Simple circuits, basic consumer electronics |

| Double-Layer | Moderate | $0.10 - $0.30 | Intermediate complexity, basic industrial control, IoT |

| Multi-Layer (4-6 Layers) | High | $0.25 - $0.75 | Complex consumer electronics, advanced industrial control, higher power electronics |

| Multi-Layer (8+ Layers) | Very High | $0.60 - $2.00+ | High-speed digital, complex signal processing, high-performance computing |

The cost per square inch is indicative and varies based on other factors like component density and the design house, but clearly demonstrates the escalating cost as PCB complexity increases. Single-layer boards are the simplest and cheapest, suitable for basic applications with straightforward routing requirements. Double-layer boards offer greater routing flexibility, accommodating more complex circuit designs while still being cost-effective for many applications. Multi-layer PCBs, however, are necessary for high-density designs that require routing of many signals, more power or complex signal integrity requirements.

Choosing the right PCB layer configuration involves balancing cost with functionality. A simpler design that uses fewer layers may reduce upfront expenses but could limit the capabilities of the board and increase routing complexity. Conversely, opting for a multi-layer design offers greater flexibility and performance, but at a higher price point. Therefore, careful assessment of application requirements and cost implications is essential before making design decisions. It’s crucial to fully understand the implications of increasing complexity, as it directly translates to higher production and layout design costs. The trade-offs between complexity and budget must be carefully considered at the outset of any PCB design project.

PCB Layout Price Calculator & Getting Accurate Quotes

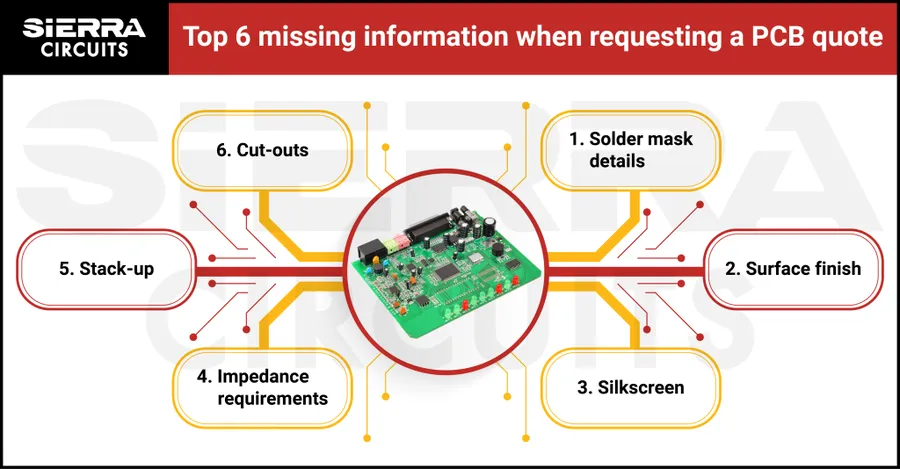

Online PCB layout price calculators can provide preliminary cost estimates, but they should be used with caution. While they offer a quick snapshot of potential costs, accurate quotes require a detailed specification of your project's requirements. Understanding the limitations of these calculators and providing comprehensive information when requesting quotes are crucial steps to obtaining precise pricing.

Here's how to navigate both price calculators and quote requests effectively:

- Using Online PCB Layout Price Calculators

These calculators typically use simplified algorithms based on basic parameters like board dimensions, layer count, and component count. They are useful for initial ballpark figures but do not account for design complexity or specialized requirements. - Limitations of Online Calculators

They often fail to consider complex routing, impedance control, blind/buried vias, specific material requirements, or component sourcing. Therefore, the estimated cost might deviate from the final price. - Essential Specifications for Accurate Quotes

To obtain precise quotes, provide detailed information such as board dimensions, layer stackup, component list (BOM), specific material requirements, impedance control requirements, routing constraints, and any special features like blind/buried vias, and test requirements. Including a schematic and a preliminary layout diagram can significantly improve the accuracy of the quote. - Reliable Places to Get PCB Layout Quotes

Consider established PCB design service providers, contract manufacturers with in-house design capabilities, or reputable freelance PCB designers. Request quotes from multiple vendors to compare costs and services, carefully reviewing their portfolios and customer feedback. - Tips for Requesting Quotes

Be as specific as possible in your requirements. Clearly define design goals, any critical specifications, and your preferred timeline. Providing clear, accurate information will enable vendors to deliver quotes that reflect the actual complexity and cost of your project. Do not hesitate to ask questions to ensure there is a clear understanding of the requirements, and be prepared to discuss them thoroughly.

Understanding the various factors that influence PCB layout price is crucial for efficient project management and cost control. The key takeaways include that pcb layout price hinges on complexity, location, design software used, and the chosen pricing model. By adopting the strategies discussed—such as optimizing design for manufacturability, seeking cost-effective global options, and using suitable design software—you can significantly reduce costs while maintaining the desired quality. As technology advances, these insights will remain relevant for ensuring cost-effectiveness in electronic design and production. Always ensure to get detailed quotes and compare the best pcb layout price before committing to your projects to maximize your budget.

AnyPCBA

AnyPCBA