Dragonfly PCB Printer Price: A Comprehensive Guide to 3D Electronics Printing

The Dragonfly PCB printer, a marvel of modern engineering, has revolutionized electronics prototyping by offering the ability to create complex circuit boards in-house. Its innovative technology combines 3D printing with conductive inks, allowing engineers to bring their designs to life with unprecedented speed and precision. However, a key question for any prospective buyer is: what about the dragonfly pcb printer price? In this article, we dive deep into the world of Dragonfly PCB printers, exploring their various models, capabilities, and, most importantly, the investment required to incorporate this transformative technology into your workflow.

Understanding the Dragonfly PCB Printer Technology

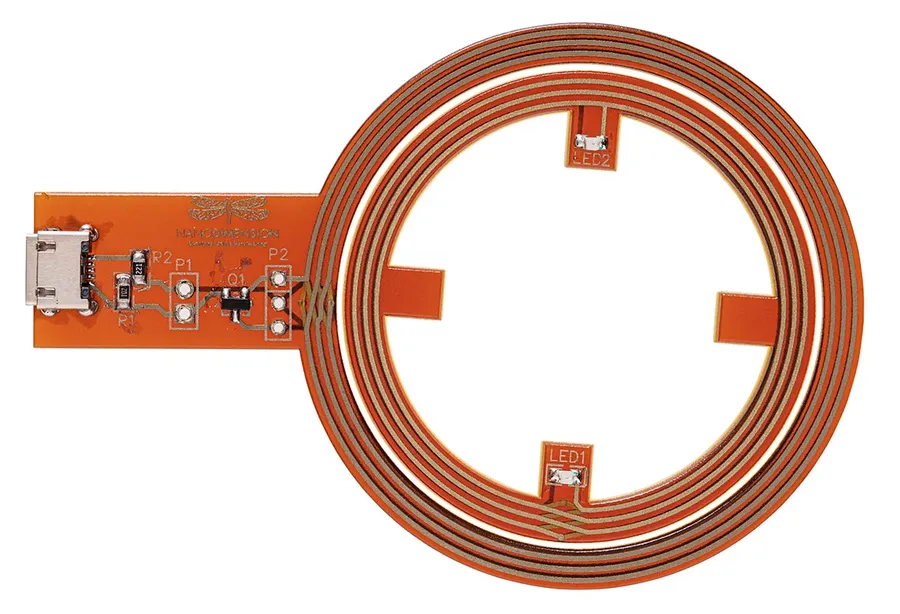

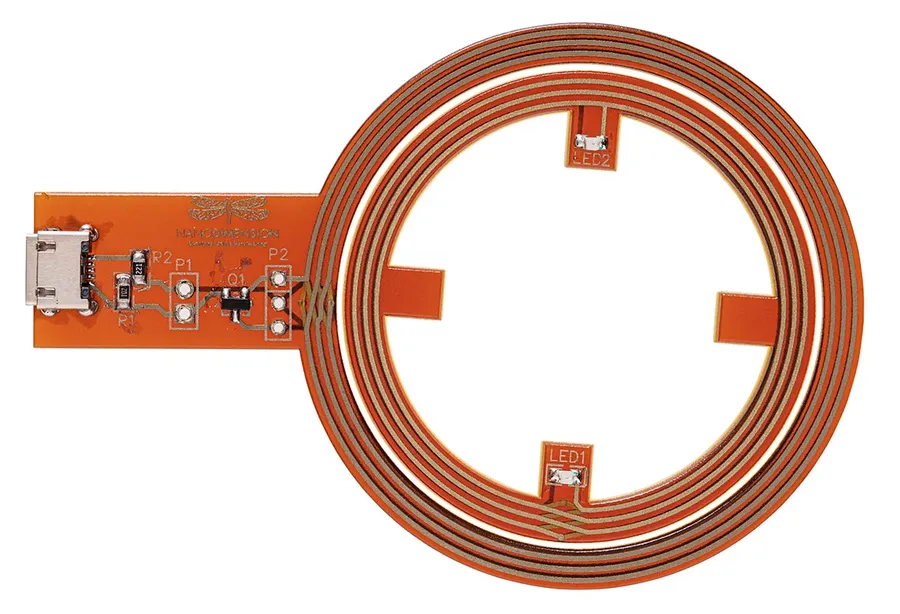

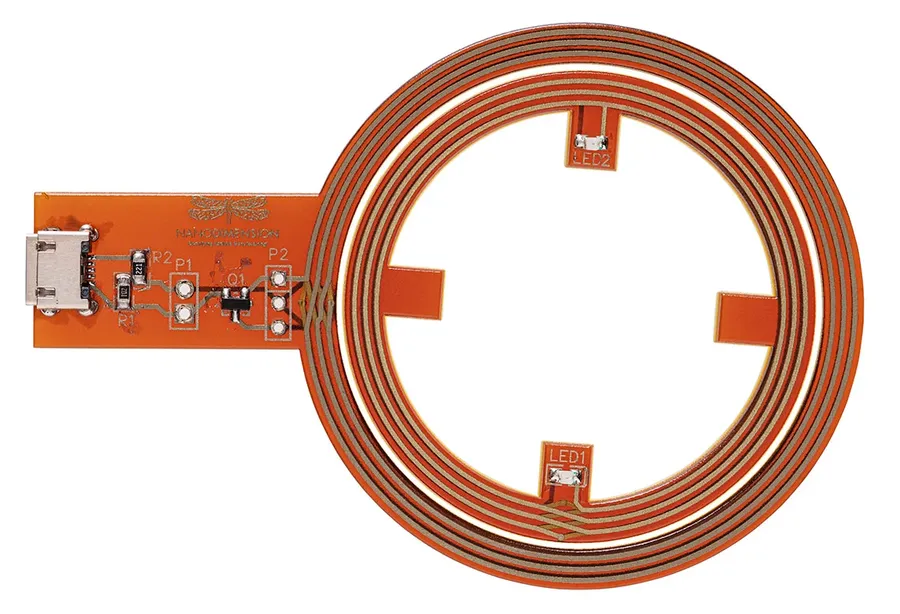

The Dragonfly PCB printer, pioneered by Nano Dimension, employs a sophisticated additive manufacturing approach to fabricate functional circuit boards, differentiating itself from traditional subtractive methods. At its core, the technology fuses inkjet deposition of proprietary conductive and dielectric inks with precise 3D printing techniques, layer by layer, to construct intricate multi-layer PCBs. This capability enables on-demand fabrication of electronic circuits, thereby accelerating prototyping cycles and offering greater design freedom.

Key aspects of the Dragonfly technology include:

- Inkjet Deposition

Specialized print heads deposit nano-particle inks with extreme precision. These inks include conductive materials (usually silver) for traces and pads, and dielectric materials for insulation. - 3D Printing Technique

The printer builds the circuit board in a layer-by-layer process, where each layer corresponds to a part of the PCB design. This allows the creation of complex multi-layer structures. - Proprietary Materials

Nano Dimension utilizes a range of proprietary materials, including conductive silver nano-particle inks and insulating polymers specifically formulated for optimal printing and electrical performance. These materials are crucial for achieving the necessary functionality. - Precise Positioning System

The system employs advanced motion control and precision alignment for the printhead, which is critical for creating precise traces and pads, ensuring consistent layer registration, and facilitating the creation of multi-layered circuits with tight tolerances. This results in a high degree of reliability and performance.

| Material Type | Function | Composition | Key Properties |

|---|---|---|---|

| Conductive Ink | Creates conductive traces and pads | Silver nano-particles in a polymer matrix | High electrical conductivity, good adhesion to substrate |

| Dielectric Ink | Provides insulation between layers | Polymer with specific electrical properties | Low dielectric constant, high dielectric strength |

| Support Material | Provides structural support during printing of complex geometries | Proprietary polymer | Removable after printing, good thermal stability |

DragonFly 2020 vs. DragonFly IV: A Comparative Analysis

The evolution of the Nano Dimension DragonFly printer from the 2020 Pro model to the DragonFly IV represents significant advancements in 3D printed electronics capabilities. This section will dissect the core differences between these two generations, focusing on improvements in technology, performance, and overall functionality.

| Feature | DragonFly 2020 Pro | DragonFly IV |

|---|---|---|

| Printing Technology | Inkjet deposition | Advanced Inkjet deposition with improved print heads |

| Materials | Proprietary conductive and dielectric inks | Enhanced conductive and dielectric nano-particle inks with higher resolution and stability |

| Resolution | Lower resolution compared to DragonFly IV | Higher resolution for finer features and complex designs |

| Build Volume | Smaller build volume | Increased build volume to accommodate larger boards and assemblies |

| Throughput | Lower throughput of PCB prototypes | Higher throughput enabled by faster print speeds and better material handling |

| Automation | More manual operation of material loading and handling | Higher levels of automated material handling |

| Software | Software suite with basic design import and print management | Enhanced software with advanced design analysis and process monitoring |

| Material Options | Limited material options | More material options to support various advanced applications |

| Precision | Standard precision | Enhanced precision for more complex and detailed circuit boards |

| Connectivity | Standard connectivity | Enhanced connectivity with multiple data transfer protocols |

| Power Consumption | Standard power consumption | Optimized power usage and efficiency improvements |

The DragonFly IV builds upon the foundational technology of the DragonFly 2020 Pro, addressing limitations and incorporating improvements driven by user feedback and advancements in materials science and inkjet printing technology. Key upgrades include higher print resolution, more material options, and a larger build volume, directly impacting the complexity and functionality of the PCBs that can be produced. The improved software suite also allows for streamlined design processes and better control over printing parameters. Overall, the DragonFly IV provides a higher level of automation, resulting in better precision, faster prototyping times, and optimized material usage.

Factors Influencing Dragonfly PCB Printer Price

The final cost of a Dragonfly PCB printer is not a single, fixed value. Instead, it's determined by a combination of factors including the specific model selected, the software suite bundled with the printer, the level of customer support provided, and any optional accessories required. Understanding these elements is crucial for accurate budgeting and cost projections.

| Factor | Description | Impact on Price |

|---|---|---|

| Printer Model (e.g., DragonFly 2020 Pro, DragonFly IV) | The specific version of the Dragonfly printer. Newer models typically include enhanced features, greater precision, and more advanced materials compatibility. | Significant. Newer and more advanced models command a higher price due to improved capabilities and performance. |

| Software Package | The software suite required to operate the printer, manage printing tasks, and design electronics for the printer, and often includes updates and features. | Moderate to significant. Comprehensive software packages with advanced features and ongoing support increase costs. |

| Support Contract | The support contract level, including the type of warranty, and support response times offered by the manufacturer. Higher levels provide faster response and more comprehensive support. | Moderate. Extended warranties, comprehensive support, and faster response times increase overall cost. |

| Additional Accessories and Consumables | Optional accessories (e.g., additional print heads, material handling systems) and consumables (e.g., specialized inks, substrates). | Moderate. Specialized inks and additional accessories contribute to the overall cost. |

| Installation and Training | On-site installation, setup, and training services provided by the manufacturer. It ensures proper system setup, user training, and efficient operation. | Moderate. Essential services like installation and training can add to the total cost of the printer. |

| Financing Options | Financing or leasing options, which may include interest rates and other costs | Moderate. Cost is determined by the finance rate. |

Dragonfly PCB Printer Price: What to Expect

The price of a Dragonfly PCB printer is a significant investment, reflecting its advanced 3D printing capabilities for electronics. Understanding the cost implications is crucial for organizations considering adopting this technology. Pricing varies based on the specific model, software packages, support services, and other factors. This section provides an overview of typical price ranges and associated costs.

Based on available market data, a new Nano Dimension Dragonfly system typically costs in the range of several hundred thousand US dollars, with the latest Dragonfly IV models being at the higher end of this range. This cost includes the printer itself, initial consumable materials, and basic software licenses. The actual cost of ownership will include several factors beyond just the printer’s base cost.

| Cost Component | Description | Estimated Cost Range |

|---|---|---|

| Printer Purchase | Initial cost of the Dragonfly system itself, including base software | $200,000 - $400,000+ |

| Software & Licenses | Cost of advanced software features, such as CAM (Computer-Aided Manufacturing) software and annual licensing | $5,000 - $20,000+ per year |

| Consumable Materials | Cost of specialized conductive and dielectric inks required for printing | $5,000 - $15,000+ per year (depending on usage) |

| Maintenance & Support | Annual maintenance contracts, technical support, and training costs | $10,000 - $30,000+ per year |

| Extended Warranties | Optional extended warranty packages to cover unforeseen issues | Varies |

| Additional Accessories | Additional accessories such as additional print heads or specialized tools | Varies |

Financing options are often available through Nano Dimension or third-party financing companies. These may include leasing and payment plans that allow companies to acquire the technology without significant upfront capital expenses. These options should be explored carefully, as total cost may vary depending on the selected plan. Ongoing operating costs include the price of consumables, mainly the specialized inks and maintenance fees. It's critical to factor in these costs when calculating the return on investment (ROI) of the system. The price also depends on the level of training and support required.

The Benefits of In-House PCB Prototyping with Dragonfly

The integration of a Dragonfly PCB printer for in-house prototyping fundamentally transforms the electronics development lifecycle, offering a paradigm shift from traditional outsourced methods. This approach yields substantial advantages in terms of time efficiency, cost management, design iteration flexibility, and overall control of the prototyping process.

- Accelerated Prototyping Cycle

The Dragonfly printer significantly reduces lead times associated with outsourcing PCB prototypes. Internal production allows for same-day iterations, enabling faster feedback loops, design refinements, and quicker transitions to production-ready boards. - Reduced Development Costs

While the initial investment in a Dragonfly system can be substantial, the long-term operational expenses are typically lower than the cumulative costs of iterative outsourcing. This advantage becomes particularly noticeable with multiple design revisions. - Enhanced Design Flexibility

The ability to rapidly test and refine designs in-house provides engineers with unparalleled design freedom. Complex and innovative layouts can be explored without the delays and restrictions imposed by external fabrication facilities. This level of control encourages innovation and optimization of board performance. - Full Control Over Intellectual Property

Keeping prototyping in-house safeguards confidential and proprietary circuit designs, minimizing the risk of external breaches or leaks, which is particularly critical for sensitive technologies or intellectual property protection. - Real-time Design Optimization

With the Dragonfly, engineers can rapidly transition from design changes to physical prototypes, permitting real-time optimization based on immediate performance data and direct observation, shortening design cycles, and ensuring more effective product development.

Who is the Dragonfly PCB Printer For?

The Dragonfly PCB printer is not a one-size-fits-all solution; its advanced capabilities cater to specific sectors and applications where rapid prototyping and custom electronic designs are crucial. This section identifies ideal use cases for the Dragonfly, focusing on the industries and project types that benefit the most from this technology.

- Aerospace and Defense

These sectors require highly specialized and often low-volume electronic components for satellites, drones, and other advanced systems. The ability to rapidly prototype and customize PCBs in-house accelerates development cycles and maintains proprietary design integrity. The Dragonfly printer facilitates quick design iterations and allows for the incorporation of cutting-edge sensor and communication technology directly onto custom PCBs. - Advanced Research and Development

Research institutions and universities benefit greatly from the ability to iterate quickly on designs for complex experiments and proof-of-concept devices. The Dragonfly printer enables researchers to rapidly prototype novel electronic systems without the constraints and lead times of traditional manufacturing processes. This can be pivotal in speeding up the innovation process in fields such as material science, quantum computing, and biotechnology. - Electronics Manufacturing and Prototyping Labs

Companies involved in electronics manufacturing and product development find that the Dragonfly printer allows them to rapidly create prototypes to evaluate the feasibility of new electronic designs and product features before going into mass production, significantly reducing development time and costs. The ability to test various designs in-house means that design issues can be addressed sooner with a more flexible approach. - Specialized Electronics for Niche Applications

The flexibility and precision offered by the Dragonfly make it suitable for creating electronics for niche applications such as wearable technology, medical devices, and customized sensors, allowing for the production of small batches of custom electronic products with unique form factors, and integrating electronics directly into a variety of materials or devices. It also supports the development of unique, bespoke electronics where mass manufacturing isn't a viable option.

Frequently Asked Questions About Dragonfly PCB Printers

This section addresses common inquiries about the Dragonfly PCB printers, providing clear answers regarding their operation, limitations, and comparisons with alternative 3D printing technologies. Understanding these aspects is crucial for potential users to make informed decisions about adopting this advanced technology for in-house PCB prototyping.

- What Software is Compatible with the Dragonfly PCB Printer?

The Dragonfly system typically integrates with standard PCB design software through file import capabilities, often supporting formats such as Gerber and STL. It is not necessarily universally compatible with all software, requiring users to verify the supported file types and ensure their design tools can generate the appropriate outputs. - What are the material limitations of the Dragonfly PCB Printer?

Dragonfly printers use specialized conductive and dielectric inks. The specific materials used limit the range of substrates, layer thicknesses, and conductor properties compared to conventional PCB manufacturing techniques. While the technology is advancing, understanding these limitations is vital for project planning. - What are the maintenance requirements for a Dragonfly PCB printer?

Like any precision equipment, Dragonfly printers require regular maintenance, including cleaning print heads, replacing ink cartridges, and ensuring the system is calibrated. Proper maintenance is critical for consistent performance and print quality, and service contracts may be available for more comprehensive support. - How does the Dragonfly PCB printer compare to other 3D printing solutions?

While most 3D printers focus on mechanical parts, the Dragonfly specializes in multi-layer circuit board printing. Compared to conventional FDM or SLA printers, the Dragonfly uses specialized materials and processes, making it unique to electronics printing. A detailed comparison of other 3D PCB printing solutions is covered in a separate section. - Can the Dragonfly PCB printer produce multilayer PCBs?

Yes, the Dragonfly is capable of producing multilayer PCBs, allowing for the creation of more complex circuit designs. The number of layers and the complexity of the design are dependent on the specific model and its capabilities. Users can create multiple conductor layers, with integrated vias and dielectric layers, all printed with the same machine. - What is the typical build volume of a Dragonfly PCB Printer?

The build volume of the Dragonfly printer is typically optimized for PCB prototyping and is not usually large, with exact dimensions differing between models. This can limit the size of PCBs that can be printed in one go, often requiring designers to consider modular designs or tiling techniques for larger projects. - Is training required to operate the Dragonfly PCB Printer effectively?

While the printer is designed to be user-friendly, some level of training or familiarization is usually necessary to operate it effectively, especially to achieve optimal print results. This includes understanding the software, material properties, and maintenance practices. Many manufacturers provide resources and training materials.

Alternatives to the Dragonfly PCB Printer

While the Nano Dimension Dragonfly stands as a prominent player in the 3D printed electronics arena, several alternative solutions cater to various needs and budgets. These alternatives often employ different technologies and materials, offering diverse capabilities in PCB prototyping and manufacturing. Understanding these options is crucial for selecting the optimal solution.

| Alternative Solution | Technology | Materials | Pros | Cons | Typical Application | Price Range (USD) |

|---|---|---|---|---|---|---|

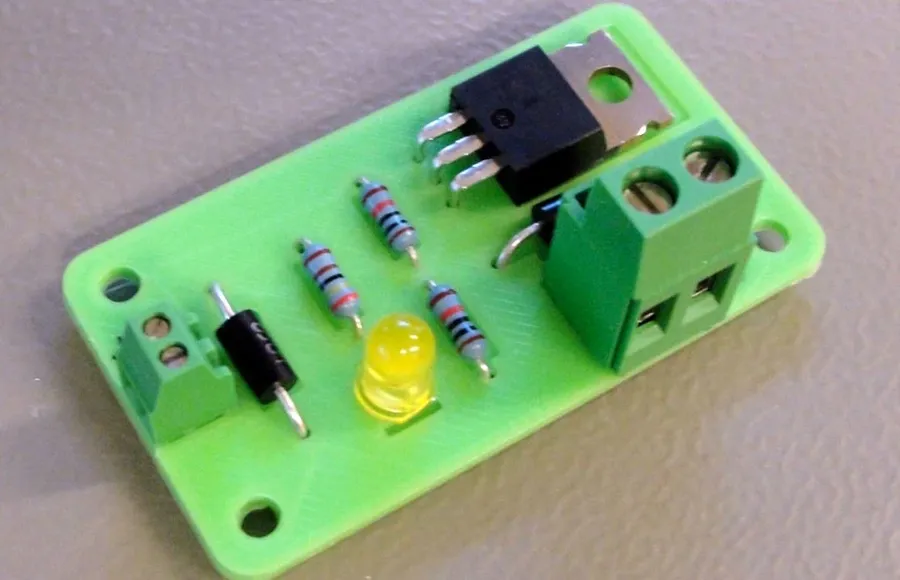

| Voltera V-One | Inkjet printing | Conductive inks, solder paste | Compact, relatively affordable, easy to use | Limited layer count, smaller print area, slower printing | Rapid prototyping, educational purposes | ~$5,000 - $10,000 |

| BotFactory Squink | Pick-and-place, dispensing | Conductive inks, solder paste, components | Automated assembly, integrated pick-and-place functionality | More complex setup, can be less versatile for high-density designs | Small batch assembly, functional prototyping | ~$15,000 - $25,000 |

| Multi3D Technologies | Aerosol Jet | Various conductive inks | High precision, fine feature printing, various material options | More expensive than inkjet options, requires specialized inks | Complex designs, advanced prototyping, research | ~$50,000 - $150,000+ |

| LulzBot TAZ Pro | Fused Deposition Modeling (FDM) | Conductive filaments, various substrate materials | Versatile, large build volume, good for creating customized enclosures | Less suitable for intricate circuitry, limited conductivity | Enclosures and housings, simpler circuit boards | ~$5,000 - $8,000 |

| Custom Built Solutions | Varies | Varies | Tailored to specific needs, can be cost-effective for large volumes | Requires in-house engineering expertise, high initial development effort | Niche applications, high-volume production | Varies widely |

The selection of a 3D PCB printing solution should be guided by specific application needs, budget constraints, and expertise available. While the Dragonfly is specialized for creating multilayer PCBs with high conductivity, other solutions might be better suited to applications requiring rapid prototyping of simpler circuits, automated component placement, or larger enclosures. Careful analysis of these alternatives is recommended to ensure the best fit for your unique manufacturing needs. It is also important to note that the cost, performance, and features of all alternatives can vary greatly depending on specific models and configurations.

Future Trends in 3D PCB Printing Technology

The field of 3D printed electronics is rapidly evolving, with future trends poised to significantly impact both the capabilities and cost-effectiveness of systems like the Dragonfly PCB printer. These advancements promise to broaden applications and potentially lower the barrier to entry for in-house rapid prototyping.

- Enhanced Material Science

Research into new conductive inks and substrate materials is paramount. Future materials will likely offer improved electrical conductivity, mechanical flexibility, and thermal stability, expanding the range of applications for 3D printed electronics. This includes the potential for creating more robust and reliable flexible circuits and wearable electronics. - Increased Precision and Resolution

Advancements in printing technology are continuously pushing the limits of precision. Expect future systems to offer higher resolution printing capabilities, allowing for the creation of increasingly complex and miniaturized electronic components. This is critical for high-density interconnect (HDI) applications and advanced circuit designs. - Integration of AI and Machine Learning

The integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is set to transform the design and manufacturing processes. AI can optimize printing parameters, predict potential failures, and enable real-time adjustments, reducing waste and ensuring higher yield rates. ML can also accelerate the design process through automated layout and routing tools. - Multi-Material Printing

Future 3D PCB printers will likely incorporate more advanced multi-material printing capabilities, allowing for the simultaneous deposition of different materials with varying electrical and mechanical properties. This is necessary for the seamless construction of multilayer circuit boards and complex embedded electronic structures. - Standardization and Software Integration

As the 3D PCB printing technology matures, expect increased efforts toward standardization in design files, printing processes, and material specifications. Enhanced software integration with CAD and EDA tools will enable a more streamlined design-to-manufacture workflow, thereby reducing design time and operational costs. - Cost Reduction

Technological advancements, coupled with economies of scale, are expected to drive down the overall cost of 3D PCB printing systems. This will expand their adoption beyond high-end research and development into broader commercial markets, making in-house prototyping more accessible.

The Dragonfly PCB printer, while representing a significant investment, offers unparalleled advantages in rapid prototyping and agile hardware development. Understanding the dragonfly pcb printer price and its associated benefits is crucial for any organization seeking to innovate and remain competitive in the fast-paced world of electronics. As technology continues to evolve, we can expect further advancements in 3D PCB printing, potentially lowering costs and expanding applications for this transformative technology.

AnyPCBA

AnyPCBA