Fujikura Printed Circuits Ltd: A Deep Dive into Innovation and Global Reach

In today's rapidly evolving electronics landscape, companies like Fujikura Printed Circuits Ltd stand at the forefront of innovation. From smartphones to complex industrial equipment, printed circuit boards (PCBs) are the backbone of modern technology. This article delves into the operations, technology, and global footprint of Fujikura Printed Circuits Ltd, revealing how they connect the world with reliable technology and contribute to the advancements we see every day.

Fujikura Printed Circuits Ltd: An Overview

Fujikura Printed Circuits Ltd. stands as a pivotal entity within the Fujikura Group's expansive electronics sector, specializing in the design, development, and manufacturing of printed circuit boards (PCBs). Operating with a significant degree of autonomy, it focuses intently on delivering high-quality, cutting-edge PCB solutions to meet the diverse demands of the global electronics market.

The Global Footprint of Fujikura Printed Circuits

Fujikura Printed Circuits Ltd. strategically positions its manufacturing facilities across the globe to ensure efficient production and delivery of its printed circuit boards (PCBs). This global network is a cornerstone of their ability to serve a diverse clientele across various industries and geographical locations.

Key manufacturing locations include:

- Japan

As the company's headquarters, Japan hosts key manufacturing facilities that focus on cutting-edge technology and high precision manufacturing. These facilities typically handle the most advanced and sensitive production requirements. - Thailand

Thailand serves as a major hub for high-volume production of PCBs. The location allows Fujikura to leverage cost advantages, and is strategically located in the Asia Pacific region to serve many customers. - Other Strategic Locations

Fujikura has other manufacturing and sales offices in the Americas and Europe which enhance customer proximity. Specific locations include, but not limited to, China, Taiwan, and Vietnam.

This global footprint ensures:

- Localized Supply Chains

Proximity to key markets and customers reduces logistical challenges and lead times, and reduces the risk of supply chain interruptions. - Responsive Customer Service

A global network allows for more responsive customer service and support across different time zones and regions. It also allows for greater flexibility in production to meet urgent customer needs. - Scalable Production Capabilities

Manufacturing in multiple locations provides scalability and allows Fujikura to meet the varying demands of customers as their business grows. - Access to Regional Expertise

Operating across regions allows Fujikura to tap into local market expertise, and specific resources or technologies which can then be integrated into global operations

| Location | Primary Focus | Key Advantages |

|---|---|---|

| Japan | Advanced technology and high precision manufacturing | Headquarters, cutting-edge R&D and production, high quality |

| Thailand | High-volume PCB production | Cost-effective production, Asia Pacific hub |

| Other Global Locations | Sales, support, and limited manufacturing | Customer Proximity and market responsiveness |

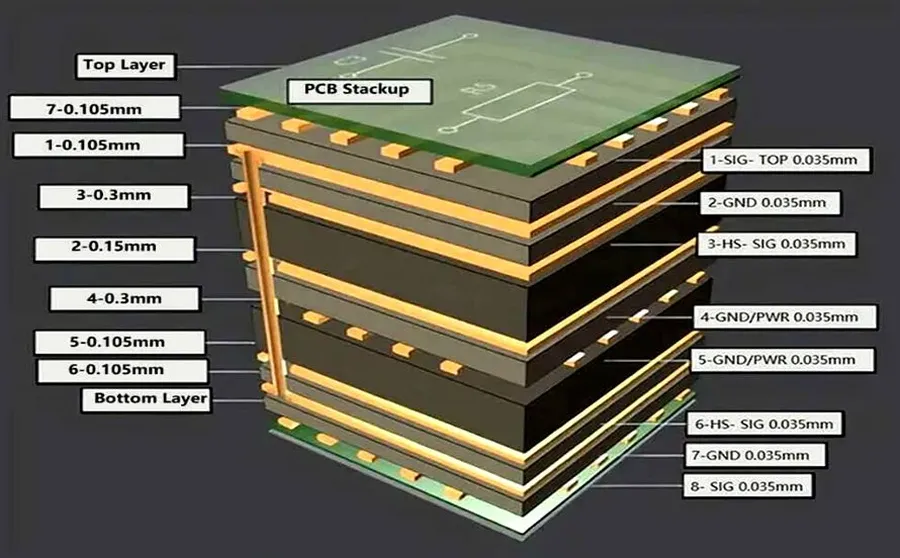

Core Technologies and Capabilities

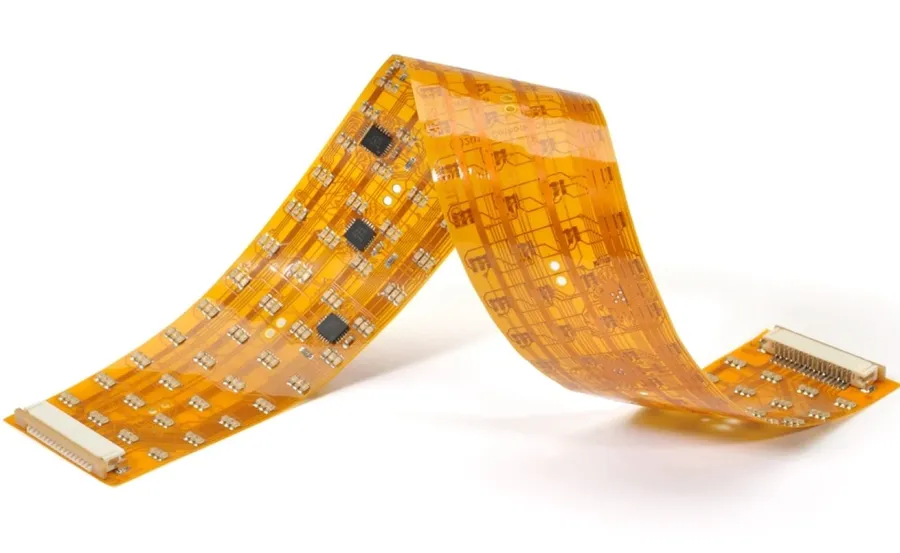

Fujikura Printed Circuits Ltd. distinguishes itself through a suite of advanced technologies and manufacturing capabilities, which are central to its ability to produce high-performance printed circuit boards (PCBs). These capabilities span from flexible PCB production to high-density interconnect (HDI) technologies, coupled with the utilization of advanced materials.

| Technology | Description | Advantages | Applications |

|---|---|---|---|

| Flexible PCBs | PCBs constructed on a flexible substrate material, such as polyimide or polyester. | Enables designs that can bend and conform to various shapes, reduced weight and space requirements. | Consumer electronics, wearable devices, automotive components, medical devices. |

| High-Density Interconnect (HDI) | PCBs featuring very fine lines and vias for increased circuit density and performance. | Smaller and lighter designs, increased functionality in compact spaces, improved signal integrity. | Smartphones, tablets, network equipment, high-performance computing devices. |

| Advanced Materials | Use of materials such as high Tg (transition temperature) laminates, low-loss dielectrics, and metal cores. | Improved thermal management, enhanced electrical performance, better reliability, greater mechanical robustness. | Aerospace, telecommunications, high-speed data transmission, high-power applications. |

| Advanced Manufacturing Processes | Utilizing advanced techniques like laser direct imaging (LDI), microvia formation, and automated optical inspection (AOI). | Higher precision, reduced defects, improved production efficiency, enhanced product quality. | All applications requiring high reliability and complex circuit designs. |

The synergy of these technologies enables Fujikura to produce PCBs that meet stringent performance requirements across diverse applications and industries. Their dedication to continuous improvement in material science, design methodologies, and manufacturing processes has secured their position as a leader in the field.

Products and Applications

Fujikura Printed Circuits Ltd. manufactures a wide array of printed circuit boards (PCBs) that serve as foundational components across diverse industries. These PCBs, varying in complexity and specifications, are instrumental in enabling the functionality of modern electronic devices, from everyday consumer goods to sophisticated industrial systems.

| Industry | Application Examples | Specific PCB Requirements | Fujikura PCB Example |

|---|---|---|---|

| Consumer Electronics | Smartphones, tablets, laptops, wearable devices, home appliances | High-density interconnect (HDI), compact size, flexible substrates, high-speed signal integrity | Flexible PCBs for foldable phones, HDI PCBs for miniaturized devices |

| Automotive | Engine control units (ECUs), infotainment systems, advanced driver-assistance systems (ADAS), in-car displays | High reliability, temperature resistance, vibration resistance, multi-layer designs, robust performance | Rigid-flex PCBs for dashboard controls, HDI PCBs for advanced sensor systems |

| Telecommunications | Base stations, network switches, routers, mobile communication devices | High-frequency signal integrity, low signal loss, precise impedance control, high-speed data transfer | High-speed PCBs for data centers, RF PCBs for antenna applications |

| Industrial Automation | Programmable logic controllers (PLCs), industrial robots, control panels, machinery monitoring systems | High durability, electrical isolation, resistance to harsh environments, high current handling capabilities | Thick copper PCBs for power systems, ruggedized PCBs for harsh environments |

| Medical Devices | Patient monitoring equipment, diagnostic tools, surgical devices, imaging systems | High reliability, high precision, biocompatible materials, low noise, small form factor | Flexible PCBs for implantable devices, high-density PCBs for medical imaging equipment |

Fujikura's Research and Development Initiatives

Fujikura Printed Circuits Ltd. strategically invests in Research and Development (R&D) to maintain its technological edge and market competitiveness. Their R&D efforts focus on pioneering advancements in materials science, manufacturing processes, and product design, driving innovation in printed circuit board (PCB) technology.

The company's R&D strategy is geared towards developing next-generation PCBs that meet the growing demands of various industries for higher performance, miniaturization, and enhanced reliability.

- Advanced Material Research

Fujikura's R&D efforts explore new materials with improved electrical, thermal, and mechanical properties. This includes research into high-performance polymers, ceramics, and composite materials for enhanced PCB functionality. - Process Innovation

The company focuses on developing more efficient, precise, and sustainable manufacturing techniques. This involves advancements in etching, plating, and lamination processes, ensuring higher quality and reduced environmental impact. - Design Techniques

R&D efforts concentrate on optimizing PCB designs for increased performance and miniaturization. This includes developing advanced layout tools and simulation software for creating complex multi-layer and HDI PCBs, and flexible PCBs. - Strategic Partnerships

Fujikura actively collaborates with research institutions and other industry partners to accelerate innovation and gain access to cutting-edge technologies. These partnerships are crucial for their R&D ecosystem and technology roadmap.

Through continuous R&D investment, Fujikura aims to enhance its product offerings and secure its position as a leader in the PCB industry, enabling it to address the evolving needs of its global customer base.

Fujikura Printed Circuits Ltd: A Supplier Perspective

Fujikura Printed Circuits Ltd. operates as a critical supplier within the global electronics supply chain, demonstrating robust partnerships, strategic customer relationships, and sophisticated supply chain management practices. Their role significantly influences global electronics trade and logistics.

As a key supplier, Fujikura Printed Circuits Ltd. manages a complex network involving material sourcing, manufacturing, and distribution to meet the demands of various industries. Their focus on maintaining consistent quality and delivery schedules is paramount.

| Aspect | Description |

|---|---|

| Partnerships | Fujikura collaborates with material suppliers, technology providers, and end-product manufacturers to ensure a seamless supply chain. These partnerships are vital for accessing innovative materials and production techniques. |

| Customer Relationships | Building strong customer relationships is key, often involving custom solutions, technical support, and long-term contracts that align with customers' product development timelines and production volumes. |

| Supply Chain Management | Fujikura employs advanced logistics and supply chain strategies, including demand forecasting, inventory management, and global distribution networks to minimize disruptions and maintain optimal inventory levels. This is crucial for handling the high demand in the electronics industry. |

| Impact on Global Trade | As a supplier of PCBs, Fujikura's production volume directly affects the availability of essential components for electronic devices worldwide, playing a significant role in the complex web of international electronics trade and logistics. Disruptions within their supply chain, can cascade through the electronics market affecting costs, availability, and timelines. |

Fujikura’s role as a supplier is not merely transactional; it involves a deep integration with customer needs and strategic adaptation to market dynamics. Their ability to anticipate and respond to technological shifts and market demands is key to maintaining their position in the competitive global electronics market.

Frequently Asked Questions About Fujikura Printed Circuits Ltd

This section addresses common inquiries regarding Fujikura Printed Circuits Ltd., providing clear and concise answers to help understand its operations, ownership, and history within the Fujikura Group.

- Who is the parent company of Fujikura Printed Circuits Ltd?

Fujikura Printed Circuits Ltd is a subsidiary of Fujikura Ltd., a global company specializing in electric wires, cables, and related products. While operating with a degree of autonomy, it functions as a core part of Fujikura's electronics business. - Who founded Fujikura Ltd, the parent company of Fujikura Printed Circuits Ltd?

Fujikura Ltd. was founded by Zenpachi Fujikura in 1885. It has grown from its origins in electric wire manufacturing to become a major international corporation with a diverse range of business activities, including printed circuit board manufacturing. - What is the operational structure of Fujikura Printed Circuits within the broader Fujikura Group?

Fujikura Printed Circuits Ltd. operates with significant independence within the Fujikura Group, focusing on printed circuit board manufacturing. This structure allows it to maintain specialized expertise and responsiveness to the specific needs of the PCB market while leveraging the resources and global reach of its parent company. - What is Fujikura Printed Circuits Ltd's main business focus?

Fujikura Printed Circuits Ltd. primarily focuses on the design, development, and manufacturing of high-quality printed circuit boards (PCBs). These PCBs are utilized across numerous industries, including consumer electronics, automotive, telecommunications, and industrial automation. - Does Fujikura Printed Circuits Ltd have manufacturing facilities outside of Japan?

Yes, Fujikura Printed Circuits Ltd. has established a global manufacturing footprint that includes facilities in Japan, Thailand, and other strategic locations. This global presence enables them to meet the needs of their international customer base efficiently. - What are some of the key technologies employed by Fujikura Printed Circuits Ltd?

Fujikura Printed Circuits Ltd. utilizes a range of advanced technologies in its PCB manufacturing processes. These include flexible PCBs, high-density interconnects (HDI), and other advanced materials, which allow for high performance and miniaturization of electronics components. - Where can I find the address for Fujikura Printed Circuits Ltd?

While specific addresses may vary depending on the location of different manufacturing or office facilities, the company's main contact information and detailed location specifics can usually be found on the official Fujikura Ltd website or through direct inquiries via their customer service channels. Please refer to the official website for the most accurate and up-to-date information.

The Future of Fujikura Printed Circuits Ltd

Fujikura Printed Circuits Ltd is strategically positioning itself for future growth by focusing on key areas such as technology adoption, sustainable practices, and market expansion. The company's trajectory is shaped by the evolving demands of the electronics industry, requiring a proactive and adaptable approach to maintain its competitive edge.

The following points outline Fujikura's strategic directions:

- Advanced Technology Integration

Fujikura is expected to increase its investment in cutting-edge technologies, including advanced materials science, nano-fabrication, and innovative interconnect technologies, to improve product performance and meet the increasing demands for miniaturization and high-speed data transmission. - Sustainability Initiatives

A key focus is on adopting more sustainable manufacturing processes and materials to minimize the environmental impact. This includes transitioning to renewable energy sources, reducing waste, and using eco-friendly materials in their PCB production. - Market Diversification and Expansion

Fujikura will likely explore new and emerging markets, such as electric vehicles, renewable energy, and advanced healthcare technologies. This diversification will help reduce reliance on traditional sectors and create new revenue streams. - Digital Transformation

The company is likely to leverage digital technologies such as AI, machine learning, and IoT to enhance operational efficiency, optimize supply chain management, and personalize customer experience. - Strategic Partnerships

Collaborations with research institutions, technology providers, and industry leaders will likely become more common to accelerate innovation and share knowledge.

By prioritizing these areas, Fujikura Printed Circuits Ltd aims to not only navigate current market trends but also to proactively shape the future of the printed circuit board industry, ensuring they continue to be a leading supplier of advanced PCB solutions.

Fujikura Printed Circuits Ltd is not just a component supplier; it's a critical enabler of the global electronics industry. Their commitment to innovation, combined with a strategic global presence, positions them as a vital partner for companies pushing the boundaries of what's possible. As technology continues to advance, Fujikura Printed Circuits Ltd, with its strong foundation in technological excellence and global reach, will continue to play a crucial role in the future of electronics manufacturing and remain a key asset within the Fujikura group. Their ability to adapt and innovate will be crucial in the coming years, and they are well-positioned to continue connecting the world with reliable technology.

AnyPCBA

AnyPCBA