Choosing the Right PCB Company: A Comprehensive Guide by [pcb company]

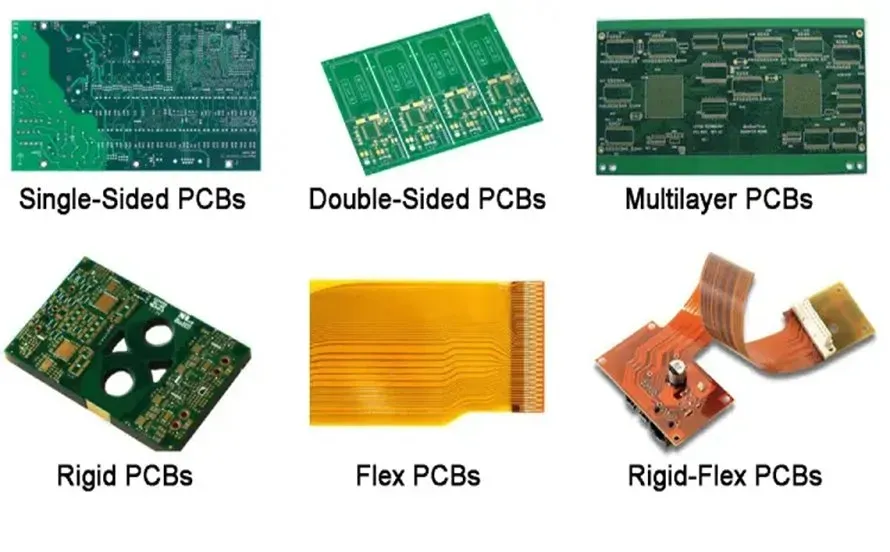

![Choosing the Right PCB Company: A Comprehensive Guide by [pcb company]](/upfile/blogs/articles/18/different-pcb-types.webp)

In today's interconnected world, printed circuit boards (PCBs) are the unsung heroes powering everything from smartphones to medical devices. Choosing the right PCB company is crucial for ensuring the success of your project, whether you're an individual maker or a large corporation. At [pcb company], we understand the importance of this decision and are here to guide you through the complexities of PCB manufacturing and assembly, helping you connect technological innovation with practicality. We'll explore what sets different PCB companies apart and how to find a partner that matches your specific needs.

Understanding Your PCB Needs: A Pre-Selection Checklist

Before engaging with any PCB company, a crucial first step involves a thorough assessment of your project's specific requirements. This proactive approach ensures a more efficient selection process, aligning you with a PCB company that can effectively meet your unique needs.

This section provides a detailed pre-selection checklist, focusing on key considerations to clarify your project scope and specifications. By systematically addressing these points, you'll be well-positioned to make informed decisions and select a PCB company that is the best fit for your project.

- Board Size and Dimensions

Accurately specify the required dimensions of your PCB. This includes length, width, and any specific dimensional tolerances that must be adhered to. - Material Selection

Identify the appropriate substrate material (e.g., FR-4, Rogers, Aluminum). Consider thermal, electrical, and mechanical performance requirements when making your choice. - Layer Count

Determine the number of conductive layers needed. This will influence the complexity of your design and the cost of manufacturing. - Trace Width and Spacing

Establish the required trace width and spacing for optimal circuit performance, taking into consideration impedance and current-carrying capacity needs. - Via Requirements

Specify the size, type, and number of vias required to connect different layers in your PCB design. - Surface Finish

Choose a suitable surface finish (e.g., HASL, ENIG, Immersion Silver). Consider the durability, solderability, and cost implications of different surface finishes. - Impedance Control

If impedance control is critical, define the required impedance values and tolerances for traces. - Special Features

Outline any special features needed, such as blind or buried vias, controlled impedance lines, or microvias. - Tolerance Requirements

Define any critical tolerances for dimensions, hole sizes, and trace widths. This affects the precision and reliability of the manufactured PCB. - Required Certifications and Standards

Identify any necessary compliance certifications or industry standards (e.g., UL, IPC, RoHS) that the PCB must meet.

By having these specifications clearly defined prior to contacting PCB companies, you will be able to quickly narrow down your choices, and help them to provide a much more accurate quote. This also significantly helps in establishing realistic expectations and ensuring better compatibility between your project needs and a company’s specific capabilities.

Key Services Offered by PCB Companies

PCB companies provide a range of essential services to bring electronic designs to life. Selecting a company that offers the specific services your project requires is crucial for success, these include prototyping, fabrication, assembly, design and testing.

| Service | Description | Importance |

|---|---|---|

| PCB Prototyping | Creation of a small number of PCBs to test design functionality and make necessary adjustments before mass production. | Essential for validating design and identifying any potential problems early on. Reduces risk and costs associated with full-scale production. |

| PCB Fabrication | The process of manufacturing the physical printed circuit board based on the design specifications. | Provides the actual physical board on which electronic components will be mounted. Precise fabrication is critical for functionality. |

| PCB Assembly | The process of mounting electronic components on the fabricated PCB using various methods like surface mount technology or through-hole mounting. | Ensures all components are correctly placed and connected according to the design. Proper assembly is critical for circuit performance. |

| PCB Design | Creating the layout of the circuit board, including component placement, routing of traces, and layer stack-up, using software tools like Altium Designer or Eagle. | It is the foundation of the entire process, affecting manufacturability, performance, and reliability. |

| PCB Testing | Verifying the functionality and reliability of the manufactured and assembled PCB through a series of electrical tests, including continuity, short circuit, and functional testing. | Validates the final product meets design specifications and performs as expected. Ensures quality and reduces risks of malfunctions. |

The selection of appropriate services from a PCB company is critical. The choice often depends on the project's complexity, volume requirements, and the resources available internally. It's advisable to look for a company offering a comprehensive range of services to facilitate a streamlined production process.

Analyzing PCB Company Specializations

PCB companies often specialize in specific areas of PCB manufacturing to maximize their expertise and efficiency. This specialization can greatly impact the suitability of a company for your project. Understanding these specializations is crucial for selecting the right partner. Some focus on rapid prototyping, allowing for quick design iterations, while others excel in large-scale production, leveraging economies of scale. Additionally, many companies concentrate on niche technologies or specific PCB types like flexible circuits or high-frequency boards.

Selecting a PCB manufacturer that aligns with your project's specific phase and requirements is essential. Mismatching your needs with a company's specialization can result in longer lead times, higher costs, or compromised quality.

| Specialization | Description | Ideal Use Case |

|---|---|---|

| Rapid Prototyping | Focuses on quick turnaround for small batches, ideal for design iteration and testing. | Early-stage development, proof-of-concept, design validation |

| High-Volume Production | Optimized for large-scale manufacturing with efficient processes. | Mass production, commercial products, large scale deployments |

| Specialized Technologies | Expertise in specific PCB types like flexible, rigid-flex, high-frequency or metal core PCBs. | Specific applications requiring niche technologies |

| Advanced Materials | Specializes in handling specific materials, like high-Tg or specific dielectric materials. | High-performance applications, extreme environments |

Consider the following when analyzing specializations:

- Project Phase

Is your project in the prototyping, pilot production, or mass production phase? - Technology Needs

Does your design require specialized materials, layer counts, or fabrication techniques? - Volume Requirements

What are the anticipated quantities of PCBs needed? - Specific Standards

Are there any industry specific standards that need to be taken into account such as medical devices or aerospace?

Comparing PCB Company Manufacturing Capabilities

Evaluating a PCB company's manufacturing capabilities is crucial to ensure they can meet your project's specific needs. This involves a thorough assessment of their technology, equipment, production capacity, and quality control measures. The right fit guarantees the delivery of PCBs that meet technical specifications and volume requirements, ultimately impacting the project's success.

To effectively compare PCB manufacturing capabilities, consider the following aspects:

- Technology and Processes

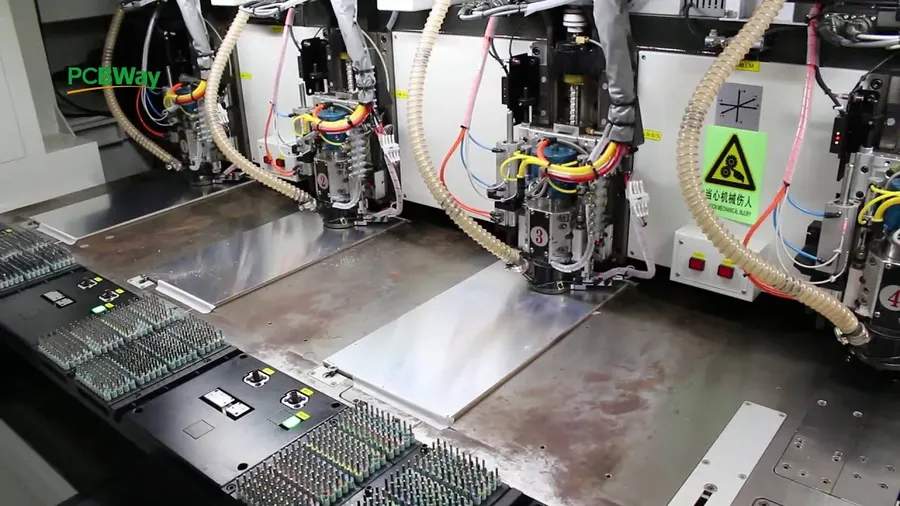

Assess the company's technology and manufacturing processes. Are they capable of producing the complexity of PCBs you need? Do they use advanced techniques like laser drilling, impedance control, or microvia technology? Look for companies using technologies relevant to your project's specifications. - Equipment and Machinery

Check the age, precision, and maintenance of their equipment. Modern and well-maintained machines improve production efficiency and the quality of the end product. Ask for details about their drilling, etching, plating, and lamination equipment. Companies with advanced machinery can handle more intricate designs and ensure consistency. - Production Capacity

Does the PCB company have the production capacity to meet your current and future demands? Can they handle both small prototype runs and high-volume production? It's essential that the manufacturer can scale up production in line with your needs, avoiding any bottlenecks. - Materials

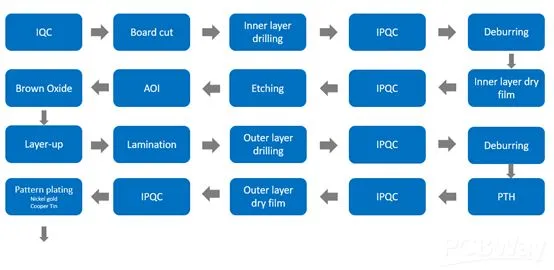

What variety of materials can the company work with (e.g., FR-4, Rogers, Aluminum)? A broader selection provides more flexibility and allows you to select the most appropriate material for your application. - Quality Control

Evaluate their quality control processes. What tests and inspections do they perform? A good company will use a range of tests, including AOI (Automated Optical Inspection), electrical testing, and impedance testing to catch issues before boards are delivered to customers.

| Capability | Description | Importance |

|---|---|---|

| Technology | Processes such as laser drilling, impedance control, microvia technology. | Critical for producing complex PCB designs and advanced electronic systems. |

| Equipment | Advanced drilling, etching, plating, and lamination machines. | Ensures precision, efficiency, and quality in PCB fabrication. |

| Production Capacity | Ability to handle varying volumes, from prototypes to mass production. | Ensures scalability and timely delivery for projects of all sizes. |

| Material Variety | Range of substrates available, such as FR-4, Rogers, and Aluminum. | Allows customization of PCB properties to fit application needs. |

| Quality Control | Testing procedures like AOI, electrical tests, and impedance testing. | Vital for maintaining high standards and minimizing defects. |

Turnaround Time and Lead Times: What to Expect

Understanding turnaround time and lead times is crucial when selecting a PCB company. These metrics directly impact your project timelines, and inconsistencies can lead to costly delays. This section will dissect typical timelines for both prototype and production orders, allowing for better planning and supplier comparison.

Turnaround time refers to the duration between placing an order and receiving the finished PCBs. Lead time, conversely, encompasses the total time required from order placement to delivery, often including fabrication, assembly, and shipping.

| Stage | Description | Typical Turnaround Time | Factors Affecting Time |

|---|---|---|---|

| Prototype Fabrication | Initial run of PCBs for testing and validation | 2-7 business days | Complexity of design, material availability, rush service |

| Production Fabrication | Large-scale PCB manufacturing | 1-4 weeks | Order volume, material lead time, production capacity |

| PCB Assembly | Component mounting on PCBs | 1-3 weeks | Complexity of assembly, component availability, volume |

| Shipping | Delivery of finished products to client | 1-7 business days | Shipping destination, carrier speed, customs procedures |

It's essential to verify these times with the PCB company directly, as they can vary significantly based on their specific processes and current workload. Furthermore, understand if the stated times are business days or calendar days.

To ensure the lead time aligns with your project schedule, consider the following:

- Request detailed timelines

Ask for clear timelines for each stage of the manufacturing process. - Factor in buffer time

Build in some extra time for unforeseen delays, especially in complex projects or peak production seasons. - Inquire about expedite options

Understand the options and costs for accelerating your order if necessary. - Evaluate the overall communication

A company that keeps you informed throughout the process can help you mitigate delays proactively.

Ultimately, understanding and comparing lead times among different PCB companies is crucial for choosing a partner that can meet your project deadlines, avoid costly delays, and maintain project momentum. A detailed analysis of these factors will contribute to more efficient project management.

Cost and Pricing Structures: Finding Value

Understanding the cost and pricing structures of PCB companies is crucial for optimizing your budget while ensuring quality and reliability. Focusing solely on the lowest price can lead to compromises in performance and durability. A balanced approach considers overall value, encompassing cost, quality, and long-term reliability of the PCB.

PCB pricing is influenced by a range of factors. These often include:

- Board Size and Layer Count

Larger boards and higher layer counts increase the cost due to more material and processing required. - Material Type

Different materials, such as FR-4, Rogers, and polyimide, have varying costs, impacting the final price. - Minimum Trace Width and Spacing

Tighter tolerances demand more precise manufacturing and can increase costs. - Quantity

Higher production volumes usually result in lower per-unit costs due to economies of scale. - Surface Finish

Different surface finishes like HASL, ENIG, and immersion silver have different processing costs. - Testing Requirements

More stringent testing procedures will increase the overall cost, particularly for complex PCB's. - Turnaround Time

Faster turnaround times often come with a premium cost.

Here is a table that showcases a comparison of different pricing models with their advantages and disadvantages:

| Pricing Model | Description | Advantages | Disadvantages |

|---|---|---|---|

| Unit Price | A fixed cost per PCB regardless of volume. | Easy to calculate costs for small projects | Can become very expensive for large-volume production runs. |

| Tiered Pricing | Price per unit reduces as volume increases. | Good for medium to large scale production runs | Requires some planning to optimize production costs, and may not be suitable for very small quantities |

| Fixed Pricing | A set cost for the whole job, regardless of small changes. | Great for small or simple designs, easy to calculate | Not economical for large projects or for designs requiring changes |

| Custom Quote | A quote based on your specific design and production requirements. | Best for complex PCB's or unique project needs. | May take a long time to get a quote, and may not be suitable for small production runs |

It is advised that to find maximum value in PCB production, do the following:

- Optimize your design

Reduce board size, layer count, and complexity where possible. - Plan your production volumes

Evaluate the best pricing tier by optimizing production volume - Negotiate with suppliers

Discuss your project requirements and potential for long-term contracts. Some manufacturers offer volume discounts. - Request quotes from multiple companies

Compare quotes from several PCB companies before making a final decision - Consider lead time trade-offs

Longer lead times can sometimes result in cost savings, if your project timeline permits

Quality Assurance and Certifications: Ensuring Reliability

Rigorous quality assurance and adherence to industry certifications are paramount when selecting a PCB company. These elements signify a company's commitment to delivering reliable and consistent printed circuit boards, crucial for the performance and longevity of electronic products. A thorough review of a manufacturer's quality processes and certifications can mitigate the risk of receiving flawed or non-compliant PCBs.

Key certifications to look for include:

- ISO 9001

Indicates a company's commitment to a robust quality management system, ensuring consistent product and service quality. It signifies that the PCB manufacturer has established a process for continuous improvement and customer satisfaction. - UL Certification

Signifies compliance with safety standards established by Underwriters Laboratories. This is important for ensuring the safety of PCBs, particularly in products where electrical safety is critical. - IPC Standards

Adherence to IPC (Association Connecting Electronics Industries) standards, which are the globally recognized industry standards for PCB design, manufacturing, and assembly, indicates that a company follows best practices. Key standards include IPC-A-600 for PCB acceptability and IPC-6012 for PCB performance and specification.

The below table provides a comparison of these key certifications and what they signify:

| Certification | Focus | Significance for PCB Manufacturing |

|---|---|---|

| ISO 9001 | Quality Management Systems | Ensures consistent quality through defined processes. |

| UL Certification | Product Safety | Guarantees PCBs meet specific safety requirements. |

| IPC Standards | Industry Standards | Indicates adherence to PCB design, manufacturing, and assembly best practices. |

Beyond certifications, it is important to inquire about a PCB company's specific quality control processes, including in-process inspection, final inspection, and testing protocols. This ensures that the PCBs you receive are consistently high quality and meet your technical specifications.

Customer Support and Communication: Building a Strong Partnership

Effective customer support and clear communication are paramount when selecting a PCB company. A responsive, knowledgeable team facilitates smooth project execution, particularly when design, production, or assembly challenges arise. A strong partnership built on mutual understanding and valued communication is essential for project success.

When evaluating customer support and communication, consider the following aspects:

- Responsiveness

The speed at which the company responds to inquiries and provides updates. Prompt responses to emails, phone calls, and online support requests are indicative of a company that values your time and business. - Knowledge and Expertise

The depth of the team's technical knowledge. They should be able to offer valuable insights and solutions to your PCB design and manufacturing questions. - Accessibility

The ease with which you can access their customer support channels. Companies should have multiple avenues for contact, such as phone, email, and online chat. - Proactive Communication

Whether the company proactively communicates updates on order progress, potential issues, and any changes in timelines. This is vital for project planning and avoiding delays. - Problem Resolution

The company's approach to handling issues that arise during the process. They should be able to offer solutions to challenges and minimize disruptions to your project.

Partnering with a PCB company that values open communication ensures that your project stays on track and that you can quickly address any questions or issues. Effective communication not only streamlines the PCB manufacturing process but also reduces risks, which leads to more predictable outcomes.

Below is a table highlighting key communication aspects to assess:

| Aspect | Description | Why it matters |

|---|---|---|

| Communication Channels | Availability of phone, email, chat, and online portals. | Provides multiple options to contact the support team based on needs. |

| Responsiveness Time | Average response time to inquiries (e.g., within 24 hours). | Indicates how promptly issues will be addressed, reducing potential delays. |

| Technical Support | Availability of technical specialists to answer complex questions. | Ensures accurate information and guidance on design and manufacturing. |

| Order Tracking | Ability to track the status of your order. | Provides visibility into the production process and allows you to plan accordingly. |

| Feedback Mechanisms | Systematic methods to collect and act upon customer feedback | Demonstrates a commitment to continuous improvement and customer satisfaction. |

Frequently Asked Questions About PCB Companies

Navigating the PCB (Printed Circuit Board) manufacturing landscape can be complex. This section addresses common questions to help you understand PCB companies and make informed decisions.

- What does PCB stand for, and what is its role in a company?

PCB stands for Printed Circuit Board. In a company, PCBs are the foundational building blocks for electronic devices. They provide mechanical support and electrical connections for components, enabling functionality across a wide range of products from consumer electronics to complex industrial systems. - What should I consider when choosing a PCB company?

When choosing a PCB company, consider several crucial factors: their manufacturing capabilities (including technology and equipment), the materials they work with, their experience with your specific type of project, their quality control processes and certifications, their turnaround times, pricing, and the quality of their customer support. - What are some of the best PCB companies in the industry?

The 'best' PCB company depends on the specific needs of your project. Some well-regarded companies include JLCPCB and PCBWay for prototyping, while larger manufacturers might offer better solutions for high-volume production. Researching companies specializing in your application is important to ensure the best fit for your project. - What is a PCB business and what services do they typically provide?

A PCB business is a company that manufactures printed circuit boards. They typically offer a range of services including PCB design, prototyping, fabrication, assembly (populating boards with components), and testing. Some PCB businesses also offer specialized services such as surface finishing, lamination, and specific technology fabrication. The range of services a PCB company offers impacts how many different aspects of a project they can provide for. - What is the difference between a PCB manufacturer and a PCB assembler?

A PCB manufacturer focuses on fabricating the bare circuit board, while a PCB assembler takes those boards and mounts electronic components onto them. Some companies offer both services, known as turnkey solutions. It's essential to understand these distinctions when choosing partners to ensure all your needs are met. - How does a PCB company handle quality assurance?

Reputable PCB companies implement rigorous quality assurance processes throughout the manufacturing process. This includes material inspection, in-process checks, automated optical inspection (AOI), electrical testing (e.g., flying probe or bed-of-nails testing), and final quality audits. Certifications such as ISO 9001 and IPC standards are important indicators of quality assurance. - What is the typical turnaround time for PCB fabrication and assembly?

Turnaround time for PCB fabrication varies based on board complexity, quantity, and the manufacturer's capacity, with prototypes typically taking shorter lead times than large production runs. Assembly times depend on the complexity of the board, the number of components, and the chosen assembly method. It's important to discuss expected timelines with the manufacturer to avoid potential delays.

Choosing the right PCB company requires a thorough evaluation of your specific needs and the capabilities of potential partners. By considering factors like specialization, turnaround time, quality, and support, you can secure a reliable and high-quality PCB supplier for your project. At [pcb company], we're committed to providing exceptional services and support to meet your PCB requirements, empowering you to bring your innovative ideas to life.

AnyPCBA

AnyPCBA