Find the Best Circuit Board Company Near You: A Comprehensive Guide

In our increasingly tech-driven world, circuit boards are the unsung heroes powering countless devices around us. From the smartphone in your hand to the complex systems in your car, these intricate components are essential. Finding the right circuit board company near you is crucial, whether you need custom manufacturing, repair services, or prototyping support. Let's explore how to pinpoint the perfect partner for your electronic projects.

Understanding Your Circuit Board Needs

Before initiating a search for a 'circuit board company near me,' it is crucial to precisely define your project requirements. This involves determining whether your needs encompass PCB manufacturing, repair services, or design assistance. A clear understanding of these specifics will significantly narrow your search and ensure you connect with a company that aligns with your project's demands.

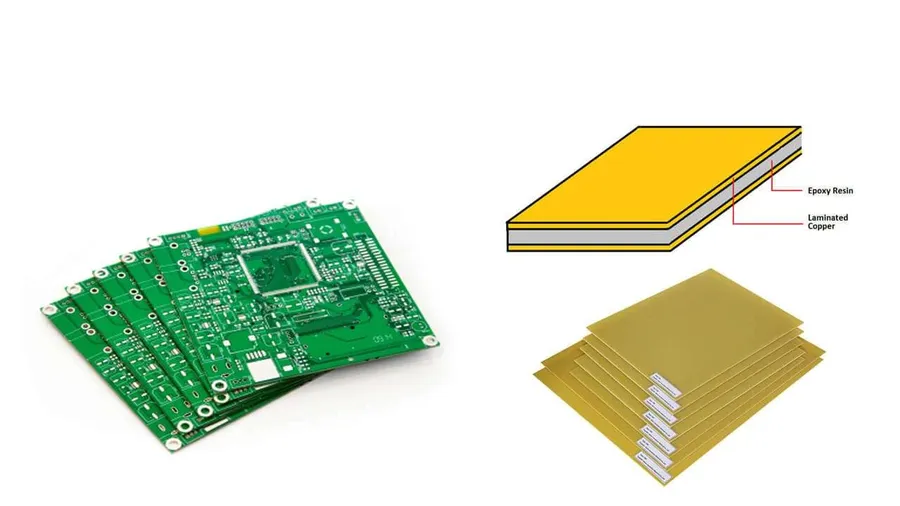

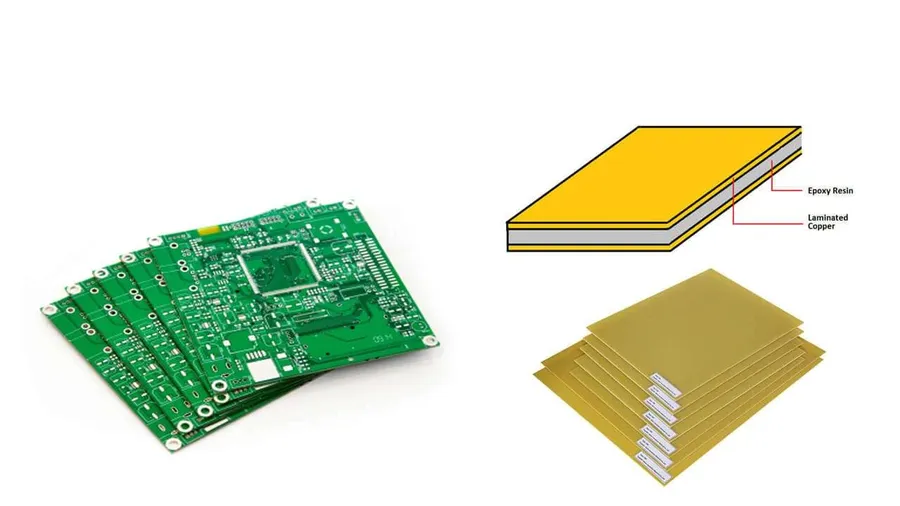

- PCB Manufacturing

This involves the physical production of circuit boards based on a design. This could range from simple single-layer boards to complex multi-layer designs. - Circuit Board Repair Services

This includes the diagnosis and repair of faulty circuit boards, which might involve component replacement, trace repair, or rework of solder joints. - Design Assistance

This includes the initial design, layout, and simulation of the circuit board before production. It's essential if you do not have in-house design capabilities.

Locating Local PCB Manufacturers

Identifying the right local PCB manufacturer is crucial for ensuring your project's success. Utilizing online directories and resources can significantly streamline this process. Focusing on manufacturers with demonstrable experience and relevant certifications will help guarantee the quality and reliability of your printed circuit boards.

To effectively locate PCB manufacturers in your area, consider these steps:

- Utilize Online Directories

Start by using online directories such as PCB Directory and ThomasNet. These platforms allow you to filter manufacturers by location, enabling you to identify those in your specific state or region. - Filter by Experience and Certifications

When reviewing potential manufacturers, prioritize those with proven experience in producing the types of PCBs you require (e.g., single-layer, multi-layer, flex PCBs). Look for manufacturers that hold relevant certifications like ISO 9001 for quality management and ISO 14001 for environmental management. These certifications indicate a commitment to high standards and responsible manufacturing practices. - Check for Specialization

Determine if the manufacturer specializes in specific types of PCBs or specific industries. Some manufacturers focus on high-frequency boards, while others might be experts in rigid-flex circuits. Matching your project needs with a manufacturer's specialization ensures better outcomes. - Review Capabilities

Assess the manufacturer's capabilities, including their production capacity, technology, and design support. Confirm that the company can handle the volume of PCBs you need and also provide assistance with PCB design, layout, and testing.

| Directory/Platform | Description | Key Features |

|---|---|---|

| PCB Directory | Specialized directory for PCB manufacturers. | Filters by location, certification, and capabilities; customer reviews. |

| ThomasNet | Industrial marketplace with a wide range of manufacturers, including PCB companies. | Extensive database with detailed company profiles; ability to request quotes. |

| Google Maps | General location-based search; good for finding smaller local options. | Can identify companies not on other directories; easy to check locations; may require further validation of capabilities. |

By leveraging these online resources and adhering to a structured approach, you can effectively locate local PCB manufacturers that are well-suited to meet your specific project requirements. This foundational step ensures you connect with a provider capable of delivering high-quality and reliable circuit boards.

Choosing a Reliable Circuit Board Repair Service

Selecting the right circuit board repair service is crucial for restoring functionality to your electronic devices or systems. When seeking a 'circuit board company near me' for repair, prioritize those specializing in component-level repairs. This focus ensures that the service can diagnose and fix specific issues on the board, rather than just replacing entire modules, which can be less cost-effective.

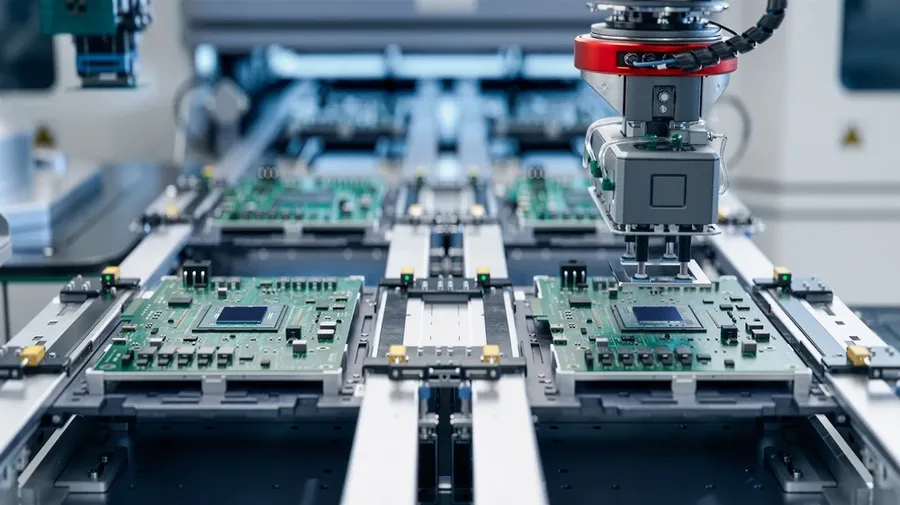

Component-level repair involves diagnosing and replacing individual components like resistors, capacitors, and integrated circuits. This requires specialized skills, equipment and a deep understanding of circuit board design and functionality. Opting for a service that offers component-level repair can save costs compared to full board replacements. Platforms like Thumbtack can provide a list of such services, but always verify reviews and their repair capabilities to ensure they align with your specific needs.

- Verify Component-Level Expertise

Ensure the repair service can diagnose and fix issues at the individual component level, not just replace entire boards or modules. - Check Reviews and Ratings

Look for customer reviews and ratings on platforms like Thumbtack and other review sites to gauge the reliability and quality of the repair service. - Assess Repair Capabilities

Confirm the service has experience with the type of circuit boards you need repaired, whether they are single-layer, multi-layer, or specific to certain applications.

Key Factors in Selecting a Circuit Board Company

Selecting the right circuit board company requires careful consideration of several key factors. These factors will directly impact the quality, cost, and timeliness of your project. Evaluating these aspects thoroughly will help ensure a successful outcome, regardless of whether you require manufacturing, repair, or design services. Here, we delve into the critical elements to assess when choosing a circuit board company.

- Turnaround Time

The time it takes for the company to complete your project, from initial design to finished product, is crucial. A shorter turnaround time can be vital for projects with strict deadlines, so look for a company that can meet your schedule without compromising quality. - Pricing Structure

Understand the company's pricing model and ensure it aligns with your budget. Inquire about material costs, labor rates, and any additional fees for design or testing. A transparent and competitive pricing structure is essential for financial planning. - Expertise in PCB Types

Circuit boards come in various types, such as single-layer, double-layer, and multi-layer PCBs. Verify that the company has proven experience with the type of board you require, as this knowledge is crucial for your project's success. Expertise can vary significantly between companies. - Production Run Capabilities

Whether you need a small batch of prototypes or a large production run, confirm the company's capability to handle your order volume. Scalability is a key factor, so look for companies with a flexible production process. - Technology and Equipment

Assess the technology and equipment used by the company. Modern equipment can ensure precision, quality, and efficiency. State-of-the-art technology suggests a commitment to quality and can handle complex designs. - Customer Support

A responsive and helpful customer support team can make your entire experience smoother. Evaluate their communication style and responsiveness, as efficient communication is crucial for smooth workflow and problem resolution. - Repair Capabilities

If repair services are a necessity, determine the company's ability to conduct component-level repairs and diagnostics, not just basic board replacement. Component-level repair expertise can save you time and money in the long run.

Comparing PCB Manufacturers: A Detailed Analysis

When selecting a PCB manufacturer, a thorough comparison is essential to ensure the chosen company aligns with your project's specific needs for quality, cost, and capabilities. This section provides a structured approach to evaluate potential partners, focusing on key aspects that directly impact the success of your circuit board project. Utilizing a comparative table can help streamline your decision-making process.

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Service Offerings | Prototype, small-batch, large-scale production, component sourcing | Primarily small to medium scale production, limited component sourcing, prototype. | Specializes in large scale production, limited component sourcing, basic prototype |

| Location | State X | State Y | State Z |

| Turnaround Time (Prototypes) | 5-7 business days | 7-10 business days | 3-5 business days |

| Turnaround Time (Production) | 2-3 weeks | 3-4 weeks | 1-2 weeks |

| Expertise | Multilayer PCBs, High-density interconnect (HDI) boards | Single and Double-layer PCBs, basic Multilayer | Large-format PCBs, specialized materials |

| Customer Reviews | 4.5 stars (150 reviews) | 4.0 stars (100 reviews) | 4.8 stars (200 reviews) |

| Certifications | ISO 9001, ROHS compliant | ISO 14001, some ROHS compliance | ISO 9001, ISO 13485 ,ROHS compliant |

| Pricing (Estimate) | Competitive, quotes required | Moderate, quotes required | Premium, quotes required |

| Minimum Order Quantity | 1-100 boards | 5-1000 boards | 100-10000+ boards |

Prototyping Services and Their Importance

Prototyping services are crucial in the PCB (Printed Circuit Board) development process, allowing for the iterative testing and refinement of a design before committing to mass production. By engaging a 'circuit board company near me' that offers prototyping, you can significantly reduce costs, mitigate risks, and optimize performance.

The core value of prototyping lies in its ability to reveal design flaws and performance limitations early in the development cycle. This proactive approach enables engineers to make necessary adjustments efficiently, avoiding costly rework and potential delays associated with scaling production. Moreover, a well-executed prototype allows for real-world testing, ensuring the final product meets the necessary performance criteria and functional requirements.

Prototyping is not merely about finding errors; it's also an opportunity to optimize design parameters, explore alternative component placements, and enhance the overall product. It enables a thorough evaluation of the PCB’s manufacturability, cost-effectiveness, and compliance with industry standards. Engaging with a local 'circuit board company near me' that prioritizes prototyping ensures the product is tailored to your specific needs, incorporating lessons learned from initial tests to deliver a higher-quality end product.

Frequently Asked Questions About Circuit Board Services

Addressing common questions regarding circuit board services is crucial for informed decision-making. This section provides clear answers to frequently asked questions about circuit board repair, manufacturing, and related services, helping you navigate the complexities of PCB selection and management.

- How much does it cost to repair a circuit board?

The cost to repair a circuit board varies greatly depending on the complexity of the board, the extent of the damage, and the components that need replacement. Simple repairs, like replacing a single capacitor, may cost as little as $50 to $100. However, more complex issues such as trace damage or IC replacements may range from $200 to $500 or even higher for specialized boards. It is essential to get a quote from the repair service after a thorough assessment of the board. - Do electricians deal with circuit boards?

While electricians are skilled in electrical wiring and systems, they typically do not specialize in circuit board repair. Circuit board work requires a deep understanding of electronics and component-level diagnostics. However, some electricians may possess experience in basic repairs and may be able to handle straightforward repairs or replacements. For detailed repairs, it is better to consult with an electronics technician or a company specializing in PCB repairs. - What is the average cost of a circuit board?

The average cost of a circuit board varies greatly based on several factors, including the board's complexity, number of layers, the materials used, production volume, and the manufacturer's pricing structure. Simple, single-layer boards for prototypes could cost a few dollars each in small quantities. In contrast, complex, multi-layer boards for specialized applications may cost several hundred dollars each. It's also important to factor in design, testing, and assembly costs when calculating the overall price. Generally, higher volume orders tend to reduce the per-unit cost. - What do you call someone who builds circuit boards?

Someone who builds circuit boards can be referred to by several titles, including a PCB assembler, a circuit board technician, an electronics technician, or an electronic manufacturing technician. The specific title often depends on the individual's responsibilities and their role within a manufacturing company, however, all of the above roles are focused on the process of creating a functional PCB. - What is the typical turnaround time for PCB manufacturing?

The turnaround time for PCB manufacturing can range from a few days to several weeks depending on the complexity of the board, the manufacturer's workload, and the order quantity. Simple, single-layer boards may have a quicker turnaround, sometimes within 24-48 hours using rapid prototyping services, whereas complex multi-layer boards, especially those involving custom materials or finishes, can take several weeks. It's important to get a clear timeline commitment when placing your order. - Can any circuit board be repaired?

While most circuit boards can be repaired to some extent, the feasibility depends on the nature and severity of the damage. Minor issues, such as a faulty component or a broken solder joint, are generally repairable. However, if the damage is extensive, like damage to multiple layers or critical components which are no longer available or where there is physical deformation of the board, repair may not be economically feasible. In such cases, it might be more cost-effective to replace the entire board. The repairability will require a thorough assessment from a professional repair service. - Are there environmentally friendly options for PCB manufacturing?

Yes, there are environmentally friendly options for PCB manufacturing, focusing on sustainable materials, eco-friendly manufacturing processes, and proper disposal techniques. This may include using lead-free solder, reducing chemical usage, employing energy-efficient equipment, and implementing recycling programs for waste and by-products. Companies can also use environmentally friendly substrates, which are produced with less environmental impact. Selecting a company that is committed to these practices can help reduce your project’s environmental impact.

The Significance of Certifications and Quality Assurance

When selecting a 'circuit board company near me', prioritizing certifications and quality assurance is crucial to guarantee the reliability and performance of your PCB products. These certifications demonstrate a commitment to quality management systems and environmental responsibility, ensuring that the manufacturer adheres to established standards.

- ISO Certifications

ISO certifications, such as ISO 9001:2015, indicate that a company follows a robust quality management system, encompassing processes from design to delivery. This certification ensures consistent product quality and process efficiency. - ROHS Compliance

Restriction of Hazardous Substances (RoHS) compliance is essential for environmental responsibility. RoHS certified manufacturers avoid using substances like lead, mercury, cadmium, and hexavalent chromium, ensuring the products are safer and compliant with environmental standards. - IPC Standards

IPC standards are industry-specific standards for PCB design, manufacturing, and assembly. Companies that adhere to IPC standards guarantee their adherence to professional fabrication and assembly practices, improving overall performance and reliability of the final product. - UL Certification

Underwriters Laboratories (UL) certification is a safety certification mark. UL listed and recognized components indicate adherence to specific safety guidelines, ensuring the board is safe for its intended use.

By choosing a circuit board company that holds these certifications, you not only mitigate the risks of product failures and recalls, but also demonstrate that you are choosing a reliable partner that meets the required quality and performance standards.

Actionable Tips for Working with PCB Companies

Effective collaboration with a circuit board company is crucial for successful PCB projects. This section outlines actionable tips to ensure clear communication, efficient project management, and ultimately, high-quality results.

- Provide Comprehensive Project Specifications

Begin by detailing your PCB requirements as thoroughly as possible. This includes the board's dimensions, layer count, materials, component specifications (BOM), functional requirements, desired performance characteristics, and any specific industry standards that need to be met. Clear specs minimize errors and revisions. - Establish Clear Communication Channels

Designate a primary point of contact within your team and the PCB company. Use email, project management tools, or regular meetings to ensure all parties are kept informed. Consistent, clear communication reduces misunderstandings and facilitates quick resolution of issues. - Request Quotes from Multiple Suppliers

Obtain detailed quotes from several PCB companies before committing to a contract. Compare pricing, lead times, and the scope of services offered. Consider the total cost, not just the price per board. - Review and Clarify Designs Meticulously

Carefully review the design and prototypes provided by the company. Look for any design flaws, errors, or misunderstandings of specifications. Be proactive in giving constructive feedback at every stage of development. - Ensure Transparency Regarding Project Timelines

Establish a clear project timeline with the PCB company, including key milestones and deadlines. Regular updates and schedule tracking are important. It is also important to agree on a process for addressing potential delays or changes to the project schedule. - Address Issues Promptly and Collaboratively

When issues arise, address them quickly and collaboratively. Work with the PCB company to develop practical solutions and make any necessary design or manufacturing adjustments. Open communication throughout this process is essential. - Maintain Detailed Records

Keep organized records of all project communications, revisions, and any changes or modifications made during the design and manufacturing process. This is extremely useful in identifying sources of errors and improving future projects.

Finding a reliable circuit board company near you doesn't have to be daunting. By assessing your needs, exploring local options, and carefully considering key factors like certifications and prototyping capabilities, you can confidently choose a partner that fits your project requirements. Whether it's for repair, manufacturing, or design services, a local circuit board company can streamline your electronics projects and bring your ideas to life. Remember to always look for options near you to save valuable time and shipping costs.

AnyPCBA

AnyPCBA