Decoding JLCPCB Pricing: A Comprehensive Guide to Costs & Savings

In today's fast-paced world of electronics, affordable and reliable PCB manufacturing is crucial. JLCPCB, a leader in the industry, offers competitive pricing for PCB fabrication and assembly. However, understanding the various factors that affect the final [jlcpcb price] is essential for budget-conscious projects. This article demystifies JLCPCB's pricing structure, exploring everything from base costs to hidden fees and providing practical strategies to keep your project costs down. Much like understanding the costs involved in building a house, knowing the intricacies of PCB manufacturing will empower you to make informed decisions and stay within your budget.

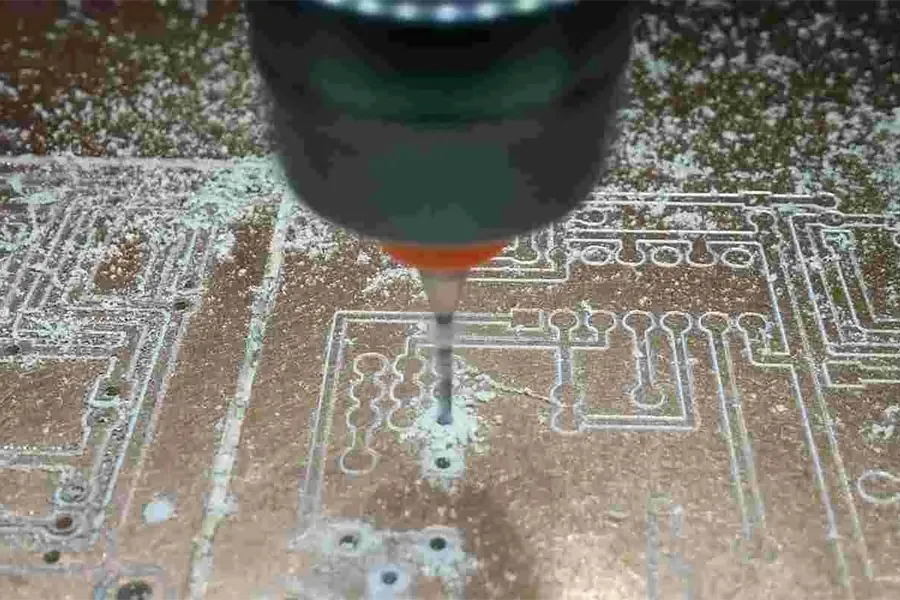

Understanding the Base PCB Fabrication Costs at JLCPCB

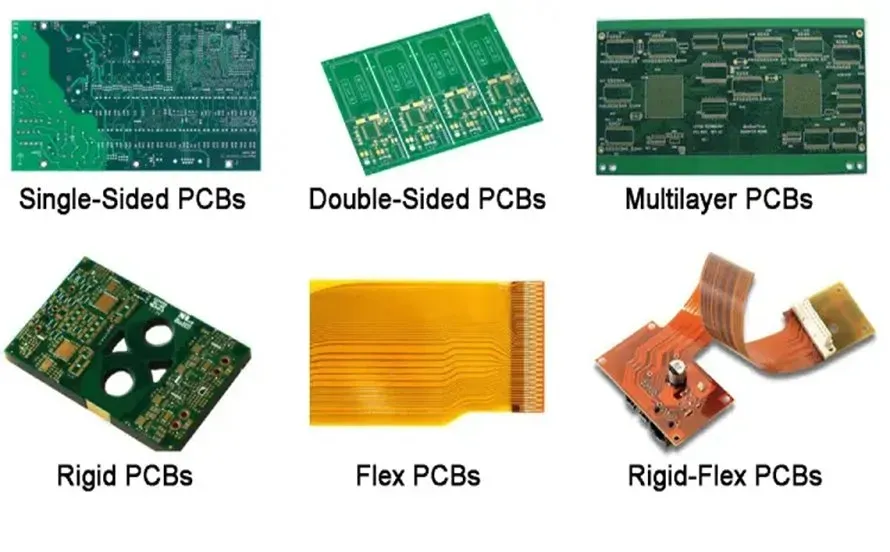

JLCPCB's base pricing for bare PCBs is determined by several key factors, primarily the layer count, board dimensions, and the quantity ordered. Starting at a low price point, JLCPCB offers a cost-effective solution for PCB fabrication. Understanding how these factors affect the overall cost is essential for budget-conscious projects.

The price per board decreases as the quantity increases, demonstrating the benefits of ordering in larger batches. The complexity of the board also plays a role, as increased layer counts inherently require more manufacturing steps and materials.

| Specification | Price Range (USD) | Notes |

|---|---|---|

| Single Layer PCB (100mm x 100mm) | $2 - $5 | Varies with quantity |

| Double Layer PCB (100mm x 100mm) | $5 - $10 | Varies with quantity and thickness |

| 4 Layer PCB (100mm x 100mm) | $10 - $20 | Price increases with complexity |

| Single Layer PCB (200mm x 200mm) | $5 - $10 | Varies with quantity |

| Double Layer PCB (200mm x 200mm) | $10 - $20 | Varies with quantity and thickness |

| 4 Layer PCB (200mm x 200mm) | $20 - $40 | Price increases with complexity |

It's also important to note that prices can fluctuate based on material type, PCB thickness, and copper weight. JLCPCB provides a range of options to accommodate different needs and budgets, and their online calculator gives immediate quotes for different combinations of these parameters.

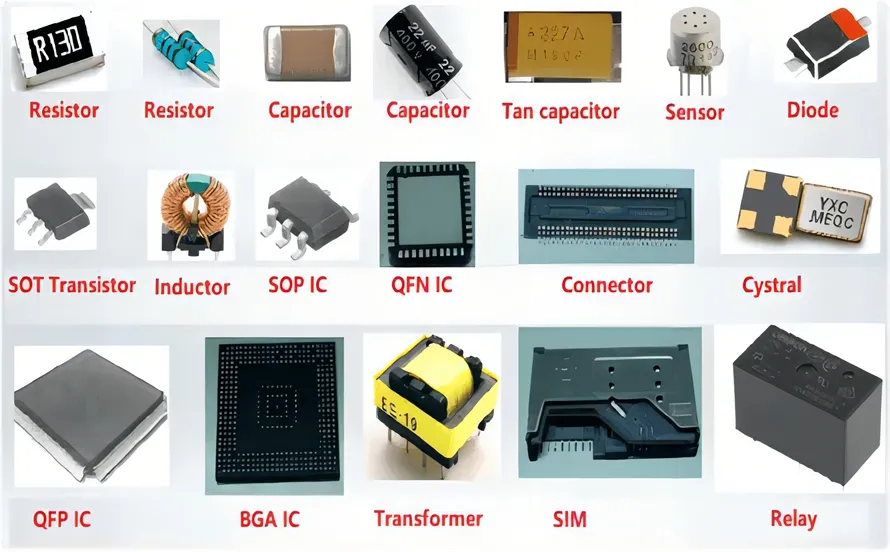

PCB Assembly Pricing Breakdown: Key Cost Components

Understanding the cost of PCB assembly at JLCPCB requires a breakdown of the various components that contribute to the final price. This section details these costs, from initial setup to the final assembly process, allowing you to see where your money goes and plan your budget effectively.

| Cost Component | Description | Typical Price Range (USD) | Factors Affecting Price |

|---|---|---|---|

| Setup Fee | One-time charge for setting up the assembly line. | $8 - $18 | Complexity of the board, number of unique components |

| Stencil Cost | Cost of creating a stencil for solder paste application. | $7 - $25 | Size of the board and the complexity of the solder pads. |

| SMT Assembly Fee per Joint | Charge for each surface mount component placed. | $0.001 - $0.015 | Type of component, number of pins, volume of components |

| Manual Assembly Fee per Component | Charge for through-hole and other manually placed components. | $0.03 - $0.20 | Complexity of component, number of pins, volume of components |

| Component Sourcing Fee | Cost to procure the required components. | Varies | Availability of components, sourcing method |

It's crucial to note that prices are approximate and can fluctuate based on specific project needs and JLCPCB’s current policies. Additionally, the total cost will depend significantly on the number of components and solder joints in the design, which will affect the SMT and manual assembly fees. Proper planning and optimization of the design can significantly impact these costs.

Hidden Fees and Extra Charges to Watch Out For

While JLCPCB offers competitive base pricing, several often-overlooked charges can significantly impact the final cost of your PCB order. Understanding these potential hidden fees is crucial for accurate budgeting and avoiding unexpected expenses. This section details these extra charges and provides strategies for minimizing their impact, helping you keep your overall JLCPCB price in check.

| Fee Type | Description | Cost Impact | Mitigation Strategies |

|---|---|---|---|

| Panelization Fee | Charges for combining multiple PCB designs or copies onto a single manufacturing panel. | Can significantly increase costs for small quantities or multiple designs. | Panelize designs yourself or reduce the number of separate designs. |

| Multiple Design Fee | Applied when different PCB designs are included in the same order, requiring separate handling. | Adds a per-design charge, potentially increasing costs for complex projects. | Consolidate designs when possible or order them separately to minimize multiple design charges. |

| Testing Fees | Costs associated with electrical testing services, such as Flying Probe or Bed of Nails testing. | Adds a significant cost, particularly for complex PCBs or large production runs. | Thoroughly check designs using simulation and testing your prototypes to avoid issues before final production. |

| Special Material Fees | Extra charges for non-standard PCB materials (e.g., aluminum substrate, high-Tg FR4, Rogers) | Increases cost based on the price and availability of the specialized material. | Stick to standard FR4 material when possible; consider the price difference carefully when selecting your materials. |

| Stencil Fee | Costs associated with the custom stencil needed for solder paste application | A mandatory fee for SMT assembly | Consider a single stencil for multiple boards that have the same components in the design. |

For example, ordering three different PCB designs each with 5 pieces can incur a 'multiple design fee' for each design. Similarly, choosing an expensive material like Rogers instead of FR4 can also dramatically increase the final jlcpcb price. For complex board designs, rigorous self-testing and simulation and use of standard materials will help avoid these cost increases.

Careful consideration during the design and order preparation phase can mitigate the impact of these hidden fees. Understanding these potential costs is essential for making informed decisions, allowing you to keep your budget in check and optimize your spending with JLCPCB. This results in more predictable and controlled expenses.

JLCPCB Shipping Costs: Factors and Optimization

Understanding JLCPCB's shipping costs is crucial for accurately estimating your total project expenses. These costs are not fixed and fluctuate based on several key parameters. By carefully considering these factors and employing strategic planning, you can effectively optimize your shipping expenses.

The primary drivers of JLCPCB shipping costs are:

- Weight of the Package

Shipping costs are directly proportional to the total weight of your order, including PCBs, components, and packaging materials. Heavier packages incur higher shipping fees. - Destination

Shipping rates vary significantly based on the destination country and region due to differing logistics networks and customs duties. Remote or less accessible areas may attract higher charges. - Shipping Method

JLCPCB offers multiple shipping options, from express to standard delivery. Each method has its associated costs, with faster options generally being more expensive.

Optimizing shipping costs involves balancing speed and expense. Here are some key strategies:

- Combine Orders

Consolidating multiple PCB orders into a single shipment can significantly reduce the per-board shipping cost. This strategy leverages economies of scale by amortizing the shipping costs across a larger number of boards. - Choose Slower Shipping Options

If your project timeline is flexible, opting for slower, more economical shipping methods can substantially lower costs compared to expedited services. Evaluate your deadlines carefully before choosing a delivery option.

JLCPCB offers several shipping methods, each with varying costs and delivery times. It is important to be aware of the options available.

| Shipping Method | Typical Delivery Time | Cost Consideration |

|---|---|---|

| Express (e.g., DHL, FedEx) | 2-7 business days | Higher cost, ideal for urgent projects |

| Standard (e.g., EMS) | 7-15 business days | Moderate cost, good for standard projects |

| Economy (e.g., Registered Airmail) | 15-30 business days | Lowest cost, suitable for non-urgent projects |

Note that the specific shipping options and their availability can vary depending on your location. It's advisable to review the available options and their estimated delivery times during the ordering process on the JLCPCB website. Always confirm with JLCPCB directly during checkout for the most accurate and up-to-date pricing and options.

JLCPCB's Special Offers, Discounts, and Promotions

JLCPCB frequently provides special offers, discounts, and promotions that can significantly reduce the overall cost of your PCB fabrication and assembly projects. These incentives are designed to attract new customers and reward loyal ones, providing opportunities to lower the [jlcpcb price] substantially. Understanding and utilizing these offers can lead to significant savings.

Promotions can vary widely, encompassing discounts on specific PCB types (e.g., single-layer boards, aluminum PCBs), special assembly service offers (e.g., free stencil, reduced pick-and-place fees), or seasonal sales. These promotions can significantly impact the final [jlcpcb price] you pay.

- New User Discounts

Often, JLCPCB provides introductory discounts for new users, encouraging them to try their services at a reduced cost. This is a great way to evaluate their capabilities without a large financial commitment. - Bulk Order Discounts

As with many manufacturers, placing larger orders often results in a lower per-unit price. JLCPCB usually offers discounts that increase with order quantity. This encourages users to consolidate projects. - Special Event Sales

JLCPCB may offer special promotions linked to holidays or anniversary events. These sales can provide excellent opportunities to save on PCB fabrication and assembly. - Free or Discounted Stencils

For SMT assembly, JLCPCB might offer free stencils or discounts on stencil costs for a certain number of boards or assemblies. This is a valuable savings opportunity since stencils often account for a substantial portion of the upfront assembly costs. - Promotions on Specific PCB Types

Periodically, certain types of boards, like aluminum PCBs, or boards with specialized materials, could be promoted. If a project aligns with such offerings, the [jlcpcb price] will be lower.

To stay informed about the latest deals and maximize your savings, it is essential to actively monitor JLCPCB's website, particularly their promotions page. You can also subscribe to their newsletters, which often announce these promotional offers. Consider following their social media channels, as deals are often announced on these platforms. Furthermore, regularly check forums and communities related to PCB design, as fellow users often post information about active promotions.

Comparing JLCPCB Pricing with Competitors like PCBWay

When selecting a PCB manufacturer, cost is a critical factor. This section offers a comparative analysis of JLCPCB's pricing against competitors like PCBWay, evaluating each option based on cost, quality, and service to determine which provides the best value. A direct comparison of the [jlcpcb price] relative to alternatives will help inform your decision.

| Feature | JLCPCB | PCBWay | Notes |

|---|---|---|---|

| Base PCB Price | Generally Lower | Competitive, sometimes higher | JLCPCB often leads with lower starting prices for standard specifications. |

| Assembly Costs | Competitive, can be lower for basic assembly | Competitive, more varied pricing tiers | Both offer assembly, but JLCPCB's base assembly pricing is often very aggressive. PCBWay offers more options, but might be pricier in some cases. |

| Shipping Costs | Variable, depends on method and weight | Variable, can be higher in some cases | Shipping costs can fluctuate based on delivery time and carrier for both, check shipping estimates carefully. |

| Engineering Fees | Relatively low | Can be higher | JLCPCB's engineering fees are often lower making it better for smaller runs or simple boards. |

| Stencil Costs | Lower, especially for combined orders | Competitive | For assembly orders, JLCPCB tends to offer cheaper stencil options for large quantity orders. |

| Quality | Good, consistent with IPC standards | Good, but can vary more | Both companies generally offer good quality, although, JLCPCB's quality control is quite strict. |

| Service | Good, responsive, but language can be an issue | Good, dedicated customer support | Both offer helpful support, but JLCPCB's customer service can vary in language comprehension |

| Parts Selection | Good for basic components | Wider selection | PCBWay gives more options in parts sourcing, while JLCPCB is good for basic component selection. |

| Specialized PCBs | Standard and rigid PCBs only | Flexible PCBs and other specialty options | If you require specialty boards, PCBWay might be better. JLCPCB is geared more toward standard designs. |

JLCPCB often wins on price, particularly for standard PCBs and basic assembly. However, PCBWay provides more options for advanced users, specialty PCBs, and a larger parts library, but these advantages might come at a higher cost. The best choice between JLCPCB and PCBWay depends on your specific project requirements. If your primary concern is keeping the [jlcpcb price] low for standard designs, JLCPCB is a strong contender. For projects that require more flexibility and customization, PCBWay might be a better choice.

Frequently Asked Questions About JLCPCB Pricing

Understanding JLCPCB's pricing structure can be complex. This section addresses frequently asked questions to clarify common concerns and provide clear, concise answers regarding their costs.

- What are the main factors influencing JLCPCB's price?

The primary factors influencing JLCPCB pricing include the PCB's layer count, dimensions, quantity, material type, and selected manufacturing options. For assembly services, additional costs are determined by the number of components, complexity, and required testing. Shipping costs are also influenced by the weight, destination, and selected service. - How much is the JLCPCB setup fee?

JLCPCB's setup fees generally depend on the type of service. For PCB fabrication, a small setup fee may apply per order but is often negligible for standard specifications. For SMT assembly, setup fees vary depending on the number of unique components and the complexity of the process. It's recommended to review the quote carefully before placing an order. - How much does 1 PCB cost?

The cost of a single PCB from JLCPCB depends greatly on its specifications. For basic PCBs with standard dimensions and a single or two-layer design, the price can be quite low, sometimes even a few dollars, especially with promotional offers. However, costs increase with more complex designs, multiple layers, and special materials. Always get a quote for your specific requirements. - Can I purchase components from JLCPCB?

Yes, JLCPCB offers a wide range of electronic components through their SMT assembly service. They can source and assemble parts based on your Bill of Materials (BOM). This simplifies the assembly process and reduces the need to manage parts from multiple suppliers. - Are there any hidden fees I should be aware of?

While JLCPCB strives for transparency, be aware of potential extra costs such as fees for panelization, multiple designs within the same order, specific material requests, and testing requirements. These extra services are usually detailed in the quote process but require careful review to avoid surprises. - What impacts the shipping cost on JLCPCB?

Shipping costs are primarily calculated based on the weight and volume of your package, the destination, and the chosen shipping method. Faster delivery options are usually more expensive, and costs increase for heavier items. Combining multiple orders can sometimes lead to savings on shipping. - How can I find the best offers from JLCPCB?

JLCPCB frequently runs special promotions and offers, often through their website and social media channels. Regularly check their website and subscribe to their newsletters to keep up-to-date on the latest deals and discounts, allowing you to reduce your overall cost on PCB fabrication and assembly.

Tips and Tricks for Reducing Your JLCPCB Costs

Optimizing costs with JLCPCB requires a strategic approach encompassing design, ordering practices, and service selection. By focusing on these key areas, users can significantly reduce their overall expenditure while maintaining the quality of their PCBs.

- Design for Cost-Effectiveness

Prioritize single-layer designs if possible, as they are generally cheaper than multi-layer boards. Minimize the use of vias and complex routing, and keep the board size as compact as functional requirements allow. These design choices will directly impact the [jlcpcb price]. - Panelization

If you require multiple boards, consider panelizing your design. JLCPCB charges per panel, not per individual board, so panelization can significantly reduce the cost per board, although extra charges may apply. - Bulk Ordering

Take advantage of volume discounts by ordering larger quantities of PCBs, where price per unit decreases significantly with increased order size. This strategy is especially cost-effective for designs with repeated use. - Component Selection

Carefully consider your component selection. Choosing commonly available parts can help to reduce costs. JLCPCBs parts library is vast, and using parts that they have in stock can often reduce assembly costs and speed up production. - Minimize Extra Services

Carefully evaluate the need for services like custom testing or specific material requirements. Opting out of unnecessary extra services will minimize the [jlcpcb price]. Ensure you only select the services that are required. - Standardized Designs

Where feasible, create modular designs that can be reused in multiple products. This reduces costs through reduced engineering time and the ability to order the same PCB in higher quantities. - Check for Promotions and Coupons

Regularly check JLCPCB's website and newsletters for coupons and special offers on various products or services. Applying these discounts can lower your costs.

By implementing these strategies, engineers and hobbyists can significantly reduce their PCB manufacturing costs without sacrificing the quality or functionality of their products.

Understanding JLCPCB's pricing structure is crucial for any electronics project. By carefully considering factors like PCB specifications, assembly requirements, and potential hidden costs, you can optimize your budget and ensure your project's success. From the initial $2 PCB fabrication cost, to assembly needs, every aspect can be managed to bring your designs to life without breaking the bank. Whether it’s a hobby project or a professional venture, this knowledge will empower you to make informed decisions, leverage discounts, and find the best value for your [jlcpcb price]. Keep exploring, keep innovating, and keep building!

AnyPCBA

AnyPCBA