Find a Reliable PCB Company Near You: A Comprehensive Guide

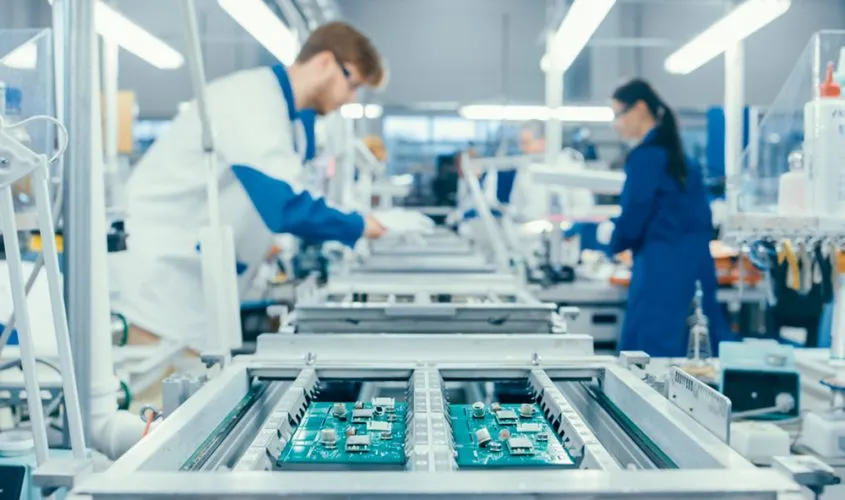

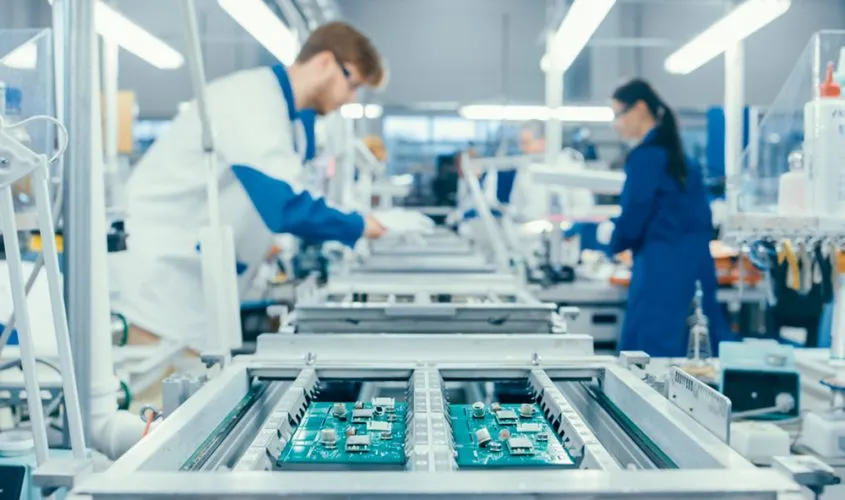

The world of electronics is underpinned by the intricate dance of printed circuit boards (PCBs). From smartphones to aerospace technology, PCBs are the unsung heroes of modern devices. If you're on the hunt for a 'pcb company near me', this guide will navigate you through the process of finding a reliable local partner that fits your project requirements. We'll explore crucial considerations for choosing a PCB manufacturer, how to assess their capabilities, and why proximity matters in the fast-paced world of electronics.

Why Choose a Local PCB Company?

Selecting a local PCB (Printed Circuit Board) manufacturer offers distinct advantages, primarily through enhanced communication, reduced lead times, and the convenience of on-site visits. These benefits contribute significantly to a more efficient and agile product development process.

- Faster Turnaround Times

Local PCB companies often provide quicker turnaround times compared to overseas manufacturers. This expedited process is critical for rapid prototyping and time-sensitive projects, allowing for faster iterations and quicker time-to-market. - Enhanced Communication

Working with a local PCB manufacturer facilitates clearer and more immediate communication. This includes real-time discussions, prompt feedback on design issues, and a better understanding of specific project requirements. Language and time zone barriers are minimized, leading to more effective collaboration. - Easier Site Visits

The convenience of visiting a local PCB facility enables first-hand inspections of manufacturing processes and quality control measures. Such access allows for direct interaction with the production team, immediate addressing of potential issues, and a better assurance of high-quality production. - Reduced Shipping Costs and Logistics

By choosing a local company, shipping distances are significantly shorter, thus reducing transportation costs and minimizing potential delays or damage during transit. This streamlined logistics process also simplifies inventory management. - Support Local Economy

Partnering with a local business helps strengthen the regional economy and supports the growth of local technology ecosystems. This fosters community development and job creation within the area.

Key Factors When Evaluating a 'PCB Company Near Me'

Selecting the right PCB company is crucial for the success of any electronics project. When searching for a 'PCB company near me,' several critical factors should be carefully evaluated to ensure the chosen supplier meets your specific needs, from technical expertise to quality assurance.

| Factor | Description | Importance |

|---|---|---|

| Manufacturing Capabilities | The range of PCB types and complexities a company can handle (e.g., single-sided, multilayer, HDI). | Crucial for ensuring the company can produce the specific PCBs required for your project. |

| Technology Expertise | The company's knowledge and proficiency in advanced PCB technologies and materials. Includes their ability to handle specific design challenges and requirements. | Ensures the PCB company can handle complex designs and cutting-edge technologies. |

| Quality Standards and Certifications | Adherence to industry quality standards (e.g., IPC standards) and relevant certifications (e.g., ISO 9001, ISO 13485). | Essential for ensuring that the PCBs are reliable and meet industry benchmarks for quality and safety. |

| Lead Times and Turnaround Speed | The typical time it takes for the PCB company to complete a manufacturing or assembly order. | Critical for projects that have tight deadlines and require quick production. |

| Prototyping Capabilities | The company's ability to provide quick-turn prototyping services for testing designs. | Allows you to test the PCB design before full-scale production, saving costs and time. |

| Pricing Structure | How the PCB company prices its services, including fabrication, assembly, and any additional value-added services. | Ensuring the pricing aligns with the project budget and provides value for money. |

| Customer Support | The availability and quality of customer support, including technical assistance, order tracking, and issue resolution. | Important for a smooth and efficient process throughout the PCB manufacturing and assembly process. |

Understanding Different PCB Manufacturing Services

Navigating the PCB manufacturing landscape requires understanding the distinct services available: fabrication, assembly, and prototyping. Each plays a crucial role in bringing an electronic product from concept to reality, with options like quick-turn assembly, turnkey solutions, and small-batch production further tailoring to specific needs.

| Service | Description | Key Focus | Typical Volume |

|---|---|---|---|

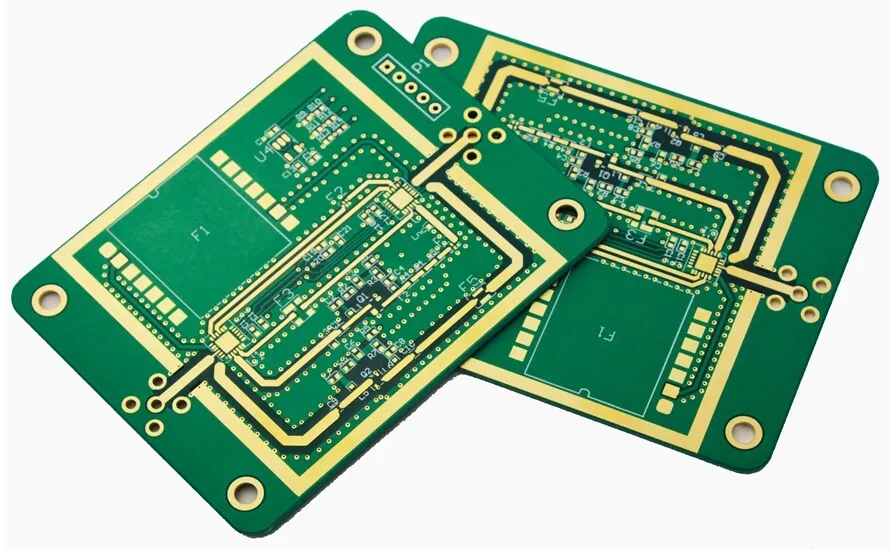

| PCB Fabrication | The core process of creating the bare printed circuit board. This involves etching, layering, and drilling to produce the physical board. | Creating the physical board | Ranges from prototype to mass production |

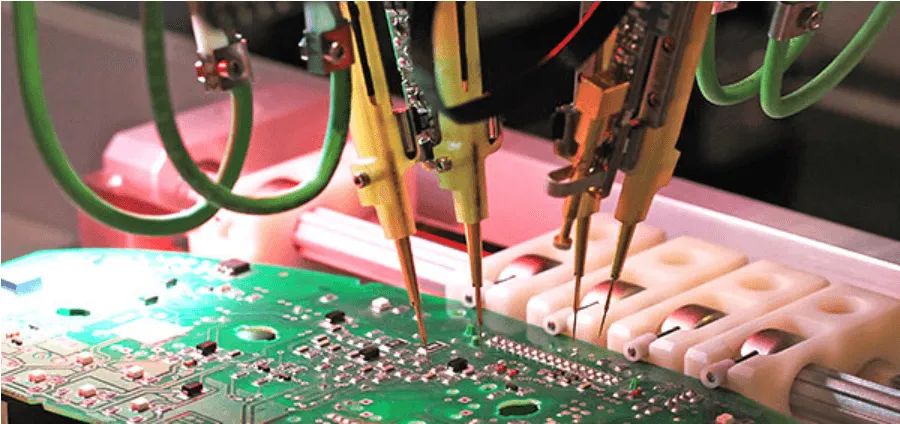

| PCB Assembly | The process of mounting electronic components onto the fabricated PCB. This includes soldering, component placement, and inspection. | Mounting components onto PCB | Ranges from small batches to large volumes |

| PCB Prototyping | A specialized service for creating a small number of PCBs for testing and design verification prior to full-scale production. | Testing and verifying designs | Small batch production |

| Quick-Turn PCB Assembly | Accelerated assembly service focusing on reducing lead times, ideal for rapid product development and testing. It's faster than standard assembly. | Rapid product development | Small to Medium Volumes |

| Turnkey PCB Solutions | A comprehensive service managing all stages of PCB production, from fabrication and assembly to component sourcing, eliminating the need for multiple suppliers. | Complete end-to-end service | Varies |

| Small-Batch Production | Manufacturing limited quantities of PCBs, suitable for specialized products or initial market testing. | Specialized product needs | Limited quantities |

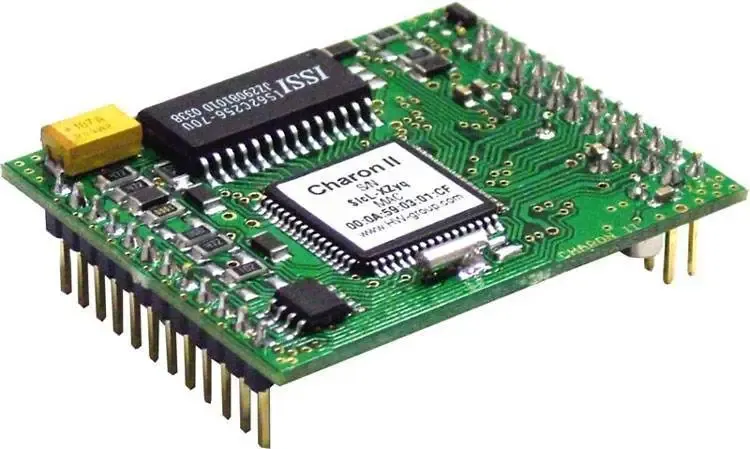

Types of PCBs Offered by Local Companies

Local PCB companies offer a variety of printed circuit boards to meet diverse application needs. Understanding the different types—single-sided, double-sided, multilayer, flexible, and rigid-flex—is crucial for selecting the optimal board for your project. Each type possesses unique characteristics influencing cost, performance, and application suitability.

| PCB Type | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Single-Sided | Copper layer on one side only. | Simple electronic devices, lighting. | Low cost, easy to manufacture. | Limited routing complexity. |

| Double-Sided | Copper layers on both sides. | More complex devices, power supplies. | Increased routing flexibility. | Higher cost than single-sided. |

| Multilayer | Three or more copper layers. | Advanced electronics, computers. | High component density, complex circuitry. | Higher cost, complex fabrication. |

| Flexible (Flex) | Uses a flexible substrate material. | Wearable tech, automotive, medical. | Lightweight, can fit in unique spaces. | Higher manufacturing cost, more sensitive to temperature. |

| Rigid-Flex | Combination of rigid and flexible boards. | Aerospace, medical devices. | Combines benefits of both flex and rigid PCBs. | Complex design and manufacturing. |

Quick Turn PCB Assembly: What to Expect

Quick turn PCB assembly refers to the expedited manufacturing and assembly process of printed circuit boards, designed to drastically reduce lead times from design to functional prototype or final product. This service is essential for projects requiring rapid prototyping or when unforeseen production needs arise, enabling faster product development cycles and reduced time-to-market.

Understanding what quick-turn PCB assembly entails, including its typical lead times, crucial scenarios, and associated benefits and challenges, is important for any project requiring rapid turnaround.

- Typical Lead Times for Quick Turn PCB Assembly

Standard lead times for quick turn PCB assembly can range from 24 hours to a few days, depending on the board complexity, material availability, and the manufacturer’s capacity. These times are significantly shorter than standard manufacturing lead times, which can take several weeks. - Scenarios Where Quick Turn PCB Assembly is Essential

Quick turn services are crucial in situations such as rapid prototyping, urgent project needs, initial design validation, time-sensitive projects, and when dealing with unexpected design changes or component shortages. They allow for immediate feedback on design implementations before committing to larger production runs. - Benefits of Quick Turn Manufacturing

The primary advantages of quick turn PCB assembly include accelerated time-to-market, rapid design iteration and validation, reduced risk of project delays, flexibility in adapting to unforeseen issues, and the ability to promptly address and incorporate design improvements. These benefits are especially significant for startups and projects with aggressive development timelines. - Challenges of Quick Turn Manufacturing

Challenges of quick turn assembly can include higher costs compared to standard manufacturing, potential limitations on complexity or materials, the necessity for meticulous planning and design preparation to minimize errors, and the need for a reliable manufacturer capable of maintaining quality within tight timeframes. Proper vetting of a manufacturer’s capabilities is crucial when pursuing quick-turn options.

Frequently Asked Questions About Choosing a PCB Company Near You

Selecting the right PCB company is crucial for the success of your electronics project. This section addresses common questions to help you make an informed decision, focusing on the practical aspects of working with a local PCB manufacturer.

- What is the best PCB company for my specific project?

The 'best' PCB company varies depending on project needs. Consider factors such as the complexity of your PCB design, required materials, production volume, and desired turnaround time. A company specializing in your specific requirements, such as quick-turn prototyping or complex multilayer boards, will be the optimal choice. Also verify if the company has the necessary certifications, and technologies to meet your project specifications. It is best to request quotes from multiple companies before you make a decision. - What does 'PCB' stand for in a company context?

In a company context, 'PCB' refers to Printed Circuit Boards. These boards serve as the foundational structure upon which electronic components are mounted and interconnected. Companies either manufacture PCBs, use them in their electronic products or both. Understanding the PCB manufacturing capabilities of a company ensures they can meet your design and production needs. - What are the typical costs for PCB manufacturing?

PCB manufacturing costs vary widely. Factors that impact cost include the board's complexity (single-sided, double-sided, multilayer), the materials used (FR-4, aluminum, flexible substrates), the quantity ordered, and the manufacturing tolerances required. Additional charges may apply for expedited production, specific surface finishes, or testing and quality inspections. Requesting a detailed quote that includes a breakdown of these costs is recommended. - How much does PCB design typically cost per hour?

The cost of PCB design depends on the designer's experience level, complexity of the design, location, and the type of service needed. Typically, hourly rates can vary from the lower end of $50 an hour to the higher end of $200 an hour. Some designers prefer a fixed-price rate, or a payment rate structure per board or per project, so it is critical to determine the payment rate structure in the contract. Design complexity will include the layers required and density of the design along with the design rules. - Are there any certifications I should look for when choosing a PCB company?

Yes, several certifications indicate a PCB company's adherence to quality and industry standards. ISO 9001 certification demonstrates a company's commitment to quality management. Other certifications, like ISO 13485 for medical devices or AS9100 for aerospace, are crucial for specific industries. IPC standards, such as IPC-A-600 for PCB acceptability, and IPC-6012 for PCB qualification and performance, are vital for ensuring product reliability. - What are the typical lead times for PCB manufacturing?

Lead times for PCB manufacturing depend on the complexity and size of the order and the manufacturer's capability. Simple PCBs can be produced within 24 hours for quick turn services. More complex multilayer boards will require several days or weeks. Additional processing such as impedance control, controlled drilling and surface finishes can increase the total lead time. Discussing the lead times with the manufacturer to ensure it meets project time constraints, is crucial for project success. - What file formats are required to order a PCB?

To order a PCB, manufacturers typically require Gerber files, which are standard CAD output files for PCB fabrication. Additional files needed are the NC drill file, and a bill of materials (BOM) which includes all the components needed for the assembly process. Make sure the Gerbers include all the layers including, copper, solder mask, silkscreen, etc. These files provide all the necessary information for manufacturing and assembling the PCB.

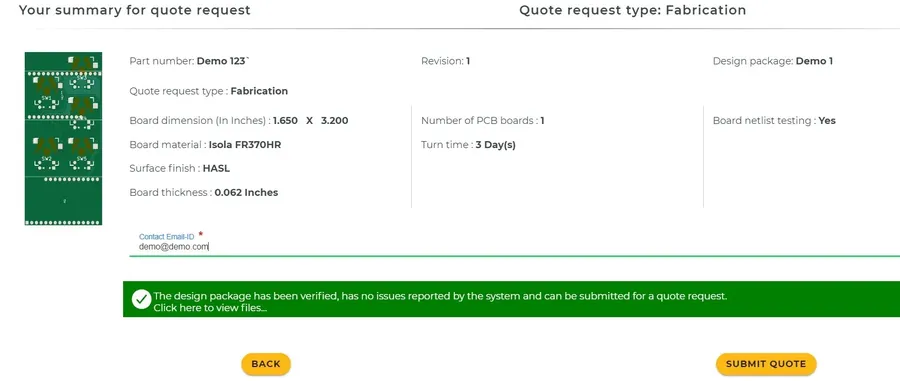

How to Get a Quote and Place an Order with a Local PCB Company

Obtaining an accurate quote and successfully placing an order with a local PCB company requires careful preparation and clear communication. This process involves several key steps, from preparing your design files to understanding the pricing structure and navigating the order fulfillment process. Detailed specifications are crucial for ensuring that the final product meets your exact requirements.

- Prepare Your Design Files (Gerber Files)

The first step is to generate Gerber files from your PCB design software. Gerber files are a standard format that contains all the necessary information for manufacturing your PCB, including copper layers, solder mask, silkscreen, and drill data. Ensure all files are accurate and complete. - Create a Bill of Materials (BOM)

A Bill of Materials lists all the components needed for assembly, including their part numbers, quantities, and specifications. Accuracy here is vital for an accurate assembly quote. Specify preferred vendors if you have them. - Define Your PCB Specifications

Clearly outline your PCB's technical requirements, including the number of layers, material (e.g., FR-4, Rogers), board thickness, copper weight, surface finish, solder mask color, and silkscreen requirements. Special needs such as impedance control should be stated explicitly. - Request a Quote

Submit your Gerber files, BOM, and PCB specifications to your chosen local PCB company. Use their online portal if available, or contact them directly via email or phone. Be specific about your delivery timeframe and any required quality standards. - Review the Quote

Carefully review the quote provided. Pay close attention to the pricing breakdown for fabrication and assembly, lead time, shipping costs, and any additional charges. Clarify any discrepancies or uncertainties. - Place Your Order

Once you are satisfied with the quote and terms, formally place your order. Often this will involve confirming your details on the company's portal, or an email confirmation. Provide any final information required for processing your order. - Track Order Progress

Most companies offer tools for tracking the progress of your order. Monitor these updates, and communicate with the manufacturer promptly if any issues arise. Good communication streamlines the overall experience.

Beyond Manufacturing: Value-Added Services of a Local PCB Company

Local PCB companies often provide a range of value-added services that extend beyond basic manufacturing. These services can significantly streamline the product development process, reduce costs, and ensure higher quality outcomes. This section details these crucial offerings, which can be a key differentiator when selecting a PCB partner.

- Design Assistance

Many local PCB companies offer design support, which can range from design review and optimization to full custom design services. This can help improve manufacturability and performance of your PCB. - Component Sourcing

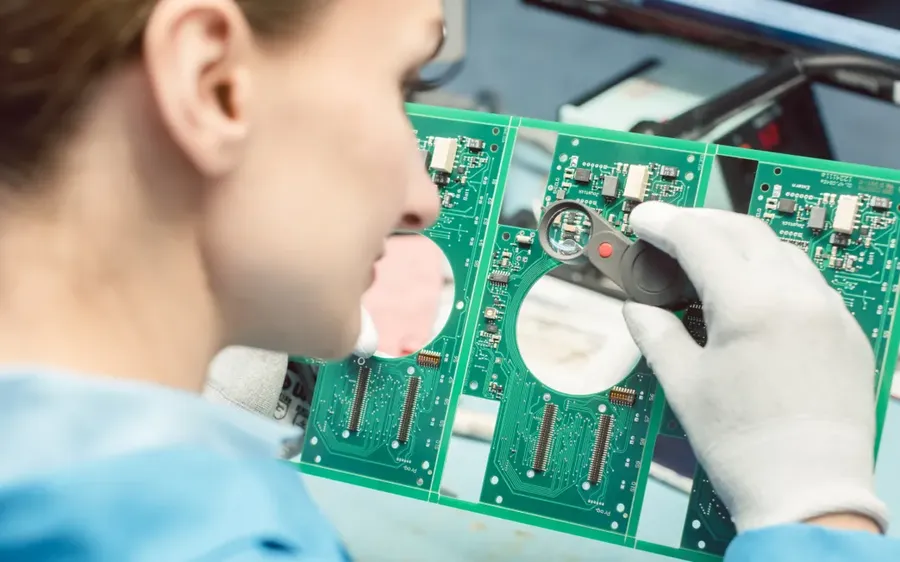

Local companies may have established relationships with component suppliers, allowing them to source parts more efficiently and potentially at better prices. They can also help navigate component availability issues. - Testing and Inspection

Comprehensive testing services, including electrical testing, functional testing, and visual inspections, ensure your PCBs meet the required specifications and are reliable for your application. This can include automated optical inspection (AOI) and in-circuit testing (ICT). - Post-Production Support

Post-production support, such as troubleshooting, rework, and revisions, is often more readily available from local companies. This can be crucial for resolving any issues that may arise after production. - Prototyping and Iteration Support

Local companies can offer rapid prototyping, allowing you to quickly test and refine your designs before mass production. This agility in iteration is extremely beneficial to the product development cycle.

| Value-Added Service | Description | Benefits |

|---|---|---|

| Design Assistance | Design review, optimization, or custom PCB design services. | Improved manufacturability, enhanced performance. |

| Component Sourcing | Efficient procurement of electronic components. | Cost savings, reduced lead times, avoids component availability issues. |

| Testing and Inspection | Comprehensive electrical, functional, and visual inspections. | Ensured reliability, reduced defects, compliance with standards. |

| Post-Production Support | Troubleshooting, rework, and revisions. | Fast resolution of issues, continuous improvement. |

| Prototyping and Iteration | Rapid prototyping services. | Fast design testing and refinement, reduced time to market. |

Future Trends in PCB Manufacturing and How Local Companies Are Adapting

The PCB manufacturing industry is rapidly evolving, driven by technological advancements and increasing demands for more complex and sustainable solutions. Local PCB companies are adapting to these trends to remain competitive and meet the changing needs of their customers. Key trends include miniaturization, high-density interconnect (HDI) technology, and sustainable practices.

- Miniaturization

The push for smaller and more compact electronic devices is driving the demand for miniaturized PCBs. Local companies are investing in advanced technologies to produce finer lines and spaces, enabling the creation of smaller, more powerful circuit boards. This includes advanced lithography techniques and precision etching processes. - High-Density Interconnect (HDI) Technology

HDI technology is crucial for meeting the demands of high-performance electronics. Local PCB manufacturers are adopting advanced HDI techniques such as microvias, blind vias, and buried vias to create more complex and efficient circuit boards. These technologies allow for greater component density and improved electrical performance. - Sustainable and Eco-Friendly Practices

There is a growing emphasis on environmentally responsible manufacturing practices. Local companies are exploring and implementing eco-friendly materials, waste reduction strategies, and energy-efficient processes. This includes using lead-free solder, water-based cleaning agents, and recycling initiatives. - Increased Automation

To enhance efficiency, reduce costs, and maintain precision, local PCB companies are integrating automation into their manufacturing processes. This includes automated assembly lines, robotic handling systems, and AI-driven inspection tools, all contributing to faster production times and higher quality standards. - Advanced Materials

The quest for better performance and reliability is leading to the use of advanced materials in PCB manufacturing. Local companies are experimenting with materials like high-frequency laminates, flexible substrates, and thermally conductive materials to cater to specialized applications such as RF and high-power electronics.

Finding the right 'pcb company near me' is crucial for the success of your electronics projects. By considering factors like location, manufacturing capabilities, and service offerings, you can establish a valuable partnership that facilitates high-quality PCB production and faster time-to-market. When seeking a 'pcb company near me', consider the long-term value of a local partner that can provide the support and quality you need, ensuring your projects not only succeed but also excel in the competitive electronics landscape.

AnyPCBA

AnyPCBA