Choosing the Right Circuit Board Company: A Comprehensive Guide

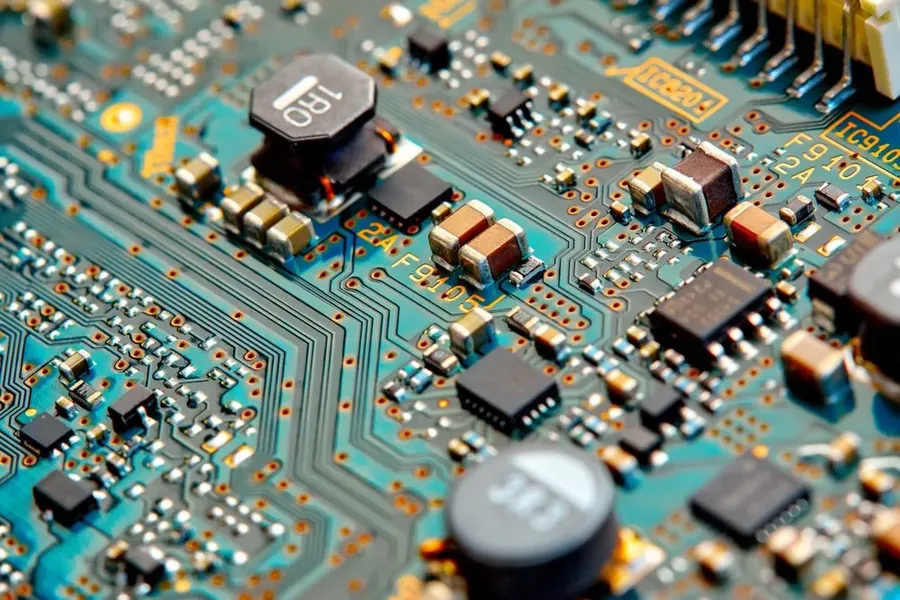

The ubiquitous circuit board, the silent workhorse behind nearly every electronic device, is crucial to modern technology. Choosing the right [circuit board company] is vital to ensuring quality, performance, and the success of your project. This guide dives deep into the world of PCB manufacturing, offering insights to help you make the best decision.

Understanding Your PCB Needs

Selecting the right circuit board company begins with a thorough understanding of your project's specific requirements. This involves defining crucial parameters such as production volume, circuit board complexity, material specifications, required lead time, and budgetary constraints. A clear articulation of these needs is essential for identifying a manufacturer capable of meeting your demands effectively.

- Production Volume

Determine whether your project requires a prototype, a small batch, or mass production. Each production scale has implications for cost, manufacturing processes, and the choice of manufacturer. - Circuit Board Complexity

Specify the complexity of the PCB, whether it is single-layer, multi-layer, or flexible. Different companies specialize in different types of PCB designs and fabrication. - Material Specifications

Identify your specific material needs, including substrate material (e.g., FR-4, aluminum, polyimide), copper thickness, and surface finish requirements. These specifications can have an impact on the performance of the circuit board. - Lead Time

Establish the expected timeframe for the production and delivery of the PCBs. Lead time requirements can influence whether to use a domestic or overseas manufacturer. - Budgetary Constraints

Define the cost limit for the project. Balancing quality with cost considerations helps select the right manufacturer within your budget.

Types of Circuit Board Companies

The circuit board manufacturing landscape is diverse, with companies specializing in various aspects of the PCB lifecycle. Understanding these specializations is crucial for selecting the right partner for your project. Companies can be broadly categorized by their service offerings, manufacturing volume, and technological expertise. This section will provide a breakdown of these categories, helping you determine which type of company best aligns with your specific requirements.

- Quick-Turn Prototype Specialists

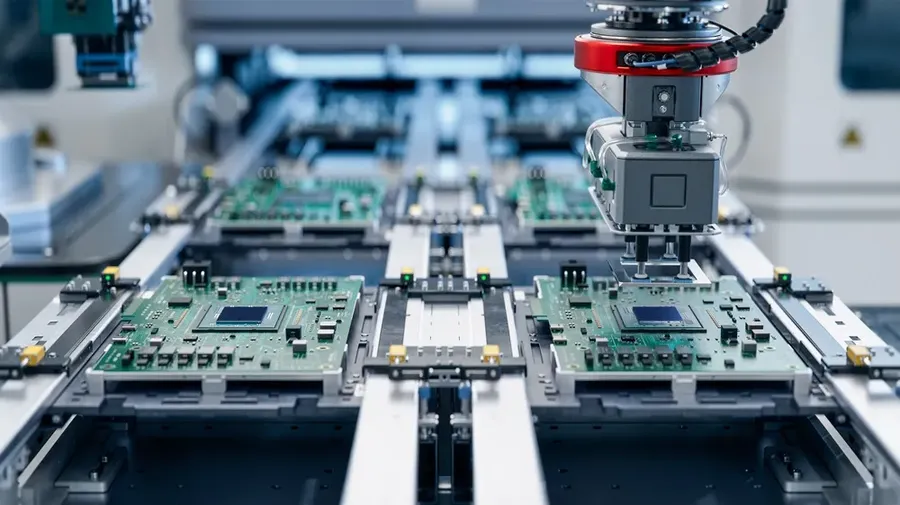

These companies focus on rapid prototyping, often with shorter lead times and smaller production runs. They are ideal for initial design iterations and proof-of-concept projects where speed is paramount. They typically offer basic to medium complexity PCBs. - High-Volume Manufacturers

These companies are geared towards mass production and offer cost advantages at scale. They are ideal for established products where large quantities are needed. They have the infrastructure to produce high volume at high quality. They are capable of handling highly complex PCBs. - Specialized Technology Manufacturers

Some manufacturers focus on specific technologies such as RF PCBs, high-speed PCBs, flex PCBs, or PCBs with unique material requirements, and have specific expertise in these areas. These manufacturers typically have experience with the stringent tolerance requirements. - Industry-Specific Manufacturers

Certain manufacturers specialize in specific industries, such as automotive, aerospace, medical, or military. They are well versed with the regulatory requirements of these fields, providing tailored solutions that comply with industry-specific standards. They often offer traceability and specific certifications. - One-Stop-Shop Providers

These companies offer both PCB fabrication and assembly, streamlining the process and reducing the number of vendors you need to manage. They are typically the most convenient if you are comfortable with them handling both. However, it may be more expensive than choosing individual specialists. - Individual Specialists

Some companies focus on a single service, such as fabrication only, or assembly only. Choosing individual specialists allows you to select the best possible provider for each service but will lead to more vendors to manage. There is also more risk of miscommunication.

Key Factors to Consider When Evaluating PCB Manufacturers

Selecting the right PCB manufacturer requires a thorough evaluation of several key factors. These factors directly impact the quality, reliability, and cost-effectiveness of the final product. Prioritizing manufacturers that demonstrate transparency and a commitment to quality is paramount, and requires close scrutiny of their certifications, manufacturing capabilities, quality control, customer support, pricing, and lead times.

| Factor | Description | Importance |

|---|---|---|

| Certifications (ISO, ROHS) | Compliance with industry standards ensures quality and environmental responsibility. | Essential for consistent quality and regulatory adherence. |

| Manufacturing Capabilities | The range of PCB types, technologies, materials, and precision they can produce. | Crucial for meeting the specific design requirements of your project. |

| Quality Control Processes | The documented procedures for ensuring the consistent quality of the final product, including tests and inspections. | Fundamental for preventing defects and ensuring reliability. |

| Customer Support | Responsiveness and expertise of support staff in addressing technical queries and concerns. | Critical for resolving issues and smooth communication during the production process. |

| Pricing Structures | Transparency of pricing models, including costs of fabrication, assembly, and extras. | Affects overall project budget and helps identify a cost effective manufacturer. |

| Lead Times | The typical turnaround time from order to delivery, considering the project timeline. | Essential for meeting project deadlines and managing supply chain effectively. |

Prototyping vs. Production: Choosing the Right Partner

Selecting the right circuit board company requires a clear understanding of whether your immediate need is for prototyping or large-scale production. While some companies excel in rapid prototyping, others are better equipped for high-volume manufacturing. Matching your project's stage to the manufacturer's specialty is crucial for efficiency and cost-effectiveness.

Here's a breakdown of key differences:

A crucial consideration is whether a company can smoothly transition from prototyping to production. Companies with both capabilities can offer a streamlined process, reducing the risk of compatibility issues or unexpected redesigns during the switch to full-scale production. Conversely, separate specialists might offer greater expertise at each phase, but the transition may be more complex.

Understanding a company's prototype process involves several key questions:

North American PCB Manufacturers vs. Overseas Options

Selecting a circuit board manufacturer involves a critical decision: whether to partner with a North American company or opt for an overseas provider. This choice significantly impacts project timelines, costs, and the overall production process. North American manufacturers often offer benefits in communication and lead time, while overseas options typically present more budget-friendly solutions.

| Factor | North American Manufacturers | Overseas Manufacturers |

|---|---|---|

| Cost | Generally higher | Generally lower |

| Lead Time | Faster turnaround | Longer lead times |

| Communication | Easier, fewer language barriers, same time zones | Potential for language barriers, time zone differences |

| Quality Control | Potentially more rigorous and transparent | Variable, may require due diligence |

| Supply Chain | More reliable due to proximity | Longer supply chains, higher risk of disruptions |

| Support | More accessible and responsive | Potentially slower and more difficult to access |

| Intellectual Property Protection | Stronger legal framework | Weaker IP protection in some regions |

The choice between North American and overseas PCB manufacturers hinges on a balance of priorities. Projects with tight deadlines or stringent quality needs often benefit from domestic partnerships, while cost-sensitive projects may find overseas options compelling. Thorough evaluation of your specific needs against the advantages and potential drawbacks is essential.

Frequently Asked Questions About Choosing a PCB Company

Selecting the right circuit board company is crucial for the success of any electronics project. This section addresses common queries and concerns that engineers and project managers face when making this decision, offering clear and concise answers based on industry best practices.

- What factors determine the 'best' PCB company?

The 'best' PCB company is subjective and depends on project specifics. Key factors include manufacturing capabilities (layer count, material compatibility), certifications (ISO 9001, AS9100), quality control procedures, pricing structure, lead times, and the ability to provide customer support. A company excelling in these areas and aligning with your project's unique needs would be considered a top choice. - Who are some of the largest PCB manufacturers in the USA?

Identifying the 'largest' PCB manufacturer can be challenging due to variations in reporting metrics. However, some of the well-established and high-volume manufacturers in the USA include companies like TTM Technologies, Sanmina, and Benchmark Electronics. These are large-scale companies with extensive capabilities and infrastructure. - Are old circuit boards valuable, and can they be recycled?

Yes, old circuit boards can be valuable primarily for the precious metals they contain, such as gold, silver, and copper. These materials can be reclaimed through specialized recycling processes. Recycling not only recovers valuable resources but also prevents harmful substances from entering landfills, making it an environmentally sound practice. - What exactly do PCB companies do?

PCB companies are manufacturers that produce the physical circuit boards used in virtually all electronic devices. They take a customer's design file (Gerber files) and fabricate boards using specified materials and techniques. This process typically involves etching, drilling, plating, and applying solder masks and silkscreen. PCB companies may also offer assembly services, populating the board with electronic components. - How can I ensure quality in PCB manufacturing?

Ensuring PCB quality starts with selecting a reputable manufacturer with certifications and transparent quality control processes. It involves detailed design reviews, adherence to industry standards (IPC standards), rigorous inspection throughout the production process, and utilizing appropriate testing methods like electrical testing and visual inspections. Always look for a provider that emphasizes quality from design input to final delivery. - What is the ideal lead time to expect from PCB manufacturers?

Lead times vary depending on the complexity of the board, order size, and the manufacturer's schedule. Quick-turn prototype runs can range from a few days to a week. Standard production runs typically take one to three weeks. It is vital to clearly communicate your timeline with the potential manufacturer and factor in potential supply chain delays. Also, be sure to confirm if the lead time includes production time and shipping time. - Is it better to use an overseas or a local PCB manufacturer?

The choice between an overseas and a local PCB manufacturer depends on your priorities. Overseas manufacturers often provide lower prices, especially for high-volume orders, but may have longer lead times and potential language and communication barriers. Local manufacturers may offer faster turnaround, better communication, and potentially greater convenience, which is often offset by the high prices. Analyze your project requirements, consider both advantages and disadvantages, and choose the one which best aligns with your budget and scheduling requirements.

A Checklist for Selecting a Circuit Board Company

Selecting the right circuit board company requires a thorough evaluation process. This checklist provides a structured approach to comparing potential manufacturers, ensuring they align with your project's specific needs and quality requirements. Utilizing this checklist will streamline your decision-making process.

| Evaluation Criteria | Checklist Items | Importance |

|---|---|---|

| Certifications | ISO 9001, ISO 14001, RoHS compliance | Ensures quality and environmental responsibility |

| Manufacturing Capabilities | Layer count, material options, minimum trace width/spacing, via types, surface finish options | Matches the complexity of your design. |

| Quality Control Processes | Automated Optical Inspection (AOI), Electrical testing, IPC standards compliance | Guarantees reliable circuit boards. |

| Material Sourcing | Use of high-quality laminates, copper, and other base materials from reputable suppliers | Impacts long-term performance and reliability. |

| Turnaround Times | Prototype and production lead times, ability to meet deadlines | Critical for project scheduling. |

| Assembly Capabilities | SMT, through-hole assembly, BGA assembly, testing capabilities | Streamlines the process, if required. |

| Communication Methods | Availability of technical support, response times, clarity of communication | Ensures smooth collaboration and problem-solving. |

| Pricing | Transparent pricing structure, cost breakdown, volume discounts | Fits within the project budget. |

| References | Customer testimonials, case studies, and any project examples | Verifies their reputation and expertise |

| Design Rule Check (DRC) | Ability to perform DRC on customer design files to ensure manufacturability | Helps to avoid mistakes and potential production delays. |

Emerging Trends in the PCB Industry

The printed circuit board (PCB) industry is in a constant state of evolution, driven by advancements in materials science, manufacturing techniques, and the ever-increasing demands of electronic devices. Understanding these emerging trends is crucial for selecting a circuit board company that can meet both current and future project requirements. This section will cover key trends shaping the PCB landscape.

- Advanced Materials

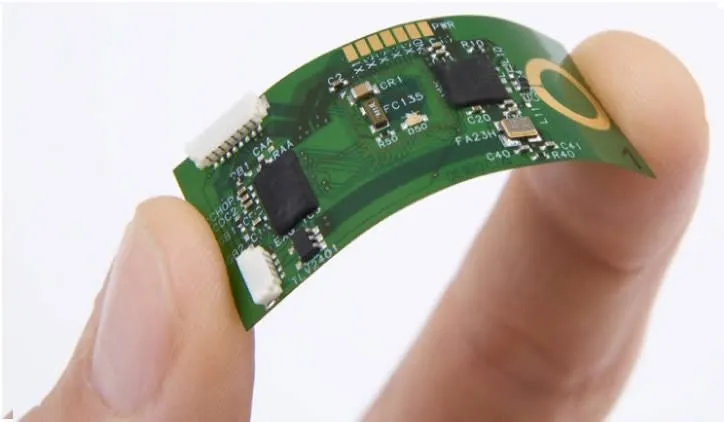

The industry is shifting towards the use of advanced materials that offer superior electrical, thermal, and mechanical properties. These include new types of laminates, resins, and conductive inks designed to handle higher operating frequencies, improve heat dissipation, and reduce signal loss, enabling more compact and efficient designs. - Flexible and Stretchable Circuits

Flexible PCBs, made using materials like polyimide, allow electronic circuits to be bent, folded, and even stretched without losing functionality. This trend is critical for wearable technologies, curved displays, and other applications where traditional rigid PCBs are not suitable. Stretchable circuits are an even more advanced technology allowing for greater mechanical deformation. This area is heavily researched for Biomedical applications, Soft Robotics, and Smart Textile. - Miniaturization

The relentless demand for smaller, lighter, and more powerful electronic devices is driving the need for miniaturization in PCB design and manufacturing. This includes the use of finer traces, smaller vias, and higher component densities. It also requires the use of Microvias, via-in-pad and HDI (high density interconnect) technology. - Sustainability and Eco-Friendly Practices

There is an increasing focus on sustainable PCB manufacturing practices. This includes the use of eco-friendly materials, reduction in waste generation, and development of more efficient manufacturing processes. Companies are exploring bio-based laminates and lead-free soldering to minimize the environmental impact. - High-Speed and High-Frequency PCBs

With the growing adoption of 5G and other high-speed communication technologies, there is a strong demand for PCBs designed to operate at higher frequencies and handle faster data rates. This includes the use of low-loss materials and careful impedance control during the design phase. - Embedded Components

Embedding passive components, such as resistors and capacitors, directly within the PCB layers allows for further miniaturization and improved performance. This approach also simplifies assembly and reduces overall component counts. The industry is quickly moving to 3D printed electronics which will have all active and passive components printed directly into the substrate.

Choosing the right circuit board company is a crucial decision impacting the success of your electronic project. A strategic approach that addresses the needs of your project, evaluates the available PCB manufacturing options, and understands key trends is important. By applying the knowledge gained in this guide, you can confidently choose a [circuit board company] that meets your present requirements and is poised to support your future endeavors.

AnyPCBA

AnyPCBA