Choosing the Right PCB Vendors: A Comprehensive Guide for 2024

In today's tech-driven world, printed circuit boards (PCBs) are the backbone of nearly every electronic device, from our smartphones to sophisticated medical equipment. Choosing the right PCB vendor is crucial for the success of your project. This article will delve into the factors you need to consider when selecting a PCB vendor, comparing options and offering guidance for both prototyping and full-scale manufacturing, helping you navigate the options and connect with the right PCB vendor for your specific needs.

Understanding Your PCB Needs

Selecting the right PCB vendor hinges on a comprehensive understanding of your specific project requirements. This preliminary assessment is crucial for aligning your needs with a vendor's capabilities, ensuring a successful and cost-effective outcome.

- Board Complexity

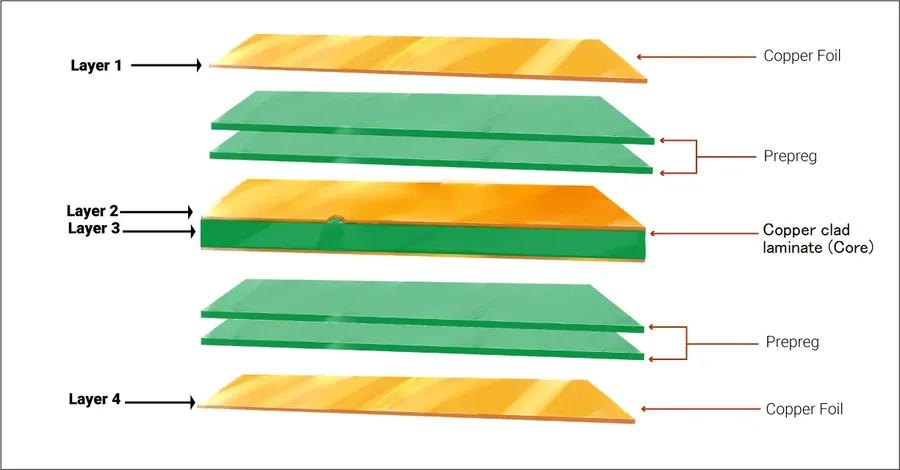

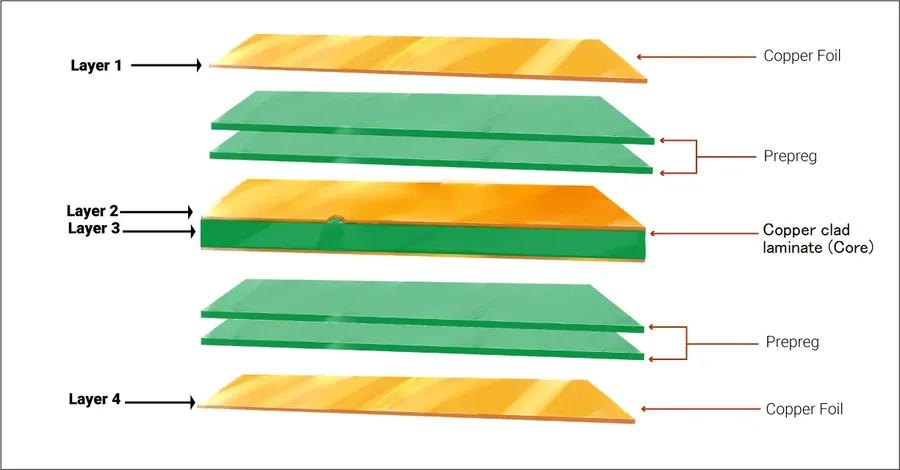

Evaluate the intricacy of your PCB design. This includes the number of layers, component density, trace width and spacing, and the presence of complex features like blind or buried vias. High complexity boards require vendors with advanced manufacturing capabilities. - Required Materials

Specify the necessary base material (e.g., FR-4, Rogers, aluminum), copper thickness, surface finish (e.g., ENIG, HASL), and solder mask colors. Different materials offer varying performance characteristics regarding impedance, thermal management, and high-frequency applications. - Tolerances

Define the acceptable variations in PCB dimensions, trace widths, and spacing. Critical applications require tighter tolerances to ensure proper functionality, impacting both the cost and manufacturing process. Adhering to IPC standards will help in communicating the requirement precisely. - Quantity

Determine the number of PCBs needed for your project. This could range from a few prototypes to high-volume production. The order volume significantly affects pricing and vendor selection, some vendors focus on low-volume prototype while others are specialized in high-volume production. - Timelines

Establish a clear timeline for project completion. Define the required lead time for manufacturing and delivery. Some vendors offer expedited services for quick-turn prototypes, while others have more standard lead times for large production runs. Consider potential delays to mitigate risks.

Key Factors to Consider When Evaluating PCB Vendors

Selecting the right PCB vendor is crucial for project success, requiring careful consideration of several key factors. These factors encompass not only the vendor's manufacturing capabilities but also their ability to meet specific project needs regarding timelines, materials, and budget. A thorough evaluation ensures that chosen vendors are aligned with both the technical and logistical demands of the project.

- Manufacturing Capabilities

Assess the vendor's ability to produce PCBs with the required complexity, including layer count, minimum trace width and spacing, via types, and surface finish options. The technologies that a vendor supports will directly impact your design options. For instance, some vendors may not offer microvias or advanced material options. - Lead Times

Evaluate the vendor's typical turnaround time for PCB fabrication and assembly. Shorter lead times are essential for rapid prototyping and time-sensitive projects, while reliable and consistent delivery schedules are critical for volume production. - Material Selection

Confirm that the vendor offers materials that meet your project requirements. This includes standard FR-4, but may extend to materials with specific thermal or electrical properties. Certain materials like Rogers or Polyimide, will affect high-frequency performance or flexible applications. - Pricing

Compare the cost of PCB fabrication and assembly across vendors, considering both unit cost and any associated fees, such as tooling and testing charges. Consider the long-term cost implications, including potential price breaks for volume orders. The lowest initial price may not represent the best long-term value. - Quality Control

Check if the vendor has robust quality control systems, such as ISO certifications and automated optical inspection (AOI). Quality is non-negotiable in reliable PCB manufacturing. Inquire about their defect rate and process control measures, such as 100% E-Test before shipping. - Customer Support

Evaluate the vendor's responsiveness and willingness to provide support during the design and manufacturing process. Effective communication can greatly affect the efficiency of the production process and the final product quality. - Geographical Location

Consider the vendor's location, factoring in shipping costs and times, as well as time zone differences for communication efficiency. Depending on whether you need domestic or international vendors for your project goals, the location can affect timelines.

Top PCB Vendors: A Comparative Analysis

Selecting the right PCB vendor is crucial for the success of any electronics project. This section provides a detailed comparative analysis of leading PCB vendors, focusing on their strengths, weaknesses, specializations, and geographical coverage. This information is designed to empower readers to make informed decisions tailored to their specific needs and project requirements.

| Vendor | Strengths | Weaknesses | Specialization | Geographical Coverage |

|---|---|---|---|---|

| JLCPCB | Cost-effective, fast turnaround, good for prototyping and small to medium batch production. | Limited material selection, may have challenges with complex boards. | Prototyping and small to medium batch PCB manufacturing. | Global, with a strong presence in Asia, serving worldwide customers. |

| PCBWay | Wide range of services (including SMT assembly), good online platform, offers a variety of materials. | Potentially higher cost compared to JLCPCB for basic PCBs, lead times can vary. | Full-service PCB manufacturing and assembly, caters to diverse needs from prototyping to production. | Global, with strong presence in Asia, serving customers worldwide. |

| Allpcb | Fast delivery, high precision capabilities, supports multilayer PCB production, good quality. | Pricing may be higher than JLCPCB for basic PCBs. | Specializes in complex PCBs, high-precision manufacturing and quick-turn prototypes. | Primarily serves customers in Asia and Europe. |

| Seeed Studio Fusion | Strong community support, good for open-source hardware, flexible manufacturing options. | Can be pricier than other budget-focused manufacturers; quality control might be inconsistent. | Small-batch production and prototyping. | Global, but primarily caters to customers in Asia and North America. |

| Eurocircuits | Focus on high quality and reliability, wide selection of materials, good for complex PCBs. | Higher price point, longer lead times than some other vendors. | Advanced PCBs for industrial and professional applications. | Strong presence in Europe and serves clients globally. |

PCB Vendors Specializing in Prototypes

For hobbyists and startups requiring rapid iterations, selecting a PCB vendor specializing in prototypes is crucial. These vendors prioritize quick-turnaround times and cost-effective solutions for initial design validation, often featuring streamlined processes optimized for small batch production and rapid delivery.

Key characteristics of prototype-focused PCB vendors include expedited manufacturing processes, lower minimum order quantities (MOQs), and user-friendly online platforms for easy ordering. Often, these vendors offer a limited range of materials and technologies, focusing on the most commonly used specifications to minimize complexity and turnaround times.

While not exhaustive, the following vendors are known for prototype PCB manufacturing:

- JLCPCB

Known for extremely competitive pricing and fast turnaround times, JLCPCB is a popular choice for hobbyists and small businesses seeking budget-friendly prototypes. They provide a wide array of fabrication options and assembly services and are very popular among the hobbyist community. They are located in China which can sometimes result in long shipping times depending on the destination. - PCBWay

PCBWay is another excellent option for prototypes, offering diverse manufacturing capabilities and a robust online platform. They provide a range of PCB materials and finishes and offer both bare boards and assembled boards. They are also located in China. They are more expensive than JLCPCB. - OSH Park

OSH Park focuses on low-volume production and prototype fabrication with a unique shared manufacturing approach, allowing for cost-effective small runs. They are located in the USA and focus on high quality boards with a purple soldermask, and have a longer lead time when compared to the Chinese vendors. - Seeed Studio Fusion

Seeed Studio Fusion offers a variety of prototype services, including PCB fabrication, assembly, and parts sourcing. They have fast turnaround times with a good balance of cost and quality. They are located in China. - Advanced Circuits

Based in the USA, Advanced Circuits offers quick-turn prototype services with a focus on quality and reliability, and they are a great option if you need a quick turnaround from a domestic supplier, however they are much more expensive than the Chinese options.

When selecting a prototype vendor, consider the following:

- Turnaround Time:

How quickly can the vendor manufacture and ship your boards? This is critical for rapid prototyping. - Cost:

Evaluate the total cost, including fabrication, shipping, and any extra charges for expedited service. - Minimum Order Quantities (MOQs):

Most prototype vendors cater to small MOQs, but confirming this is essential to avoid ordering more boards than needed. - Material Options:

Ensure that the vendor supports the necessary board materials (FR-4, Aluminum, etc.) and finishes (HASL, ENIG, etc.) needed for your specific application. - Design Rules and Constraints:

Verify that the vendor’s manufacturing capabilities align with your design requirements. Some vendors have specific design rule limitations or minimum trace/spacing requirements. - Assembly Services:

If needed, assess the vendor’s assembly capabilities and if they provide necessary services like SMT component placement. - Customer Support:

Responsive customer support can be invaluable, especially if issues arise during fabrication or shipping. Consider online chat or local presence if support is a priority.

Prototype PCB vendors are essential for early-stage hardware development, enabling quick and affordable design testing. Understanding their strengths and limitations will empower engineers and hobbyists to iterate rapidly and validate their concepts efficiently before scaling up for mass production.

PCB Vendors for High-Volume Production

For high-volume PCB production, selecting the right vendor is crucial to ensure consistent quality, reliability, and cost-effectiveness. These vendors must demonstrate robust capabilities in handling large orders, maintaining tight tolerances, and employing rigorous quality control measures.

Key factors to consider include the vendor’s manufacturing capacity, their adherence to industry standards (e.g., IPC standards), their ability to manage supply chain logistics, and their experience with large-scale projects. These vendors typically utilize advanced manufacturing equipment and automated processes to meet the demands of high-volume production.

Furthermore, reliability in delivery times and consistency in product quality are paramount. A robust quality control system, including in-process checks and final inspections, is essential to minimize defects and ensure the boards meet the required specifications. The vendor should also be capable of providing comprehensive traceability for each board.

| Factor | Description | Importance for High Volume |

|---|---|---|

| Manufacturing Capacity | Ability to produce large quantities within specified timeframes. | High |

| Quality Control | Rigorous processes to minimize defects and ensure product consistency. | High |

| Automation | Use of automated equipment for efficiency and precision. | High |

| Material Management | Efficient handling and storage of materials to ensure quality and traceability. | Medium |

| Logistics | Ability to manage large shipments and global distribution. | Medium |

| Supply Chain Management | Reliable sourcing and management of raw materials to ensure consistent production. | Medium |

| Industry Standards Compliance | Adherence to industry standards, e.g., IPC standards. | High |

Navigating PCB Assembly Services

PCB assembly services streamline the manufacturing process by integrating component placement and soldering directly onto the bare printed circuit boards. This unified approach offers significant advantages, including reduced production time, minimized errors, and enhanced reliability. Understanding the benefits and available vendor options is key to optimizing your product development cycle.

Key aspects of PCB assembly services include:

- Component Sourcing

Many vendors offer component sourcing, alleviating the burden of procuring parts independently. This ensures that all necessary parts are available for assembly. - Automated Assembly

Utilizing advanced machinery for precise component placement and soldering, reducing manual labor and improving assembly accuracy. - Testing and Inspection

Most vendors perform testing and inspection after assembly, which ensures the functionality of the PCB. - Turnkey Solutions

Comprehensive services where the vendor handles the entire process from PCB fabrication to final assembly and testing. This reduces complexity for the customer.

Choosing the right vendor for PCB assembly depends on factors like project complexity, required component types (SMT, through-hole, etc.), and assembly volumes. Consider vendors that can provide seamless integration with PCB fabrication for a more streamlined process.

| Feature | Benefits |

|---|---|

| Reduced Lead Times | Integrating assembly into PCB fabrication significantly shortens the overall production cycle. |

| Improved Quality Control | Unified services allow for better quality monitoring at all stages of production. |

| Cost Efficiency | Streamlined processes, reduce costs associated with separate assembly services. |

| Reduced Handling Errors | Automated assembly minimizes human errors in component placement and soldering. |

By utilizing PCB assembly services, you can focus on design and other critical aspects of your product development cycle, with the knowledge that your PCBs will be assembled correctly and efficiently.

Frequently Asked Questions About PCB Vendors

This section addresses common inquiries regarding PCB vendors, providing concise, insightful answers to assist in your selection process. We aim to clarify key questions and offer a deeper understanding of the PCB manufacturing landscape.

- Who is the largest PCB supplier globally?

Identifying the 'largest' PCB supplier depends on the metric used (revenue, production volume, etc.). However, companies like AT&S, TTM Technologies, and Unimicron consistently rank among the top global PCB manufacturers based on revenue and market share. These companies have extensive manufacturing capabilities, serving a broad range of industries. - Which PCB vendor offers the best quality?

The notion of 'best' PCB quality is subjective and depends on the specific application, required tolerances, and material needs. High-quality PCB manufacturing often involves rigorous quality control processes, advanced equipment, and strict adherence to industry standards. Vendors like TTM Technologies, for example, are known for their high-reliability PCBs often required in aerospace and defense applications. Choosing a vendor should align with your project-specific quality needs. - Who are the major manufacturers of PCBs?

Major PCB manufacturers include companies like JLCPCB, PCBWay, TTM Technologies, AT&S, and Unimicron. These companies represent a mix of different scales, specialties, and geographic footprints, offering a broad range of services and capabilities from prototyping to high volume production. Each caters to specific niches, industries, and geographic regions. - What does the acronym 'PCB' stand for?

PCB stands for Printed Circuit Board. It's a board made from non-conductive material, such as fiberglass or composite, with conductive pathways, tracks, and pads. These pathways connect electronic components, allowing electrical signals to pass between them. PCBs form the foundation of nearly all modern electronic devices. - How to choose the right PCB vendor for my project?

Selecting a PCB vendor involves careful consideration of multiple factors. First, you need to define your project requirements including board complexity, quantity, material specifications, and necessary tolerances. Then, evaluate vendor capabilities based on manufacturing capacity, quality control, lead times, and pricing. For prototypes, consider quick-turn vendors; for high-volume production, focus on reliability and consistency. Thorough research, reviews and potentially a trial run can help finalize your decision. - What are the differences between prototype and production PCB vendors?

Prototype PCB vendors specialize in quick-turn, small batch production often used for initial design verification. They usually offer faster lead times and lower costs for small volumes but may not be equipped to handle mass production. Production PCB vendors are designed for large-scale manufacturing, with robust quality control and consistent manufacturing processes, which ensures reliability for high-volume orders. Their pricing models are structured for large quantities and long-term production schedules. - What are the key factors to consider regarding PCB pricing?

PCB pricing is influenced by several key factors: board complexity (number of layers, density of features), material selection (FR-4, Rogers, etc.), quantity of boards, lead time required, and any additional fabrication steps such as surface finishes. Understanding how these elements impact costs is essential when comparing quotes from various vendors. Additionally, some vendors have more favorable rates at higher quantities, while others specialize in low-volume but highly complex boards. Understanding your pricing tradeoffs allows more informed vendor selection.

Future Trends in PCB Manufacturing and Vendor Selection

The printed circuit board (PCB) manufacturing landscape is rapidly evolving, driven by technological advancements and increasing demands for higher performance and sustainability. Understanding these emerging trends is crucial for making informed decisions when selecting PCB vendors in the coming years. These shifts encompass advancements in materials, manufacturing processes, and a heightened focus on environmentally responsible practices, all of which will significantly influence the future of PCB design and vendor relationships.

- Advanced Materials

The future will see a surge in the use of advanced materials like composites, ceramics, and flexible substrates, to meet the demand for higher performance, lighter, and more durable PCBs. These materials also offer superior thermal management capabilities, critical for high-density electronics. - Sustainable Manufacturing Practices

Environmental concerns are driving a push towards sustainable PCB manufacturing. This includes the adoption of eco-friendly materials, reduced waste, and energy-efficient manufacturing processes. Vendors who embrace these practices will become increasingly important in the future. - Miniaturization and High-Density Interconnects (HDI)

The demand for smaller and more powerful electronic devices is leading to the adoption of HDI technologies. These technologies enable denser circuitry, allowing for increased functionality in smaller form factors. Future PCB vendors must possess the equipment and expertise to handle these more complex designs. - Automation and Artificial Intelligence (AI)

Automation and AI are playing a bigger role in PCB manufacturing. AI driven defect detection, optimized layouts and predictive maintenance will result in increased productivity, lower production costs and improved accuracy. PCB vendors are expected to integrate these technologies to stay competitive. - Additive Manufacturing (3D Printing)

3D printing for PCB manufacturing is moving from niche application to a viable method for quick turnaround times and complex designs. This technology allows faster prototyping and more design freedom. The use of 3D printing will become more common among specialized vendors. - Integration of Embedded Components

Embedding components directly into PCBs reduces size and improves reliability. This trend requires high precision manufacturing and will be offered by select vendors.

Actionable Steps for Selecting the Right PCB Vendor

Selecting the right PCB vendor is a critical step in ensuring the success of your electronics project. This process requires a structured approach, focusing on your specific needs and project goals. By following a step-by-step method, you can identify a vendor that aligns with your requirements in terms of quality, cost, and lead time.

- Define Your Project Requirements

Before reaching out to any PCB vendor, compile a detailed list of specifications. This includes the type of PCB (single-layer, multi-layer, flex), material (FR-4, aluminum, etc.), dimensions, layer count, copper thickness, surface finish, and any specific design rules. The more precise the requirements, the more efficient the vendor selection. - Identify Potential Vendors

Research and create a list of potential PCB vendors, considering factors such as location, specialization, and reputation. Utilize online resources, industry forums, and recommendations from peers. This initial list should be diverse to ensure a broad selection of services. - Request Quotations

Contact the potential vendors and request detailed quotations, ensuring you provide the exact requirements outlined in step one. Compare not just the price, but also lead times, shipping costs, minimum order quantities, and any tooling or setup fees. Make sure to check if the price quoted covers all the specs you need, including quality assurance tests and certifications. - Evaluate Vendor Capabilities

Assess the capabilities of each vendor, focusing on their manufacturing technology, equipment, and quality control systems. Verify their capacity to meet your technical and quantity needs, reviewing the machinery used and inspection procedures. Check if they have the necessary certifications (e.g., ISO) and positive feedback from clients. - Request Samples or Prototypes

Prior to placing a large order, request samples or prototypes from the top contenders. This step allows you to assess the quality of the PCB directly and identify any issues before they become costly. It’s also crucial to check their response time to feedback and how well they handle revisions. - Review Lead Times and Shipping

Confirm that the vendor can meet your project timelines. Verify the stated lead times and shipping options, factoring in potential delays. Make sure they use reliable shipping methods and can provide tracking. Discuss their order management processes and how they handle potential disruptions. - Consider Customer Support

Effective communication and responsive customer support can be crucial, especially when dealing with complex projects. Assess each vendor's responsiveness, communication style, and how quickly they resolve issues. A vendor who provides pre-sale and after-sale support is invaluable. - Negotiate and Finalize

Negotiate the pricing, terms, and conditions with your preferred vendor. Agree on all project requirements and confirm all terms and conditions before initiating the final contract. Make sure all responsibilities are outlined in the contract and that a dispute resolution process is in place. - Establish Ongoing Communication

After finalizing the contract, establish regular channels for communication with your vendor. Discuss any concerns, revisions or production progress and ensure they are receptive to any adjustments needed. A successful partnership relies on transparency and collaboration.

Choosing the right PCB vendor is a critical decision that impacts the quality and success of your electronic projects. By understanding your specific needs and evaluating factors like manufacturing capabilities, lead times, and pricing, you can confidently select a PCB vendor, such as JLCPCB or PCBWay, that aligns with your objectives. Whether you require rapid prototyping or large-scale production, making a well-informed decision ensures that your final product will meet the necessary performance and reliability standards. The future of PCB manufacturing is always evolving, so keeping up to date with the latest trends ensures you select the best PCB vendors, and maintain a competitive edge in your designs.

AnyPCBA

AnyPCBA