Finding Reliable PCBs Near You: A Comprehensive Guide

Printed circuit boards (PCBs) are the unsung heroes of modern electronics, powering everything from our smartphones to complex industrial machinery. Finding a reliable source for PCBs near you is crucial for both hobbyists and businesses. This article will guide you through the process of locating PCB manufacturers, understanding PCB disposal, and answering your burning questions about these essential components. Let's dive in and make sense of the PCB landscape near you.

Understanding Your PCB Needs

Before initiating a search for 'pcbs near me,' it's crucial to precisely define your project's requirements. This involves determining the production volume—whether you need a single prototype, a small batch, or mass production quantities—as well as the specific materials and technical specifications essential for your design. Accurate upfront planning significantly streamlines the selection process and ensures you source PCBs that perfectly match your project needs.

Identifying Local PCB Manufacturers and Suppliers

Locating suitable PCB manufacturers and suppliers requires a strategic approach, blending online research with industry-specific networking. The goal is to identify local entities that not only offer the required services but also align with your project's specific needs, such as expertise, production timelines, and technological capabilities. Focusing on 'pcb service near me' is crucial to minimize logistical hurdles and enable better communication.

Begin by exploring several avenues:

- Online Directories

Utilize online directories, such as Thomasnet, industry-specific platforms, and Google Maps, to find PCB manufacturers within your geographical area. These platforms often provide company profiles, contact details, and customer reviews, allowing for an initial assessment. - Industry Associations

Contact industry associations like the IPC (Association Connecting Electronics Industries). They often maintain lists of member companies, which can be a valuable resource for identifying qualified local manufacturers. Membership in such associations is often a good indicator of a company's commitment to quality and standards. - Personal Recommendations

Seek recommendations from colleagues, peers, or other professionals within the electronics industry. Personal referrals can often provide insights into a manufacturer's capabilities and reliability that might not be apparent through online research. - Local Trade Shows and Exhibitions

Attend relevant trade shows and exhibitions in your area. These events provide an excellent opportunity to meet representatives from various PCB manufacturers, discuss your specific requirements face-to-face, and evaluate their offerings directly.

When evaluating potential PCB suppliers, consider the following factors:

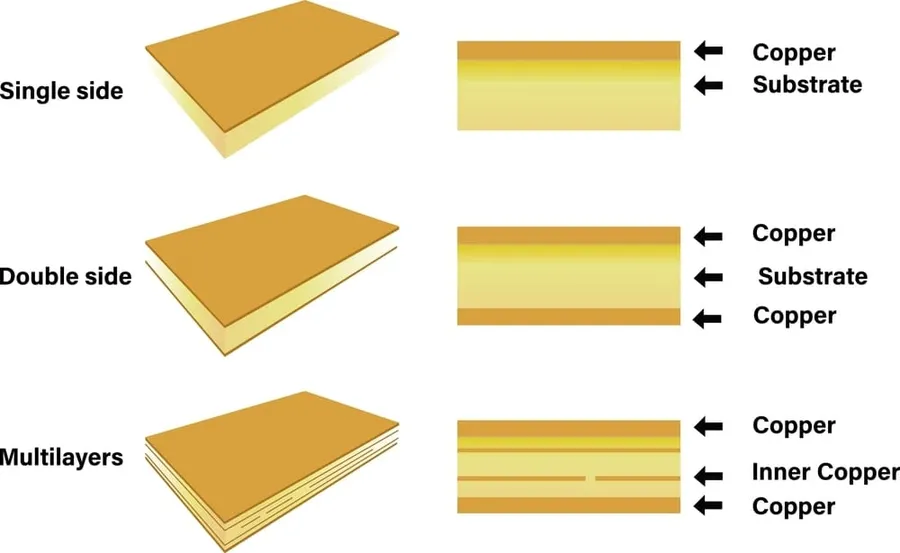

- Expertise and Specialization

Assess the manufacturer's expertise in producing the specific type of PCB you require (e.g., single-sided, double-sided, multilayer, flexible). Consider the complexity of your project and whether they have the necessary equipment and experience. - Turnaround Times

Evaluate their typical lead times for both fabrication and assembly, and make sure these times align with your project timelines. Confirm their ability to meet your project deadlines. - Technological Capabilities

Consider the available technologies and equipment, such as precision drilling, plating capabilities, surface mount technology (SMT) assembly, and testing equipment. Ensure they have the capabilities to meet the specific design requirements of your board. - Customer Support

Effective communication and technical support are essential. Choose a manufacturer that offers responsive customer service and is willing to assist with design for manufacturability (DFM) issues.

Key Factors to Consider When Choosing a PCB Manufacturer

Selecting the right PCB manufacturer is crucial for ensuring the quality and success of your electronic projects. Careful evaluation based on key factors, including certifications, material availability, assembly capabilities, testing protocols, and turnaround times is essential to make the right choice for your project. Ignoring these can lead to increased costs, delays, and compromised product performance.

- Certifications

Look for manufacturers with relevant certifications such as ISO 9001, which indicates a commitment to quality management systems. These certifications ensure that the manufacturer adheres to standardized processes. - Material Availability

Ensure that the manufacturer can provide the specific materials needed for your project (e.g., FR4, flex, aluminum). Different applications require different base materials, so versatility in this area is important. - Assembly Capabilities

Determine if you require assembly services in addition to fabrication. Some manufacturers offer both, which can streamline your process and reduce the need to work with multiple vendors. Verify if they handle surface mount (SMT) or through-hole technologies. - Testing Processes

Inquire about the manufacturer's testing procedures, which may include electrical testing, AOI (Automated Optical Inspection) or X-ray inspections. Comprehensive testing is essential for identifying defects before the PCBs move into application. - Turnaround times

Understand the estimated manufacturing and shipping timelines. Consider both standard and expedited options to find a solution that aligns with your project deadlines. Be clear on the lead time and how this corresponds to your project timeline.

PCB Fabrication and Assembly Services

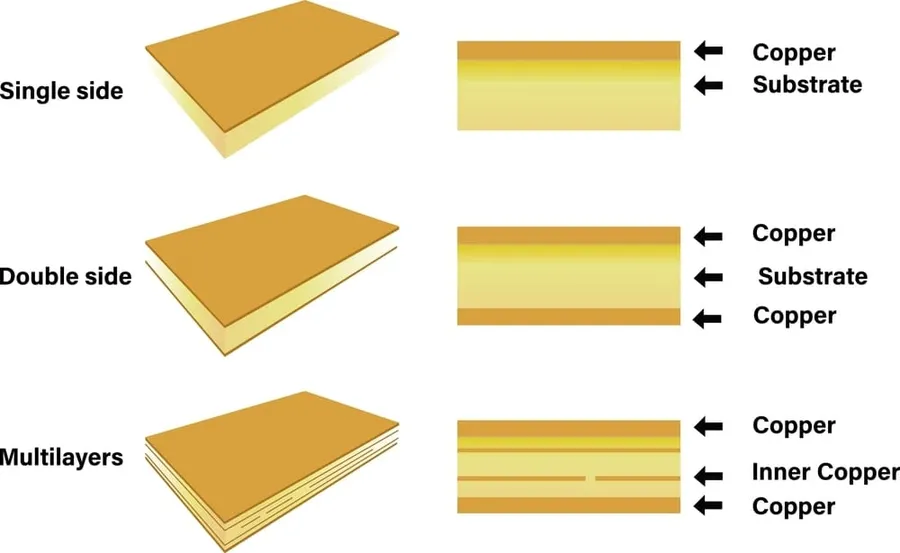

When sourcing PCBs, it's crucial to distinguish between fabrication and assembly services. Fabrication refers to the manufacturing of the bare printed circuit board, while assembly involves mounting electronic components onto the fabricated board. Understanding this distinction is vital to ensure that your 'pcbs near me' search yields a supplier that meets your project's specific requirements.

Some manufacturers provide both services, offering a comprehensive 'turnkey' solution that streamlines the process. Others may specialize in either fabrication or assembly, requiring you to engage with multiple vendors. Your decision should depend on factors such as complexity, volume and how much time you want to invest on your project's logistics. Verify if 'pcbs near me' offer a full range of manufacturing and assembly services.

- PCB Fabrication

This involves producing the bare board using materials such as FR4, flex, or aluminum, with specific layer counts, thicknesses, and copper weights defined by your design. This is a specialized process utilizing precision manufacturing equipment and processes. - PCB Assembly

This service involves the placement and soldering of electronic components onto the bare board. Techniques used include surface mount technology (SMT) and through-hole technology (THT). Quality assurance, such as automated optical inspection (AOI), is an important part of this process. - Turnkey Solutions

A single provider handles both fabrication and assembly, which can simplify project management, reduce the number of vendors to coordinate, and enhance overall project efficiency. Turnkey solutions are often quicker and cheaper due to the reduction in logistics and communication overhead.

Pricing and Cost Optimization Strategies

Securing the most favorable pricing for your PCBs involves proactive budget discussions with potential manufacturers and exploring options to optimize your design and material selections. Obtaining multiple quotes ensures you receive the highest value for quality printed circuit boards near you.

Here's how to navigate cost considerations:

- Transparent Budget Communication

Clearly articulate your budget constraints upfront. This allows manufacturers to suggest cost-effective alternatives without compromising performance. - Design for Manufacturing (DFM)

Adopt DFM principles. Simpler designs with standard components and layer counts can significantly reduce manufacturing costs. Working closely with the manufacturer during the design phase is key. - Material Choice Optimization

Consider material options. While FR4 is the most common choice, other materials may be more cost-effective for your specific application. Be open to alternatives suggested by the PCB manufacturer. - Panelization Strategies

Utilize panelization whenever possible. Placing multiple PCBs on a single panel during fabrication reduces production costs and waste. Discuss with the manufacturer to understand panelization options. - Order Volume Optimization

Explore the impact of order volume on price. Ordering in larger quantities can lead to per-unit cost reductions. Optimize your order quantity to achieve better pricing without overstocking. - Surface Finish Considerations

Surface finishes such as HASL (Hot Air Solder Leveling) are often less expensive than ENIG (Electroless Nickel Immersion Gold). Choose a finish that is suitable for your application to save on costs. - Component Sourcing

Consider leveraging the manufacturer's component sourcing network. They may have established relationships with suppliers, leading to lower component costs. Compare their rates with your own suppliers. - Competitive Quotations

Request quotations from multiple manufacturers. This allows you to compare pricing, lead times, and services to ensure you get the best value for your investment. Ensure you are comparing apples to apples by providing the same specifications.

PCB Disposal and Environmental Responsibility

Proper PCB disposal is crucial due to the environmental and health hazards associated with polychlorinated biphenyls. Adhering to local and national guidelines is essential to mitigate these risks, therefore selecting manufacturers with environmentally responsible practices and utilizing designated PCB recycling facilities is paramount to ensure proper waste management.

- Understanding PCB Regulations

Familiarize yourself with local, state, and federal regulations regarding PCB disposal. These regulations often specify acceptable disposal methods and may impose penalties for improper handling. - Environmentally Responsible Manufacturing

Choose PCB manufacturers that prioritize environmental responsibility. This includes practices such as reducing waste generation, using eco-friendly materials, and having systems in place for proper handling and disposal of PCB-containing waste. - PCB Recycling Facilities

Research and utilize PCB recycling facilities in your area. These facilities specialize in the safe and effective treatment of PCBs, preventing them from entering landfills or contaminating the environment. - Safe Handling Practices

Implement strict handling procedures to prevent spills or leaks of PCB containing materials. This includes proper storage, transportation, and handling methods. - PCB alternatives

Where possible, seek alternatives to PCB materials. Substituting PCB materials with environmentally friendly alternatives reduces the risks associated with PCB handling and disposal.

Frequently Asked Questions About PCBs

Understanding PCBs (Polychlorinated Biphenyls) is crucial for both their application and safe handling. This section addresses common questions regarding their history, usage, and environmental impact, ensuring clarity on the complete PCB lifecycle.

- Where are PCBs most commonly found?

PCBs, while now largely banned, were historically prevalent in electrical equipment like transformers and capacitors, as well as in building materials such as caulking, paints, and sealants. Older industrial equipment and some legacy building structures may still contain these substances. - What was a common source of PCBs?

A primary source of PCBs was their use as dielectric fluids in electrical equipment due to their insulating and fire-resistant properties. Additionally, they were used as plasticizers and additives in various industrial and commercial applications prior to their ban. - Are PCBs still used in the US?

The manufacture of PCBs was banned in the US in 1979 under the Toxic Substances Control Act. However, existing equipment containing PCBs may still be in service, and these must be managed according to EPA regulations, including proper disposal, to prevent environmental and health hazards. Current use is limited to specific, tightly regulated situations. - What are PCBs used for today?

Today, PCBs are not intentionally manufactured in the US. Any remaining PCBs are primarily found in legacy applications that were installed before the ban. Ongoing efforts focus on the safe removal and disposal of these substances, following environmental safety protocols. - How can I ensure the safe disposal of PCBs?

PCB disposal must be handled according to local and national environmental regulations. This typically involves using certified waste disposal facilities equipped to handle hazardous materials. Never dispose of PCB-containing materials in regular trash or through unauthorized means to avoid environmental contamination. - What is the environmental impact of PCBs?

PCBs are persistent organic pollutants (POPs) that can bioaccumulate in the environment, meaning they build up in living organisms and the food chain. They are toxic to wildlife and humans, and can cause a range of health issues including developmental, neurological, and reproductive problems. - How can I find PCB recycling facilities near me?

To locate PCB recycling facilities, consult your local environmental protection agency or department of public works. These agencies often maintain lists of authorized facilities and can provide guidance on proper disposal procedures. Search online using terms like 'hazardous waste disposal facilities near me' to find relevant service providers.

Comparing Local PCB Options: Key Parameters

When selecting a local PCB manufacturer, a systematic comparison is crucial to ensure the best fit for your project. This section outlines the key parameters you should evaluate to make an informed decision. By carefully assessing each factor, you can identify a manufacturer that aligns with your specific requirements, budget, and timeline.

| Parameter | Description | Importance |

|---|---|---|

| Location | Geographic proximity to your location. | Reduces shipping costs and lead times. Facilitates easier communication and site visits. |

| Turnaround Time | The time taken from order placement to delivery of finished boards. | Critical for time-sensitive projects. Consider both fabrication and assembly times. |

| Material Options | The range of materials the manufacturer can process (e.g., FR4, flex, aluminum) | Ensures the manufacturer can meet your application's specific material needs and performance requirements. |

| Assembly Services | Whether the manufacturer offers both PCB fabrication and component assembly. | Convenient for a full-service solution; otherwise, you'll need to coordinate with multiple vendors. |

| Minimum Order Quantity | The minimum number of PCBs the manufacturer is willing to produce. | Important for prototyping or small batch runs; large MOQs can be prohibitive for initial testing or small projects. |

| Certifications (e.g., ISO 9001) | Formal recognition of the manufacturer's quality management system. | Indicates a commitment to quality control and process consistency, reducing the risk of defects and ensuring reliable PCBs. |

| Cost Per Board | The price for each PCB produced. | Compare quotes from multiple manufacturers. Consider total cost, not just unit price, factoring in shipping and potential revisions. |

| Shipping Time | The time taken to ship boards to your specified destination. | Impacts total lead time and project schedules. Consider domestic and international shipping options and costs. |

| Specialized Services | Unique manufacturing capabilities beyond the basics such as blind and buried vias or impedance control. | Crucial for complex boards and for certain demanding applications. |

| Testing Procedures | The types of tests offered (e.g., electrical testing, AOI inspection) | Ensures board functionality and reliability. Thorough testing reduces the risk of failures in the field. |

| Customer Support | Responsiveness, clear communication, and willingness to resolve issues. | Facilitates smooth project management and addresses potential problems quickly |

Table: PCB Manufacturer Comparison

The following table provides a template for comparing local PCB suppliers based on key criteria. It's important to tailor these parameters to your project specific needs. Use this table to gather data from potential vendors for an effective and balanced evaluation.

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Location | City A | City B | City C |

| Turnaround Time | X days | Y days | Z days |

| Material Options | FR4, Flex, etc. | FR4 only | FR4, Aluminum |

| Assembly Services | Yes | No | Yes |

| Min Order Quantity | 100 | 10 | 1000 |

| ISO Certification | Yes | No | Yes |

| Cost per board | $x | $y | $z |

| Shipping time | A days | B days | C days |

Table: PCB Manufacturer Comparison

The following table provides a structured comparison of potential PCB manufacturers, aiding in the selection process based on key parameters relevant to your specific needs. This allows for a side-by-side analysis, ensuring you choose the best partner for your project.

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Location | City A | City B | City C |

| Turnaround Time | X days | Y days | Z days |

| Material Options | FR4, Flex, etc. | FR4 only | FR4, Aluminum |

| Assembly Services | Yes | No | Yes |

| Min Order Quantity | 100 | 10 | 1000 |

| ISO Certification | Yes | No | Yes |

| Cost per board | $x | $y | $z |

| Shipping time | A days | B days | C days |

Finding the right PCBs 'near me' involves more than just a quick search. It requires understanding your project's needs, evaluating potential manufacturers, and considering environmental responsibility. By carefully assessing your options, you can secure high-quality PCBs and contribute to a sustainable future. Remember, finding reliable pcb service near me is the key to a successful project. This will ensure your electronics projects are not only functional but also high quality.

AnyPCBA

AnyPCBA