How to Order Custom Circuit Boards: A Comprehensive Guide

In our increasingly interconnected world, custom circuit boards are the unsung heroes powering countless devices. From the smartphone in your hand to the complex machinery in factories, PCBs form the bedrock of modern electronics. This guide will navigate you through the process of how to order custom circuit board, ensuring you get the best results for your project.

Understanding Your Needs Before You Order Custom Circuit Board

Before initiating the custom circuit board ordering process, a thorough understanding of your project's specific requirements is paramount. This upfront clarity not only streamlines the subsequent stages but also minimizes potential errors and cost overruns. Accurately defining parameters such as physical dimensions, circuit complexity, substrate materials, and the number of layers is essential for effective communication with manufacturers and ensures that the final product aligns with the design specifications.

- Size and Dimensions

Precisely specify the length, width, and thickness of the board to ensure it fits correctly within its enclosure and application. - Circuit Complexity

Determine the density of components and traces required, which will influence the fabrication process and cost. - Material Selection

Choose the appropriate substrate material (e.g., FR-4, Rogers) based on electrical performance requirements like signal frequency and thermal properties. - Layer Count

Decide on the number of conductive layers needed, as this directly affects the routing capabilities and cost. - Application Requirements

Understand the application’s specific requirements, such as operating temperature, signal integrity needs, and environmental constraints. - Tolerance Requirements

Specify the necessary tolerances for board dimensions and feature sizes, which can impact the manufacturing process.

Choosing the Right PCB Manufacturer: Factors to Consider

Selecting the optimal PCB manufacturer is paramount for the success of any electronic project, directly impacting the quality, cost, and timeline of the final product. This decision necessitates careful consideration of various factors, ensuring that the chosen manufacturer aligns with the specific requirements of your design and project constraints.

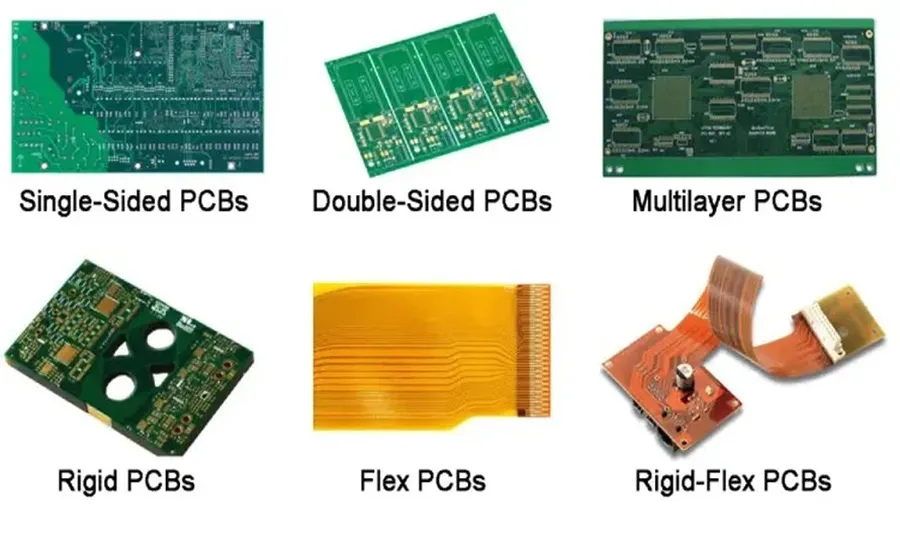

- Manufacturer Capabilities and Specializations

Assess the manufacturer's technological capabilities to ensure they can produce PCBs that match your design's complexity. This involves checking their equipment for precision and their experience with specialized materials, layer counts, and advanced manufacturing processes. Some manufacturers specialize in high-frequency PCBs, others excel in high-density interconnect (HDI) designs, while others may focus on flexible PCBs. Matching your project's specific needs with the manufacturer's expertise is crucial for achieving optimal results. - Minimum Order Quantity (MOQ)

MOQ refers to the minimum number of PCBs a manufacturer requires for a single order. This can be particularly important for smaller projects or prototypes. If your project needs only a few boards, choose a manufacturer with a low MOQ or one that offers prototyping services. High MOQs can result in unnecessary costs and excess stock if you don't require a large number of PCBs. - Turnaround Time (Lead Time)

Turnaround time is the duration from placing the order to receiving the finished PCBs. This is a critical factor in project scheduling. Some manufacturers offer expedited services for a premium, which is useful for time-sensitive projects. However, it is important to understand that the turnaround time often depends on the complexity of the PCB and the manufacturer's current workload. - Pricing Structure and Transparency

The cost of PCB manufacturing depends on various factors, including size, layer count, materials, and quantity. A transparent pricing structure is vital to ensure no hidden costs arise during the ordering process. Compare quotations from multiple manufacturers to get the best value. Consider not only the price but also what the price includes, such as shipping and any other fees. - Certifications and Quality Standards

Certifications such as ISO 9001 indicate that the manufacturer adheres to specific quality management standards. A certified manufacturer is more likely to produce consistent and reliable PCBs. Also check for compliance with environmental standards like RoHS which restricts the use of hazardous materials. These certifications are important indicators of a manufacturer's commitment to quality and sustainability. - Geographic Location

The manufacturer's location can affect shipping costs and delivery time. Local manufacturers may offer quicker turnaround and easier communication, while overseas options might offer lower prices. However, consider the potential time delays and communication barriers that may occur with distant manufacturers. - Customer Reviews and Feedback

Checking online reviews and testimonials can offer insights into a manufacturer's reliability, quality, and customer service. Look for consistent patterns in the reviews, both positive and negative, to assess the manufacturer’s strengths and areas for improvement. Direct feedback from other customers can provide a more nuanced understanding beyond what the manufacturer advertises.

Online PCB Ordering Platforms: Convenience and Speed

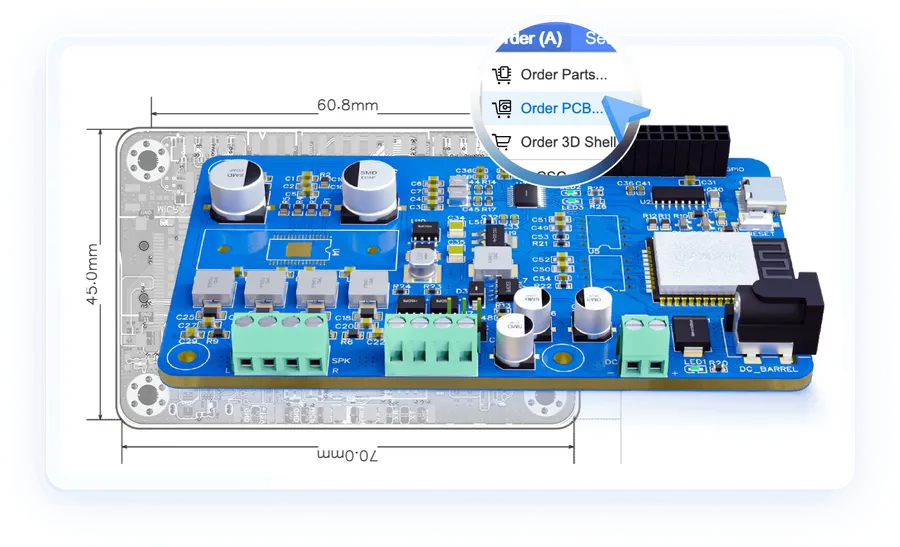

Online platforms have revolutionized the way custom circuit boards are ordered, offering unprecedented convenience and speed compared to traditional methods. These platforms allow for instant quotes, efficient file uploads, and real-time tracking, streamlining the entire process from design submission to delivery.

- Instant Quoting

Online platforms provide instant pricing based on the specifications of your custom circuit board design. This allows for quick budget assessments and eliminates the delays associated with manual quotation processes. - Simplified File Uploads

These platforms support various file formats, typically Gerber files, for uploading your PCB designs directly. This eliminates the potential for miscommunication or errors that can occur with traditional file transfer methods. - Real-Time Order Tracking

Once an order is placed, users can monitor its status through the online system. This transparency significantly improves the customer experience by providing clear insight into the order's progress, including manufacturing, assembly, and shipping. - Faster Turnaround Times

By automating many steps, including quote generation and order processing, online platforms generally offer faster turnaround times than traditional methods. This reduced lead time is particularly valuable for rapid prototyping and time-sensitive projects. - Improved Communication

Online systems often integrate communication tools that allow users to directly interact with the manufacturer’s support team. This direct line of communication facilitates quicker responses to queries and promotes efficient problem-solving.

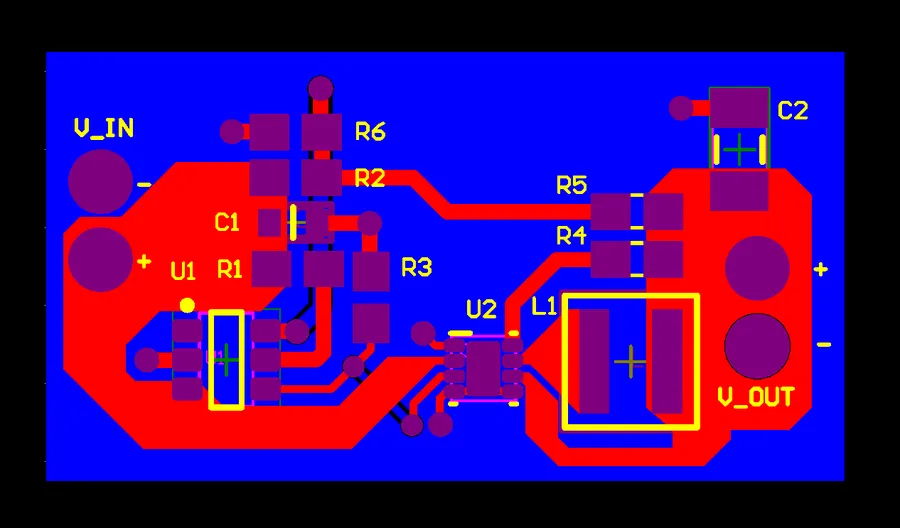

Preparing Your Design Files for a Custom PCB Order

The crucial step before submitting your design to a manufacturer for a custom circuit board is preparing your design files to adhere to manufacturing standards. Proper file preparation is essential to ensure your circuit board is fabricated correctly and efficiently, ultimately avoiding costly delays and errors.

Typically, manufacturers require Gerber files, which are the industry-standard format for PCB manufacturing data. These files contain all necessary information for fabricating your board, including copper layers, solder masks, and silkscreen layers. Different manufacturers may have their own specific requirements, so it's essential to confirm with your chosen manufacturer before submitting files.

- Gerber Files (.GBR):

This is the most crucial format, containing information about copper layers, solder mask, silkscreen, drill data, and board outline. - Drill Files:

These files, usually in Excellon format (.DRL), specify the location and size of all the holes in your PCB. Ensure your drill files are accurate. - Centroid Files (.CEN or .XYRS):

Also called pick-and-place files, these files are used by automated assembly machines to place components accurately onto the board. - Netlist Files:

A netlist describes the connectivity of the board; some manufacturers find it useful for verification and cross-checking. - Bill of Materials (BOM):

A detailed list of all electronic components required for your PCB, including part numbers, manufacturer information, and quantities, is essential for assembly. - Board Outline:

Ensure the board outline is clearly defined and consistent across all file layers. - Readme file

Any additional information that needs to be communicated to the fabricator for specific requirements.

It is also important to check that the layer order of your Gerber files matches the stackup design of your PCB to avoid manufacturing errors. Always use the same units throughout all your design files and double-check the file names. This ensures a smooth fabrication process and an accurate product.

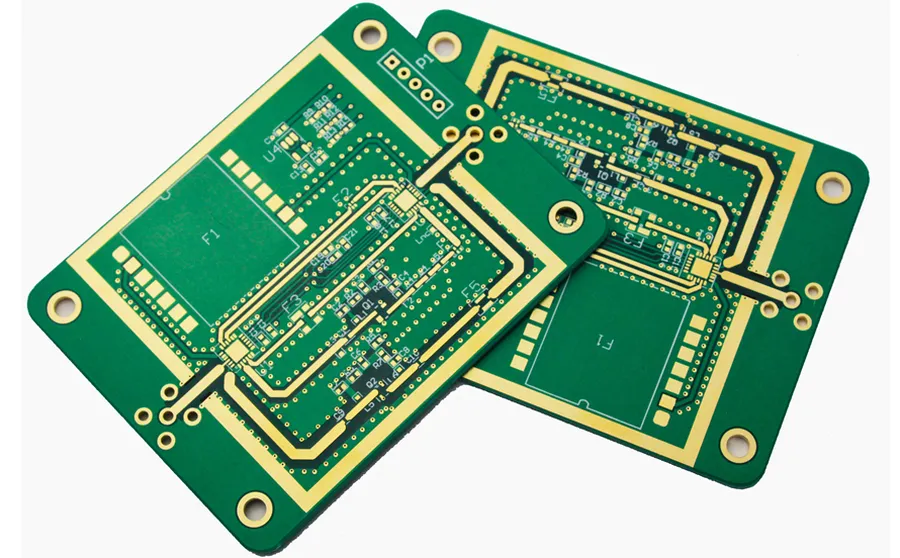

Understanding PCB Manufacturing Processes and Quality Standards

A thorough understanding of PCB manufacturing processes and adherence to quality standards are crucial for ensuring the reliability and performance of your custom circuit boards. This knowledge empowers you to make informed design and ordering decisions, ultimately minimizing potential issues and optimizing the final product.

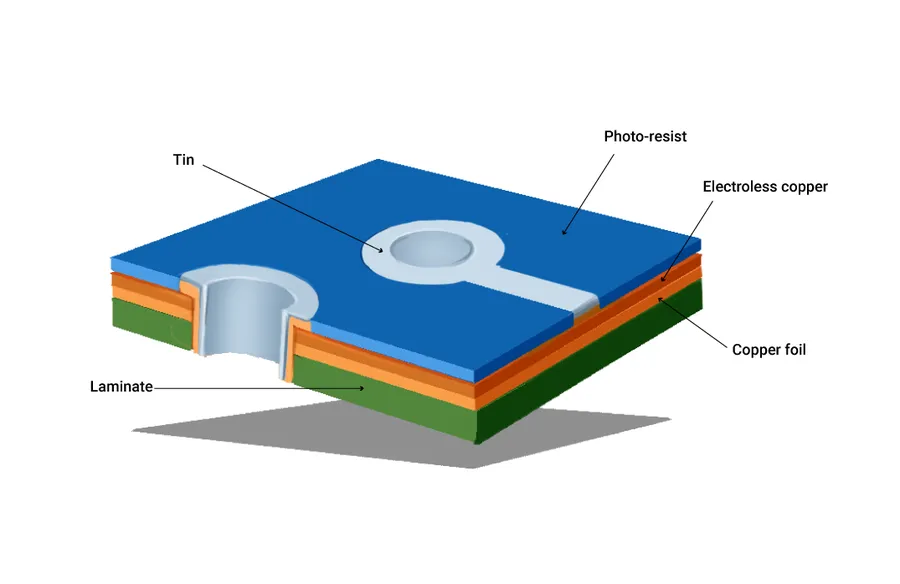

Several key manufacturing processes are involved in PCB fabrication:

- Etching

This process removes unwanted copper from the board, leaving behind the desired circuit traces and pads. - Drilling

Precise holes are drilled for component mounting and vias, which are conductive pathways between layers. - Lamination

This process bonds together multiple layers of the PCB, creating a multilayer structure when required. - Surface Finishing

Various finishes are applied, such as HASL, ENIG, or immersion tin, to protect the copper and improve solderability.

Quality standards, such as ISO 9001, ensure consistent and reliable PCB manufacturing. Selecting a manufacturer with certifications demonstrates their commitment to quality and process control.

| Process | Description | Impact on Quality |

|---|---|---|

| Etching | Removal of unwanted copper | Trace accuracy and impedance |

| Drilling | Creating holes for components and vias | Component fit and layer alignment |

| Lamination | Bonding of PCB layers | Structural integrity and layer adhesion |

| Surface Finishing | Protective coating on exposed copper | Solderability and corrosion resistance |

Cost-Effective Strategies for Ordering Custom Circuit Boards

Optimizing costs when ordering custom circuit boards requires a strategic approach, focusing on design choices, material selection, and order management. By implementing a few key strategies, significant savings can be realized without compromising the quality or functionality of the final product.

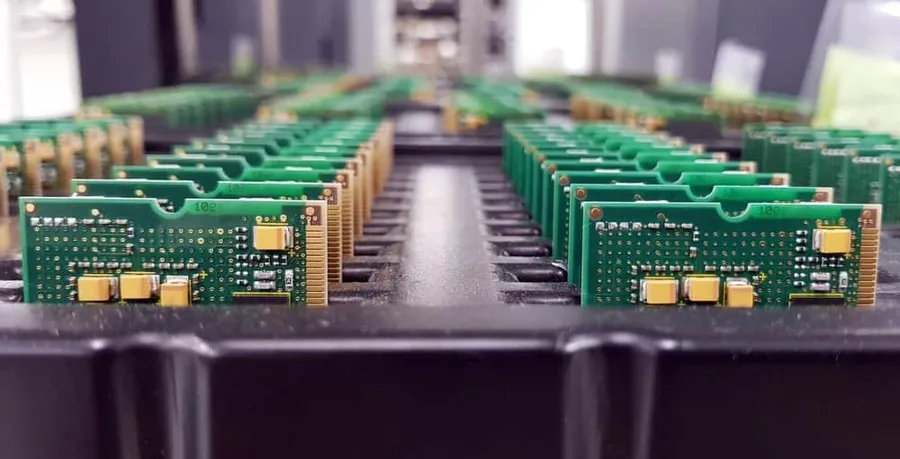

- Panelization

Panelizing your PCB design involves grouping multiple copies of the same or different designs onto a single manufacturing panel. This method reduces material waste and lowers the per-unit cost, especially for smaller boards. Ensure your manufacturer supports panelization and adheres to your design requirements. - Standard Materials and Sizes

Opting for standard materials (like FR-4) and commonly used board sizes can reduce costs, as they are typically stocked in large quantities by manufacturers. Customized or exotic materials, while offering performance advantages, often come with higher price tags due to limited availability and custom manufacturing processes. - Minimizing Board Features

Unnecessary features such as complex shapes, excessive vias, or overly tight tolerances can increase manufacturing complexity and, consequently, costs. Simplify your designs to what is functionally necessary. This can lead to a significant reduction in manufacturing time and cost. Consider the necessity of each feature. - Bulk Ordering

Ordering in larger quantities can drastically lower the per-unit cost of your PCBs. Manufacturers offer volume discounts as their production setup costs are spread over more units. If your project allows, consolidating your orders can yield substantial savings, but ensure you have sufficient storage and a plan for using the larger batch. - Design for Manufacturability (DFM)

Adhering to Design for Manufacturability principles early on can save time and resources. This includes considerations like appropriate trace widths, clearances, and via sizes based on your manufacturer's capabilities, which ultimately leads to avoiding errors and minimizing the need for costly reruns. - Careful Component Selection

Choosing commonly available and more affordable components can reduce both the component costs and the total board cost. Standard package sizes and readily available parts will lead to cost reduction overall. Also consider the assembly costs associated with your selection.

Frequently Asked Questions About Ordering Custom Circuit Boards

This section addresses common inquiries about ordering custom circuit boards, providing practical answers to help you navigate the process effectively. These frequently asked questions cover essential aspects such as order tracking, payment methods, handling quality issues, and troubleshooting common problems.

- How can I track my custom circuit board order?

Most manufacturers provide a tracking number once your order ships. You can typically use this number on the manufacturer's website or the shipping carrier's site to monitor the progress of your delivery. - What payment options are usually available when ordering custom PCBs?

Common payment methods include credit cards (Visa, MasterCard, American Express), PayPal, and wire transfers. The availability of these options can vary by manufacturer. Some manufacturers may also offer payment through direct bank transfer. - What should I do if I encounter a quality issue with my custom PCBs?

First, document the issue with clear photos or videos. Contact the manufacturer immediately, providing them with this documentation. Most reputable manufacturers have quality control procedures and will work to rectify any problems, usually offering replacement boards or refunds based on the issue's severity and their policies. - What are some common troubleshooting steps for custom circuit board issues?

Common troubleshooting steps involve checking for shorts, opens, and incorrect component placement, ensure components are correctly oriented, and verify the correct board layout against the schematic. Use a multimeter for continuity checks, and visually inspect for any soldering issues or damage. If using automated assembly, review the assembly files and ensure no discrepancies exist. - Do manufacturers offer rush order options for custom PCBs, and what are the implications?

Many manufacturers offer rush order options for an extra fee. Rush orders typically reduce the lead time significantly, enabling faster production. However, this may come with increased costs. Inquire about availability and costs before confirming such an order to understand potential trade-offs. - What are typical file formats required when I place a custom circuit board order?

Gerber files (.GBr) are the standard file format. This format includes various layers for copper, solder mask, silkscreen, and drill files. Additionally, you may also need a netlist, drill file, and bill of materials (BOM) depending on the manufacturer's requirements. Always double check the preferred file types with the manufacturer you are working with. - What are the common causes for delays in custom PCB fabrication?

Delays in custom PCB fabrication can arise from several factors. Common causes include complex board designs which need extra engineering time, unexpected material shortages, manufacturing bottlenecks, and errors in the design files requiring iterations. Review your files and ensure a smooth production.

Comparing Different PCB Manufacturers

Selecting the appropriate PCB manufacturer is crucial for ensuring the successful fabrication of your custom circuit boards. This section provides a comparative analysis of leading PCB manufacturers, focusing on critical parameters such as pricing, turnaround times, manufacturing capabilities, and customer reviews. This comparison aims to equip you with the necessary information to make an informed decision tailored to your specific project requirements.

| Manufacturer | Pricing | Turnaround Time | Capabilities | Customer Reviews | Notes |

|---|---|---|---|---|---|

| PCBWay | Competitive, varies with complexity and quantity | Fast, typically 24 hours to a few days for prototypes | Wide range, from basic to complex multilayer boards, flexible PCBs, etc. | Generally positive, noted for good service and quality | Strong for rapid prototyping and small to medium production runs. Offers a wide selection of materials, advanced features like blind and buried vias, and impedance control, they also offer assembly services. |

| JLCPCB | Very affordable, especially for small orders | Relatively fast, 1-3 days for prototypes | Good for basic to mid-complexity boards, limited advanced features | Mixed, generally good for the price point, with occasional reports of quality issues | Economical option for hobbyists and small-scale projects. They can also offer assembly services. It may not be suitable for complex or high precision designs. |

| DigiKey | Varies, usually higher price point for custom boards | Moderate to long, depends on the manufacturer they use | Good overall, but more focused on standard components and smaller quantity PCBs. | Generally very positive, but not direct feedback on PCB manufacturing itself | Better suited for purchasing components, but offers PCB fabrication services through partner manufacturers. Good choice when consolidating components and PCB orders. |

| ALLPCB | Reasonable pricing, bulk discounts available | Fast, generally 24 to 48 hours turnaround time | Good for all kind of PCB board. good for prototype and mass production. | Generally positive, many positive feedback. | Offers wide range of capabilities,good customer service and value |

| Eurocircuits | Higher price range for high-quality PCBs | Moderate, varies based on order complexity | Highly specialized in high-precision PCBs, high tech and complex boards. | Very positive, good service and support for European region | Suitable for specialized or high-reliability applications with complex designs. High performance demands. |

Ordering custom circuit boards is crucial for bringing your electronic inventions to life. By understanding your requirements, carefully selecting a manufacturer, and adhering to best practices, you can ensure a successful outcome for your project. When you're ready to order custom circuit board, make sure to consider the factors we've discussed and plan accordingly. The right approach will get your PCBs produced quickly and efficiently.

AnyPCBA

AnyPCBA