Get Instant Online PCB Assembly Quotes: A Comprehensive Guide

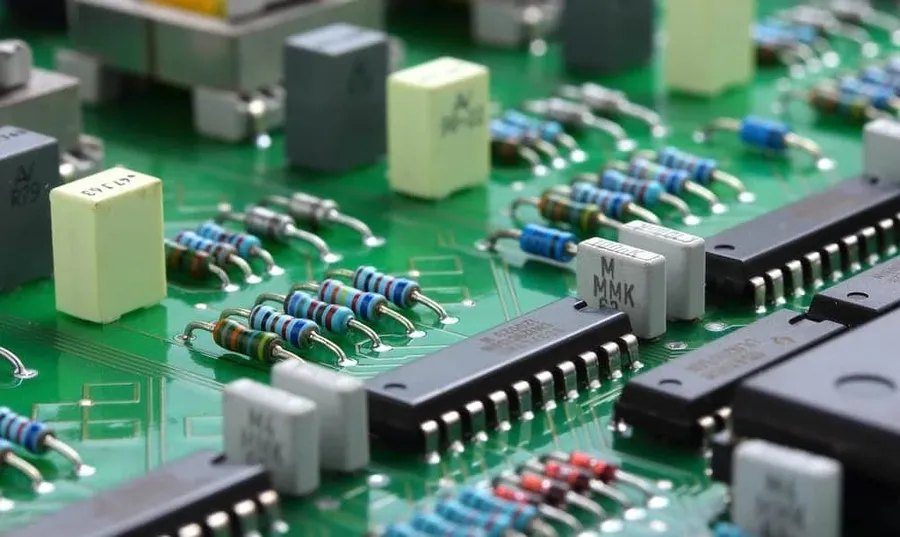

In today's fast-paced electronics world, getting a quick and accurate [online pcb assembly quote] is crucial for project success. This guide will walk you through the process, helping you understand the factors influencing cost and how to make informed decisions for your PCB assembly needs.

Understanding the Basics of PCB Assembly Quotes

The cost of an online PCB assembly quote is influenced by several key factors, each playing a critical role in the final price and timeline. Understanding these core elements enables more accurate cost estimation and allows for informed decision-making during the design and manufacturing process. This knowledge is crucial to optimizing both the design and the procurement strategy, ensuring that the project remains within budget and schedule.

| Factor | Description | Impact on Quote |

|---|---|---|

| Board Size | The physical dimensions of the PCB. | Larger boards typically require more materials and processing time, increasing cost. |

| Number of Layers | The number of conductive layers in the PCB stack-up. | More layers add complexity and material costs, resulting in higher pricing. |

| Component Types | The variety and type of components used (e.g., surface mount, through-hole, passive, active). | Complex components and those with specific requirements can increase assembly costs. |

| Component Quantities | The total number of individual components on the PCB. | Larger quantities may qualify for volume discounts, while small quantities can increase per-unit costs. |

| Assembly Complexity | The intricacy of the assembly process, including fine-pitch components, BGA assembly, and double-sided placement. | Higher assembly complexity translates to increased labor costs and potential for higher reject rate, increasing the overall price. |

| Material Selection | The choice of PCB substrate material (e.g., FR-4, high-Tg, aluminum) and surface finishes (e.g., HASL, ENIG). | Specific materials and finishes can affect cost based on availability and processing difficulty. |

| Order Quantity | The number of assembled PCBs in a single order | Larger quantities usually result in lower per-unit costs due to economies of scale, while smaller prototype runs may have higher costs. |

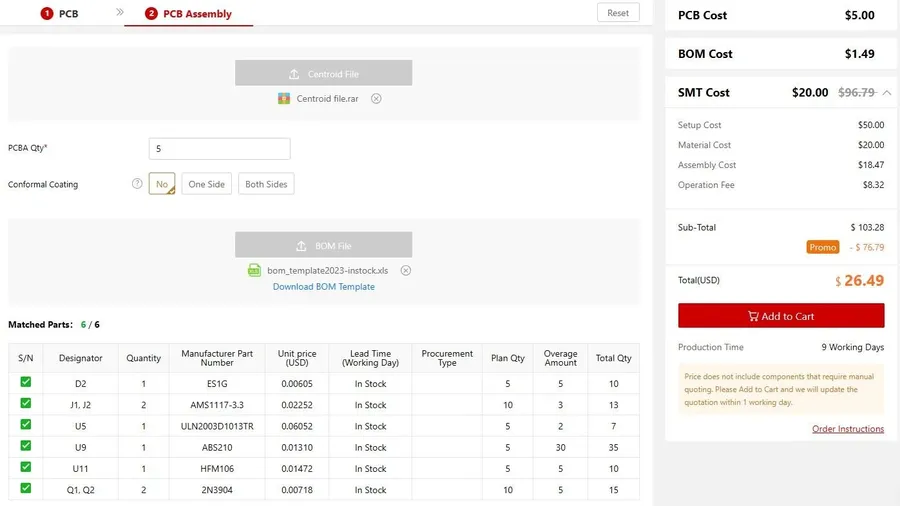

How to Obtain an Instant Online PCB Assembly Quote

Securing an instant online PCB assembly quote involves utilizing specialized tools provided by PCB manufacturers. This process requires precise and comprehensive project data to ensure an accurate cost and lead time estimation. The following steps outline how to effectively use these tools, focusing on the information required and the process of submission.

- Prepare Your Design Files

The cornerstone of an accurate quote is your design data. This typically includes Gerber files (RS-274X format), which define the physical characteristics of your PCB, such as copper layers, solder mask, and silkscreen. Ensure these files are generated correctly from your PCB design software. - Compile a Bill of Materials (BOM)

A complete and accurate BOM is essential. This document lists each component required for assembly, including manufacturer part numbers, reference designators (e.g., R1, C2), and quantities. The BOM should also specify component package types and any special assembly requirements. Any inaccuracies or missing parts in the BOM will directly impact the quote and potentially lead to delays during the assembly process. - Specify Assembly Instructions

Provide detailed assembly instructions which include specifications such as the specific locations of components not covered by the CAD data, specific part orientations, as well as detailed information regarding any special handling, assembly, and cleaning requirements. Clearly defined instructions will ensure an accurate quote and avoid costly errors later. - Select PCB Specifications

Specify the number of layers, board dimensions, material type, finish, and any special requirements for the PCB itself. These specifications have an impact on the board's overall cost and manufacturability and are directly related to the cost of assembly. - Choose Your Assembly Options

Online quote tools often allow for different assembly options, such as surface mount technology (SMT), through-hole, or mixed assembly. You may also need to specify single-sided or double-sided assembly. Choosing the right option is essential to ensure a proper assembly process and cost calculation. - Upload Files and Submit

Once you have prepared your design files, BOM, assembly instructions, and board specifications, upload them to the chosen online quoting tool. Review all information carefully before final submission. This can often be done through a secure file upload or direct import from CAD software. Most vendors will provide a web based viewer to confirm that your data is correct. - Review and Analyze the Quote

After submission, the online tool will generate an instant quote. Review the quote carefully, paying close attention to the breakdown of costs, lead times, and any additional charges. Ensure the quote aligns with your expectations and project budget before committing to production.

Comparing PCB Assembly Quotes: Key Factors

Evaluating PCB assembly quotes extends beyond simply identifying the lowest price; a comprehensive comparison considers price, lead time, quality, and the support services offered. This holistic approach ensures you select a partner that aligns with your project's specific needs and provides the best overall value.

| Factor | Description | Impact |

|---|---|---|

| Price | The total cost for PCB assembly, often varying by quantity, component type, and service options. | Directly affects project budget; lowest price doesn't always mean best value. |

| Lead Time | The duration from order placement to the delivery of assembled PCBs. | Impacts project timeline; shorter lead times are crucial for quick prototyping and production. |

| Quality | The standards of materials, manufacturing processes, and testing procedures employed. | Determines the reliability and functionality of assembled PCBs; higher quality often means less defects and better performance |

| Support Services | The level of technical assistance, communication, and problem resolution offered by the assembly provider. | Critical for addressing issues, ensuring smooth project progression, and managing complexities. |

When comparing quotes, it is important to avoid focusing solely on the lowest price. Cheaper quotes might involve trade-offs in quality, such as the use of lower-grade components, inadequate testing, or longer lead times, which can have significant implications on the final product. It's imperative to consider the trade-offs between the cost and other factors such as lead time, quality and support in order to choose the right partner to ensure project success.

Common Mistakes to Avoid When Requesting Quotes

Requesting an accurate online PCB assembly quote hinges on the precision of your specifications. Errors in this process can lead to significant discrepancies in pricing, production delays, and unexpected costs. Avoiding these common pitfalls through meticulous preparation and clear communication is crucial for a smooth and cost-effective assembly process.

- Incomplete or Inaccurate Bill of Materials (BOM)

A BOM missing components, incorrect part numbers, or inaccurate quantities is a primary source of quoting errors. This can result in either underestimated initial quotes or additional expenses and delays when these discrepancies are identified during the assembly process. Always double-check and ensure the BOM precisely reflects your design and includes all necessary components, referencing the manufacturer's part numbers where applicable. - Ambiguous Assembly Instructions

Vague or incomplete assembly instructions can lead to misinterpretations by the assembly house, resulting in incorrect component placement, orientation, or soldering techniques. Clearly specify any unique assembly requirements, such as polarity markings, specific soldering processes, or specific component mounting procedures. Supporting diagrams or detailed written descriptions can mitigate ambiguity and reduce potential errors. - Incorrect Gerber File Submission

Submitting outdated or incompatible Gerber files can lead to quoting inaccuracies and potential manufacturing errors. Verify that the correct version of your Gerber files are uploaded. These files must align with the latest version of your PCB design. Ensure that all layers, including copper, solder mask, and silkscreen layers, are included and correct. - Failure to Specify Required Quality Standards or Testing

Different applications may require specific quality or testing standards (e.g., IPC standards, functional testing requirements). Failing to define these during the quoting process may lead to quotations which may not be appropriate for the application in mind. Explicitly mentioning relevant standards ensures that the assembly house takes the appropriate measures for both manufacturing and validation. This may also affect the quote provided. - Underestimating Quantity and Assembly Turnaround Time

Requesting a quote for an underestimated quantity or unrealistic assembly timeframe can lead to pricing escalations or delays as you try to expedite production. Carefully consider your actual project requirements in relation to lead time and the quantity needed. Be open to negotiating reasonable time frames based on the complexities of the order to help with an accurate and timely quote. - Ignoring Design for Manufacturability (DFM) Issues

Designs that ignore standard manufacturing guidelines (DFM) can increase production complexity and costs. Issues may include components too close together, via sizes too small for manufacturing, or incorrect land patterns. Identifying DFM issues early via a review before submitting a quote will allow for design adjustments to facilitate cost-effective PCB assembly. Communicate with your PCB assembly partner to help you correct these DFM issues.

Frequently Asked Questions About Online PCB Assembly Quotes

This section addresses common queries regarding online PCB assembly quotes, providing clarity on factors influencing cost, turnaround times, and the overall process. Understanding these aspects is crucial for accurate budgeting and successful project completion.

- How does the complexity of my PCB design impact the online PCB assembly quote?

The complexity of a PCB design directly affects the assembly quote. More complex designs, which might involve a higher density of components, finer pitch components, or multi-layer boards, require more intricate assembly processes. These processes often involve specialized equipment and more labor, resulting in higher costs. For instance, components like Ball Grid Arrays (BGAs) or fine-pitch QFNs require advanced placement and soldering techniques, increasing the cost compared to simpler surface-mount components. - What is the typical turnaround time for PCB assembly after receiving an online quote?

Turnaround time for PCB assembly can vary significantly based on several factors including the complexity of the assembly, the quantity ordered, and the manufacturer's current workload. Generally, standard assemblies may take from a few days to a couple of weeks. However, for expedited services, some manufacturers offer assembly in as little as 24 to 48 hours, albeit at a premium. It's important to discuss lead times specifically with your chosen manufacturer and factor in the time for component procurement if you are not providing them. - What are the different methods for PCB assembly, and how do they affect the quote?

PCB assembly methods generally fall under two main categories: surface mount technology (SMT) and through-hole technology (THT). SMT is the dominant method today, where components are placed directly onto the surface of the PCB. It's typically more cost-effective for mass production. THT, where component leads are inserted into holes in the PCB, is often used for larger, more robust components. The choice between SMT and THT or a combination of both will impact the assembly process and, consequently, the quote. Advanced methods, such as mixed technology, can also impact costs and the complexity of the process. Additionally, automated assembly will generally reduce per-unit assembly cost when compared to manual assembly, especially for higher quantities. - How do I choose the right PCB assembly house from online quotes?

Choosing the right PCB assembly house involves considering several factors beyond just the cost. Firstly, assess their experience and capabilities by reviewing their past work and certifications. Secondly, evaluate their customer support responsiveness. Thirdly, compare lead times and ensure their schedule aligns with your project's timeline. Finally, review customer testimonials and online reviews. It's essential to opt for a manufacturer that not only offers a competitive quote but also demonstrates the capability to produce high-quality assemblies consistently. It is always wise to get quotes from multiple manufacturers for a single design, as the cost and lead-time can vary substantially. - What information do I need to provide for an accurate online PCB assembly quote?

To obtain an accurate online PCB assembly quote, you will need to provide the following essential information: Gerber files for the PCB design, a detailed Bill of Materials (BOM) that lists all components, assembly drawings if applicable, and specific assembly instructions or requirements. The BOM must include the manufacturer's part number, reference designators, and quantities for every component. Clear and complete documentation is crucial for an accurate quote and avoids delays from misunderstandings or incorrect component ordering and can often be used to justify differences in prices from different suppliers. - What other factors can affect the online PCB assembly quote?

Beyond the previously mentioned considerations, several additional factors can significantly affect your online PCB assembly quote. These include the type of components (e.g., standard vs. custom, lead time on components), the number of layers on your board, the size of the PCB itself, whether you require special testing, and the volume of your order. All of these factors impact the manufacturer's labor and material costs, thereby shaping the final quote. For example, high volumes usually reduce per-unit assembly costs due to economies of scale. Additionally, requesting conformal coating, special testing, or custom packaging will all add to the price.

The Importance of BOM (Bill of Materials) Accuracy for Quotes

An accurate Bill of Materials (BOM) is paramount for obtaining reliable online PCB assembly quotes. The BOM serves as the cornerstone for precise cost calculations, encompassing all the necessary components, their specifications, and quantities required for assembling your printed circuit board. Errors or omissions in the BOM will inevitably lead to inaccurate quotes, potential delays, and increased overall project expenses.

A comprehensive BOM typically includes the following essential details:

- Manufacturer Part Number

The specific part number assigned by the component manufacturer, ensuring accurate identification. - Reference Designator

The unique identifier for each component on the PCB layout (e.g., R1, C2, U3). - Quantity

The number of each component required for a single PCB assembly. - Component Description

A clear description of the component, including its value, package type, and tolerances. - Footprint

The package or physical dimensions of the component. - Alternative Part Numbers

If applicable, provide alternative parts from other manufacturers.

Failure to provide an accurate BOM leads to several detrimental outcomes:

- Inaccurate Costing

The assembly house will have difficulty calculating the correct material costs, leading to either a higher initial quote or a change order later. - Part Procurement Delays

Missing or incorrect information about components will cause procurement delays and push out your project timeline. - Increased Assembly Costs

If the wrong components are procured or placed, rework will cause increased overall assembly costs. - Quality Issues

If a component’s value or rating is incorrectly specified, it can compromise performance and reliability.

To ensure your BOM is ready for accurate quoting, consider these best practices:

- Verify Part Numbers

Double-check all manufacturer part numbers against official datasheets. - Use Accurate Reference Designators

Ensure all components are clearly and correctly labelled on your schematic and PCB layout. - Include all Components

Make sure even small passive components and hardware items are in your BOM. - Specify Critical Attributes

Note down important specifications such as capacitance, resistance, tolerance, voltage rating, etc. - Check for Footprint Errors

Confirm the component footprint matches the physical package - Consult Datasheets

Always refer to the datasheets for the most accurate component information. - Regularly Review BOM

Before submitting a request, review it for any errors. Reviewing by another member on your team will catch mistakes you may have missed.

Tips for Reducing Your PCB Assembly Costs

Optimizing PCB assembly costs requires a strategic approach that encompasses design, component selection, and production volume. By implementing design for manufacturability (DFM) principles and carefully choosing components, manufacturers can reduce the overall price per board.

- Design for Manufacturability (DFM)

Implementing DFM principles from the design phase reduces manufacturing complexities. Standardizing component footprints, minimizing the number of unique parts, and using larger component sizes for easier assembly. For example, choosing 0603 components instead of 0402 where possible can significantly reduce assembly costs. - Component Standardization

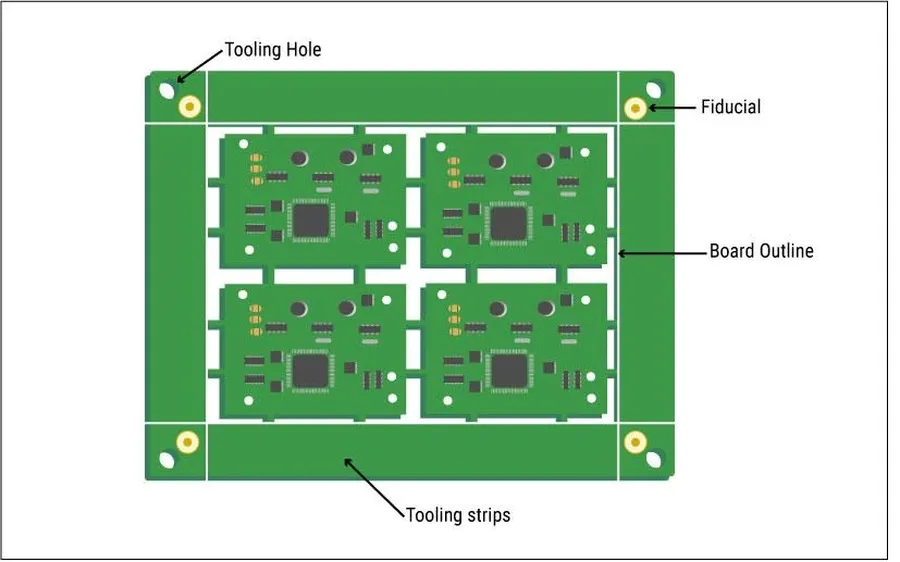

Using common, widely available components simplifies the supply chain and reduces purchasing costs. If multiple components share a similar function, pick one. Opt for components that are readily available from multiple suppliers. - Panelization

Panelizing your PCB design, also known as arraying, involves placing multiple PCBs onto a larger panel. This can reduce material waste, assembly time, and overall costs. Always confirm with your assembly house before panelizing. - Optimizing Quantities

Ordering PCBs and components in quantities that qualify for volume discounts is also essential. This allows for bulk buying of components and reduces the per-unit cost of assembly. - Consider Alternate Components

Exploring less expensive, equivalent alternate components can cut costs considerably. Always verify the specifications and reliability of alternate components thoroughly, it should function exactly the same as the primary component. - Streamline Design

Keep the design as simple as possible. Fewer layers, through-hole rather than surface mount components (when feasible), will reduce costs. - Clear and Accurate Documentation

Provide comprehensive and clear assembly drawings, schematics and other documents. This helps to avoid errors and speeds up the assembly process, ultimately saving costs.

Choosing the Right Online PCB Assembly Partner

Selecting the appropriate online PCB assembly partner is crucial for the success of any electronics project. A reliable partner ensures not only an accurate online PCB assembly quote but also consistent quality, adherence to timelines, and effective support throughout the production process. This choice impacts overall cost-efficiency and the final product's reliability.

Evaluating potential partners requires careful assessment across multiple dimensions, including their technical capabilities, manufacturing expertise, customer service, and past project performance.

- Technical Capabilities

Assess the manufacturer's range of services, including the types of PCB assembly they offer (e.g., SMT, through-hole, mixed), component placement accuracy, and their ability to handle complex designs. Certifications such as ISO 9001 and IPC standards compliance are strong indicators of process control and quality. - Manufacturing Expertise

Consider their experience with similar projects, paying attention to the complexity of assembly, component size, and tolerance requirements. Proven experience in assembling boards with comparable specifications to your requirements offers assurance of capability. Look for details about their equipment and technology, ensuring they have modern, well-maintained equipment to handle your assembly demands. - Customer Support and Communication

Evaluate the responsiveness and helpfulness of their customer support team. Timely and clear communication can drastically reduce the risks of errors and delays. A dedicated account manager or readily available engineering support can make the whole quoting and assembly process more efficient and transparent. Confirm they offer clear methods of contact and prompt response times. - Customer Reviews and Testimonials

Review past customer feedback on independent platforms to evaluate other users' experiences with the manufacturer's services, quality of work, on-time delivery, and responsiveness. Investigate both positive and negative feedback to gain a balanced view. Seek out case studies and project portfolios demonstrating their past success and variety of capabilities. - Quoting and Transparency

Verify the accuracy and detail of the quote provided, ensuring all costs are clearly identified and explained, including tooling, setup charges, and other potential fees. Understand the payment terms and conditions beforehand. A partner with clear and transparent pricing will help you avoid unexpected costs. A breakdown of the quote can help you to understand each cost component, which promotes accountability. - Delivery Times and Lead Times

Assess the delivery times provided for your project timeline. Lead times should be realistic and transparent, and on-time delivery is crucial to keeping your project on schedule. Confirm they have production capacity and logistics arrangements to support your project requirements. If time is a critical component, explore options to compress lead times.

By thoroughly evaluating these factors, you can select a reliable PCB assembly partner who can transform your initial online PCB assembly quote into a successfully manufactured product.

Obtaining a precise [online pcb assembly quote] is essential for budget planning and project success. By understanding the factors that influence cost and utilizing online quote tools efficiently, you can confidently proceed with your PCB assembly. Remember to compare your options and choose the right partner for long-term success in your electronics endeavors.

AnyPCBA

AnyPCBA