Choosing the Right PCB Electronics Company: A Comprehensive Guide

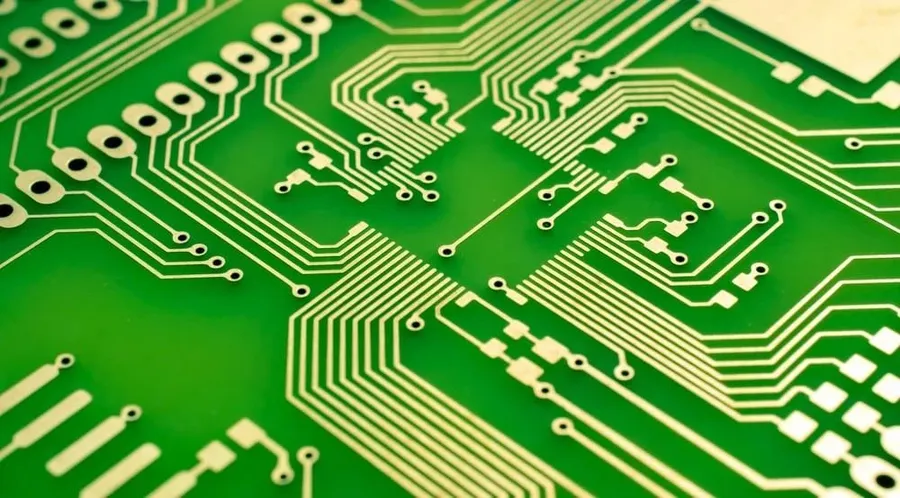

In today's interconnected world, printed circuit boards (PCBs) are the unsung heroes powering almost every electronic device we use. Selecting the right PCB electronics company is crucial for product success, regardless of whether you are designing a simple sensor or a sophisticated computing system. This article helps guide you through the key factors to consider when choosing a PCB partner, ensuring your designs are brought to life with quality and efficiency. Let's delve into the essentials for identifying a suitable PCB electronics company and explore strategies for a fruitful collaboration.

Understanding Your PCB Needs

Before engaging with a PCB electronics company, a meticulous evaluation of your project's specific requirements is paramount. This foundational step ensures the selection of a partner that can effectively meet your unique needs, encompassing factors such as board complexity, production volume, material specifications, and project timelines. A precise understanding of these parameters is crucial for successful PCB manufacturing.

- Board Complexity

Assess the intricacy of your PCB design. This includes the number of layers, trace widths and spacing, via types, and component density. High-complexity designs require advanced manufacturing capabilities. - Production Volume

Determine the number of PCBs you need. This affects pricing, lead times, and the manufacturing process used (prototype vs. mass production). - Material Specifications

Define the required PCB substrate materials based on thermal, mechanical, and electrical requirements. FR-4, aluminum, and specialized laminates each have distinct properties. For example, high-frequency applications require materials with specific dielectric properties. - Project Timeline

Establish a realistic timeframe for your project, encompassing design, fabrication, assembly, and testing. This helps align expectations with potential PCB partners. - Specific Component Requirements

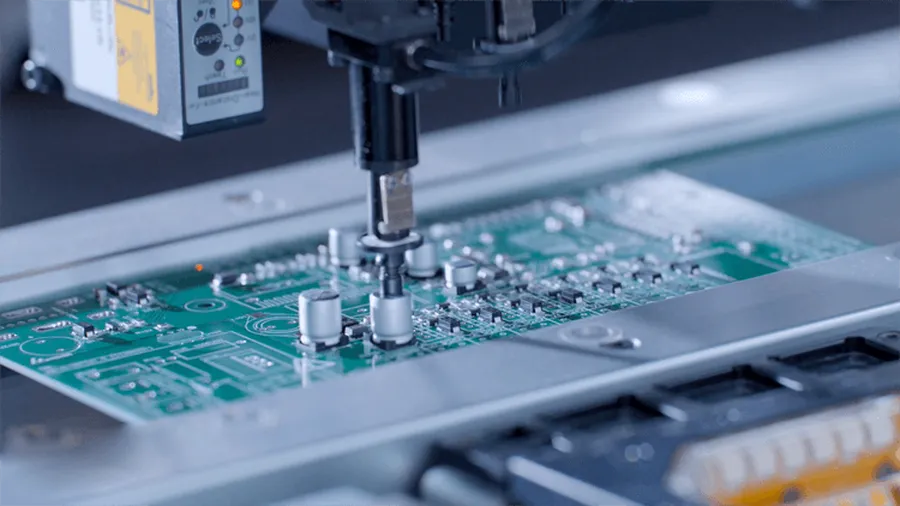

Outline any specific components or assembly processes necessary for your project. This includes surface mount (SMT), through-hole, or mixed component types, as well as any specialized handling or assembly needs.

Key Factors to Evaluate in a PCB Electronics Company

Selecting a PCB electronics company requires a thorough evaluation that goes beyond just the quoted price. A comprehensive assessment should include the company's expertise, certifications, technological capabilities, quality control measures, lead times, and the quality of their customer support. These factors collectively determine a company’s ability to consistently deliver high-quality PCBs.

| Factor | Description | Importance |

|---|---|---|

| Expertise | Years of experience in PCB manufacturing, specialized knowledge in different PCB types and technologies. | Ensures the company understands complex designs and can avoid common production pitfalls. |

| Certifications | Compliance with industry standards such as ISO 9001, IPC standards. | Demonstrates commitment to quality management and adherence to industry best practices. |

| Technology Capabilities | Advanced manufacturing processes like SMT (Surface Mount Technology), through-hole, multi-layer boards, fine-pitch components, advanced materials handling. | Enables the production of complex boards with high precision and reliability. |

| Quality Control Processes | Rigorous testing procedures including Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and functional testing. | Reduces defects and ensures high quality boards. |

| Lead Times | The time it takes from order placement to delivery. | Crucial for project timelines and should be consistent with project schedules. |

| Customer Support | Availability of technical support, communication channels, and responsiveness. | Essential for resolving issues and maintaining a smooth production process. |

Types of PCB Services Offered

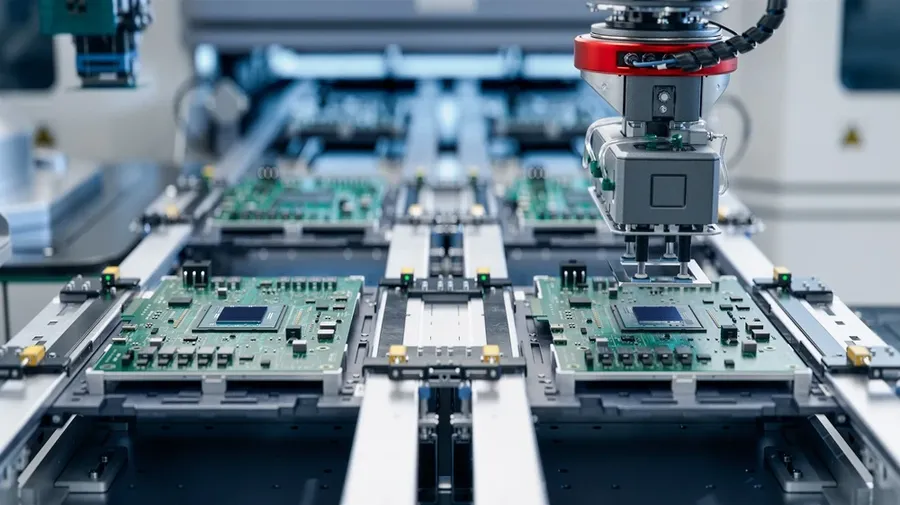

PCB electronics companies offer a spectrum of services, each crucial at different stages of product development. Selecting a provider that offers the specific services aligned with your project requirements, from initial prototyping to final assembly and testing, is essential for streamlining the process and ensuring a seamless transition between stages. This approach minimizes potential compatibility issues and reduces the complexities of managing multiple vendors.

| Service Type | Description | Key Considerations |

|---|---|---|

| PCB Design & Layout | Creation of PCB schematics and layout from a concept or circuit design. | Ensure the company has skilled designers with the experience to handle your PCB complexity and requirements. Verify their CAD software compatibility. |

| PCB Prototyping | Production of small quantities of PCBs for design verification and testing. | Check the company's lead time for prototypes and the ability to transition seamlessly to full-scale production. Fast turnaround is crucial for iterative designs. |

| PCB Fabrication | Manufacturing bare PCBs according to the design files. | Evaluate their material capabilities (e.g., FR-4, flex PCBs), manufacturing precision, and ability to meet tight tolerances. Verify they can achieve your desired layer count and board thickness. |

| PCB Assembly | Mounting of electronic components onto the bare PCBs. | Assess their component placement accuracy, soldering methods, and capabilities with different component types (SMT, through-hole). Check their capacity for your production volume requirements. |

| PCB Testing | Functional and in-circuit testing to ensure the PCB works correctly. | Confirm the type of testing they offer (e.g., automated optical inspection (AOI), in-circuit testing (ICT)). Rigorous testing is key to ensuring reliability. |

| Other services | Specific services like conformal coating, potting, and specialized assembly | Confirm if they provide niche services you may require. This can streamline your process further. Check to see if they will work on customer specified parts. |

Geographic Location and Supply Chain Considerations

The decision of whether to partner with a domestic or international PCB electronics company is a pivotal one, directly influencing cost, lead time, and quality control. Evaluating these factors in the context of your supply chain strategy is crucial for optimized project outcomes.

| Factor | Domestic PCB Company | International PCB Company |

|---|---|---|

| Cost | Potentially higher initial cost due to labor and overhead. | Often lower manufacturing cost due to lower labor and operational expenses. |

| Lead Time | Generally shorter lead times due to proximity. | Longer lead times can be expected due to shipping and customs processes. |

| Communication | Easier communication due to similar time zones and potential language. | Communication can be challenging due to time zone differences and potential language barriers. |

| Quality Control | Easier to conduct on-site audits and address quality issues promptly. | Quality control requires robust procedures, may have challenges with on-site auditing. |

| Shipping | Lower shipping costs and easier logistics. | Higher shipping costs and more complex logistics, potential for delays at customs. |

| Supply Chain | Potentially more robust and resilient, easier to manage. | Potentially more vulnerable to disruptions and require more sophisticated planning. |

Evaluating the PCB Company's Technology and Equipment

A PCB electronics company's technological prowess is a direct indicator of its ability to produce high-quality printed circuit boards. The sophistication of their equipment and manufacturing processes directly impacts the precision, reliability, and overall quality of the final product. A thorough evaluation of their technology is essential before selecting a manufacturing partner.

Key aspects to consider include:

- State-of-the-Art Equipment

Assess whether the company utilizes advanced equipment capable of producing PCBs with high accuracy, including fine trace widths and small vias. This includes equipment for drilling, etching, plating, and imaging. Look for equipment that supports a high degree of automation to ensure consistency and repeatability. - Material Processing Capabilities

A reputable company should have the capacity to process a wide range of PCB materials, including FR-4, high-frequency laminates, flexible substrates, and metal core PCBs. Inquire about their experience with your specific material requirements. - Advanced Technology

Consider whether the company is using advanced technologies such as laser direct imaging (LDI), laser drilling, or controlled impedance manufacturing. - Automation and Control Systems

High levels of automation and process control are essential to ensure consistent quality and to lower manufacturing costs. The level of automation within the manufacturing process is a critical factor in determining a company's ability to scale production. - Maintenance and Calibration

Inquire about the company's maintenance schedule and calibration practices for their equipment. Properly maintained and calibrated equipment is essential for achieving consistent results and reducing the risk of manufacturing errors.

| Technology Aspect | Importance | Questions to Ask |

|---|---|---|

| Equipment Sophistication | Directly affects PCB accuracy and features. | What is the age and capability of your equipment? Do you utilize automated processes? |

| Material Processing | Ensures boards can be made with diverse substrates. | What materials are you capable of processing? Have you worked with [your material]? |

| Advanced Tech | Enhances manufacturability of complex designs | Do you offer LDI, laser drilling, and controlled impedance? |

| Automation | Ensures consistent production and scale. | How automated is your production line? Is there process control monitoring? |

| Maintenance | Maintains accuracy and reduces errors. | What is your equipment maintenance and calibration protocol? |

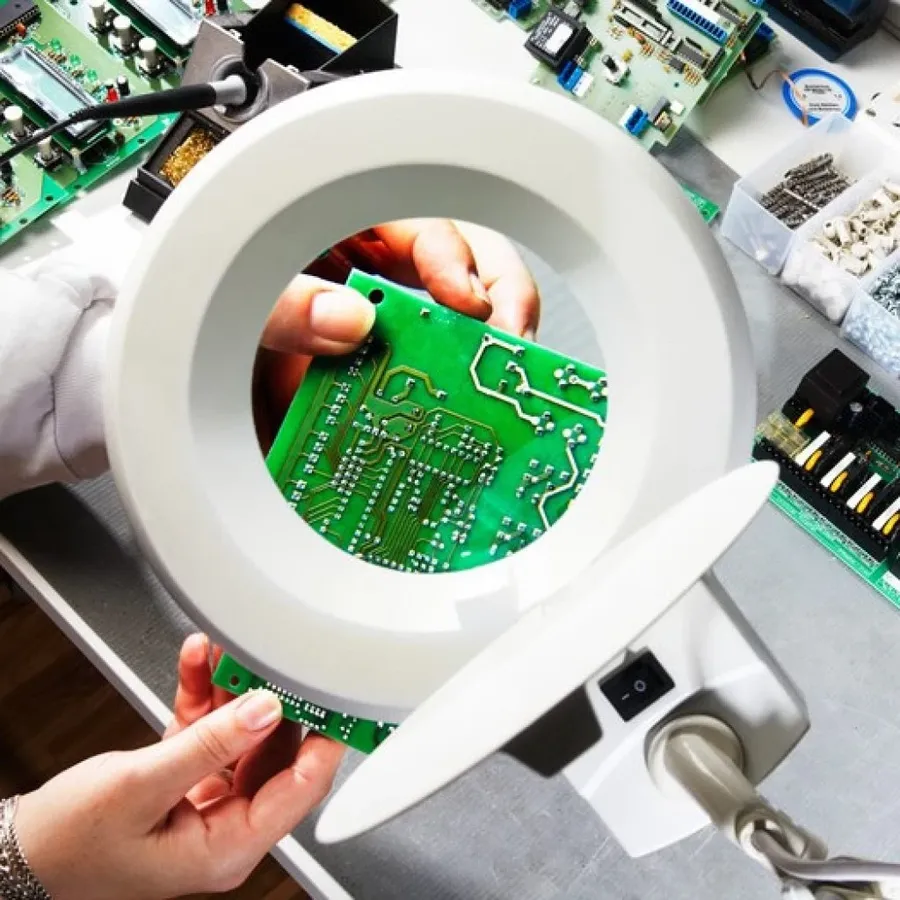

Quality Control and Certifications

Rigorous quality control and adherence to industry certifications are paramount when selecting a PCB electronics company. These practices directly impact the reliability and long-term performance of the printed circuit boards (PCBs), making them a critical evaluation factor.

The adherence to quality control standards is not merely a matter of compliance; it is an indicator of a PCB company's commitment to excellence and their ability to consistently produce high-quality, dependable PCBs. This commitment should encompass all stages of production, from design review to final inspection. Certifications provide an additional layer of assurance that the company adheres to established industry best practices.

- Key Quality Control Processes

A comprehensive quality control system will incorporate processes such as: design rule checks (DRC), automated optical inspection (AOI), in-circuit testing (ICT), and functional testing. These processes detect potential defects early in the production cycle, reducing the chance of costly errors further down the line. - ISO 9001 Certification

ISO 9001 is an internationally recognized standard for quality management systems. A company with ISO 9001 certification demonstrates that it has implemented robust quality management practices throughout its operations. It provides a framework for continuous improvement and ensures that the company can consistently meet customer requirements. - IPC Standards Adherence

IPC standards are a suite of industry-specific standards developed by the IPC - Association Connecting Electronics Industries. These standards cover various aspects of PCB manufacturing, including design, fabrication, assembly, and testing. Adherence to IPC standards signifies that a company is using industry-accepted best practices. - Material Traceability

An effective quality control system should include traceability of materials. This allows for any material or manufacturing process-related issues to be identified and addressed efficiently. Traceability is important for isolating a failure to determine the root cause and can help in corrective actions. - Statistical Process Control (SPC)

SPC is a quality control methodology that employs statistical methods to monitor and control a process. By using SPC, PCB manufacturers can achieve consistent product quality by addressing sources of variation and taking corrective actions.

| Certification/Standard | Description | Benefit |

|---|---|---|

| ISO 9001 | International standard for quality management systems | Demonstrates robust quality practices and continuous improvement |

| IPC Standards | Industry-specific standards for PCB manufacturing | Ensures best practices in design, fabrication, and assembly |

| UL Certification | Safety certification by Underwriters Laboratories | Indicates that the PCBs meet safety requirements for end use |

| RoHS Compliance | Restriction of Hazardous Substances Directive | Guarantees that the PCB is free from certain hazardous materials |

Cost and Payment Terms Analysis

While cost is a significant factor in choosing a PCB electronics company, it should not be the sole determinant. A comprehensive analysis of quotes should consider the total cost, including fabrication, assembly, and testing, as well as lead times, payment terms, and any potential hidden fees. Prioritizing long-term value over the lowest initial cost is crucial for ensuring both quality and consistency.

| Factor | Description | Considerations |

|---|---|---|

| Total Cost | Encompasses all expenses, from raw materials to final testing. | Breakdown of costs to understand each element, evaluate quantity discounts, and consider tooling costs. |

| Lead Times | The time taken from order placement to delivery. | Balance lead times with project timelines, understand expedited options, and plan for potential delays. |

| Payment Terms | Agreements on payment schedules and methods. | Discuss payment milestones, preferred methods, and credit facilities. |

| Hidden Fees | Unforeseen costs that can arise during production. | Clarify all potential additional charges, such as testing, engineering change orders, and shipping. |

| Long-Term Value | The overall cost-effectiveness considering quality, reliability, and consistency. | Evaluate the cost of rework, defects, and delayed project completion. |

Frequently Asked Questions About PCB Electronics Companies

Navigating the selection process for a PCB electronics company can raise numerous questions. This section addresses common inquiries to provide clarity and aid in making informed decisions. The 'best' choice depends heavily on project specifics, and size doesn't always equate to suitability.

- What is the best PCB company?

The 'best' PCB company is subjective and contingent on your specific project needs. Factors include the complexity of the board, required volumes, materials, and required delivery timelines. Instead of seeking the single 'best,' focus on finding a company that aligns with your specific requirements and budget. Research capabilities, certifications, and past performance are important to consider. - Who is the largest PCB manufacturer in the USA?

Identifying the absolute 'largest' PCB manufacturer can be challenging as market positions shift, and private companies often do not publicly report their sales volumes. Size does not determine the suitability of a PCB partner, or necessarily indicate superiority in quality, innovation, or expertise. A company may be large due to focusing on high-volume standard boards, which might not be suitable for complex designs or low-volume high-mix production. It is far better to look at the company's suitability in terms of their skills and abilities. - What does PCB stand for in electronics?

PCB stands for Printed Circuit Board. It is a foundational component in nearly all electronic devices, serving as a structural base to which electronic components are attached and a conductive pathway to interconnect those components. PCBs are the backbone of all modern electronics. - What is PCB in company?

In the context of a company, 'PCB' typically refers to the Printed Circuit Boards that the company designs, manufactures, or uses in its products. It can also refer to a department or group within a company that is responsible for PCB design, fabrication, or assembly. The use of PCBs is generally an indication that a company deals with the manufacturing of electronics or some sort. - Should I choose a domestic or international PCB manufacturer?

The choice between domestic and international PCB manufacturers involves trade-offs. Domestic suppliers often offer faster turnaround times, better communication, and potentially stricter quality control, but often at a higher cost. International manufacturers, particularly from Asia, often provide more competitive pricing, however, communication may be more challenging, and lead times may be longer. Supply chain stability, risk tolerance, and communication styles all factor into this decision. - What certifications should a PCB electronics company have?

Key certifications include ISO 9001, demonstrating a commitment to quality management systems, and IPC standards (e.g., IPC-A-600 for acceptability of printed boards), which are the benchmark for PCB manufacturing. Specific certifications related to your industry (e.g., automotive or aerospace) may also be necessary. The presence of these indicates that the company has implemented effective processes to deliver consistent and high-quality products. - How do I assess a PCB company's technology and capabilities?

Evaluate the company's equipment and processes for high-precision manufacturing. Look for advanced technologies like SMT (Surface Mount Technology), fine-line trace width, and capabilities with complex materials. Ask them about their process control, which ensures that your boards will be manufactured consistently with each production run. Verify their ability to deliver the specific specifications you require by asking for data on their manufacturing equipment, and confirming their level of process expertise.

Building a Strong Partnership with Your Chosen PCB Company

Establishing a robust partnership with your PCB electronics company is paramount for ensuring the success of your project. This goes beyond a simple client-vendor relationship, aiming instead for a collaborative environment where clear communication, mutual understanding, and proactive problem-solving are prioritized. This approach reduces errors and drives higher quality outcomes.

- Communicate Clearly and Consistently

Provide detailed specifications, project requirements, and design files. Be responsive to questions and engage in open dialogues to ensure both parties are aligned. - Address Questions Promptly

Be proactive in answering any queries from the PCB company to facilitate smooth and quick manufacturing. Delays in communication will result in errors or delays in the project. - Provide Regular Feedback

Offer feedback on prototypes and finished PCBs. This helps refine the process, meet your quality standards, and improve future projects. - Regular Check-ins

Schedule regular meetings to review progress, discuss any challenges, and align project timelines. This provides more control over the production. - Share Project Goals and Challenges

Communicate overall business and project goals, and be transparent about potential challenges. The PCB company can offer solutions or alternatives when issues arise.

Selecting the right PCB electronics company is critical to the success of your project. By carefully considering the factors mentioned in this article—from understanding your specific needs to thoroughly evaluating potential partners—you can ensure you partner with a company that not only meets your technical requirements but also contributes to your project's overall success. A reliable PCB partner, like our [pcb electronics company], will provide you with the peace of mind that your PCB production is in capable hands, allowing you to focus on innovation and growth.

AnyPCBA

AnyPCBA