Global Leaders: Top PCB Companies Shaping the Electronics Industry

Printed circuit boards (PCBs) are the unsung heroes of modern electronics, quietly powering everything from smartphones to spacecraft. In this dynamic industry, several companies stand out for their innovation, quality, and scale. These are the global giants that shape technological progress. We'll delve into the world's top PCB companies, such as TTM Technologies, AT&S, and PCBONLINE, exploring what makes them leaders and how their work impacts our daily lives.

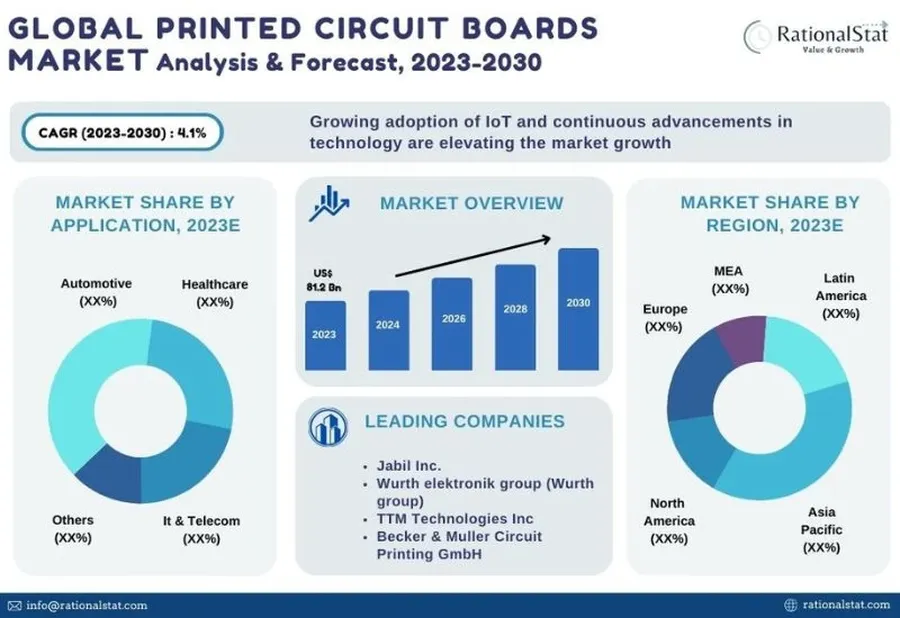

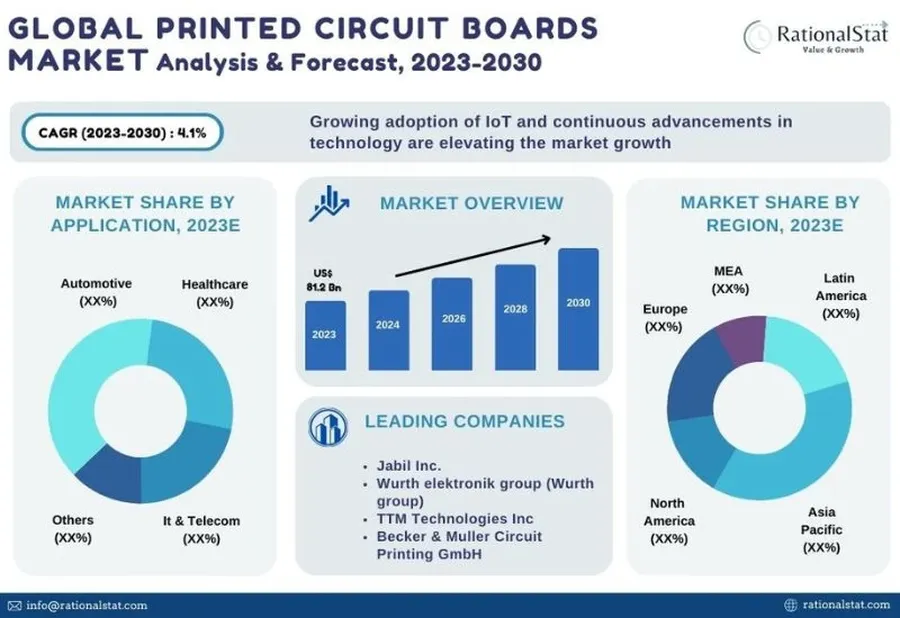

The Global PCB Market: An Overview

The global printed circuit board (PCB) market is a critical component of the electronics industry, serving as the foundational platform for nearly all electronic devices. This market, characterized by its substantial size and consistent growth, is driven by the ever-increasing demand for electronic products across various sectors, from consumer electronics to aerospace and automotive. The top PCB companies play a pivotal role in shaping this landscape through their technological advancements, production capabilities, and market influence.

Key market trends include the miniaturization of electronics, the rise of high-density interconnect (HDI) PCBs, and the increasing adoption of flexible and rigid-flex PCBs. These trends are largely driven by the continuous pursuit of smaller, more efficient, and higher-performing electronic devices. The PCB market's growth is further propelled by the expansion of IoT (Internet of Things), 5G technology, and electric vehicles, all of which rely on advanced PCB designs. Market analysis reveals a clear correlation between these emerging technologies and the demand for innovative PCB solutions, with top PCB companies leading the charge in research and development to meet these needs. These companies' ability to adapt to and anticipate market trends is essential for their continued success and influence in the global electronics sector.

Top PCB Companies by Revenue and Market Share

The global printed circuit board (PCB) industry is dominated by a select group of companies that command significant revenue and market share. These top players are critical in shaping technology advancements and driving innovation within the electronics sector. This section provides an in-depth look at these leading manufacturers, highlighting their financial performance and global impact.

| Company | Headquarters | Estimated Annual Revenue (USD) | Market Share | Key Strengths |

|---|---|---|---|---|

| Zhen Ding Technology | Taiwan | ~5 Billion | ~6-8% | High-volume production, diverse PCB types, strong in FPC. |

| Unimicron | Taiwan | ~4.5 Billion | ~5-7% | Advanced technologies, HDI PCBs, large capacity. |

| TTM Technologies | USA | ~3 Billion | ~4-5% | Aerospace & defense, complex boards, quick-turn services |

| Nippon Mektron | Japan | ~2.5 Billion | ~3-4% | Automotive and industrial, high-reliability PCBs, flexible boards. |

| Samsung Electro-Mechanics | South Korea | ~2.2 Billion | ~3-4% | Advanced HDI, semiconductor packaging, high density PCB solutions. |

| Ibiden | Japan | ~2 Billion | ~2-3% | IC substrates, complex multilayer PCBs, high-end boards. |

| Kingboard Chemical | Hong Kong | ~1.8 Billion | ~2-3% | High-volume production, cost-effective solutions, wide range of PCB materials. |

These revenue figures and market share data are estimates based on the latest available financial reports and market research. The actual numbers may vary slightly due to the dynamic nature of the industry and the ongoing fluctuations in the global electronics market.

Leading PCB Manufacturers in North America

North America is a significant hub for PCB manufacturing, housing several leading companies that drive innovation and set industry standards. This section delves into the capabilities and specializations of key players in the United States and Canada, highlighting their contributions to the global electronics landscape.

| Company | Headquarters | Specialization | Technology Leadership |

|---|---|---|---|

| Advanced Circuits | Aurora, Colorado, USA | Quick-turn PCBs, prototype PCBs | Focus on rapid prototyping and small to medium volume production. |

| Sanmina | San Jose, California, USA | High-complexity PCBs, system integration | Leading in high-mix, high-complexity manufacturing and supply chain solutions. |

| TTM Technologies | Costa Mesa, California, USA | Advanced PCBs, HDI boards, RF PCBs | Known for its expertise in highly engineered and technically advanced products. |

| Amphenol Printed Circuits | Nashua, New Hampshire, USA | Rigid, flex and rigid-flex PCBs | Expertise in high reliability applications and quick turnaround |

| Summit Interconnect | Anaheim, California, USA | Complex PCBs, HDI boards | Specialized in high-technology PCB manufacturing. |

| Epec Engineered Technologies | New Bedford, Massachusetts, USA | Custom PCBs, flexible circuits, embedded solutions | Focus on custom engineered solutions, offering a broad range of PCB technologies |

| Multek (A division of Flextronics) | Milpitas, California, USA | High-volume PCBs | Part of a large global manufacturing company focusing on scale and efficiency. |

| APCT | Santa Clara, California, USA | High-reliability PCBs | Focused on delivering high quality, high reliability and complex printed circuit board manufacturing |

| Libra Industries | Mentor, Ohio, USA | Complex, high reliability PCBs | Provide a wide array of PCB manufacturing capabilities, with special emphasis on complex builds |

| Saline Lectronics | Saline, Michigan, USA | High-mix, low-volume PCBs | Well regarded for its high quality, low to mid volume PCB manufacturing. |

These North American companies not only contribute significantly to the regional economy but also play a critical role in the global supply chain of PCBs. Their technological advancements and manufacturing capabilities ensure that the electronics industry remains well-supported with high-quality components.

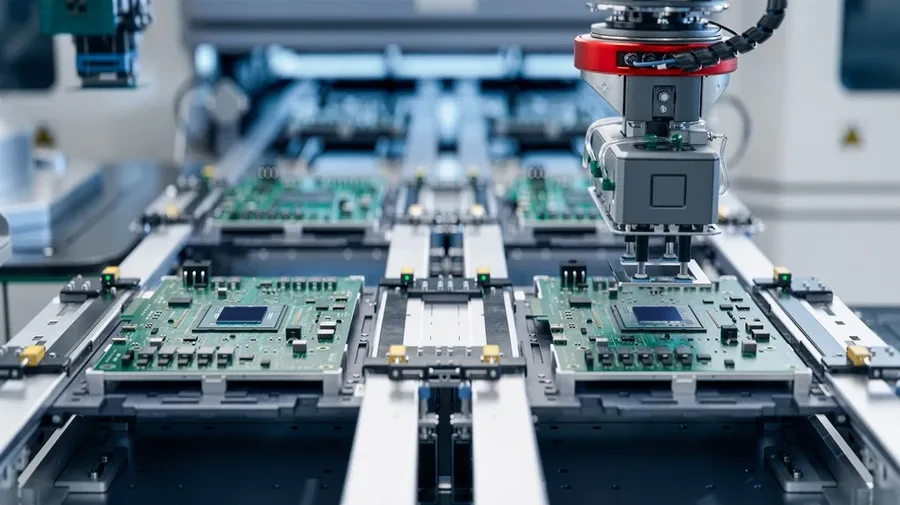

Asian PCB Giants: Powerhouses of Production

Asia stands as the epicenter of PCB manufacturing, housing some of the world's largest and most influential companies. These manufacturers are characterized by their immense production capacities, technological advancements, and significant impact on the global electronics supply chain. This section profiles key players from Taiwan and China, highlighting their contributions to the industry.

| Company Name | Country/Region | Key Strengths | Global Impact |

|---|---|---|---|

| Zhen Ding Technology | Taiwan | High-volume production, advanced technology, flexible PCBs | Major supplier to global electronics brands, significant market share |

| Unimicron | Taiwan | HDI and advanced PCBs, strong R&D capabilities | Leading provider of high-end PCBs, extensive international footprint |

| PCBONLINE | China | Diverse PCB solutions, rapid prototyping, large-scale manufacturing | Emerging leader in the Chinese market, expanding international presence |

| Hemeixin PCB | China | Specialized in multilayer PCBs, cost-effective solutions | Key manufacturer in the domestic Chinese market, growing global export capabilities |

Specialized PCB Manufacturers: Niche Leaders

The electronics industry relies on specialized PCB manufacturers who provide advanced solutions beyond standard printed circuit boards. These niche leaders possess unique expertise in fabricating complex boards like flexible PCBs, high-density interconnect (HDI) boards, and Radio Frequency (RF) PCBs, crucial for applications that demand specific performance or form factors. These companies contribute significantly to technological progress by enabling the design and production of increasingly sophisticated electronic devices.

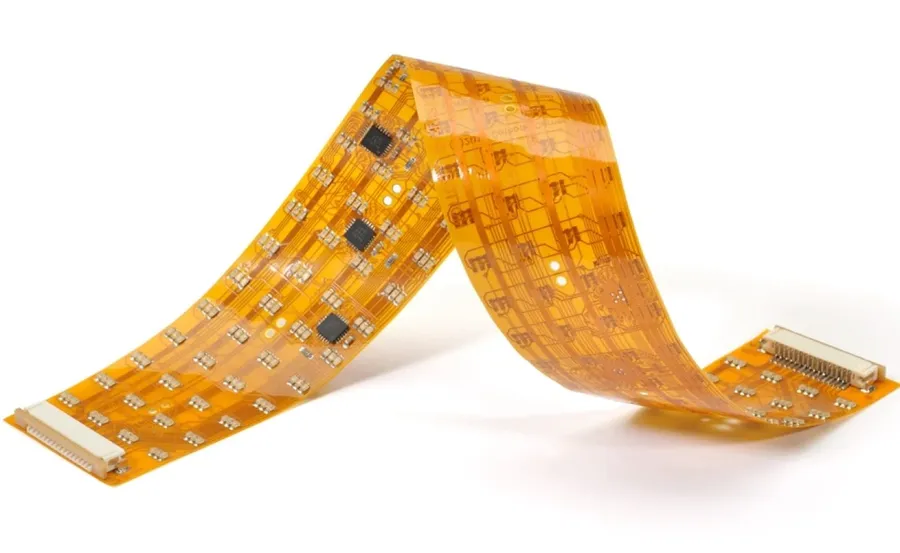

- Flexible PCBs

Flexible PCBs are built on a flexible substrate, allowing them to bend and conform to various shapes. This type of PCB is essential for applications with space constraints or where dynamic flexing is required, such as wearable electronics and automotive displays. Manufacturers specializing in flexible PCBs often utilize advanced materials and processes to ensure the reliability and durability of the final product. Key considerations include the flex material, conductor thickness, and bend radius. - High-Density Interconnect (HDI) Boards

HDI PCBs feature finer lines, smaller vias, and higher connection pad density compared to standard PCBs. These are critical for compact electronics like smartphones and tablets, where space is at a premium. HDI manufacturing requires specialized equipment and techniques, such as microvia drilling, laser direct imaging, and sequential lamination, to achieve the high level of precision required. Special attention is placed on controlled impedance, signal integrity, and thermal management. - RF PCBs

RF PCBs are designed to operate effectively at radio frequencies and are used in wireless communication systems, radar technology, and high-frequency signal processing. RF PCB manufacturing demands a deep understanding of impedance control, dielectric constants, and material properties at high frequencies. Manufacturers often use specific substrates, such as Teflon or ceramic-based materials, to minimize signal loss and ensure high performance. Precise fabrication and testing are paramount for signal integrity and optimal performance.

| PCB Type | Key Features | Applications | Manufacturing Requirements |

|---|---|---|---|

| Flexible PCBs | Bendable substrate, versatile shapes | Wearable devices, automotive displays | Advanced materials, precise lamination |

| HDI PCBs | Fine lines, microvias, high density | Smartphones, tablets, compact devices | Microvia drilling, laser imaging, sequential lamination |

| RF PCBs | Impedance control, high-frequency operation | Wireless communication, radar systems | Specialized substrates, precise testing |

Comparing PCB Manufacturing Services: Cost vs. Quality

Selecting a PCB manufacturing service involves a critical trade-off between cost, quality, and turnaround time. Understanding these factors is crucial for project success, as the right balance can significantly impact both budget and product reliability.

| Factor | Low-Cost Provider | Mid-Range Provider | High-End Provider |

|---|---|---|---|

| Cost | Lowest | Moderate | Highest |

| Quality | Basic, acceptable for simple applications | Good, suitable for most applications | High, for critical and complex applications |

| Turnaround Time | Longest | Moderate | Shortest |

| Technology | Limited to basic PCBs | Supports a wide range of PCB types | Offers cutting-edge and specialized technologies |

| Materials | Standard and cost-effective materials | Offers a variety of materials with some specialty options | High-performance, specialty, and custom materials available |

| Customer Support | Limited | Responsive | Dedicated support with engineering expertise |

| Certification | Minimal certifications | Standard certifications, e.g., ISO | Comprehensive certifications, e.g., AS9100, medical certifications |

Frequently Asked Questions About Top PCB Companies

This section addresses common queries about PCB manufacturing and the top companies in the industry, providing clear and concise answers to enhance understanding.

- What criteria define the 'best' PCB company?

The 'best' PCB company varies depending on project requirements. Key criteria include manufacturing quality and precision, technological capabilities (such as HDI or flexible PCB production), material availability, adherence to industry standards (IPC), production capacity, lead times, cost-effectiveness, and customer support. A company excelling in one area may not be the best fit for every project. It’s essential to prioritize based on specific needs. - Who are the largest PCB suppliers in terms of production volume?

The largest PCB suppliers are typically those with significant production facilities and high revenue. Companies like Zhen Ding Technology, Unimicron, and TTM Technologies are among the largest globally, owing to their extensive manufacturing capabilities and high-volume production. These companies often cater to large-scale electronics manufacturers. - Which companies are the primary manufacturers of PCBs?

Numerous companies manufacture PCBs globally. Major players include Zhen Ding Technology, Unimicron, TTM Technologies, and other significant manufacturers in Asia, North America, and Europe. These companies often handle various types of PCB manufacturing from simple single-layer boards to complex multi-layer and HDI boards. - What are the key factors to consider when selecting a PCB manufacturer?

Selecting the right PCB manufacturer involves careful consideration of several factors. These include the manufacturer's technological capabilities (e.g., their ability to produce the specific types of PCBs needed), material availability, adherence to industry standards and quality certifications (like ISO 9001 or AS9100), cost, lead time, production capacity, and their experience with similar projects. It is also vital to evaluate their customer support and communication. - Which PCB design software is considered the best for professional use?

The choice of PCB design software depends largely on specific needs and expertise, however, industry standards like Altium Designer, Cadence Allegro, and Mentor Graphics Xpedition are widely considered top-tier for professional use. These tools offer advanced features for complex designs, simulation, and collaboration. Other software options include KiCad (open-source), EAGLE (now part of Autodesk), and OrCAD. Each has its strengths and weaknesses depending on design requirements. - How can I verify a PCB manufacturer's certifications and quality standards?

To verify a manufacturer's certifications, request documentation such as ISO 9001, ISO 14001, or AS9100 certificates. Additionally, look for IPC standards compliance, which indicates adherence to industry-recognized quality benchmarks. Check their website for quality policy statements and ask for references or case studies. Some manufacturers also conduct audits from third-party organizations, which can confirm their quality standards. - What is the typical lead time for PCB manufacturing and how can it be optimized?

Lead time for PCB manufacturing varies widely, from a few days for simple prototypes to several weeks for complex, high-volume orders. Factors influencing lead time include design complexity, material availability, the manufacturer’s workload, and the chosen shipping method. To optimize it, ensure complete and error-free design files, communicate specific timelines early in the process, consider domestic manufacturers for quicker turnarounds, and choose standard materials whenever possible.

The Future of PCB Manufacturing: Innovations and Trends

The printed circuit board (PCB) industry is undergoing rapid transformation, driven by the relentless pursuit of smaller, faster, and more efficient electronic devices. Key innovations are reshaping manufacturing processes, materials, and design methodologies, impacting how PCBs are conceived and produced. These changes are crucial for supporting the growing demands of various sectors, including consumer electronics, automotive, aerospace, and healthcare.

- Miniaturization and High-Density Interconnect (HDI)

The trend towards smaller and more portable devices necessitates the development of PCBs with increasingly finer lines and spaces, as well as higher interconnection densities. HDI technology, utilizing microvias and advanced layer stacking, allows for more functionality within a smaller footprint. This is crucial for compact devices such as smartphones and wearables. - Embedded Components

Embedding components directly within the PCB substrate reduces size and increases performance by minimizing parasitic inductance and capacitance. This technique improves signal integrity, allows for better thermal management, and further reduces the overall device size. Embedded passives and active components are becoming more common. - Flexible and Stretchable PCBs

Flexible PCBs (FPC) are increasingly in demand for applications that require bending or flexing, while stretchable PCBs enable electronics to conform to complex 3D shapes, opening opportunities in wearables, medical devices, and automotive interiors. Advances in material science and conductive inks are enhancing the durability and performance of these flexible and stretchable PCBs. - Sustainable Manufacturing Practices

Growing environmental concerns are pushing the industry towards more sustainable manufacturing processes. This involves reducing waste, using environmentally friendly materials, and developing energy-efficient production methods. The use of bio-based substrates and water-based inks is also gaining traction, moving the industry towards a circular economy model. - Additive Manufacturing and 3D Printing

Additive manufacturing, including 3D printing, is being used to fabricate PCBs with complex geometries and customized features, enabling rapid prototyping, on-demand manufacturing, and reduced material waste. This approach provides greater design flexibility and opens new possibilities for integrating electronics into intricate shapes and designs. - Artificial Intelligence (AI) in PCB Design and Manufacturing

AI-powered tools are being leveraged to optimize PCB design, automate manufacturing processes, and enhance quality control. AI can be used for layout optimization, design for manufacturability checks, predictive maintenance, and defect detection, reducing errors and accelerating production cycles. - Advanced Materials

The use of advanced materials such as low-loss substrates, high-thermal conductivity materials, and specialized inks are driving PCB performance by improving signal integrity, heat management, and reliability. Ongoing research into new materials will continue to shape PCB technology.

How to Choose the Right PCB Manufacturer for Your Project

Selecting the appropriate PCB manufacturer is a critical step in any electronics project, directly influencing the final product's quality, cost, and time to market. A well-informed decision, focusing on project-specific needs and manufacturer capabilities, is essential for success. Partnering with a top PCB company is a strategic advantage, ensuring access to advanced technologies and expertise that can significantly impact the project's outcome.

- Project Specifications

Clearly define your PCB requirements, including layer count, materials, size, and any special requirements like impedance control or high-frequency performance. Match these specifications with the manufacturers capabilities. - Budget Constraints

Determine the budget allocated for PCB manufacturing, and identify providers who can meet your requirements without compromising on quality. Compare quotes from various manufacturers considering different price points for different production volumes and lead times. - Lead Times

Assess the required turnaround time for your project. Some manufacturers offer quicker turnaround times, which may be necessary for prototype or urgent projects. However, rapid turnaround times often come at a premium. Plan your project schedule considering production and delivery times. - Manufacturer Certifications

Verify that the manufacturer holds necessary certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and IATF 16949 (automotive industry). These certifications ensure adherence to international standards and consistent manufacturing processes. Confirm if their certification covers the materials or manufacturing process you need for your project. - Technology and Capabilities

Evaluate the technology and capabilities offered by the manufacturer, such as the minimum trace width and spacing, via size, and the type of materials they can process, to make sure it aligns with your project needs. This assessment will ensure they can produce the PCB with the necessary precision and performance and that it is compatible with the manufacturing requirements for the application in which the PCB will be used. - Production Volume

Consider your project's production volume, whether it's a small prototype run or a large-scale production. Select a manufacturer that can scale according to your production needs and growth plans, as some are more specialized in high-volume production while others are better suited for small batches. - Communication and Customer Support

Assess their customer support and communication processes, responsiveness, language capabilities and time zones to make sure you can communicate in a timely manner during the project. Clear communication ensures smooth project execution, from the initial quotation to production completion.

The PCB industry is a crucial sector driving the modern tech landscape, with top PCB companies like TTM, AT&S, and PCBONLINE leading the charge. These companies, with their advanced technologies and large-scale manufacturing capabilities, enable the creation of groundbreaking electronic devices. By understanding the landscape of these global leaders, businesses and engineers can make informed decisions about their PCB needs and stay at the forefront of technological advancements. The future of electronics hinges on the continuous innovation and reliable production of these critical components.

AnyPCBA

AnyPCBA