Bittele Electronics Inc: Your Reliable PCB Assembly Partner

In the fast-paced world of electronics, finding a reliable partner for PCB assembly is crucial. Since 2003, Bittele Electronics Inc. has been a trusted name, offering comprehensive turnkey PCB services. This article explores what makes Bittele a dependable choice, delving into their services, quality standards, and commitment to supporting innovation and manufacturing advancements in industries like yours.

Bittele Electronics Inc.: A Brief Overview

Founded in 2003, Bittele Electronics Inc. has established itself as a comprehensive, full-service provider of printed circuit board (PCB) assembly solutions. With a focus on delivering high-quality, reliable services, Bittele caters to a diverse clientele, ranging from startups to large-scale enterprises.

Core Services Offered by Bittele Electronics

Bittele Electronics provides comprehensive PCB assembly services, focusing on prototype assembly, low to mid-volume production, and complete turnkey solutions, catering to diverse client needs from initial design to final product.

- PCB Prototype Assembly

Bittele specializes in rapid PCB prototype assembly, allowing clients to quickly test and refine their designs. This service is crucial for early-stage product development, ensuring that design flaws can be identified and corrected before large-scale production. - Low to Mid-Volume PCB Production

Meeting the requirements of clients that need a limited quantity of assembled PCBs, Bittele offers low-to-mid-volume production. This service is ideal for pilot runs, niche markets, or specialized applications that do not require mass production. - Turnkey PCB Assembly Solutions

Bittele's turnkey service handles all aspects of PCB assembly, from component procurement to final assembly and testing. This comprehensive approach streamlines the production process, reducing lead times and complexity for clients by providing an all-in-one solution. This includes managing the entire supply chain for PCB manufacturing.

Advanced PCB Manufacturing Capabilities

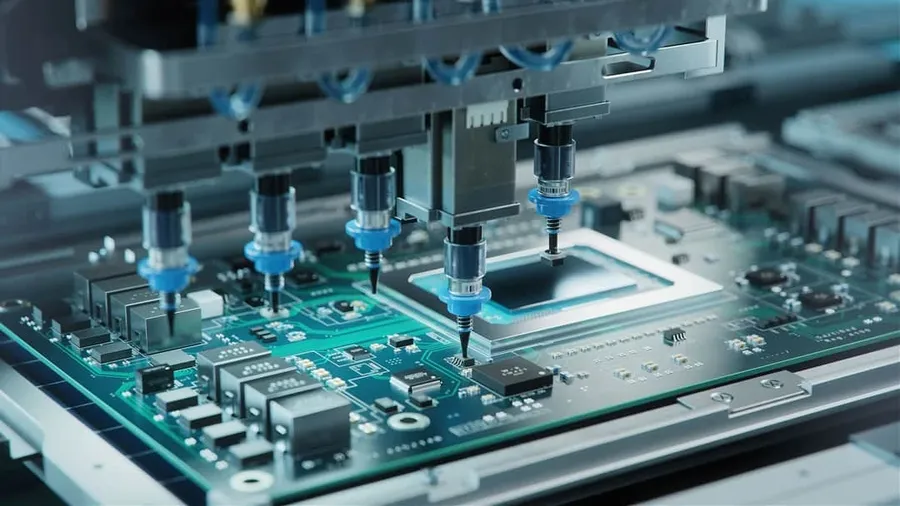

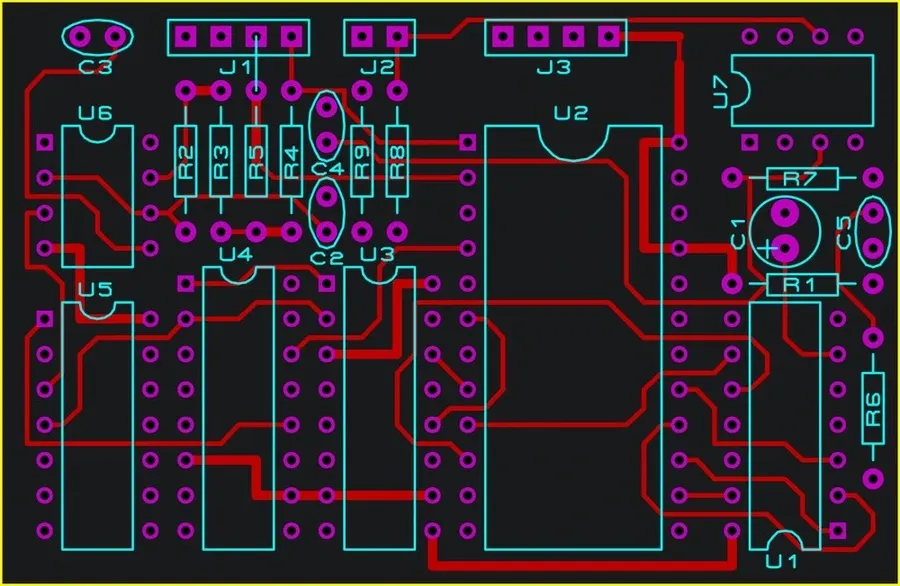

Bittele Electronics Inc. distinguishes itself through its advanced technological capabilities in PCB fabrication and assembly, leveraging cutting-edge equipment and processes to deliver high-quality and reliable products. This commitment to technological advancement ensures precision, efficiency, and the ability to handle complex PCB designs.

Bittele's facility is equipped with state-of-the-art machinery for various aspects of PCB manufacturing. This includes automated pick-and-place machines, reflow soldering ovens, automated optical inspection (AOI) systems, and X-ray inspection equipment. The integration of these technologies allows for high-precision component placement, consistent soldering, and rigorous quality checks, all of which are critical for producing reliable and high-performing PCBs.

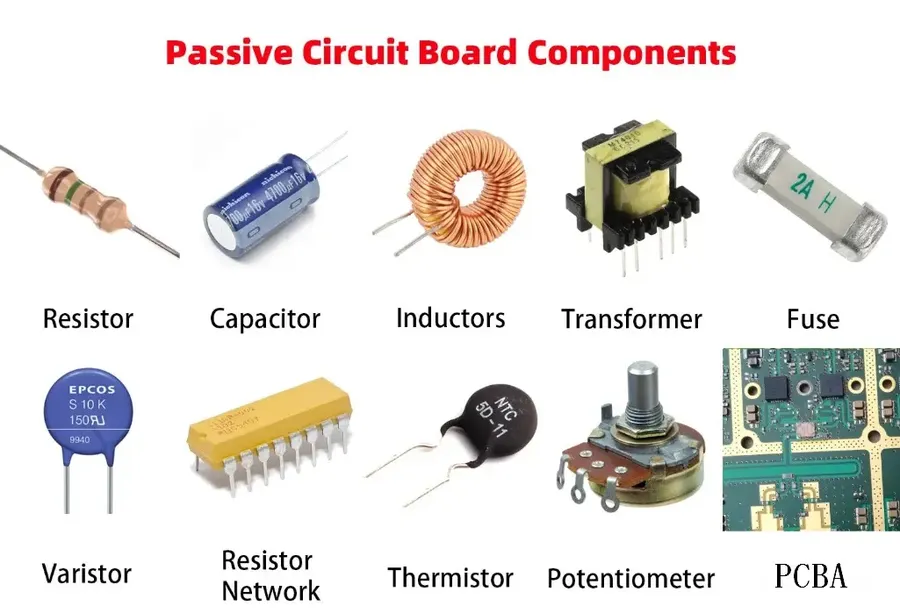

The company's advanced manufacturing processes include capabilities for handling surface mount technology (SMT), through-hole assembly, and mixed technology assembly. Furthermore, they can handle a wide variety of board materials, including FR-4, aluminum, and flexible substrates, and a range of finishes like ENIG, HASL, and immersion tin. These advanced processes, combined with robust quality control measures, result in consistent and reliable PCB production.

| Capability | Description | Benefit |

|---|---|---|

| Automated Pick-and-Place Machines | High-speed, precise component placement | Increased accuracy and reduced assembly time |

| Reflow Soldering Ovens | Controlled heating and cooling for consistent solder joints | Reliable connections and improved board performance |

| Automated Optical Inspection (AOI) | Automated inspection of solder joints and component placement | Early detection of defects and enhanced quality control |

| X-Ray Inspection | Non-destructive inspection of hidden solder joints and connections | Detection of subsurface defects and increased reliability |

| SMT Assembly | Surface mount technology component placement | Enables high-density and compact designs |

| Through-Hole Assembly | Insertion of components through holes on the PCB | Suits larger, more robust components |

| Mixed Technology Assembly | Combination of SMT and through-hole | Flexibility to handle different types of components on one PCB |

Quality Assurance and ISO Certifications

Bittele Electronics demonstrates a strong commitment to quality through rigorous quality assurance processes and adherence to international standards. This commitment is underscored by their achievement of key ISO certifications, most notably the ISO 13485 certification for medical device manufacturing, demonstrating their capability to meet stringent quality requirements in the medical field, and other industry related certifications.

The pursuit of quality at Bittele is not merely a compliance exercise but is integral to their operational philosophy, impacting every stage of their PCB assembly process. This focus on quality ensures that clients receive reliable, high-performance products consistently.

- ISO 13485 Certification

Specifically geared towards medical device manufacturing, this certification requires a highly controlled quality management system. It ensures that Bittele's processes for PCB assembly in medical applications meet the rigorous standards required for such critical applications. The certification involves regular audits and demonstrations of continuous improvement. - Other Relevant Certifications

In addition to ISO 13485, Bittele maintains other relevant certifications that align with quality standards within the electronics manufacturing industry. These may include certifications for general quality management or specific industry requirements, reflecting their wide-reaching quality standards. - Impact on Production

The ISO certifications directly affect manufacturing processes by mandating adherence to documented procedures, process control, and robust material management. This ensures consistency and quality in every manufactured product, which is crucial for industries where precision is essential, such as medical and aerospace. - Continuous Improvement

Bittele's dedication to quality is also reflected in their commitment to continuous improvement. This entails regular evaluation of their processes and an active pursuit of better manufacturing techniques and standards, which further solidifies their reputation as a quality-focused PCB assembly provider.

Bittele's Improved Facility and Inventory Management

Bittele Electronics Inc. has made significant investments in upgrading its facilities to enhance both inventory management and overall production capabilities, enabling them to offer more efficient and reliable services to their clients. These improvements directly translate to faster turnaround times, better quality control, and a more streamlined manufacturing process.

Recent upgrades include the implementation of advanced inventory tracking systems. These systems use real-time data to monitor stock levels of various electronic components, allowing Bittele to proactively manage supply chains and reduce the risk of production delays due to part shortages. The improvements also involve optimizing warehouse space to allow for increased inventory capacity and faster retrieval, thereby significantly improving workflow efficiency. This translates to better cost management for clients through optimized manufacturing times and lower material handling costs.

The facility improvements have also resulted in a more streamlined production line. Bittele has integrated new, automated machinery that enhances both precision and speed in PCB assembly. This enhanced production flow, coupled with the upgraded inventory management system, helps reduce the time from when an order is placed to when it is shipped out, providing clients with faster access to their finished products. Furthermore, the improved facility allows for better scalability to accommodate larger production orders and various project needs.

These enhancements ensure that Bittele maintains rigorous quality control protocols. The new facility is designed to facilitate seamless movement between assembly processes, reducing potential bottlenecks and errors. The better monitoring systems also allow for greater visibility at each stage of manufacturing, so issues can be addressed promptly, ensuring a higher quality product for the customer. The culmination of these advancements underscores Bittele's continuous dedication to quality and operational efficiency.

Global Reach and Customer Support

Bittele Electronics Inc. has cultivated a global presence, extending its PCB assembly services to a diverse international clientele. This extensive reach is underpinned by a robust customer support system designed to ensure dependable and efficient service delivery, regardless of geographical location.

Bittele's commitment to customer satisfaction is evident in its global support model, which is tailored to meet the unique needs of clients worldwide. The company operates with an understanding of the complexities and nuances of international trade and logistics, ensuring seamless project execution from initial consultation to final delivery.

- International Client Base

Bittele serves a wide spectrum of industries across the globe, demonstrating its capacity to meet diverse manufacturing requirements and quality standards. This broad reach provides valuable experience in catering to various project needs and regulatory environments. - Responsive Customer Service

The company prioritizes prompt and effective communication with its clients. Dedicated account managers and technical support teams are available to provide assistance, address concerns, and ensure projects proceed smoothly. - Efficient Logistics and Shipping

Bittele has established efficient international shipping and logistics processes, with the aim of minimizing delays and ensuring products reach customers in a timely fashion. These logistics capabilities are critical for customers in different regions who require dependable delivery schedules. - Localized Support and Communication

Understanding that effective communication is fundamental to successful partnerships, Bittele strives to offer support that is sensitive to clients' local language and cultural needs, enhancing collaborative project management. - Commitment to Continuous Improvement

Bittele is dedicated to constantly improving its customer service processes. The company uses feedback from clients and conducts internal reviews to refine its support mechanisms and achieve superior customer outcomes.

Bittele Electronics vs. Competitors: A Comparative Analysis

Choosing the right PCB assembly partner is crucial for project success. This section provides a comparative analysis of Bittele Electronics against other PCB assembly providers, focusing on key differentiators such as turnaround time, pricing, and quality. The goal is to provide a clear perspective on how Bittele stacks up in the competitive landscape, enabling informed decision-making.

| Feature | Bittele Electronics | Competitor A | Competitor B | Competitor C |

|---|---|---|---|---|

| Turnaround Time (for prototypes) | 2-5 Days | 3-7 Days | 5-10 Days | 2-7 Days |

| Turnaround Time (for low-mid volume) | 1-3 Weeks | 2-4 Weeks | 3-5 Weeks | 2-4 Weeks |

| Pricing (for prototypes) | Competitive | Slightly Higher | Higher | Competitive |

| Pricing (for low-mid volume) | Competitive | Moderate | Higher | Competitive |

| Quality Standards | ISO 13485 Certified (Medical) | ISO 9001 Certified | Industry Standard | ISO 9001 Certified |

| Specialization | Full-Service PCB Assembly | Primarily Prototypes | Larger Volume Production | Full-Service PCB Assembly |

| Customer Support | Dedicated Project Managers | General Customer Service | Limited Support | Dedicated Account Manager |

| Advanced Manufacturing Capabilities | Yes | Limited | Yes | Yes |

Frequently Asked Questions About Bittele Electronics Services

This section addresses common questions regarding Bittele Electronics' PCB assembly services, providing clear and concise answers to help you understand their capabilities and processes. These FAQs draw upon common user queries and related searches to offer comprehensive information.

- What types of PCB assembly services does Bittele Electronics offer?

Bittele Electronics provides a comprehensive range of PCB assembly services, including prototype assembly, low to mid-volume production runs, and turnkey solutions. They handle surface mount (SMT), through-hole, and mixed technology assemblies. - What are the typical lead times for PCB assembly at Bittele?

Lead times at Bittele Electronics vary based on the complexity of the project, component availability, and production volume. For standard prototype assembly, lead times can be as short as a few days, while larger production runs may take a few weeks. Detailed lead times are provided during the quotation process. - Does Bittele Electronics have a minimum order quantity (MOQ)?

While Bittele Electronics is flexible, they generally cater to low to mid-volume production. While they do not enforce strict MOQs, smaller runs may impact the overall cost per unit. It is best to discuss specific project needs during the quotation process to get the most accurate information. - What file formats are required for PCB assembly at Bittele Electronics?

Bittele Electronics requires standard industry files such as Gerber files, bill of materials (BOM) in formats like CSV or Excel, and centroid (pick and place) files to ensure accurate and efficient assembly. Providing clear and accurate design data is crucial to avoid delays. - What is the process for getting a quote from Bittele Electronics?

To obtain a quote, you typically need to submit your design files (Gerber, BOM, and centroid files) via their website or through their sales team. Please ensure that all file specifications and special requirements are clearly mentioned in your quote request. The quotation process will give a price and detailed timeline. - Is Bittele Electronics ISO certified, and if so, which standards?

Bittele Electronics is committed to quality and holds ISO 13485 certification, which is vital for manufacturing medical devices. Other ISO certifications may be held as well, so it's advisable to check their website or inquire directly about the most current certifications. - Does Bittele Electronics offer Design for Manufacturability (DFM) checks?

Yes, Bittele Electronics offers DFM checks as part of their service. They will review your design files to identify potential manufacturing issues and provide recommendations for optimization before production begins. This helps to ensure that the PCBs are manufactured efficiently and accurately.

How to Start Your Project with Bittele Electronics

Initiating a PCB assembly project with Bittele Electronics is a straightforward process designed to ensure efficient and accurate manufacturing. This section provides a practical guide on how to begin, covering key steps from requesting a quote to managing your project.

- Requesting a Quotation

The first step involves submitting your project details for a quotation. Provide detailed specifications such as PCB design files (Gerber files, BOM, etc.), assembly requirements, and quantity. Accurate information is crucial for a precise quote. Consider clearly stating any specific material or tolerance requirements. If you do not have full design files, provide what you have. - Preparing Your Design Files

Ensure your design files are complete, accurate, and in the required format. This typically includes Gerber files for PCB fabrication, a Bill of Materials (BOM) listing all components, centroid or pick-and-place files for assembly, and any assembly drawings or special instructions. The cleaner and more accurate your design files, the faster the process will go. Verify all components are currently available and have sufficient lead time if needed. - Project Management and Communication

After receiving your quotation and placing an order, Bittele Electronics assigns a dedicated project manager to guide you through the production process. They will keep you updated on progress, manage any questions or changes, and ensure the project is completed on time and to your specifications. Open and consistent communication is key to a smooth and successful project.

Bittele Electronics Inc. stands out as a reliable and versatile partner for PCB assembly, offering full turnkey solutions for both prototypes and production runs. Their dedication to quality, combined with continuous facility upgrades, makes them a dependable choice for companies worldwide. Whether you're developing cutting-edge medical devices or innovative electronics, consider Bittele Electronics Inc. for your next PCB project, supported by their strong industry experience and commitment to excellence.

AnyPCBA

AnyPCBA