Finest Printed Circuit Board Ltd: Your Partner in PCB Excellence

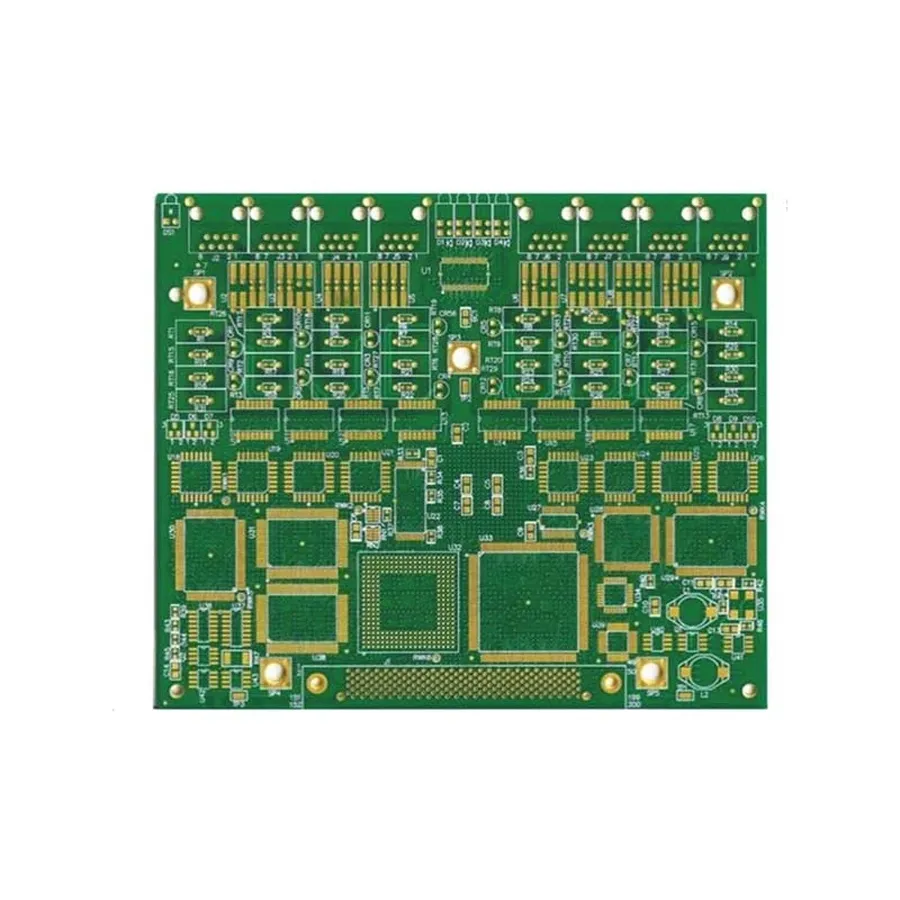

In today's fast-paced tech landscape, the reliability and performance of electronic devices are crucial. At the heart of these devices lies the printed circuit board (PCB). Finest Printed Circuit Board Ltd stands as a beacon of innovation and quality in the PCB industry, offering a comprehensive suite of PCB manufacturing and assembly services. This article delves into the core strengths of Finest Printed Circuit Board Ltd, exploring its history, services, and commitment to delivering excellence. We'll examine how they've become a key partner for businesses seeking reliable and cutting-edge PCB solutions.

The History and Evolution of Finest Printed Circuit Board Ltd

Finest Printed Circuit Board Ltd. was established in 2003, marking the beginning of its journey to becoming a prominent player in the PCB manufacturing industry. The company's evolution reflects its ability to adapt to the dynamic landscape of technological advancements and changing industry demands, demonstrating significant growth from its inception to the present day.

From the outset, Finest PCB has been focused on delivering high-quality PCBs. Its growth trajectory is marked by a series of strategic expansions in manufacturing capabilities, process optimization, and service offerings. The company's history is characterized by a commitment to staying at the forefront of PCB technology, allowing it to meet the diverse needs of its customers effectively.

Comprehensive PCB Manufacturing Services

Finest Printed Circuit Board Ltd provides a full spectrum of PCB manufacturing services, catering to diverse electronic applications with precision and reliability. Their capabilities extend from basic single-sided boards to complex multi-layered designs, ensuring they meet a wide range of customer requirements.

| PCB Type | Description | Typical Applications |

|---|---|---|

| Single-Sided PCBs | A basic board with conductive traces on one side. Cost-effective and suitable for less complex applications. | Simple electronic devices, LED lighting, basic sensors. |

| Double-Sided PCBs | Traces on both sides, allowing for more complex circuits. Often uses plated through-holes (PTH). | Power supplies, audio equipment, automotive electronics. |

| Multi-Layer PCBs | Three or more layers of conductive material separated by insulation. Enable highly complex circuits. | High-end computing, telecommunications, aerospace equipment. |

| Flexible PCBs | PCBs manufactured on flexible substrates that can be bent, twisted, and folded | Wearable electronics, medical devices, automotive components, and aerospace applications |

| Rigid-Flex PCBs | Combining rigid and flexible PCB layers into a single board | Advanced consumer electronics, medical devices, and aerospace equipment |

The company also utilizes a variety of materials to meet specific application needs:

| Material | Description | Applications |

|---|---|---|

| MCPCB (Metal Core PCB) | Features a metal base for enhanced thermal management, essential for heat dissipation. | High-power LED lighting, power electronics, automotive applications. |

| CEM-1 | Composite epoxy material, cost-effective and suitable for less demanding applications. | Consumer electronics, basic audio equipment, less demanding digital circuits. |

| CEM-3 | A higher-performance composite material offering improved electrical and mechanical properties compared to CEM-1. | Automotive electronics, industrial control systems, moderately complex electronic circuits |

| FR-4 | A common glass-reinforced epoxy laminate with good dielectric properties, and versatile for various applications. | Wide range of applications including most consumer electronics and industrial control boards. |

Advanced PCB Assembly Capabilities

Finest Printed Circuit Board Ltd offers comprehensive PCB assembly services, encompassing Surface Mount Technology (SMT), through-hole assembly, and mixed technology assembly. These capabilities allow the company to address a wide range of client needs, from prototyping to high-volume production runs, ensuring the precise and efficient integration of electronic components onto printed circuit boards.

| Assembly Type | Description | Applications | Advantages |

|---|---|---|---|

| SMT Assembly | Automated process where components are mounted directly onto the surface of a PCB using solder paste and reflow soldering. | High-density, complex circuit designs, consumer electronics, portable devices. | High speed, precision, miniaturization capabilities, cost-effective for volume production. |

| Through-Hole Assembly | Manual or automated process where component leads are inserted through holes in the PCB and soldered on the opposite side. | High-reliability applications, power electronics, connectors, components requiring mechanical strength. | Strong mechanical bond, good for larger components, suitable for prototyping and low-volume production. |

| Mixed Technology Assembly | Combination of SMT and through-hole assembly to integrate both types of components on a single PCB. | Complex designs that require both surface mount and through-hole components, industrial control systems, aerospace applications. | Flexibility in design, optimum use of component characteristics, broad compatibility with different technologies. |

Finest Printed Circuit Board Ltd's assembly processes leverage advanced machinery and techniques to ensure high-quality, reliable assemblies. They also offer services for prototype assembly, allowing clients to test and validate their designs before large-scale production. This adaptability is critical in today's fast-paced electronic product development cycle.

Finest Printed Circuit Board Ltd's Technology and Equipment

Finest Printed Circuit Board Ltd leverages advanced technology and high-precision equipment to ensure the production of top-quality and reliable PCBs. Their commitment to technological advancement allows them to consistently meet the stringent demands of modern electronics manufacturing, ensuring both precision and efficiency in their processes.

| Equipment Category | Specific Technology/Equipment | Purpose/Function |

|---|---|---|

| Imaging & Exposure | Laser Direct Imaging (LDI) | High-resolution pattern generation on PCB panels, crucial for fine-line PCBs |

| Drilling | CNC Drilling Machines | Precise drilling of vias and component holes, ensuring accurate connectivity between layers |

| Plating | Automated Plating Lines | Uniform copper plating for conductivity and solderability, enhancing overall PCB performance |

| Etching | Automated Chemical Etching Systems | Precise removal of unwanted copper, creating the desired circuit patterns accurately |

| Soldermask Application | Automated Screen Printing/Spray Coating | Precise application of solder resist, protecting the circuits and preventing solder bridging during assembly |

| Surface Finishing | ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling) | Provides a reliable solderable surface, ensuring effective component connections |

| Assembly | SMT Pick-and-Place Machines, Reflow Ovens | Accurate placement and soldering of surface mount components, crucial for high-density PCBs |

| Testing | Automated Optical Inspection (AOI), Electrical Testing Machines | Rigorous inspection of PCBs for any defects or errors, ensuring high quality and reliability |

The company’s investment in these advanced tools and equipment reflects its dedication to providing superior PCB solutions. This allows Finest Printed Circuit Board Ltd to produce PCBs with greater precision, consistency, and reliability.

Commitment to Quality Assurance and Certifications

Finest Printed Circuit Board Ltd. places paramount importance on quality assurance, implementing rigorous controls throughout the PCB manufacturing and assembly processes. This commitment is reflected in their adherence to industry standards and certifications, ensuring the delivery of reliable and high-performance products.

The company's quality assurance strategy encompasses various stages, from raw material procurement to final product testing. Each stage is meticulously monitored using advanced testing equipment and inspection procedures to identify and rectify any deviations from the required specifications. This meticulous approach guarantees that every PCB leaving their facility meets stringent quality benchmarks, minimizing the risk of defects or performance issues.

- Rigorous Testing Protocols

Finest Printed Circuit Board Ltd. employs a comprehensive suite of testing protocols, including electrical testing, impedance control, and functional testing, to ensure that each PCB performs according to the design specifications. - Adherence to Industry Standards

The company is committed to complying with relevant industry standards such as IPC (Association Connecting Electronics Industries) standards, which guide best practices in PCB manufacturing and assembly. - Certifications

Finest Printed Circuit Board Ltd. actively pursues relevant certifications to demonstrate their commitment to quality and process control. These may include ISO certifications, specific to quality management systems or environmental compliance, which act as independent validation of their manufacturing capabilities and commitment to continuous improvement. - Traceability

Implementing robust traceability measures, Finest Printed Circuit Board Ltd maintains detailed records of each production batch, enabling identification of individual parts. This also ensures transparency for clients, and allows for effective troubleshooting should any issues arise.

Finest Printed Circuit Board Ltd's Global Reach and Partnerships

Finest Printed Circuit Board Ltd has established a significant global presence, serving a diverse international customer base through strategic partnerships. The company's commitment to understanding and adapting to the unique needs of clients across various regions and industries is a key factor in its success. They have cultivated a global network that allows them to effectively support projects of all scales and complexities, from initial prototyping to large-scale mass production. Multi-language capabilities ensure seamless communication and support for international clients, further reinforcing their dedication to customer satisfaction.

The company has strategically expanded its reach through alliances with leading technology providers and distributors. These collaborations enable them to leverage advanced manufacturing processes and maintain a competitive edge. By fostering partnerships in various geographical locations, Finest Printed Circuit Board Ltd ensures they can meet customer demands efficiently and effectively, irrespective of location.

Finest Printed Circuit Board Ltd's ability to cater to a wide range of industries is a testament to their adaptability and expertise. They provide printed circuit boards to sectors including consumer electronics, telecommunications, medical devices, and automotive. This versatility is driven by a deep understanding of industry standards and a commitment to providing high-quality products tailored to specific requirements. Their multi-faceted approach to customer service, combined with strong supply chain management, allows them to offer a streamlined and dependable service to a global clientele.

Frequently Asked Questions About Finest Printed Circuit Board Ltd

This section addresses common inquiries about Finest Printed Circuit Board Ltd, providing clarity on their services, capabilities, and processes. We aim to offer comprehensive answers to help you understand how Finest PCB can meet your specific PCB manufacturing and assembly requirements.

- What are the typical lead times for PCB manufacturing at Finest Printed Circuit Board Ltd?

Lead times vary depending on the complexity and quantity of the PCBs ordered. Standard lead times for simple single and double-sided boards can be as short as a few days, while more complex multilayer boards or large production runs may take several weeks. We recommend contacting our sales team directly with your specific project requirements for an accurate lead time estimate. - Does Finest Printed Circuit Board Ltd have minimum order quantity (MOQ) requirements?

While Finest Printed Circuit Board Ltd accommodates both small and large production runs, there may be minimum order quantities depending on the specific type of PCB and required process. We are very flexible, and you should contact our team to discuss your needs. - What types of PCB design assistance does Finest Printed Circuit Board Ltd offer?

Finest Printed Circuit Board Ltd provides support for PCB design, including design review and optimization assistance to ensure manufacturability and reliability. Our engineering team can work with your design files to identify potential issues and suggest improvements before fabrication. We can also provide full design services based on your requirements. - What types of PCBs does Finest Printed Circuit Board Ltd specialize in?

Finest Printed Circuit Board Ltd specializes in a variety of PCB types, including single-sided, double-sided, and multi-layer PCBs. We also manufacture boards using specialized materials such as MCPCB, CEM-1, CEM-3, and FR-4. Our expertise extends to PCBs for diverse applications, from simple electronics to complex, high-density applications. - What manufacturing standards and testing procedures does Finest Printed Circuit Board Ltd adhere to?

Finest Printed Circuit Board Ltd adheres to strict industry standards, such as IPC standards, to ensure the quality and reliability of our PCBs. Our manufacturing process incorporates rigorous testing and inspection procedures at every stage, including electrical testing, impedance testing, and dimensional checks, to ensure PCBs meet our high standards. - Can Finest Printed Circuit Board Ltd support both prototype and mass production runs?

Yes, Finest Printed Circuit Board Ltd offers full support for both prototyping and mass production of PCBs. We have the capability and flexibility to handle low volume prototypes for design verification, as well as large production runs to meet market demands. Our process is optimized to seamlessly transition from prototype to mass production, ensuring high quality throughout the process. - What are the benefits of choosing Finest Printed Circuit Board Ltd for PCB manufacturing and assembly?

Choosing Finest Printed Circuit Board Ltd provides numerous benefits, including extensive industry experience, advanced technological capabilities, a commitment to quality, and a customer-focused service approach. Our one-stop service model for both PCB manufacturing and assembly significantly streamlines the process, improves turnaround times and helps save costs. We focus on delivering high-quality, reliable PCB solutions tailored to your specific needs.

Why Choose Finest Printed Circuit Board Ltd?

Partnering with Finest Printed Circuit Board Ltd offers a compelling blend of experience, advanced technology, customer-centric service, and a steadfast commitment to delivering top-tier PCB solutions. Their one-stop service model streamlines the entire process from manufacturing to assembly, ensuring both cost-effectiveness and operational efficiency for their clients.

- Extensive Experience:

With two decades of experience in the PCB industry, Finest Printed Circuit Board Ltd brings a deep understanding of diverse manufacturing needs and challenges. This long-standing expertise translates to reliable and high-quality output. - Technological Prowess:

The company leverages state-of-the-art technology and equipment, ensuring precision and consistency in both manufacturing and assembly processes. Their commitment to continuous technological upgrades positions them at the forefront of PCB production. - Customer-Focused Approach:

Finest Printed Circuit Board Ltd prioritizes client satisfaction, offering tailored solutions to meet specific requirements. Their ability to manage projects from initial design to final delivery demonstrates a commitment to customer success. - Quality Assurance:

Quality is paramount at every stage, from material selection to final product inspection. Finest Printed Circuit Board Ltd's rigorous quality control processes ensure the reliability and performance of each PCB they produce. - Comprehensive One-Stop Service:

The one-stop service model streamlines manufacturing and assembly, saving clients time and reducing complexity. This integrated approach leads to cost savings and improved project management efficiency.

Finest Printed Circuit Board Ltd exemplifies excellence in the PCB manufacturing and assembly sector. With a strong history, advanced technology, and a commitment to quality, they are a reliable partner for businesses seeking top-tier PCB solutions. Their ability to deliver diverse PCB types, coupled with a one-stop service model, positions them as a key player in the industry. Whether it's a prototype or a large-scale production, Finest Printed Circuit Board Ltd provides the quality and reliability necessary to power today's technologies.

AnyPCBA

AnyPCBA