Baxi Boiler Circuit Board Price: Understanding Costs & Options

When a Baxi boiler stops working, the circuit board (PCB) is often a prime suspect. Like the brain of your boiler, this component controls all its essential functions. Understanding the baxi boiler circuit board price is crucial for homeowners facing potential repairs. Just like a modern car relies on its computer, a boiler's PCB ensures its smooth operation, bridging the gap between complex technology and home comfort. This article will delve into the factors influencing these costs and the best approach for a fix.

Why Does a Baxi Boiler PCB Fail?

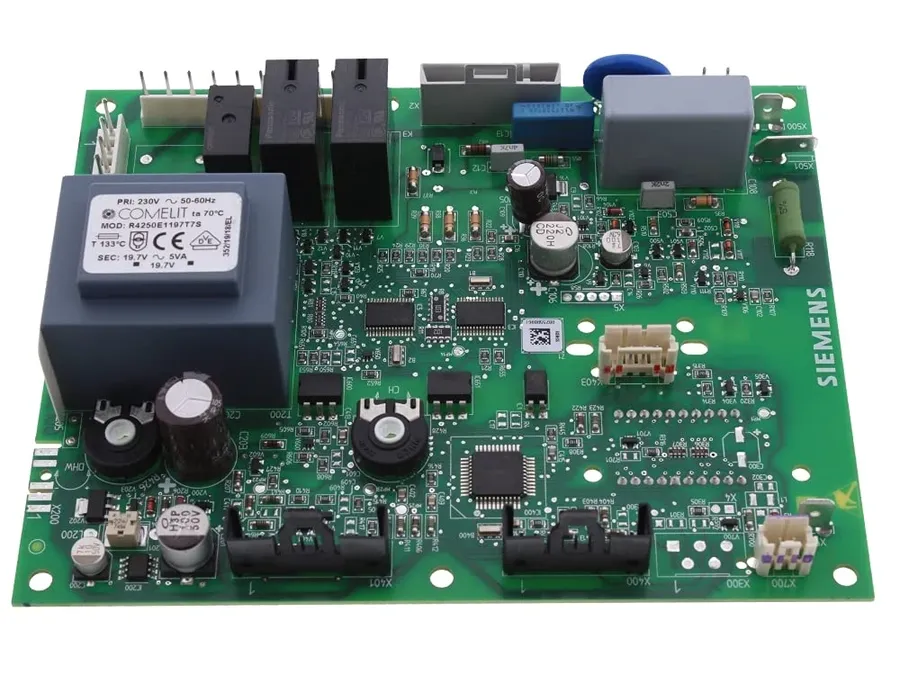

The Printed Circuit Board (PCB) is the central control unit of a Baxi boiler, orchestrating its various functions. Failures in this component can stem from several root causes, typically involving electrical, environmental, or age-related factors that compromise its functionality.

- Electrical Surges

Sudden spikes in voltage, often from lightning strikes or power grid fluctuations, can overwhelm the sensitive electronic components on the PCB, causing irreparable damage. These surges can burn out delicate circuits, leading to malfunction or complete failure. - Age-Related Wear and Tear

Like all electronic devices, boiler PCBs have a finite lifespan. Over time, the components can degrade due to constant heating and cooling cycles, causing solder joints to weaken, capacitors to dry out, and other parts to fail, leading to erratic behavior or failure of the board. - Water Damage

Leaks or condensation within the boiler unit can expose the PCB to moisture, causing corrosion and short circuits. Water damage is a significant threat to the delicate electrical pathways of the PCB, often resulting in malfunctions that are difficult to repair. - Component Failure

Individual components on the PCB, such as resistors, capacitors, and transistors, can fail due to manufacturing defects, wear and tear, or exposure to extreme conditions. When such a component fails, it can disrupt the PCB's normal operation, causing the boiler to malfunction. - Overheating

Insufficient ventilation around the boiler or a malfunctioning heat exchanger can lead to excessive heat buildup, which can damage the sensitive components of the PCB. Prolonged exposure to high temperatures can degrade the insulation and lead to premature failure.

Factors Influencing Baxi Boiler Circuit Board Price

The price of a replacement Baxi boiler circuit board (PCB) is not fixed and is influenced by several key factors. Understanding these can help you anticipate costs and make informed decisions when a replacement is needed. These factors include the specific boiler model, the availability of the part, and whether you opt for a new or refurbished component. Each of these considerations has a direct impact on the final cost you will incur.

- Boiler Model

Each Baxi boiler model often has a unique PCB designed to work with its specific functions and control systems. This model-specific design means that a PCB for a newer, more advanced model may cost more than one for an older, simpler model. The complexity of the board and its associated software contribute to these variations in cost. - Availability and Demand

The availability of a specific PCB can significantly affect its price. If a particular model is older or less common, the parts may be more difficult to source, potentially increasing costs due to limited supply. Conversely, if a boiler model is very popular, the demand for its PCB can influence prices as well. Market dynamics play a key role in fluctuations of PCB pricing. - New vs. Refurbished Condition

As an alternative to new PCBs, refurbished PCBs offer a lower cost option. However, they may not come with the same level of warranty as new ones and their reliability can vary. Refurbished PCBs have been previously used, but they have been tested, repaired, and brought back to a functioning state. This difference in condition directly affects the cost, warranty, and perceived reliability of the PCB. - Supplier

The source from which you purchase your PCB can affect the price. Manufacturers, authorized retailers, and third-party suppliers each have their own pricing structures. Buying directly from Baxi or a trusted retailer might cost more but ensures authenticity. Third-party suppliers might offer lower prices but the quality and authenticity may not be guaranteed. - Geographic Location

Pricing can also differ based on your location. The cost of parts is not uniform across countries or even within regions of the same country. Local market factors, shipping costs, and regional taxes all contribute to geographic variances in price.

Average Cost of a Baxi Boiler PCB Replacement

The cost of replacing a Baxi boiler Printed Circuit Board (PCB) can vary significantly based on several factors. This section will provide a general overview of the typical price range, encompassing both the cost of the part itself and the associated labor charges for installation.

It's crucial to understand that these figures are indicative and should serve as a guideline. Actual costs may be lower or higher, based on your location, the specific Baxi model, and the complexity of the job.

| Cost Component | Estimated Range | Notes |

|---|---|---|

| Baxi PCB Part | £150 - £400 | Prices vary depending on the specific model and whether the part is new or refurbished. |

| Labor (Professional Installation) | £150 - £300 | Labor costs will depend on the engineer's hourly rate, the complexity of the job and the region. |

| Total Replacement Cost | £300 - £700 | This estimate combines both the price of the PCB and professional installation costs. |

These figures are estimates and subject to change. It is recommended to obtain several quotes from qualified heating engineers to get the best price for your specific situation.

New vs. Refurbished Baxi Boiler PCBs: Pros and Cons

When facing a faulty Baxi boiler PCB, a key decision is whether to opt for a new or refurbished replacement. This choice significantly impacts cost, reliability, and the overall lifespan of your boiler. Understanding the pros and cons of each option is essential to make an informed decision that aligns with your budget and long-term needs.

Baxi PCB Part Numbers and Model Compatibility

Identifying the correct Printed Circuit Board (PCB) part number is crucial when sourcing a replacement for your Baxi boiler. Using an incompatible PCB can lead to boiler malfunction, damage, or complete system failure. Baxi boilers are designed with specific PCBs tailored to their individual models; therefore, ensuring accuracy in part number identification is paramount for safe and effective repairs.

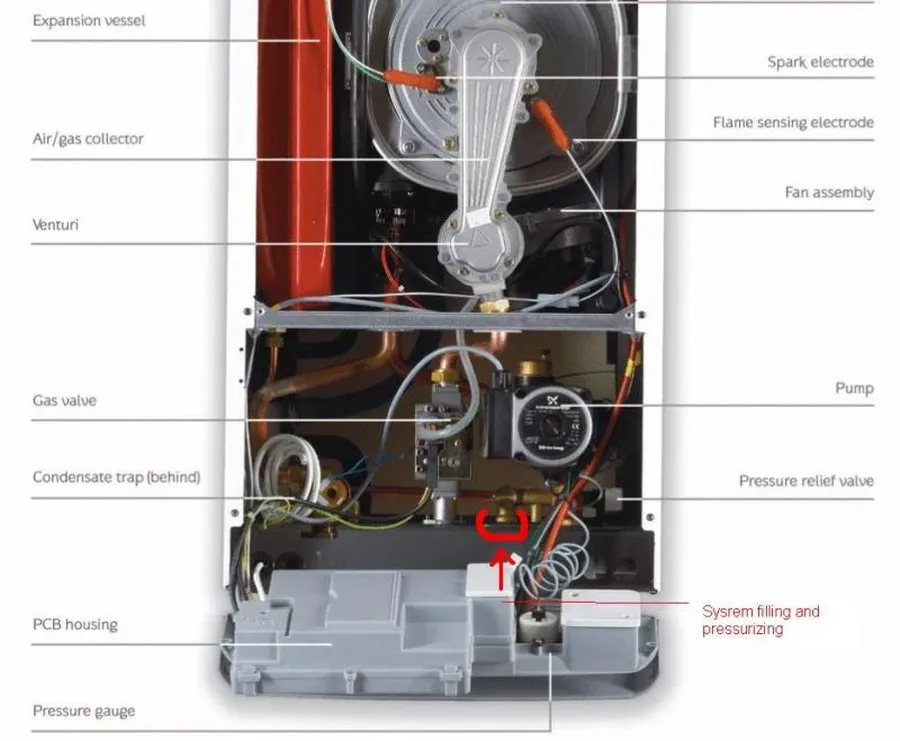

- Locating the Part Number

The part number is typically found on a label affixed to the PCB itself. This label may also include a barcode or other identifying information. The location of the PCB varies depending on the Baxi boiler model but is generally found within the control panel housing. In some cases, the part number may also be printed on the boiler's external casing or in the boiler's documentation. - Importance of Model Specificity

Baxi manufactures a wide array of boilers, each with varying specifications and electronic control systems. As such, a PCB designed for one Baxi boiler model is unlikely to be compatible with another. Referencing the boiler model number is as essential as the PCB part number. Typically, this will be stated on the rating plate of the boiler. - Cross-Referencing with Official Documentation

Always cross-reference the identified PCB part number with the manufacturer's documentation or official parts listings. Baxi provides detailed parts manuals for each boiler model, which can be accessed online or through authorized Baxi service providers. These manuals are reliable sources to confirm the correct PCB part number. Using online part finder tools may also assist in the process, but verifying the data against the manufacturer's manual should always be completed. - Using Online Resources and Professional Assistance

Numerous online resources and boiler part suppliers often provide tools and databases to assist in finding compatible PCBs. However, errors may occur. When in doubt, it's recommended to consult a qualified heating engineer. A professional can identify the correct PCB for your specific Baxi model, ensuring the replacement is correct and safe for use.

Do You Need a Professional to Replace Your Baxi PCB?

Replacing a Baxi boiler Printed Circuit Board (PCB) involves electrical work and precise fitting, necessitating a careful consideration of whether to undertake this task DIY or hire a qualified professional. This decision carries significant implications for safety, warranty, and the long-term performance of your boiler.

| Factor | DIY Replacement | Professional Replacement |

|---|---|---|

| Cost | Lower upfront cost for labor; potential risk of incorrect installation leading to higher costs later. | Higher upfront cost for labor but reduced risk of errors and associated future expenses. |

| Safety | High risk of electrical shock or incorrect connections. Gas safety regulations need to be adhered to. | Lower risk as professionals are trained in safety procedures and compliant with gas safe guidelines. |

| Warranty | DIY installations usually void manufacturer's warranty on the boiler and potentially on the new PCB. | Professional installations often maintain the manufacturer's warranty, as well as offering guarantees on the work done. |

| Expertise | Requires detailed knowledge of boiler electronics and a deep understanding of installation processes. | Professionals have the necessary qualifications, certifications, and experience, ensuring proper installation. |

| Time | Can be time-consuming without experience. | Usually quicker due to the professional's efficiency and familiarity with the process. |

| Tools | May require specific tools not commonly available. | Professionals have all the tools necessary for the job. |

Based on these considerations, while attempting a DIY replacement might seem like a cost-saving measure initially, the risks associated with safety, warranty, and potential for mis-installation make a professional replacement generally the more prudent choice for a Baxi boiler PCB.

Frequently Asked Questions About Baxi Boiler PCBs

This section addresses common queries concerning Baxi boiler Printed Circuit Boards (PCBs), aiming to provide clear and concise answers to help you understand their function, cost, and maintenance.

- How much does it cost to replace a PCB on a Baxi boiler?

The cost to replace a Baxi boiler PCB varies depending on the model and whether you opt for a new or refurbished part. Generally, you should expect to pay between £200 to £600, including the cost of the part and labor. The labor cost depends on the complexity of the work, and your location. - What exactly is a PCB on a Baxi boiler?

A Printed Circuit Board (PCB) is the central electronic control unit of your Baxi boiler. It manages the boiler's operations, such as firing up, maintaining temperature, and responding to user commands. It acts as the 'brain' of the boiler, ensuring all components work in harmony. - Can I replace the boiler PCB myself?

While it might be tempting to replace the PCB yourself, it is generally not recommended due to the complexity of the task and the risks associated with working with gas appliances and electrical components. Improper installation can lead to further damage to the boiler, void your warranty, or even pose serious safety hazards. It is advisable to hire a qualified professional for this work. - Is it cheaper to repair or replace the boiler PCB?

In many cases, it is more cost-effective to replace a faulty PCB rather than attempt to repair it. Repairs can be unreliable, and the cost of diagnosing and fixing the issue may approach the cost of a new board. New boards also come with warranties, offering further protection. - How long does a Baxi boiler PCB last?

The lifespan of a Baxi boiler PCB varies based on factors such as usage, voltage fluctuations, and environmental conditions. On average, a well-maintained PCB can last 8 to 15 years. It's important to note that proper maintenance, protection against power surges and environmental factors will extend the boards' lifespan. - Does a new Baxi boiler come with a PCB warranty?

Typically, a new Baxi boiler and its PCB come with a manufacturer's warranty, usually ranging from 1 to 10 years, depending on the model and manufacturer. When purchasing a new boiler or PCB, it's crucial to understand the terms and conditions of the warranty to safeguard your investment. - Will a refurbished PCB work in my Baxi boiler?

Refurbished PCBs can be a more affordable option than buying new. Ensure you purchase from a reputable seller who provides a warranty, and verify that the PCB is compatible with your specific boiler model. However, while usually functionally equivalent, remember the lifespan of a refurbished board may be less than that of a new component.

Troubleshooting: When a Baxi Boiler PCB Might Be the Issue

Identifying a faulty Baxi boiler PCB (Printed Circuit Board) can be crucial in diagnosing boiler malfunctions. Common indicators include specific error codes displayed on the boiler's control panel, intermittent heating or hot water supply, and complete failure of the boiler to operate. These symptoms often point to issues with the PCB's ability to properly control boiler functions.

- Error Codes Displayed

Many Baxi boilers display specific error codes when a PCB malfunction is detected. These codes are detailed in your boiler's manual and can help pinpoint PCB-related issues. Reference the manufacturer's guide to interpret specific error codes. - Intermittent Operation

If your Baxi boiler works sporadically, cutting off and on at random intervals, this can indicate a failing PCB. The PCB's inability to regulate the boiler's system may cause the boiler to operate unpredictably. - Complete Boiler Failure

A completely unresponsive boiler where no lights illuminate or error codes are displayed can often point to a dead PCB. This means the PCB is no longer sending commands to the boiler’s components. - Pilot Light Issues (if applicable)

For boilers with a pilot light, difficulties in ignition or maintaining a stable flame can be linked to PCB malfunctions. The PCB controls the ignition sequence. - Inconsistent Heating or Hot Water Temperatures

If the boiler delivers erratic water temperatures or fails to achieve the desired set temperature, it may be due to an unstable signal from the PCB.

Tips to Extend the Life of your Baxi Boiler PCB

Prolonging the lifespan of your Baxi boiler's Printed Circuit Board (PCB) involves proactive maintenance and a keen understanding of its vulnerabilities. By implementing preventive measures, you can significantly reduce the risk of premature failure and costly replacements, ensuring the longevity and optimal performance of your heating system.

- Ensure Stable Power Supply

Electrical surges and fluctuations are a major threat to sensitive electronic components like the PCB. Install a surge protector to shield your boiler from voltage spikes that can cause damage. - Regular Boiler Servicing

Annual professional servicing is crucial. A qualified technician can identify and address minor issues before they escalate, which could indirectly affect the PCB. This includes checking for leaks, cleaning internal components, and ensuring correct combustion settings. - Prevent Water Damage

Water intrusion is detrimental to electronic circuits. Regularly inspect your boiler for any leaks or signs of moisture ingress. Address these immediately to avoid corrosion and short circuits within the PCB. - Maintain Proper Ventilation

Ensure that the boiler's ventilation is clear and unobstructed. Overheating can stress the PCB's components, causing premature failure. Avoid placing objects around the boiler that might restrict airflow. - Avoid DIY Repairs

Unless you are a certified technician, do not attempt to perform repairs yourself. Incorrect handling or improper installations can severely damage the PCB, potentially voiding the warranty and creating a hazardous situation. - Monitor System Pressure

Keep a consistent eye on the boiler's pressure gauge. Pressure fluctuations, whether too high or too low, can overwork the system and indirectly stress electronic components. Maintain the pressure within the recommended range.

Understanding the baxi boiler circuit board price is key to maintaining a warm and efficient home. While costs can vary, knowing the factors, considering refurbished options, and whether to DIY or hire a professional will help you to make the best decision. Remember, regular boiler maintenance can reduce the likelihood of PCB failure, saving on potential costs in the future. Keeping your home's 'brain' in tip top shape will ensure many years of hassle-free heating.

AnyPCBA

AnyPCBA