Finding the Best Mobile PCB Stand: Price, Features & Value

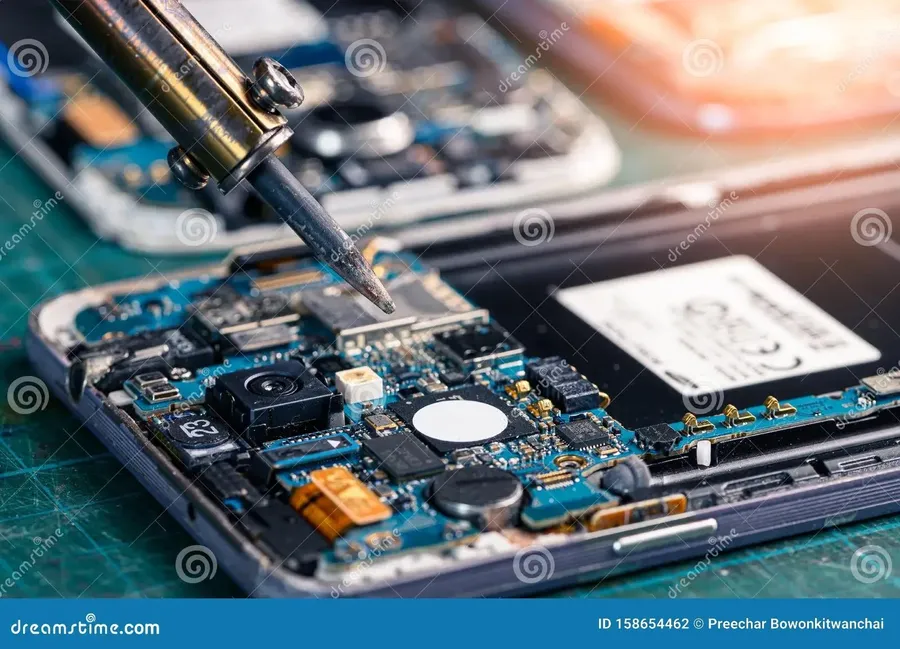

In today's tech-driven world, the ability to repair our own devices is increasingly valuable. At the heart of many electronic repairs lies the need for a reliable PCB (Printed Circuit Board) stand. These unassuming tools are the unsung heroes of mobile phone repair, providing stability and precision crucial for intricate soldering work. Whether you're a seasoned technician or an enthusiastic DIYer, understanding the nuances of the mobile PCB stand price and features can significantly impact your repair efficiency and success. This article delves deep into the world of PCB stands, exploring price points, key features and how to choose the right one for you.

Understanding the Importance of a Mobile PCB Stand

A mobile PCB stand is a fundamental tool for electronics repair, providing the necessary stability and precision for working with delicate circuit boards. Its importance stems from its ability to secure the PCB, allowing technicians to perform soldering, component replacement, and other intricate tasks with reduced risk of damage or error. Without a dedicated stand, the risk of slippage, accidental shorts, and imprecise work is significantly increased.

- Stability:

A PCB stand firmly holds the board in place, preventing movement that could lead to component damage or soldering errors. This is especially critical when working with small surface mount components. - Precision:

By maintaining a consistent working position, a PCB stand enables technicians to make precise solder joints and component placements. This precision is crucial for ensuring the longevity and functionality of the repaired device. - Ease of Access:

A quality stand allows easy access to all areas of the PCB, allowing free movement of soldering irons, hot air rework tools, and testing probes. The improved access and visibility, enables faster and more efficient repairs. - Reduced Risk of Damage:

By providing a stable platform, a PCB stand reduces the risk of accidental bending or breaking of the board, leading to fewer costly repairs and higher customer satisfaction.

Key Features to Look for in a Mobile PCB Stand

Selecting the correct mobile PCB stand is crucial for efficient and precise electronic repairs. Key attributes of a high-quality stand include material composition, adjustability, heat resistance, and compatibility with diverse board sizes. Each of these characteristics significantly impacts the stand's performance and suitability for various repair tasks.

- Material Composition

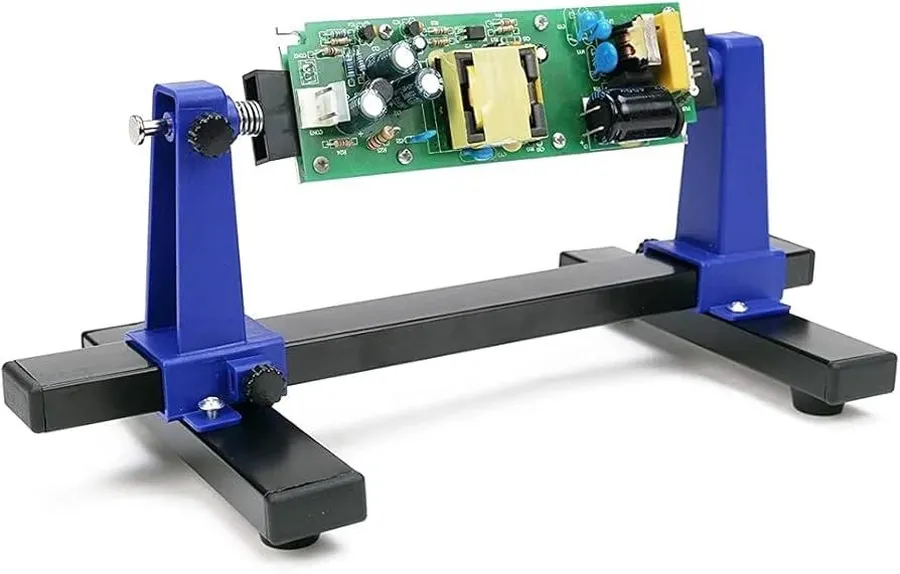

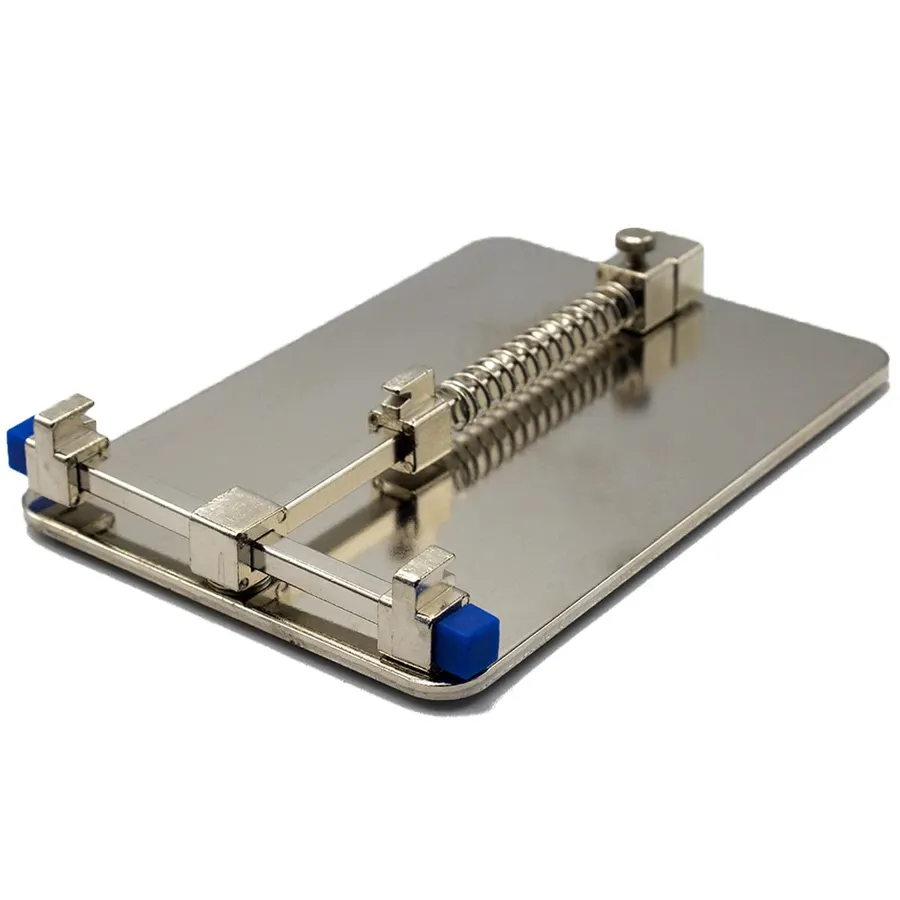

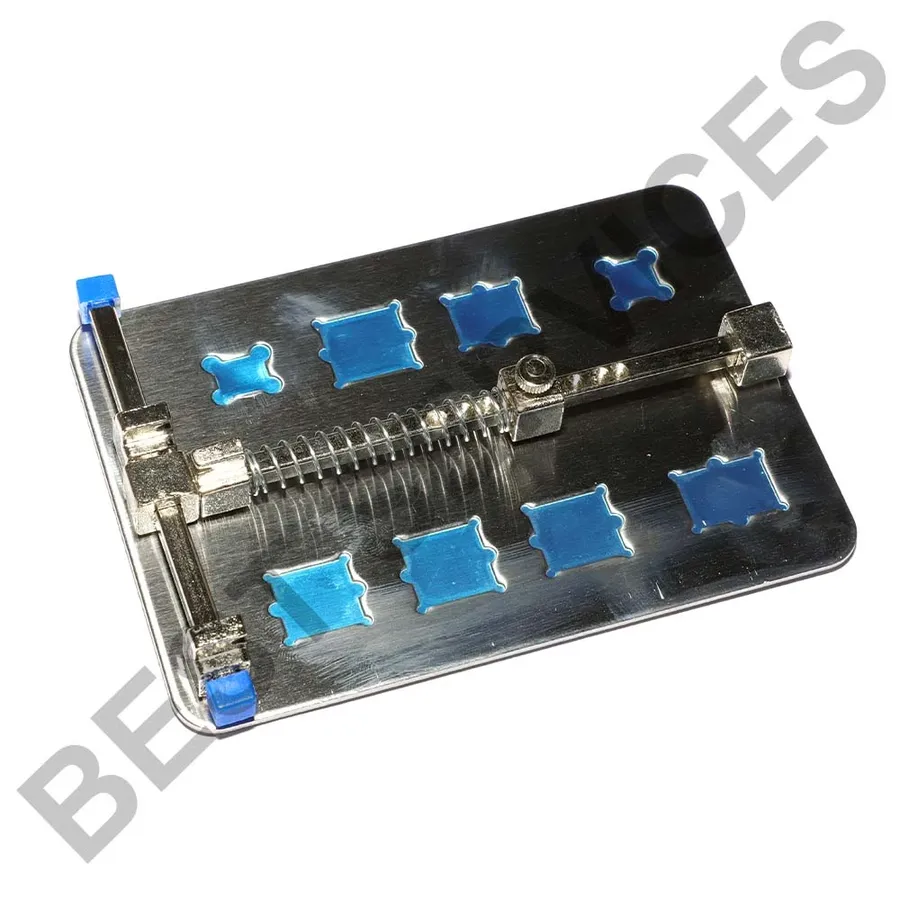

The material from which a PCB stand is constructed dictates its durability and thermal properties. Common materials include aluminum, stainless steel, and various composites. Aluminum offers a good balance of strength and weight, stainless steel provides exceptional durability and resistance to corrosion, while composites can offer specific properties like improved heat resistance. The material directly influences the stand's ability to withstand daily use, exposure to soldering temperatures, and overall longevity. - Adjustability

A versatile PCB stand should offer a range of adjustability options, including height, tilt, and rotation. These adjustments are necessary to accommodate different board sizes and configurations, allowing the user to position the PCB at an optimal angle for repair tasks. The clamping mechanism should be firm enough to secure the PCB without damaging delicate components. - Heat Resistance

During soldering and hot air rework processes, the PCB stand is inevitably exposed to heat. High heat resistance is essential to prevent deformation or melting of the stand itself, and to ensure that it doesn't transfer heat to the PCB, potentially damaging its components. This is an important safety and functionality consideration. - Compatibility with Board Sizes

The PCB stand must be compatible with the range of board sizes you'll be working on. A universal design with variable clamping is optimal for diverse boards including larger tablets and the smallest of smartphones. Consider the stand's clamping range and ensure it will securely hold your most common PCB sizes.

| Feature | Importance | Considerations |

|---|---|---|

| Material Composition | Durability, Thermal Properties | Aluminum, Stainless Steel, Composites |

| Adjustability | Versatile Positioning, Optimal Viewing | Height, Tilt, Rotation, Secure Clamping |

| Heat Resistance | Safety, Prevents Damage | High Melting Point Materials |

| Board Size Compatibility | Fits Different Devices | Clamping Range, Universal Design |

Mobile PCB Stand Price: A Detailed Price Analysis

The cost of a mobile PCB stand varies significantly based on several factors, including build quality, materials, brand reputation, and the features offered. Understanding these variables is crucial for making an informed purchase that aligns with your budget and technical requirements. This section provides a detailed price analysis to guide your decision-making process.

| Category | Typical Price Range | Features | Target User | Expected Lifespan |

|---|---|---|---|---|

| Entry-Level | $10 - $25 | Basic adjustability, usually plastic or light metal construction, simple clamps or clips. | Hobbyists, beginners, occasional use. | 1-2 Years |

| Mid-Range | $25 - $60 | Improved adjustability, durable metal construction, better stability, enhanced gripping mechanisms. | Frequent users, mobile repair technicians with moderate workloads. | 3-5 Years |

| Professional-Grade | $60 - $150+ | High-precision adjustability, robust materials (e.g., stainless steel, aluminum alloy), heat resistance, magnetic base, advanced clamping mechanisms, additional features like component trays. | Professional repair centers, engineers, high-volume repair technicians. | 5+ Years |

Several factors contribute to the price variations observed across different mobile PCB stands. Material selection is a primary cost driver. Stands made from high-grade materials such as aluminum alloy and stainless steel command a higher price due to their durability and heat resistance, as compared to basic plastic or lighter metals. Similarly, the level of adjustability and the precision of the clamping mechanisms also affect pricing. Stands with advanced adjustment capabilities, such as 360-degree rotation or adjustable height, tend to be more expensive. Brand reputation further influences cost; well-established brands known for high-quality repair tools often sell their products at a premium. Lastly, specialized features, such as heat resistance, magnetic mounts, and component trays, also add to the overall price of the stand.

When considering your purchase, it's important to evaluate your specific needs against these price points. Entry-level models are suitable for simple projects and occasional use. However, those performing repairs regularly or handling complex tasks will find that the enhanced features and durability of mid-range or professional-grade stands justify the higher price. Investing in a quality stand ensures stability and safety, thereby minimizing risks of damage to the board or injury during the repair process.

Popular Brands and Models of Mobile PCB Stands

The mobile repair industry relies heavily on reliable tools, and PCB stands are no exception. This section provides an overview of leading brands like Mechanic and Sunshine, examining some of their popular models. We'll evaluate these stands based on their price, key features, and user feedback to help guide purchasing decisions.

| Brand | Model | Price Range (USD) | Key Features | User Feedback |

|---|---|---|---|---|

| Mechanic | iBoot PCB Fixture | 25-40 | Universal compatibility, heat resistant, adjustable clamps | Generally positive, noted for stability and ease of use |

| Mechanic | Mini PCB Holder | 15-25 | Compact, basic design, suitable for smaller boards | Good for beginners, some complaints about limited adjustability |

| Sunshine | SS-601A Universal PCB Holder | 20-35 | Rotatable, adjustable width, sturdy base | Popular for its versatility, some concerns about clamp durability |

| Sunshine | SS-T12A Multi-functional Fixture | 40-60 | Multi-functional, high temperature resistance, precise clamping | Favored by professional technicians for advanced tasks |

These brands, Mechanic and Sunshine, are known for their focus on tools specific to electronics and mobile repair. Mechanic, for example, is often recognized for its robust build quality and innovative designs, while Sunshine offers a blend of affordability and functionality. However, individual model reviews can vary based on the specific needs of the user. When choosing, it's important to consider the specific type of work and volume of use.

Choosing the Right PCB Stand for Your Needs

Selecting the appropriate PCB stand is crucial for efficient and effective mobile device repairs. The ideal stand depends heavily on the specific demands of your work, considering factors such as the frequency of use, the types of repairs you typically perform, and the overall environment where you work. This section provides a structured approach to help you identify the stand that best suits your unique requirements.

| Use Case | Typical Repair Type | Recommended Stand Type | Key Features | Considerations |

|---|---|---|---|---|

| Occasional Hobbyist | Simple component swaps, screen replacements | Basic, lightweight stand | Affordable, easy to use, stable enough for small boards | Adjustability not critical, prioritize portability |

| Frequent DIY User | Regular repairs on various devices, complex soldering | Adjustable stand with good stability | Sturdy build, versatile adjustment options, suitable for different board sizes | Look for heat resistance, consider magnetic mounts |

| Professional Technician | High-volume, detailed repair work, micro-soldering | Professional grade stand with advanced features | Heavy-duty build, precise adjustability, heat resistance, anti-static features | Prioritize durability and high precision, consider additional accessories |

By aligning your needs with these use-case profiles, you can make a more informed decision when selecting a PCB stand. Remember to also consider your budget and any specific preferences you may have regarding materials and additional features. This analysis will lead to a choice that enhances your repair workflow and productivity.

Where to Buy Mobile PCB Stands: Online vs. Offline

Acquiring a mobile PCB stand involves considering both online and offline retail options, each offering distinct advantages and disadvantages. Selecting a reliable source is crucial to ensure product authenticity and value, which are essential for effective and safe electronic repairs.

Online marketplaces and direct-to-consumer websites are readily available, providing a wide selection of brands and models. Physical stores, including electronic supply stores and specialized repair shops, allow for hands-on product inspection.

| Factor | Online Retailers | Offline Retailers |

|---|---|---|

| Selection | Extensive, wide variety of brands and models | Limited to the store's stock |

| Price | Often competitive due to lower overhead costs; frequent discounts and sales | Potentially higher prices |

| Convenience | Convenient shopping from home; 24/7 availability. | Requires travel to the store; limited operating hours |

| Inspection | Reliance on product descriptions and images; limited physical inspection | Allows for hands-on examination of products; immediate availability |

| Shipping | Requires shipping time; additional cost | Immediate purchase; no shipping costs |

| Returns | Often offers return policies with conditions | Potentially more straightforward return processes |

| Counterfeit Risk | Higher risk, requires thorough vetting of the seller. | Lower risk, typically purchasing from authorized retailers. |

When selecting a retailer, consider the following to avoid counterfeit products and ensure a satisfactory purchase:

- Seller Reputation

Check customer reviews and ratings on the seller's platform. Verify the seller's credibility and history before making a purchase. - Authenticity Verification

Look for certifications or official partnerships with known brands if possible. Some brands provide QR codes or serial numbers on the product packaging for online verification. - Warranty and Return Policies

Make sure that warranty and return policies are clearly stated and that they offer reasonable options. Understand the terms and conditions, especially for online retailers. - Price Benchmarking

Compare pricing across multiple retailers to detect unusually low prices, which might indicate a counterfeit item. Compare the price with the manufacturer's recommended price. - Secure Payment Methods

Use secure and reputable payment methods to protect your financial data. Avoid making payments via unsecured methods.

Frequently Asked Questions about Mobile PCB Stands

This section addresses common queries regarding mobile PCB stands, offering concise and authoritative answers to help users make informed decisions. These questions explore material choices, adjustability, compatibility, and other key aspects of PCB stand functionality.

- What is the best material for a PCB stand?

The ideal material for a PCB stand combines durability, heat resistance, and stability. Common choices include aluminum alloys, stainless steel, and certain high-strength plastics. Aluminum offers a good balance of weight and heat dissipation, while steel provides superior rigidity. The best choice often depends on the specific repair environment and the frequency of use. - Are there adjustable mobile PCB stands?

Yes, many mobile PCB stands offer adjustable features. These adjustments may include height, angle, and clamping mechanisms to accommodate various PCB sizes and allow for optimal positioning during repair work. Adjustable stands significantly improve ergonomics and precision by allowing technicians to customize the setup for their comfort and the specific task at hand. - How can I ensure the PCB stand is compatible with my device?

Compatibility is typically determined by the stand's clamping mechanism and overall design. Check the stand's specifications for supported board dimensions and mounting capabilities. Some stands offer universal compatibility, while others are designed for specific types of devices. The key is to ensure the stand can securely hold your specific PCB without excessive force or potential damage. Consider your device's typical PCB size when selecting a stand. - What price range should I expect for a quality mobile PCB stand?

The price for a quality mobile PCB stand can vary significantly. Entry-level models may start around $20, while professional-grade stands can cost upwards of $100 or more. Factors like material, brand, adjustability, and features impact the price. Investing in a robust stand provides better stability, durability, and can ultimately improve repair outcomes. - How important is heat resistance in a PCB stand?

Heat resistance is crucial in a PCB stand because soldering and rework operations generate significant heat. A stand with inadequate heat resistance can deform or compromise the stand's integrity, potentially impacting the safety and precision of your repair work. Stands made from aluminum alloys or with ceramic inserts offer good heat dissipation, making them suitable for frequent soldering. - Can a PCB stand improve repair precision?

Absolutely, a PCB stand significantly improves repair precision by providing a stable, non-slip platform. This prevents the PCB from shifting during soldering, component replacement, or other delicate repair processes, reducing the chance of error and improving the overall quality of repair. The stand's stability ensures a more controlled and accurate working environment. - Are magnetic PCB stands beneficial?

Magnetic PCB stands provide added convenience and stability by allowing quick and secure PCB placement using magnetic mounts. This is particularly beneficial for small or oddly-shaped boards. However, it’s crucial to ensure that the magnets don’t interfere with the PCB’s electronic components, which may require careful placement. Overall, they offer convenience and efficiency.

Tips for Maintaining Your Mobile PCB Stand

Proper maintenance of your mobile PCB stand is crucial for ensuring its longevity and consistent performance. By following simple guidelines for cleaning and storage, you can safeguard your investment and maintain the precision it provides during delicate repair work. These practices minimize wear and tear and help the stand withstand the rigors of daily use in a repair environment.

- Regular Cleaning

Clean your PCB stand regularly to prevent the buildup of flux, solder, and debris. Use a soft, lint-free cloth dampened with isopropyl alcohol (IPA) for cleaning. Avoid using harsh chemicals or abrasive cleaners that could damage the stand's finish or material. - Disassembly for Deep Cleaning

Periodically disassemble the stand to clean components individually. This allows for thorough removal of any accumulated debris that may be trapped in joints or crevices. Make sure to reassemble correctly and confirm all components are securely fitted after cleaning. - Lubrication

If your stand has moving parts, such as adjustable knobs or clamps, apply a small amount of non-conductive lubricant periodically to ensure smooth operation. This reduces friction and prevents components from sticking, prolonging the life of these mechanisms. - Proper Storage

When not in use, store your PCB stand in a dry, clean environment to prevent corrosion or damage. Consider storing it in a case or container to protect it from dust and physical impacts. Avoid storing the stand in humid or extreme temperature conditions. - Inspection

Regularly inspect the stand for any signs of damage, wear, or loose parts. Tighten any screws or clamps and replace damaged components to maintain stability and accuracy. Early detection of issues can prevent more significant problems down the line. - Avoid Overloading

Never exceed the weight limits of the PCB stand. Overloading can cause damage to the stand itself and could also result in inaccurate positioning or even damage to your PCBs. Ensure you use the stand for the purpose it was designed.

Advanced Features and Add-ons for PCB Stands

For advanced mobile PCB repair work, several specialized features and add-ons can significantly enhance a PCB stand's utility. These enhancements cater to intricate tasks, offering greater precision, safety, and efficiency. Understanding these advanced options helps users select the best tools for complex repair needs.

- Built-in Heat Resistance

High-end PCB stands often feature materials with exceptional heat resistance. This is crucial when performing soldering or hot air rework, protecting the stand from damage and ensuring the workspace remains safe. Materials such as ceramic or high-temperature alloys are often utilized. - Magnetic Mounts and Clamps

Magnetic mounts and clamps provide a secure and versatile way to hold PCBs of different shapes and sizes without the need for traditional screw-based clamps. These magnetic options allow for rapid setup and adjustments, particularly beneficial for quick component change-outs and adjustments. - Integrated Magnifying Lenses

Some PCB stands come equipped with magnifying lenses, which offer a detailed view of the PCB components, essential for micro-soldering and the repair of surface-mount components. Integrated lenses enhance precision and reduce eye strain during lengthy repair sessions. - Adjustable Arms and Articulating Joints

Stands with adjustable arms and articulating joints increase versatility by enabling the user to position the PCB at the optimal angle for different tasks. This helps to improve ergonomics, and provides easier access to hard-to-reach areas of the board. - Anti-static Features

Electrostatic discharge (ESD) can damage sensitive electronic components. Some premium stands incorporate anti-static features, such as grounding points or conductive materials, minimizing the risk of damage from static electricity. - Integrated LED Lighting

Built-in LED lighting is an additional feature that illuminates the work area, ensuring a clear view of the components and solder joints. This is especially useful for fine work, and reduces reliance on external lighting, while improving visibility. - Vacuum Suction Bases

For increased stability, vacuum suction bases adhere securely to the workbench. This reduces any accidental movement during complex tasks, and are especially helpful when working on a board with fine or delicate components

Choosing the right mobile PCB stand is vital for any technician or hobbyist engaged in phone repairs. Understanding the diverse range of available options and their respective mobile PCB stand prices allows you to make an informed purchasing decision. With the right stand, you can greatly improve your workflow, precision, and overall success rate in soldering and phone repair. Ultimately, investing in a quality PCB stand isn't just about buying a tool; it's about ensuring that every repair you undertake is performed with the highest level of stability and efficiency.

AnyPCBA

AnyPCBA