Choosing the Right PCB Fabrication Company: A Comprehensive Guide

In today’s interconnected world, printed circuit boards (PCBs) form the backbone of electronic devices. Selecting the right PCB fabrication company is a critical step in bringing any electronic product to life. This article explores key considerations, various services provided, and offers practical advice to help engineers, hobbyists, and businesses choose a PCB fabrication partner that aligns with their project requirements. Through a detailed look at the market, we aim to connect innovative ideas with top-tier manufacturing capabilities.

Understanding Your PCB Needs

Selecting the right PCB fabrication company hinges on a thorough understanding of your project's specific demands. Before initiating contact with any fabricator, a detailed assessment of your requirements is crucial to ensure that the chosen partner can deliver a product that meets your specifications, budget, and timeline.

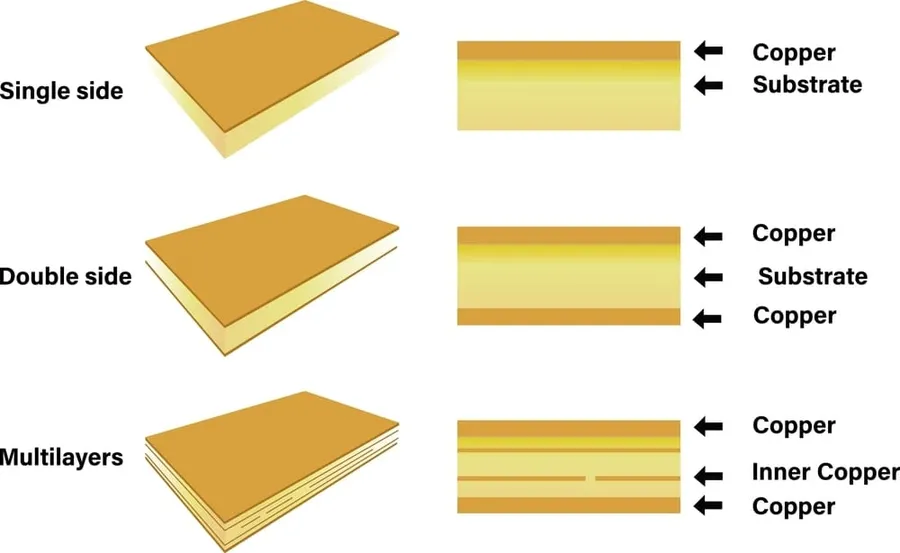

- Board Type

Determine the necessary complexity: single-layer for simple circuits, double-layer for increased density, or multi-layer for complex, high-density designs. Each type impacts cost and lead time. - Size and Dimensions

Accurately measure the required board dimensions. Larger boards often increase fabrication costs and may have specific panelization requirements. - Complexity

Evaluate the density of the design, including the number of components, trace width and spacing, and via requirements. Highly complex PCBs may need specialized processes. - Material Requirements

Specify the base material of the PCB, most commonly FR-4 for standard applications. Other materials, such as Aluminum or high-frequency laminates, may be necessary for certain applications. - Quantity

Clarify whether you need a single prototype, small-batch manufacturing, or mass production. The quantity directly affects the per-unit cost and manufacturing process. - Application-Specific Needs

Consider factors like impedance control, thermal management, and specialized surface finishes if applicable to your application.

Key Services Offered by PCB Fabrication Companies

PCB fabrication companies offer a range of services that extend beyond simply manufacturing circuit boards. These services can significantly impact the success and efficiency of your electronics project. Understanding what each service entails, and determining which are necessary for your specific needs, is crucial for selecting the right fabrication partner.

- PCB Design and Layout

This service involves translating your circuit schematic into a physical PCB layout. It includes component placement, trace routing, and ensuring the design adheres to manufacturing guidelines. Some companies offer comprehensive design services, while others focus solely on manufacturing. Design is paramount to the manufacturability and performance of the PCB. - Prototype PCB Fabrication

Prototype fabrication involves producing a small number of boards for testing and validation. This allows you to identify and fix any design flaws before moving to mass production. Fast turnaround times and cost-effectiveness are essential for this stage. It is a crucial step in minimizing the risk associated with design. - PCB Assembly

This service involves mounting electronic components onto the fabricated PCBs. It ranges from manual assembly for small prototypes to automated processes like SMT (Surface Mount Technology) assembly for large-scale production. PCB assembly can significantly speed up development and production cycles. The precision and quality of this service is essential to the performance of the final product. - SMT Assembly

SMT (Surface Mount Technology) assembly is a specific type of automated PCB assembly that uses machines to precisely mount surface mount components onto the PCBs. SMT assembly is essential for complex and high-density boards. It is also vital for mass production of consumer electronics. This requires specialized machinery and expertise. - Testing Services

Testing services ensure the quality and functionality of the assembled PCBs. This includes electrical tests, functional tests, and in-circuit testing (ICT). Comprehensive testing is critical for ensuring that the PCB meets the design specifications. Testing services can also greatly help to locate defects early, which can significantly reduce costs. - Supply Chain Management

This service includes the sourcing, storage, and delivery of electronic components needed for the PCB assembly. Effective supply chain management minimizes delays and ensures component quality. Proper management reduces costs and ensures consistent production.

Evaluating PCB Fabrication Capabilities

Selecting a PCB fabrication company requires a thorough assessment of their manufacturing capabilities to ensure they align with your project's technical specifications. Key parameters to evaluate include minimum track width and spacing, layer count, material options, surface finish, and tolerances. These factors directly influence the performance and reliability of your final product.

| Capability | Description | Importance |

|---|---|---|

| Minimum Track Width/Spacing | The smallest width of conductive traces and the distance between them. | Crucial for high-density designs and signal integrity; directly affects the board's density and performance. |

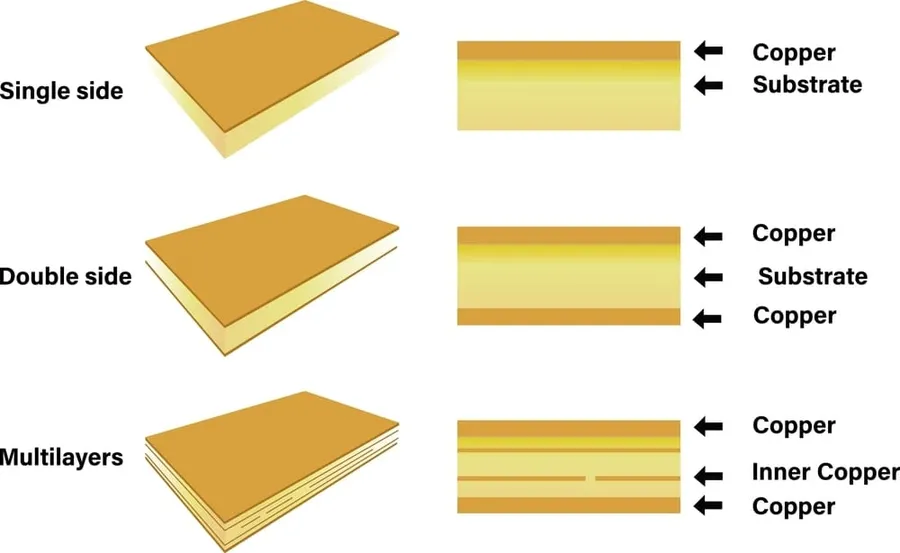

| Layer Count | The number of conductive layers in the PCB. | Determines the complexity of the routing; more layers allow for more complex designs. |

| Material Options | Types of materials used for the PCB substrate (e.g., FR4, Aluminum). | Affects electrical, thermal, and mechanical properties. FR4 is common, while Aluminum provides better heat dissipation. |

| Surface Finish | The type of plating or coating applied to the PCB pads (e.g., HASL, ENIG). | Ensures solderability and corrosion resistance. Different finishes have different cost and performance characteristics. |

| Tolerance | The allowable variation in the manufacturing process. | Impacts the accuracy and consistency of the boards, particularly critical for high-precision applications. |

Turnaround Time and Lead Times

Turnaround time, the duration from order placement to when PCBs are ready for shipment, is a critical factor when selecting a PCB fabrication company. It's essential to evaluate both standard lead times and the availability of expedited services, particularly for time-sensitive projects where delays can be costly.

| Factor | Description | Impact |

|---|---|---|

| Standard Lead Time | The typical time required for PCB fabrication under normal conditions. | Affects overall project timelines; longer lead times can push back project completion. |

| Expedited Services | Faster turnaround options for urgent projects, often at a premium. | Critical for quick prototyping and addressing unexpected delays. |

| Prototype Turnaround | Lead time specifically for initial prototype boards. | Essential for validating designs quickly and iterating if needed. |

| Production Run Turnaround | Time required for fabricating larger quantities for mass production. | Impacts manufacturing schedules and inventory management. |

| Factors Affecting Lead Times | Complexity, layer count, material availability, and current workload of the fabrication company | Can cause fluctuations in quoted lead times |

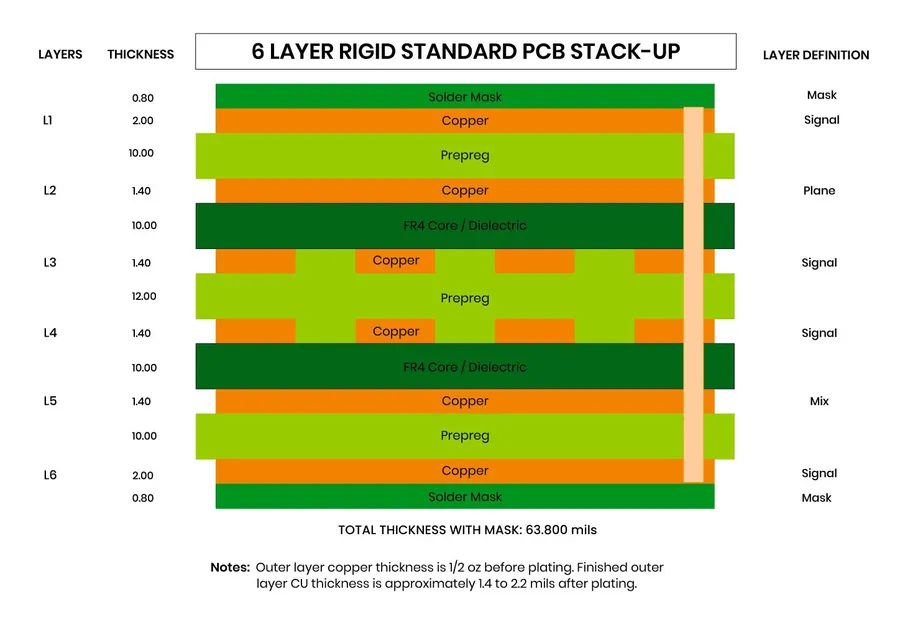

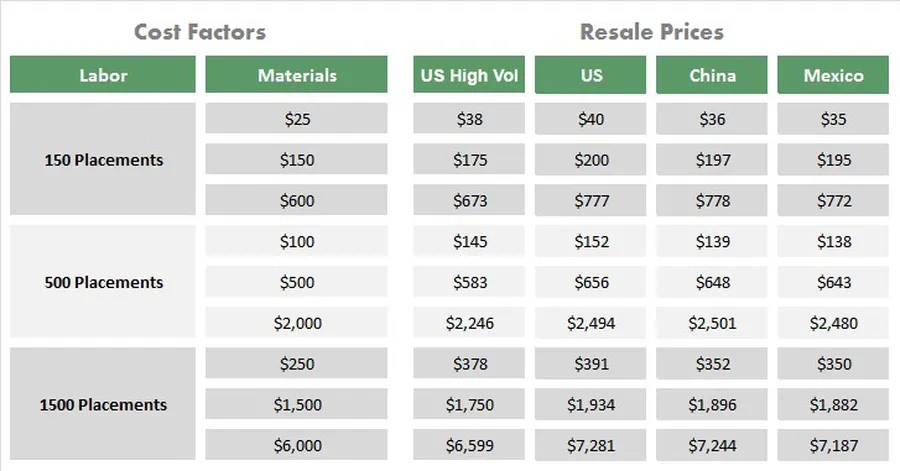

Cost Analysis: Balancing Price and Quality

Selecting a PCB fabrication company requires a meticulous cost analysis that extends beyond the per-board price. A thorough evaluation includes assessing setup costs, testing fees, and other service charges to ensure the overall value aligns with the project's requirements without compromising quality.

A comprehensive cost analysis is crucial when choosing a PCB fabrication partner. It's essential to understand all potential costs and how they affect the project budget.

- Per-Board Cost:

The unit price for each PCB is a primary factor, but it is not the only cost determinant. Lower per-board costs may mask higher overall expenses, especially for smaller runs. - Setup Costs:

These costs are incurred before manufacturing begins, encompassing tooling, preparation, and program setup. While they are often one-time fees, they should not be overlooked, particularly for prototype or small-batch projects. - Testing Costs:

Costs associated with electrical testing, functional testing, or other types of quality verification. Testing is vital to ensure reliability and avoid costly failures but will add to the overall project expenditure. - Other Service Charges:

Consider charges for additional services like design rule checking, panelization, or expedited shipping. These can significantly impact the total project cost, so transparent and detailed cost breakdowns are essential.

Prioritizing companies that demonstrate a commitment to quality alongside competitive pricing is essential. Value is defined by the total cost of ownership, including reliability, rather than solely the initial price. A lower initial cost should not compromise the long-term performance and reliability of the final product.

Quality Control and Certifications

Rigorous quality control and adherence to industry certifications are paramount when selecting a PCB fabrication company. These measures ensure the long-term reliability and performance of your printed circuit boards, minimizing the risk of defects and failures.

A robust quality control process should encompass several stages, from raw material inspection to final product testing. Key aspects include:

- Incoming Material Inspection:

Verifying that all raw materials (laminates, copper foils, etc.) meet specified standards before fabrication begins. - In-Process Inspection:

Regular checks at each stage of the manufacturing process to catch any deviations early. - Automated Optical Inspection (AOI):

Using cameras to scan the boards and detect defects such as shorts, opens, and incorrect component placement. This is crucial for multilayer PCBs and fine-pitch components. - Electrical Testing:

Checking the electrical integrity of each board using dedicated test equipment (e.g., flying probe or bed-of-nails testers). This verifies connectivity and identifies shorts and opens. - Final Visual Inspection:

Performing a final human check of the fabricated PCB before shipment, ensuring all specifications are met. - Dimensional Accuracy Checks:

Verifying the physical dimensions of the board are within the required tolerances, preventing fit issues during assembly.

Relevant certifications indicate a commitment to quality management:

- ISO 9001 Certification:

Indicates that the company has a quality management system in place. This means that processes are documented and standardized, resulting in more consistent products. - UL Certification:

If UL-certified, PCB fabrication companies have proven that their boards meet stringent safety standards, which is especially important in safety-critical applications. - IPC Standards:

Adherence to IPC standards (the Association Connecting Electronics Industries), is a key indicator that the company follows industry best practices. Specifically, check for IPC-A-600 (Acceptability of Printed Boards) and IPC-6012 (Qualification and Performance Specification for Rigid Printed Boards).

Prioritizing PCB fabrication companies with documented quality processes and relevant certifications ensures a higher degree of reliability in your finished products. Always request documentation of certifications and test results as part of your due diligence. In addition, consider asking for samples to evaluate the company's manufacturing capabilities before committing to large-scale production.

Customer Support and Communication

Effective customer support and clear communication are paramount when selecting a PCB fabrication company. A responsive and communicative partner not only aids in resolving technical issues but also significantly contributes to the smooth and timely progression of your project. The ability to quickly receive assistance and clear information can prevent costly delays and misunderstandings.

Key aspects to evaluate include the availability of technical support, the responsiveness of their communication channels (email, phone, chat), and the clarity of their communication practices. A reliable partner should be proactive in addressing concerns and providing regular project updates.

Frequently Asked Questions About PCB Fabrication Companies

This section addresses common queries regarding PCB fabrication, providing concise and informative answers to assist you in making well-informed decisions when selecting a PCB fabrication partner.

- How much does PCB fabrication typically cost?

The cost of PCB fabrication varies significantly depending on several factors, including the complexity of the board (number of layers, feature sizes), the materials used (FR4, aluminum, etc.), the quantity of boards ordered, and the chosen fabrication company. Prices can range from a few dollars for simple, single-layer boards in large quantities to hundreds or even thousands for complex, multi-layer designs in smaller volumes. Obtaining quotes from multiple companies is crucial for accurate cost assessment. - Which PCB fabrication company is considered the best for small batch production?

The 'best' PCB fabrication company for small batches depends largely on specific project requirements. Some companies excel in rapid prototyping with quick turnaround times, while others may prioritize high-quality materials or intricate design capabilities. JLCPCB and PCBWay are often cited for cost-effectiveness, while companies like Sierra Circuits or Sunstone Circuits may be preferred for their quality and advanced capabilities. It's best to evaluate based on project needs rather than a generic 'best' option. - Who is the largest PCB manufacturer in the USA?

Identifying the single 'largest' PCB manufacturer in the USA can be difficult due to the private nature of many companies. However, companies like TTM Technologies and Sanmina Corporation are often cited as major players in the US market. These companies offer a wide range of PCB fabrication and assembly services, catering to large-scale production demands, but it is essential to verify this information based on their updated revenue and output reports. - What exactly does PCB fabrication involve?

PCB fabrication is the process of creating a physical printed circuit board from a digital design. It involves several steps, including: (1) applying a copper layer to a substrate material like FR4, (2) etching away unwanted copper to create the circuit traces and pads, (3) drilling holes for component insertion or vias, (4) applying solder mask and silkscreen layers, and (5) applying the final surface finish (e.g. HASL, ENIG). The process combines chemical, mechanical, and optical methods to produce the final product. - What is the standard material used for PCBs?

The most common material used in PCB fabrication is FR-4, a composite material made of woven fiberglass cloth and epoxy resin. FR-4 is popular due to its good mechanical and electrical properties, flame retardancy, and relatively low cost. However, specialized materials like aluminum, polyimide, and Rogers are used in applications that require high thermal conductivity, flexibility, or high-frequency performance. - What is the typical turnaround time for PCB prototyping?

The turnaround time for PCB prototyping can vary significantly based on several factors including the fabrication company, the complexity of the board, and any additional services requested. Simple prototype PCBs might be produced in as little as 24-48 hours if expedited services are used, while more complex designs might take up to a week or two to complete. It's important to check with your specific manufacturer for their current lead times.

Comparing Top PCB Fabrication Companies

Selecting the right PCB fabrication company is crucial for the success of any electronics project. This section provides a comparative analysis of leading PCB fabrication companies, highlighting their strengths and weaknesses across key parameters like cost, quality, speed, and service offerings. This comparison table is intended to assist users in making an informed decision tailored to their specific project requirements.

| Company | Cost | Quality | Speed | Services | Strengths | Weaknesses |

|---|---|---|---|---|---|---|

| JLCPCB | Very Competitive | Good for standard PCBs | Fast Turnaround | Prototype, Small Batch, SMT Assembly | Low cost, fast turnaround, wide service offering | Quality can vary on complex designs, customer service can be slow |

| PCBWay | Competitive | High Quality | Moderate Turnaround | Prototype, Small Batch, SMT Assembly, Advanced PCBs | Good quality, wide range of options, strong technical support | Slightly higher cost compared to JLCPCB |

| Sierra Circuits | Higher | Very High Quality | Moderate to Slow | Advanced PCB, HDI, Flex, Rigid-Flex | High-quality, specialized in advanced PCB technologies | Higher cost, longer lead times |

| Sunstone Circuits | Moderate to Higher | High Quality | Moderate Turnaround | Prototype, Small Batch, Advanced PCB | Good quality, reliable service, user-friendly platform | Higher price for larger volumes |

| Advanced Circuits | Higher | High Quality | Moderate Turnaround | Prototype, Small Batch, Advanced PCB | High-quality, good for complex designs, strong support | Higher cost, not ideal for very small orders |

Choosing the right PCB fabrication company is paramount for a successful project. By carefully evaluating your needs, considering the available services, and comparing different companies, you can secure a reliable partner capable of delivering high-quality PCBs. Companies like JLCPCB offer a good balance of cost, quality, and speed, but the ideal choice depends on your unique project requirements. Selecting a reputable PCB fabrication company is a strategic step that can significantly impact the cost, quality and time-to-market of your electronic products, ensuring your designs come to life as intended.

AnyPCBA

AnyPCBA