Finding the Cheapest PCB Printer: A Comprehensive Guide for Makers

The ability to prototype your own printed circuit boards (PCBs) is a game-changer for electronic hobbyists and professionals alike. While advanced PCB manufacturing services are readily available, they often come with a price tag that can hinder rapid prototyping and experimentation. This article explores various avenues to obtain a 'cheapest PCB printer' including DIY methods and affordable machines, providing a pathway for everyone to access PCB fabrication at a reasonable cost. We'll cover techniques, equipment, and services to help you prototype your electronics project without compromising quality.

Understanding the Landscape of PCB Printing

The realm of Printed Circuit Board (PCB) fabrication encompasses diverse methodologies, each with distinct advantages and limitations. For budget-conscious users seeking the 'cheapest pcb printer' solution, a clear understanding of these options – etching, milling, and direct printing – is crucial for making informed decisions. This section provides an overview of each method to guide your choice.

| Method | Description | Pros | Cons | Cost Considerations |

|---|---|---|---|---|

| Etching | Uses chemical reactions to remove unwanted copper, leaving the desired circuit pattern. | Relatively inexpensive for simple designs, suitable for mass production, well-established process. | Requires chemicals and careful handling, can be challenging for fine details, can be time consuming, environmental impact related to disposal. | Low material cost but has higher setup costs for chemicals and tools, and can be time-consuming |

| Milling | Employs a CNC machine to physically cut away the copper from a board, creating the circuit pattern. | Good for prototyping, no chemicals involved, allows for quick iterations, precise. | Can be slow for large boards, not suitable for mass production, tools can break, limited to two layers, higher cost for more complex designs. | Moderate upfront investment in a CNC machine and tooling, higher running cost per board |

| Direct Printing | Involves directly printing conductive inks or materials onto a substrate to form circuits. | Potentially rapid prototyping, no chemicals involved, minimal material waste, enables flexible circuits | Still an emerging technology, often costly for equipment, limited material choices and layer capabilities, accuracy and reliability can be challenges. | High initial cost for equipment, limited options for affordable models, and can be costly to operate per board. |

DIY PCB Fabrication Methods: A Budget-Friendly Approach

For hobbyists and makers seeking the most economical path to PCB fabrication, DIY methods offer a compelling alternative to professional services or direct PCB printers. These approaches, while requiring more hands-on effort, significantly reduce costs and provide a deeper understanding of the PCB creation process.

Several DIY techniques stand out for their affordability and accessibility, each with its own set of requirements and cost implications. Let's explore the most common ones:

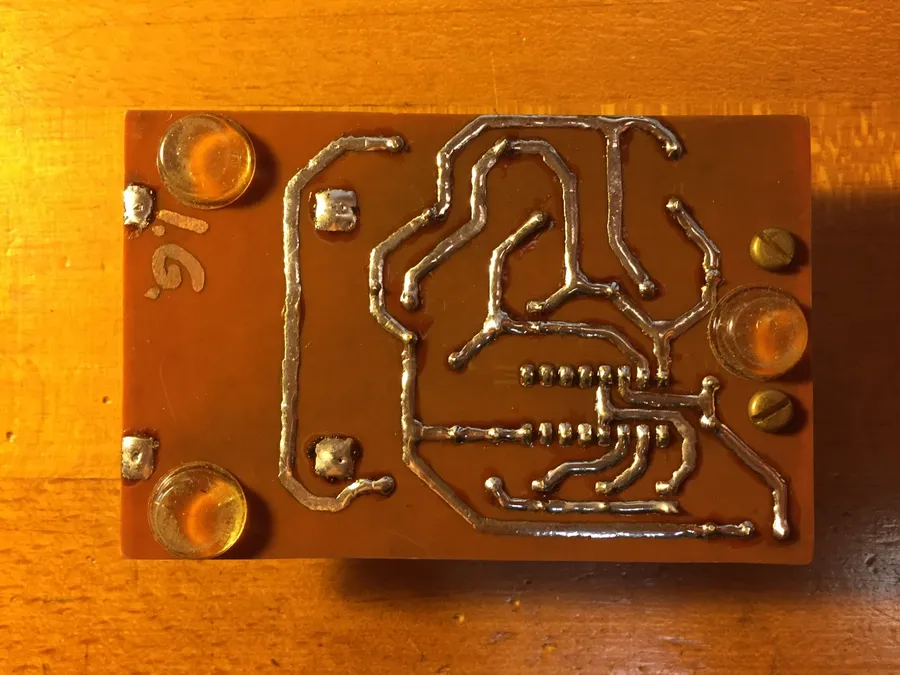

- Toner Transfer

This method uses a laser printer to transfer a PCB design onto copper-clad board using toner. The board is then etched to remove unwanted copper. The equipment needed includes a laser printer, glossy paper, an iron or laminator, etching solution (ferric chloride or ammonium persulfate), and basic safety equipment. This method is relatively low-cost and good for simple PCBs with larger traces but may have limitations in achieving very fine details and can have a lower success rate compared to other methods. - Photoresist Etching

Photoresist etching involves using UV light to transfer a design onto a photosensitive PCB board, followed by etching. Equipment includes a UV light source, transparency film, photoresist-coated PCB boards, developer solution, etching solution, and safety gear. This process offers improved precision over toner transfer, leading to finer features on the final PCB. However, the photoresist materials increase the cost. - CNC Milling

CNC milling uses a CNC machine with a milling bit to remove copper from a PCB board, creating the circuit traces. Required equipment includes a CNC milling machine capable of handling PCBs, specialized milling bits, and PCB material. CNC milling offers excellent precision and can handle complex designs, including multilayer boards. However, a dedicated CNC mill is a significant investment, making it less suitable for absolute beginners. It also produces dust, which requires a proper setup to address.

| Method | Equipment Needed | Cost | Complexity | Precision | Pros | Cons |

|---|---|---|---|---|---|---|

| Toner Transfer | Laser printer, glossy paper, iron/laminator, etching solution | Low | Low | Low to Medium | Cheap setup, easy to learn | Lower precision, can be unreliable, best for simple designs |

| Photoresist Etching | UV light source, transparency film, photoresist PCB boards, developer, etching solution | Medium | Medium | Medium to High | Higher precision, better for smaller features | Higher material costs, more steps |

| CNC Milling | CNC milling machine, PCB bits, PCB material | High | Medium to High | High | Very precise, good for complex boards | High equipment cost, requires expertise, dust production |

Affordable PCB Manufacturing Services: An Alternative to DIY

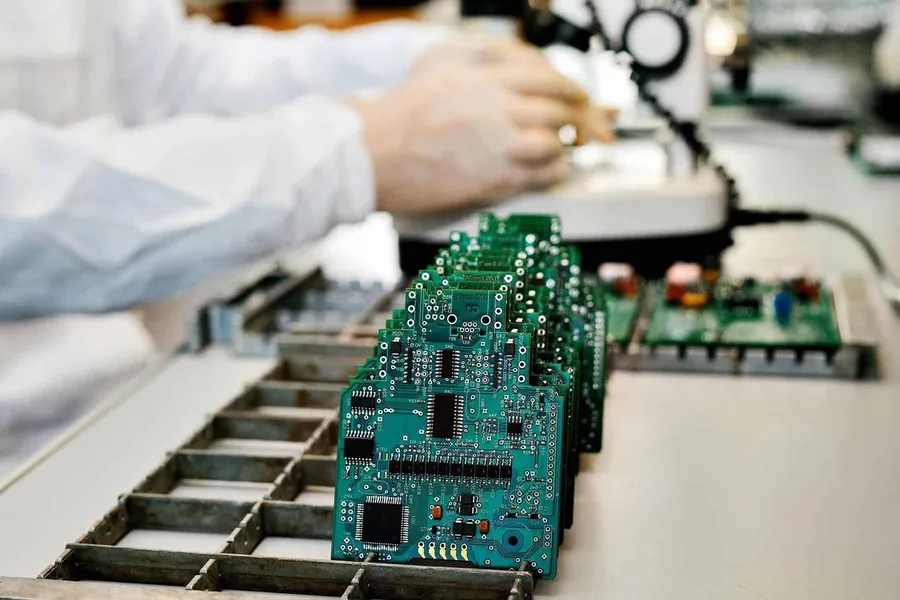

For those seeking cost-effective alternatives to DIY PCB fabrication, online manufacturing services offer a compelling solution. Companies like JLCPCB, PCBWay, and EasyEDA provide competitive pricing for PCB production, often at a lower overall cost than setting up a fully equipped home lab. However, understanding the tradeoffs is crucial for making informed decisions, focusing primarily on the balance between cost, lead time, and specific project requirements.

| Service | Typical Cost (per board) | Minimum Order Quantity | Lead Time | Key Advantages | Key Disadvantages |

|---|---|---|---|---|---|

| JLCPCB | Very low, e.g., ~$2 for 5 PCBs | 5 | 2-7 days | Extremely affordable, fast turnaround for small orders, a wide range of options for materials, thickness, etc. | Shipping times may be longer to some locations; more complex designs may incur additional costs. |

| PCBWay | Low, e.g., ~$5 for 10 PCBs | 5 | 3-8 days | Good balance of price and quality, offers a variety of advanced PCB options such as flex PCBs, excellent customer support | May be slightly more expensive than JLCPCB for simple designs |

| EasyEDA | Low, e.g., ~$6 for 10 PCBs | 5 | 3-8 days | Integrated design tool and manufacturing service, good for beginners, fast quoting system | May have less options for advanced PCB specifications. |

Key factors to consider when using online PCB manufacturing services include the minimum order quantity (MOQ), which is often set at 5 or 10 boards, and delivery times, which can vary depending on your geographic location and chosen shipping method. The cost per board decreases significantly with larger orders, making these services ideal for batch production or when you anticipate needing multiple prototypes. It's also important to note that while these services are generally inexpensive, additional features like specialized finishes, non-standard board thicknesses, or very complex designs may incur extra fees. Understanding these nuances can prevent unexpected budget increases.

Low-Cost PCB Printer Options: Evaluating Entry-Level Machines

Entry-level PCB printers offer a more accessible pathway to in-house prototyping compared to high-end models. These machines, often found on platforms like Amazon and Alibaba, balance cost with functionality, targeting users who need basic PCB printing capabilities without a large capital investment. While they may not match the precision and speed of professional machines, they serve as a valuable tool for hobbyists and small-scale projects.

| Feature | Entry-Level Direct PCB Printers | Stencil Printers |

|---|---|---|

| Printing Method | Direct Inkjet or similar technology | Manual or semi-automatic application of solder paste through stencils |

| Cost | Generally lower, often under $1000 | Lower initial investment, often under $500 (manual) or $1000-$2000 for semi-automatic |

| Complexity | Moderate learning curve, requires understanding of ink and substrate compatibility | Simpler to use, focuses on precise solder paste application after the PCB is fabricated |

| Precision | Limited precision compared to professional methods, suitable for basic designs | High precision in solder paste application when used with a high-quality stencil |

| Typical Use Cases | Prototyping basic single or double-layer boards, educational purposes | PCB assembly process, essential for surface mount component soldering |

| Materials | Specialized conductive inks or similar materials | Primarily used with solder paste, not directly involved in PCB creation |

When evaluating these machines, consider factors such as printing resolution, supported materials, and the level of technical support provided. While many entry-level machines offer basic capabilities, the long-term running cost (ink/consumable cost) should also be a key consideration.

Desktop PCB Printers: Features and Cost Analysis

High-end desktop PCB printers, such as the Voltera V-One, represent a significant investment over entry-level options, yet they offer capabilities that can be crucial for rapid prototyping and advanced PCB fabrication. This section explores the features, costs, and benefits of these advanced machines, comparing them with lower-cost alternatives.

| Feature | Entry-Level PCB Printers | High-End Desktop PCB Printers (e.g., Voltera V-One) |

|---|---|---|

| Price Point | Generally under $1,000 | Typically $5,000 and above |

| Printing Method | Often direct ink dispensing or simple etching processes | Advanced ink dispensing, conductive inks, and multilayer capabilities |

| Resolution and Accuracy | Limited resolution and accuracy may impact complex designs | Higher resolution and greater accuracy suitable for intricate designs |

| Material Compatibility | Restricted to basic inks and materials | Wider range of materials, including conductive inks and solder pastes |

| Multilayer Capability | Generally no multilayer PCB production | Multilayer PCB fabrication with precise registration |

| Ease of Use | Often simple setup with limited features | More complex but with advanced software integration |

| Prototyping Speed | Slower prototyping due to manual processes | Faster prototyping with automated printing |

| Maintenance and Durability | Lower maintenance, parts may need frequent replacement | Higher quality components, requiring less maintenance |

The decision to invest in a high-end desktop PCB printer hinges on the specific needs of the user. For those involved in advanced prototyping, research, or developing complex electronics, the increased cost may be justifiable. However, for basic prototyping, education, or hobbyist use, entry-level or DIY methods might suffice and offer a more cost-effective solution.

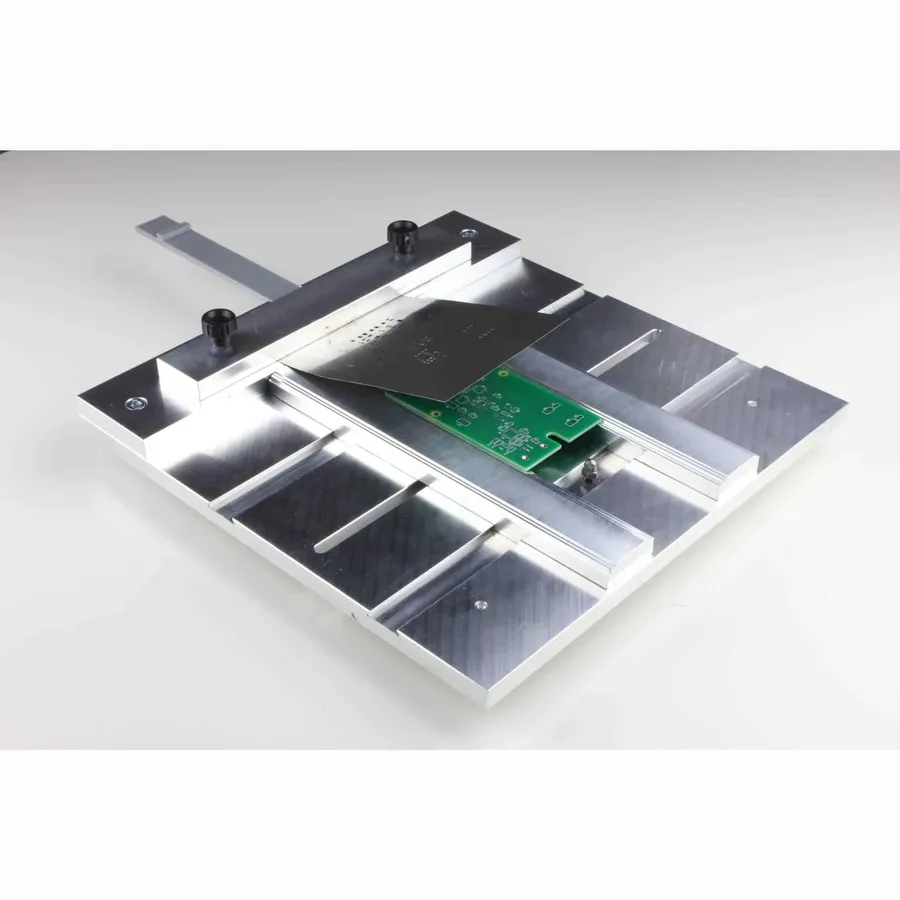

Stencil Printers: An Overview

Stencil printers are essential tools in PCB assembly, primarily used for the precise application of solder paste onto circuit boards before component placement. This section elucidates their function, operation, and the utility of low-cost options for hobbyists and small-scale production.

The fundamental purpose of a stencil printer is to transfer solder paste accurately onto the pads of a PCB. This process ensures that when components are placed and reflowed, each solder joint will be consistent, reliable, and electrically sound. Stencil printers utilize a thin sheet (the stencil) with precisely cut openings that correspond to the solder pad locations on the PCB. Solder paste is applied to this stencil and then spread across the surface, transferring paste only to the open areas.

Manual stencil printers, often the most affordable option, typically comprise a frame to hold the stencil taut and a base to secure the PCB. The user applies solder paste and uses a squeegee to spread it evenly across the stencil, transferring the paste onto the board. While manual models lack the automation of high-end machines, they offer an acceptable and economical solution for small-batch assembly.

| Feature | Manual Stencil Printers | Automated Stencil Printers |

|---|---|---|

| Cost | Low (typically under $200) | High (thousands of dollars) |

| Operation | Manual solder paste application and squeegee operation | Automated solder paste dispensing and squeegee motion |

| Precision | Dependent on user skill, acceptable for most hobbyist needs | Higher precision and repeatability |

| Throughput | Low (suited for small batch production) | High (suited for medium to large batch production) |

| Complexity | Simple and easy to use | More complex setup and operation |

| Suitability | Hobbyists, small-scale prototyping and production | High volume manufacturing |

Low-cost manual stencil printers are typically found on online marketplaces like Amazon or AliExpress, and are frequently used to assemble prototypes and small-scale productions. The use of stencil printers can significantly enhance the precision of solder paste application which improves the reliability of the assembled boards.

While automated stencil printers offer superior accuracy and higher throughput, they come at a significant cost. For users focused on prototyping or small runs, a manual stencil printer is often the most economical and practical solution, bridging the gap between hand soldering and high-volume PCB assembly.

Frequently Asked Questions About PCB Printing and Cost-Effective Solutions

This section addresses common questions regarding PCB printing, focusing on cost-effective methods and solutions, including considerations for the 'cheapest pcb printer' approach.

- What is the most economical way to produce a PCB?

The most economical approach often depends on the complexity and quantity of PCBs needed. For simple, single-sided boards in small quantities, DIY methods like toner transfer or photoresist etching are the cheapest options. These methods require minimal initial investment in specialized equipment. For larger quantities or more complex designs, utilizing budget-friendly online PCB fabrication services becomes more cost-effective due to economies of scale. - What is the most affordable PCB finish?

The most affordable PCB finish is typically HASL (Hot Air Solder Leveling) using leaded solder. This finish is cost-effective, provides good solderability, and is widely available from PCB manufacturers. However, leaded HASL is less environmentally friendly than lead-free options, and has been restricted in many applications. Lead-free HASL is a similarly priced alternative. ENIG (Electroless Nickel Immersion Gold) is another popular finish, but it is generally more expensive than HASL but provides better protection against oxidation. - Which type of printer is typically used for PCB production?

While some advanced direct-write PCB printers exist, they are generally not the method used by most manufactures. The majority of PCB manufacturers rely on subtractive methods rather than additive such as printing. They utilize techniques like photo etching or chemical milling with lithography tools. Direct PCB printers, especially entry-level models, are primarily used for prototyping, rather than mass production due to cost-inefficiency, lack of capability to print multiple layers and reliability issues. Stencil printers are used for solder paste application, not directly for printing circuit traces, but are critical for PCB assembly. - How much does a single PCB cost to produce?

The cost of a single PCB can vary dramatically. DIY methods can cost as little as a few dollars for materials for small PCBs and are often driven by the time investment of the maker. Online PCB services have significantly reduced costs, with a basic PCB costing a few dollars to $5-10 in small quantities but the cost will be reduced at larger quantities. For complex designs with multiple layers, the cost increases. Additionally, factors like the number of boards, finish, and delivery times can impact the price. Always calculate shipping and handling as part of the total cost, and avoid express shipping where possible. - What are some methods to reduce cost when prototyping PCBs?

To minimize prototyping costs, consider the following: use single or double layer boards to avoid the complexities of multilayer manufacturing, optimize the PCB size to reduce material usage, use a HASL finish due to its cost-effectiveness, consider panelizing your design to make the most use of PCB manufacturing panel size, and shop for PCB services that offer low-cost prototyping options. - Is it worth investing in a low-cost desktop PCB printer?

Investing in a low-cost desktop PCB printer is often a consideration for makers and small businesses involved in frequent prototyping. While these printers can provide in-house PCB creation, they typically have significant limitations in terms of accuracy, layer capabilities, material compatibility, and reliability when compared to professional manufacturing services. The decision is ultimately based on balancing cost, time, and the complexity of your PCB designs. They are best used as complimentary tools rather than replacements for PCB fabrication services. - What are the advantages of using a PCB service over DIY?

Utilizing a PCB fabrication service over DIY methods can result in higher quality PCBs, greater design complexity capabilities, multi-layer boards, professionally finished surfaces and vias and reduced time investment. These services also offer reliability and repeatability advantages that home methods cannot reach, especially for designs that require precision or high-volume production. The increased cost is often offset by the improved quality, reliability and efficiency.

Choosing the Right Method: Factors to Consider

Selecting the optimal PCB fabrication method involves a careful evaluation of project requirements, budget constraints, and desired precision. The 'cheapest pcb printer' solution isn't always the best fit; it's crucial to balance cost with the specific needs of your project.

To make an informed decision, consider the following factors:

- Project Complexity

Assess the intricacy of your design, including the number of layers, the density of components, and the required trace widths and clearances. Simple, single-layer designs may be suitable for DIY methods, while complex, multi-layer boards may necessitate professional services or advanced equipment. For instance, a simple LED circuit can be easily prototyped with toner transfer while a high-speed digital board will likely need more robust fabrication methods. - Prototyping Volume

The quantity of PCBs you need will significantly impact cost-effectiveness. If you are only making one or two PCBs, DIY methods or small-batch PCB services may be more cost-effective. However, for larger quantities, online PCB manufacturing services usually offer substantial price breaks, rendering them more suitable. For example, a one-off hobby project might use a cheap method, while a production run would need PCB manufacturing services. - Budget Limitations

Establish a clear budget and compare the costs of different fabrication methods. DIY options, like toner transfer or chemical etching, often have lower upfront costs, but may require more time and resources. PCB printers or milling machines involve a greater initial investment but could offer a lower cost per PCB. For example, toner transfer might cost a few dollars, while a low-cost PCB printer might cost a few hundred dollars. - Desired Precision

Consider the required accuracy and quality of the PCB. DIY methods can be challenging for fine details, tight clearances, or multi-layer designs, where online services or high-end equipment offer better results. For example, if you're designing a board for very fine-pitch components, professional services will give a higher probability of success. - Turnaround Time

Evaluate the urgency of your project. DIY methods can be quicker for simple prototypes but are time-consuming, while online manufacturing services may have longer lead times that need to be accounted for. A project with a tight deadline may have to use professional services, while a hobby project might be suitable for a DIY option with a longer timeframe. - Required Skill Level

Assess your comfort level with DIY techniques or your ability to use advanced equipment. DIY methods demand practical skills and may involve more experimentation. Professional services or easy-to-use PCB printers require less hands-on experience. If you have a lack of skills in fabrication, then you should consider services or tools that have simple interfaces.

By carefully considering these factors, you can make a well-informed decision about the most suitable PCB fabrication method for your project, ensuring that you not only save money but also achieve the desired quality and functionality.

Tips for Saving Money on PCB Prototyping

Optimizing PCB designs and strategically choosing materials are critical for cost-effective prototyping. This section provides practical advice for minimizing expenses, enabling budget-conscious makers to produce PCBs without sacrificing quality or functionality. By leveraging these tips, users can effectively lower their prototyping costs and refine their designs more efficiently.

- Optimize PCB Design for Manufacturing (DFM)

Careful attention to DFM guidelines is key to reducing costs. Simplifying designs, avoiding extremely fine traces and spacing, using standard component sizes, and increasing via size will reduce manufacturing complexity, thus reducing costs. - Choose Cost-Effective Materials

Selecting appropriate materials has a significant impact on cost. For most applications, standard FR-4 substrate is sufficient and cheaper than more exotic materials. For low-frequency application consider using single sided PCB to reduce cost. - Leverage Batch Deals from PCB Services

Often, PCB manufacturers offer discounts for larger quantities. If possible, design your PCB in a panel and order multiple boards at once. This can significantly reduce the unit cost per PCB. - Panelize your PCBs

When ordering from a PCB fab, optimizing space on a manufacturing panel can reduce cost. Panelize your PCBs to maximize the usage of the panel size offered by the manufacturer. - Avoid unnecessary features or complex geometries

Every additional cut, drill or complex via adds to the manufacturing cost. Minimize the number of layers, and keep the design as simple as possible to reduce costs. - Consider the size and shape of your PCB

Smaller PCB size equates to smaller cost of raw material usage and reduced price. Optimize the size of your PCB for the functionality you need.

Finding the 'cheapest pcb printer' solution is a balancing act between budget, quality, and required prototyping speed. While DIY methods can be incredibly affordable, they require time and effort. Low-cost PCB printers and stencil printers offer an alternative for those seeking convenience. Online services like JLCPCB are ideal for high-quality yet affordable production runs. By understanding the options and considering your individual needs, you can effectively choose the most economical and efficient way to bring your electronic designs to life. The right choice will allow you to rapidly innovate without overspending on the tools you need.

AnyPCBA

AnyPCBA