Buy Printed Circuit Boards: A Comprehensive Guide for Beginners to Professionals

From the intricate electronics in our smartphones to the robust systems in industrial machinery, printed circuit boards (PCBs) are the unsung heroes of the modern world. If you're considering buying printed circuit boards, whether for a hobbyist project or a large-scale manufacturing endeavor, this guide is designed to demystify the process, ensuring you make informed choices every step of the way. We will delve into various PCB types, explore reputable suppliers, and guide you through the ordering process, connecting technical jargon to practical decisions and empower you to confidently buy printed circuit board.

Understanding Different Types of Printed Circuit Boards

Printed circuit boards (PCBs) are the foundation of modern electronics, providing the electrical connections and mechanical support for electronic components. Selecting the appropriate PCB type is crucial for any project, directly impacting performance, cost, and manufacturability. This section details the primary types of PCBs, their distinguishing characteristics, typical applications, and the factors that guide their selection.

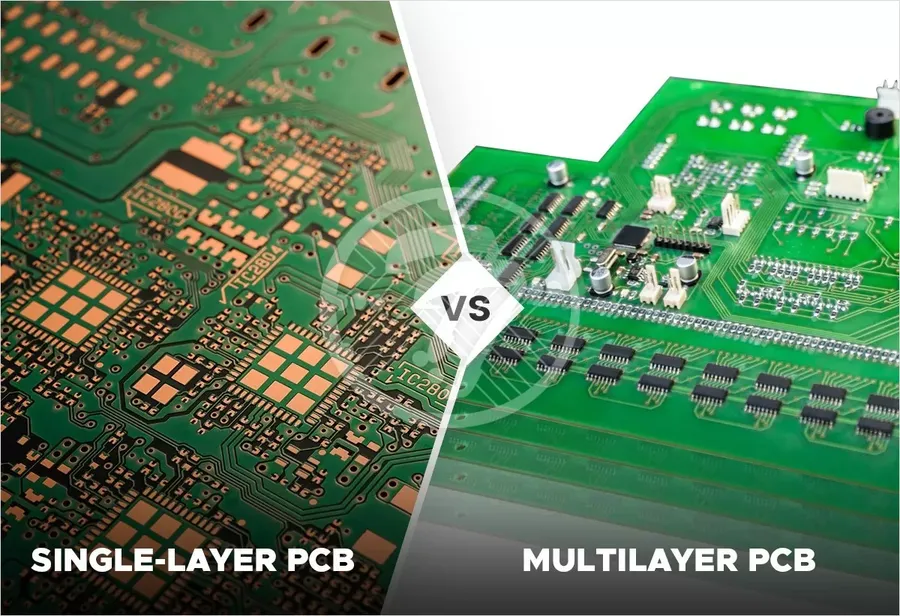

- Single-Sided PCBs

These boards have conductive copper tracks on only one side of the insulating substrate. They are the simplest and most cost-effective type, suitable for basic and low-density circuits. Applications include simple lighting circuits, sensor boards, and basic control circuits where complex interconnections are not required. - Double-Sided PCBs

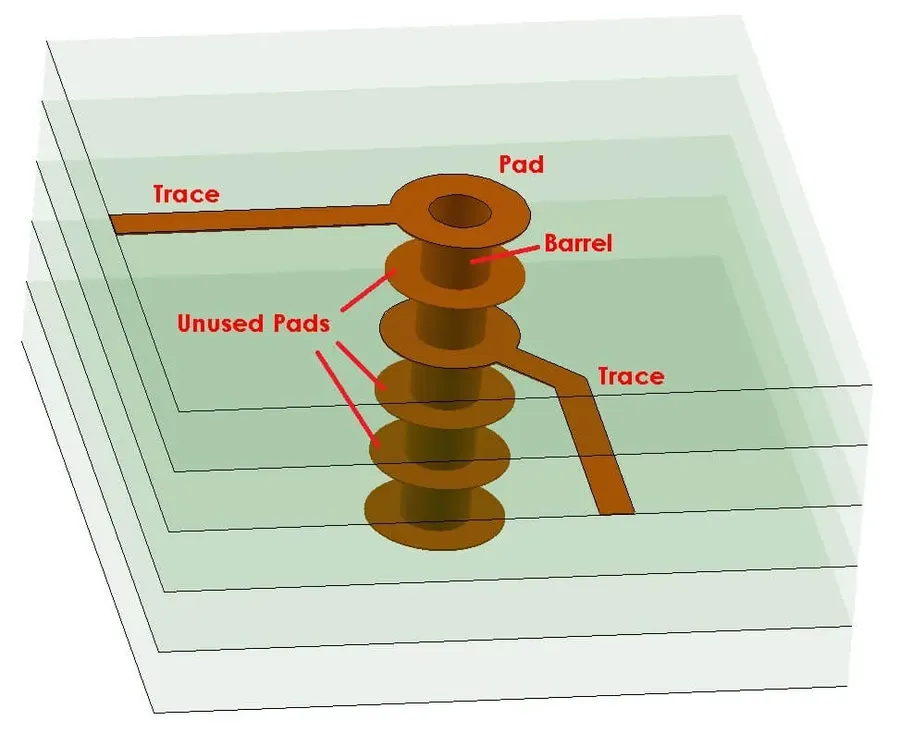

Double-sided PCBs have conductive layers on both sides of the substrate. They allow for more complex routing and higher component density compared to single-sided boards. They are widely used in intermediate-complexity applications such as power supplies, consumer electronics, and basic industrial controls. Interlayer connections, known as vias, connect traces on the top and bottom layers. - Multilayer PCBs

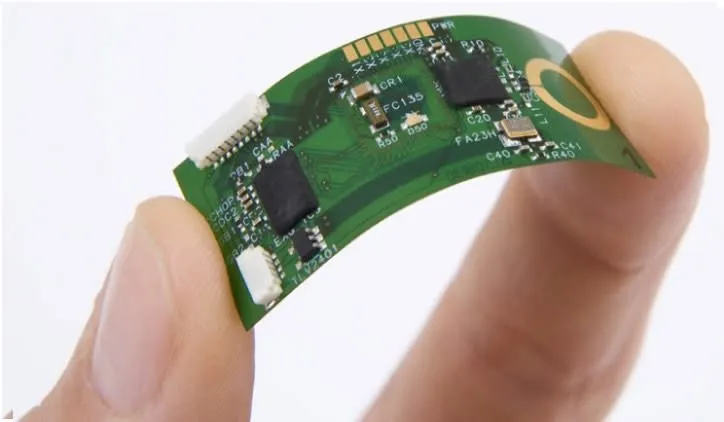

Multilayer PCBs consist of three or more conductive layers embedded within an insulating substrate. These boards offer significantly higher circuit density and routing flexibility, making them suitable for highly complex electronics. Applications include computer motherboards, high-speed networking equipment, and sophisticated medical devices. They are more expensive and require a more precise manufacturing process. The number of layers is usually expressed as an even number because of the manufacturing process; boards can be built using an odd number, but this is highly unusual. - Flexible PCBs (Flex PCBs)

Flexible PCBs are constructed using a flexible substrate material such as polyimide or polyester, allowing the board to be bent or folded. These boards are used in applications requiring space savings or dynamic movement. Common uses include wearables, automotive electronics, and camera assemblies. - Rigid-Flex PCBs

Rigid-flex PCBs combine the advantages of both rigid and flexible PCBs into a single board. They feature rigid sections for component mounting and flexible sections to enable interconnectivity and mechanical adaptability. They are utilized in advanced electronics that need the ruggedness of rigid boards and the flexibility of flex circuits, such as medical and aerospace equipment.

Key Factors to Consider When Buying PCBs

Selecting the right printed circuit board (PCB) requires careful evaluation of several key factors that directly impact performance, cost, and reliability. These factors range from the base materials used to the precision of the manufacturing process, each demanding attention to ensure the final product meets the project's specific needs.

| Factor | Description | Impact on Performance and Cost |

|---|---|---|

| Material Type | The base material of the PCB, e.g., FR-4, aluminum, Rogers, etc. | FR-4 is cost-effective and suitable for most applications; Aluminum provides better thermal management; Rogers provides excellent high-frequency performance, but costs more. |

| Board Thickness | The overall thickness of the PCB. | Thicker boards are more rigid and can handle heavier components, while thinner boards are more flexible and lighter. |

| Copper Weight | The thickness of the copper layers, measured in ounces per square foot. | Heavier copper weights allow for higher current carrying capacity, while lighter weights are more cost-effective for lower power applications. |

| Surface Finish | The type of plating applied to the copper pads, such as HASL, ENIG, or immersion tin. | ENIG provides excellent solderability and long-term reliability, while HASL is cost-effective but less flat. The surface finish impacts long-term durability and signal integrity. |

| Layer Count | The number of conductive layers within the PCB. | More layers increase the board's complexity, allowing for more intricate routing and signal separation, but also increase cost. |

Choosing the Right PCB Supplier

Selecting a suitable PCB supplier is critical to ensuring the quality, cost-effectiveness, and timely delivery of your printed circuit boards. This decision involves evaluating several key factors, encompassing certifications, manufacturing capabilities, turnaround times, customer feedback, and overall cost, to secure a dependable partnership for your PCB needs.

- Certifications (ISO, UL)

ISO 9001 certification demonstrates a supplier's commitment to quality management systems, while UL certification indicates compliance with safety standards. These certifications are crucial for ensuring the reliability and safety of the manufactured PCBs. - Manufacturing Capabilities (Prototype, Small Batch, Mass Production)

Assess whether the supplier can handle your specific order volumes. Some suppliers specialize in prototypes and small batches, while others are geared for mass production. Match the supplier's capabilities to your project’s phase and scale requirements. - Turnaround Time

Evaluate the lead time for PCB fabrication, from order placement to delivery. Faster turnaround times may be necessary for urgent projects but can come at a higher cost. Balance your timeline needs with your budget constraints. - Customer Reviews and Reputation

Research the supplier's reputation through online reviews and customer testimonials. Positive feedback indicates reliability and quality, while negative feedback serves as a red flag. Consider reaching out to past clients for direct insights. - Cost

Compare pricing from multiple suppliers, considering not just the base price but also any additional charges, such as tooling fees or shipping. Lower costs should not compromise quality and certification requirements.

Navigating the PCB Ordering Process

Successfully ordering printed circuit boards requires a clear understanding of the necessary steps involved, from preparing design files to finalizing the purchase. This section provides a detailed, step-by-step guide to streamline the PCB ordering process, ensuring accurate fabrication and timely delivery.

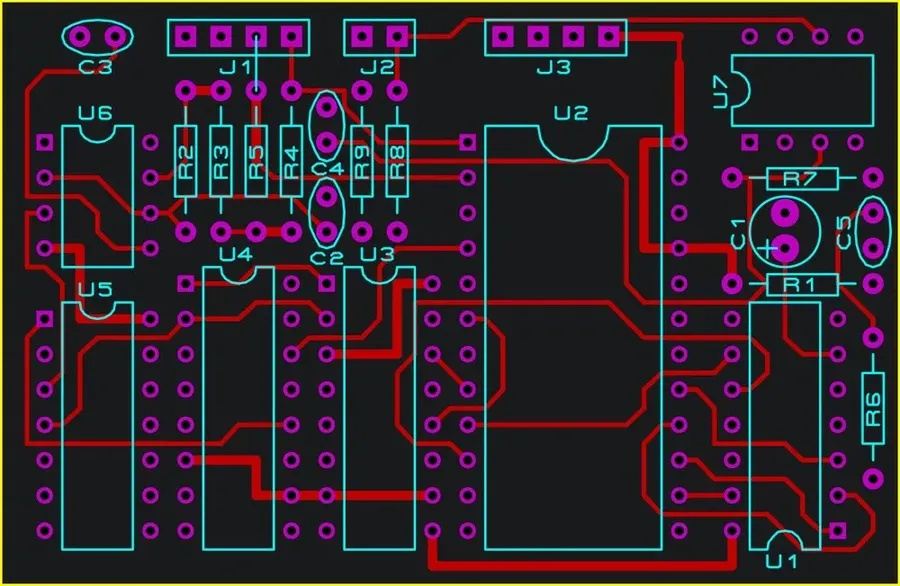

- Prepare Gerber Files

Gerber files are the industry-standard format for PCB fabrication data. These files, generated by your PCB design software, contain the geometric information for each layer of your board (copper, silkscreen, solder mask, etc.), drill information, and board outline. Ensure your Gerber files are correctly exported and thoroughly reviewed, as errors at this stage can lead to manufacturing defects. Verify the files with a Gerber viewer to catch any discrepancies before submitting. - Choose PCB Specifications

Beyond Gerber files, detailed specifications are crucial for accurate PCB manufacturing. This includes selecting the appropriate material (e.g., FR-4, aluminum), specifying the desired board thickness, copper weight (thickness of the copper layers), and surface finish (e.g., HASL, ENIG). Other critical factors include the number of layers for your board (single, double, multi), and the solder mask and silkscreen colors. A precise selection is crucial for board functionality and durability based on your application requirements. - Request Quotes

After finalizing your Gerber files and PCB specifications, obtaining quotes from multiple manufacturers is advisable. Provide them with your Gerber files and detailed specifications to ensure accurate price estimates. When reviewing quotes, do not only focus on price; consider the manufacturer's capabilities, lead time, quality standards (certifications), and reputation. Be wary of overly cheap offers as they can sometimes compromise quality. Compare quotes and make sure they include all relevant costs. - Place Orders

After selecting a manufacturer and agreeing on a quote, proceed to place your order. Be sure to double check all specifications, quantities, and delivery information before confirming your order. Many manufacturers offer online ordering systems that streamline this process. Always keep a record of your order confirmation and communication for future reference. Monitor your order's progress through the manufacturer's tracking system if available, or by contacting their support team.

Comparing PCB Manufacturing Options

Selecting the right PCB manufacturing option is crucial for both project success and cost efficiency. This section provides a comparative overview of various PCB manufacturing avenues, focusing on key factors that influence your decision when you buy printed circuit boards.

| Factor | In-House Prototyping | Small Batch Assembly | Full-Scale Mass Production | Overseas Manufacturing |

|---|---|---|---|---|

| Volume | Very low (1-10 boards) | Low to medium (10-500 boards) | High (1000+ boards) | Medium to very High (500+ boards) |

| Cost per Board | Highest due to manual process and material waste | Moderate but higher than mass production | Lowest due to economy of scale | Lower due to reduced labor costs, potential tariffs and shipping cost to consider |

| Lead Time | Fastest (few days) | Moderate (1-2 weeks) | Longest (several weeks) | Moderate to long (2-8 weeks including shipping) |

| Equipment Requirement | Basic tools and equipment such as etching machine, drilling machine, laminating machine. | Specialized assembly equipment | High volume production line with pick and place machine, solder reflow oven | Requires no upfront investment. |

| Quality Control | Variable; depends on skills, limited testing capabilities | Improved with standard assembly procedures | Stringent QC process with automated testing | Variable; relies on the manufacturer's QC standards |

| Flexibility | High, easy to make modifications | Moderate | Low, design needs to be finalized | Moderate; changes can be challenging |

| Material Selection | Limited, typically standard FR-4 | Wider range with common options | Wide range of materials and finishes available | Wide range of materials and finishes available |

| Suitability | Rapid prototyping and simple board testing | Pilot projects, small runs before mass production | Cost-effective for products that require very high volume production | Cost-effective for mass production but can involve risks and complexities |

Frequently Asked Questions About Buying Printed Circuit Boards

This section addresses common queries related to purchasing printed circuit boards (PCBs), providing clear and concise answers to guide your buying decisions. These questions are based on the user's actual concerns and the common questions when choosing to buy printed circuit board.

- How much does a printed circuit board (PCB) typically cost?

The cost of a PCB varies significantly based on several factors, including the complexity of the design (number of layers, trace density), the type of materials used (FR-4, aluminum, etc.), the surface finish required (HASL, ENIG, etc.), the quantity ordered, and the turnaround time. Simple, single-layer boards in small quantities can cost a few dollars, while complex, multilayer boards with high-end finishes can cost hundreds or even thousands of dollars for a small batch. For a more accurate quote, it's essential to get a quote from the PCB manufacturer with specific design files and requirements. - How to estimate the budget for my PCB project?

To estimate the budget for your PCB project, start by defining your technical specifications, including material type, board dimensions, layer count, and desired finish. Obtain quotes from several PCB manufacturers, specifying the order quantity and delivery time. Consider the cost of design software or service if you don't do design in-house, as well as assembly costs if needed, and add a contingency for unexpected expenses. Also, factor in shipping and tax. - Is it worth replacing a PCB board?

The decision to replace a PCB board depends on several factors. If the cost of repair is close to or exceeds the cost of a replacement, it may be more economical to replace it, especially for older boards where components might be difficult to source. Also, consider the time investment of repairs vs. the benefits of a new board which may come with updated components, improved reliability, and a warranty. Evaluate the availability of new boards from the manufacturer and consider the potential performance and reliability improvements if the board is new. - What is the difference between a Printed Wiring Board (PWB) and a Printed Circuit Board (PCB)?

The terms PWB (Printed Wiring Board) and PCB (Printed Circuit Board) are often used interchangeably, but historically, they had subtle differences. A PWB refers to the bare board with only conductive pathways, while a PCB contains these pathways and the electronic components mounted to it. Today, with the integration of component mounting technology on the same board, this distinction is largely historical. In most cases, PCB is the most commonly used term and means the circuit board with components and the printed conductive pathways. - What are the key factors that affect PCB cost when you buy printed circuit board?

The cost of a printed circuit board is influenced by several key factors, including: the complexity of the design, the type of material (FR-4, aluminum, etc.), the number of layers, the thickness of the copper layers, the type of surface finish (HASL, ENIG, etc.), the required tolerances, the size of the board, the volume of the order, the manufacturing process, and the lead time needed. More complex designs with tighter tolerances, higher layer counts, and specialized materials lead to higher costs. Ordering in large volumes can reduce per-unit costs, while expedited production will typically increase costs. - How does the material type impact PCB cost?

The material type used in PCB construction significantly influences its cost and performance. FR-4, a common fiberglass composite, is cost-effective for general-purpose applications. However, specialized materials like aluminum for thermal management, or high-frequency laminates for RF applications, are more expensive due to their advanced properties and complex manufacturing. Choosing the right material depends on your project's functional and thermal requirements, and the material's price affects the overall cost of the PCB. - How does surface finish affect PCB cost and performance?

The surface finish of a PCB impacts both its cost and performance. HASL (Hot Air Solder Leveling) is a low-cost option but may not be ideal for fine-pitch components. ENIG (Electroless Nickel Immersion Gold) is more expensive but provides better solderability, planarity, and corrosion resistance. Other finishes like Immersion Tin or Silver offer different performance and cost trade-offs. Choosing the appropriate finish depends on the PCB's requirements, assembly technology, and environmental conditions. It also affect the final cost of the PCB.

Tips for Optimizing PCB Design for Manufacturing

Optimizing your PCB design for manufacturing (DFM) is crucial for ensuring a smooth production process, minimizing errors, and ultimately reducing costs. By considering manufacturing limitations and best practices during the design phase, you can avoid costly rework and delays. These tips aim to bridge the gap between design intent and manufacturing realities.

- Maintain Adequate Spacing and Clearance

Ensure sufficient spacing between traces, pads, and components. This prevents shorts and facilitates proper soldering. Consult your chosen manufacturer's design rules for their minimum spacing requirements. - Use Standard Component Packages

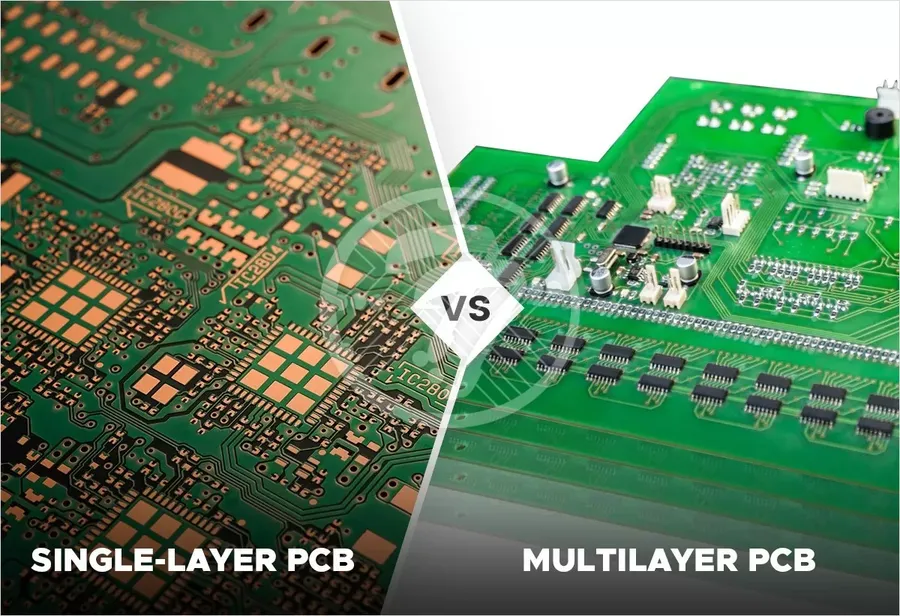

Choosing standard component packages readily available reduces lead time and cost. Non-standard or hard-to-source components may lead to delays and increased procurement costs. - Clearly Define Layer Stackup

Provide a clear and detailed layer stackup diagram in your design files. This includes material type, thickness, and copper weight for each layer. Clear documentation reduces the risk of manufacturing errors. - Incorporate Fiducial Marks

Place fiducial marks on your PCB design to improve the accuracy of automated assembly processes. These marks allow pick-and-place machines to align the PCB accurately, reducing placement errors. - Utilize Design Rule Checks (DRC)

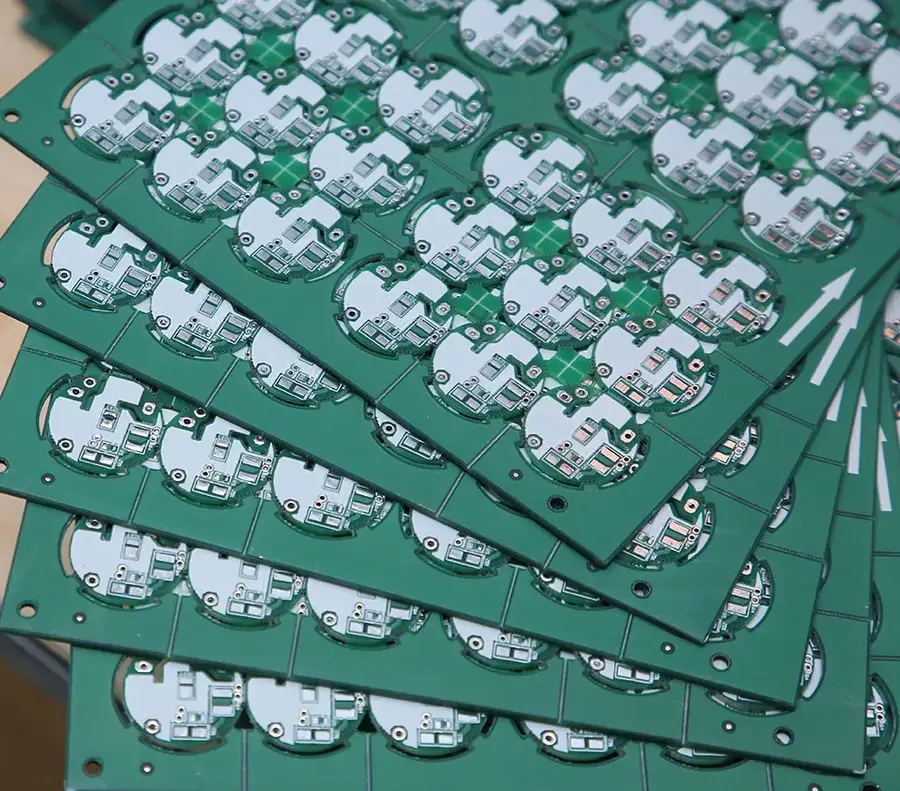

Before submitting for manufacturing, thoroughly run DRC checks within your PCB design software. This will identify design rule violations, and prevent issues that might occur in the manufacturing stage. Ensure that the manufacturer's design rules are used for these checks. - Panelize Your Design Appropriately

If ordering multiple PCBs, consider panelizing the design. This allows manufacturers to handle several boards at once, reducing production time and cost. Panelization requires careful layout to ensure proper separation after manufacturing and also allow for a robust board. - Avoid Sharp Angles

Sharp angles in trace routing are prone to acid traps during the etching process and can impact signal integrity. Opt for rounded corners or 45-degree angles for better manufacturability. - Optimize Trace Widths

Consider the current carrying capacity of traces based on the trace width and copper weight. Properly sized traces minimize impedance issues and prevent overheating. - Clearly Specify Surface Finishes

Specify the desired surface finish clearly (e.g., ENIG, HASL, etc.) for your PCBs. This is important because different surface finishes have different impacts on solderability, corrosion resistance, and other functional characteristics.

Future Trends in Printed Circuit Board Technology

The printed circuit board (PCB) industry is in constant evolution, driven by demands for smaller, faster, and more efficient electronic devices. This section explores the cutting-edge developments shaping the future of PCB technology, from advancements in flexible and rigid-flex boards to the integration of novel materials.

- Advanced Materials

The pursuit of enhanced performance is pushing the adoption of advanced materials in PCB fabrication. These include low-loss dielectrics for high-frequency applications, thermally conductive substrates for improved heat dissipation, and bio-based materials for more sustainable manufacturing processes. For instance, research into materials with lower dielectric constants and loss tangents is crucial for applications in 5G and beyond, reducing signal degradation at high frequencies. - Miniaturization and High-Density Interconnect (HDI)

As electronic devices continue to shrink, PCBs must accommodate higher densities of components. HDI technologies, including microvias, finer lines and spaces, and stacked vias, are becoming increasingly prevalent. The ability to pack more functionality into less space is pivotal in markets such as mobile devices, wearables, and IoT devices. The development of advanced packaging techniques also contributes to this trend. - Flexible and Rigid-Flex PCBs Evolution

Flexible PCBs and rigid-flex PCBs are becoming increasingly important for devices with complex shapes or in dynamic applications. Innovations in material science and manufacturing processes have improved the reliability and performance of these PCBs. Expect to see more integration of flex and rigid-flex boards in various industries, including automotive and aerospace, as they enable smaller form factors and unique designs. - Embedded Components

Embedding components directly into the PCB substrate offers numerous benefits, such as reduced size, increased reliability, and improved electrical performance. This technique involves embedding passive components such as resistors and capacitors within the PCB layers and also active components directly within the PCB structure, which enables a more integrated and compact solution. This approach results in reduced signal path lengths and enhanced electrical performance. - Additive Manufacturing (3D Printing) of PCBs

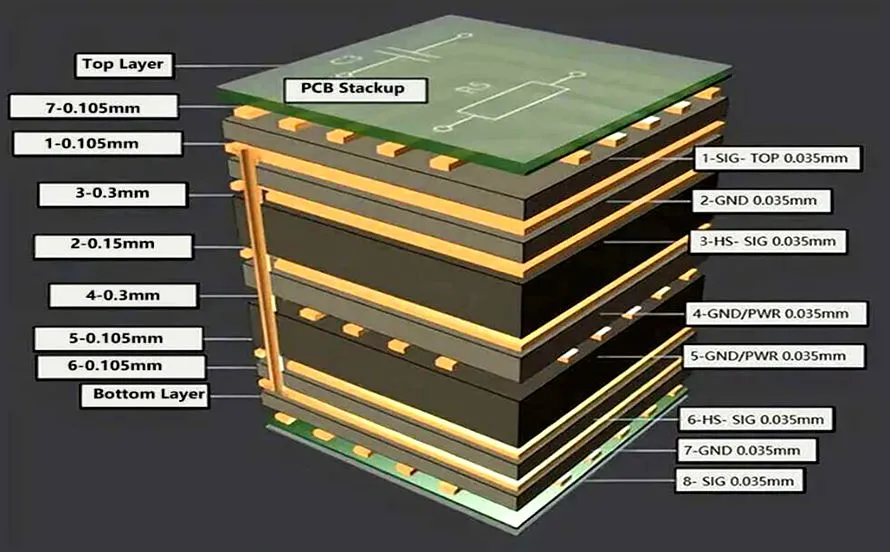

Additive manufacturing techniques, also known as 3D printing, are emerging as a viable method for creating PCBs, enabling the fabrication of complex structures with greater flexibility and customization. 3D printing can be used for both prototyping and production of PCBs, offering faster turnaround times and lower costs. This is particularly beneficial for creating complex and customized PCBs with features that traditional manufacturing methods find challenging to produce. - Sustainable and Eco-Friendly PCB Manufacturing

The industry is shifting towards greener manufacturing processes. Innovations in reducing waste, minimizing the use of hazardous materials, and developing more efficient production techniques, including recycling and environmentally friendly substrates, are becoming critical aspects of PCB production. This will become even more important as regulations tighten and consumer awareness increases. - Advanced Testing and Inspection

As PCBs become more complex, advanced testing and inspection techniques are crucial for ensuring quality and reliability. Methods like automated optical inspection (AOI), X-ray inspection, and electrical testing are constantly being refined to detect defects and ensure the integrity of intricate designs. These processes are becoming increasingly automated to meet the demands of high-volume production.

Purchasing the right printed circuit board is crucial for the success of any electronics project. By understanding the various PCB types, considering critical factors, and carefully selecting your supplier, you can ensure that you buy printed circuit board which not only meets your specifications but also your project timeline and budget. As technology advances, staying informed about the latest trends will enable you to leverage cutting-edge solutions and maintain a competitive edge.

AnyPCBA

AnyPCBA