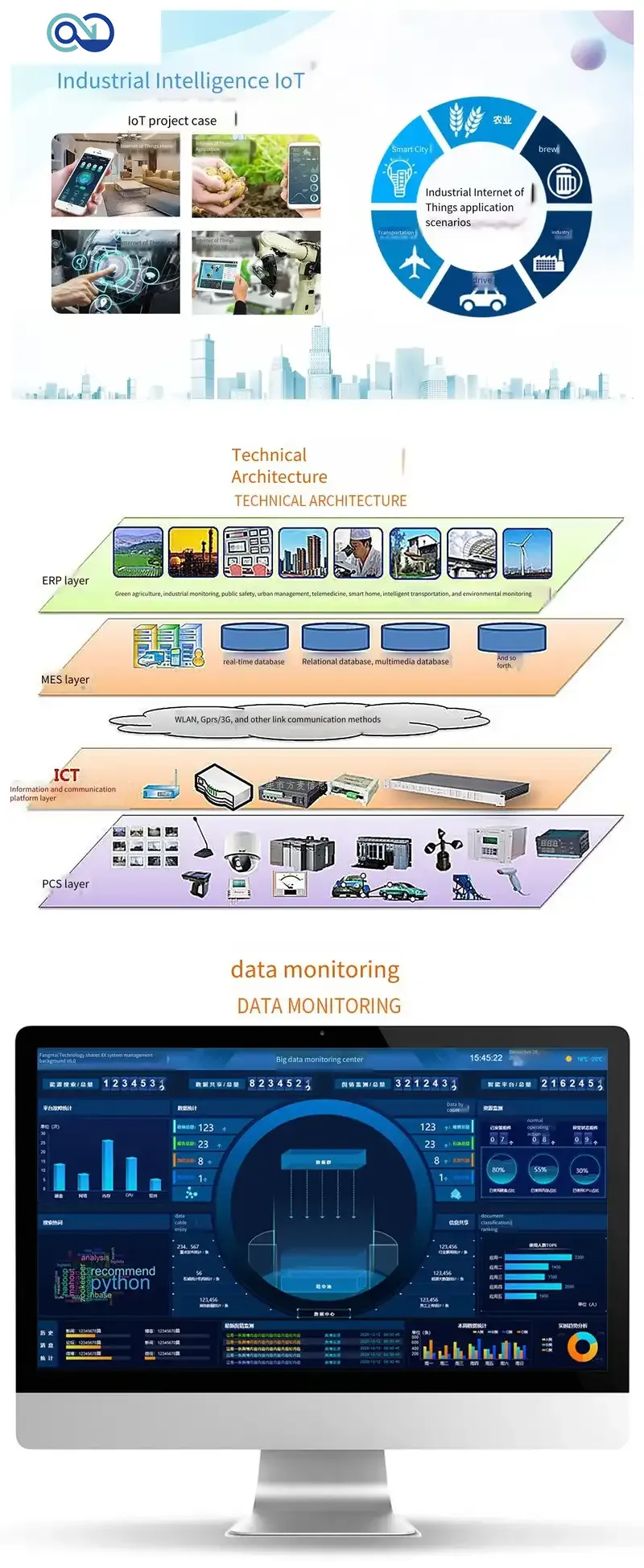

Industrial Smart IoT (Internet of Things) Solution

In an era defined by rapid technological advancement, the Industrial Internet of Things (IIoT) stands as a transformative force, revolutionizing how industries operate and innovate. Just as the human nervous system connects every part of our body for seamless function, IIoT connects machines, sensors, and systems within an industrial environment, creating a vast network of intelligent data. At Zero One Solution Limited, we recognize that the backbone of these sophisticated IIoT systems lies in robust, reliable, and high-performance Printed Circuit Boards (PCBs). This article delves into how our cutting-edge PCB solutions are pivotal in designing and deploying state-of-the-art Industrial Smart IoT systems, enabling businesses to achieve unprecedented levels of efficiency, productivity, and informed decision-making.

Understanding the Core of Industrial Smart IoT (IIoT)

Industrial Smart IoT (IIoT) represents the convergence of industrial operations with the Internet of Things, creating a network of interconnected devices, machines, and systems. Unlike consumer IoT, which focuses on enhancing daily life, IIoT is geared towards optimizing industrial processes, improving efficiency, and driving data-driven decision-making. It's about leveraging data from connected assets to unlock actionable insights, leading to enhanced productivity, reduced downtime, and improved overall performance.

Key components of IIoT include:

- Connected Sensors and Devices:

These devices collect real-time data from equipment and processes, providing a constant stream of information. - Communication Networks:

Reliable networks are crucial for transmitting data from sensors to central systems, utilizing technologies like Wi-Fi, cellular, and LPWAN. - Cloud Computing Platforms:

The cloud provides the infrastructure for storing, processing, and analyzing the vast amounts of data generated by IIoT devices. - Data Analytics and Visualization:

Advanced analytics tools transform raw data into actionable insights, presented through user-friendly dashboards and reports. - Applications and Software:

Software applications leverage the analyzed data to automate processes, optimize performance, and enable predictive maintenance.

The core benefits of implementing IIoT solutions include:

- Enhanced Operational Efficiency:

IIoT enables real-time monitoring and optimization of processes, leading to increased productivity and reduced waste. - Data-Driven Insights:

Access to comprehensive data allows for informed decision-making, identifying trends, and predicting potential issues. - Predictive Maintenance:

By analyzing sensor data, IIoT can predict equipment failures, enabling proactive maintenance and minimizing downtime. - Improved Safety:

IIoT solutions can monitor environmental conditions and equipment performance to identify potential safety hazards. - Increased Agility:

IIoT enables businesses to quickly adapt to changing market conditions and customer demands.

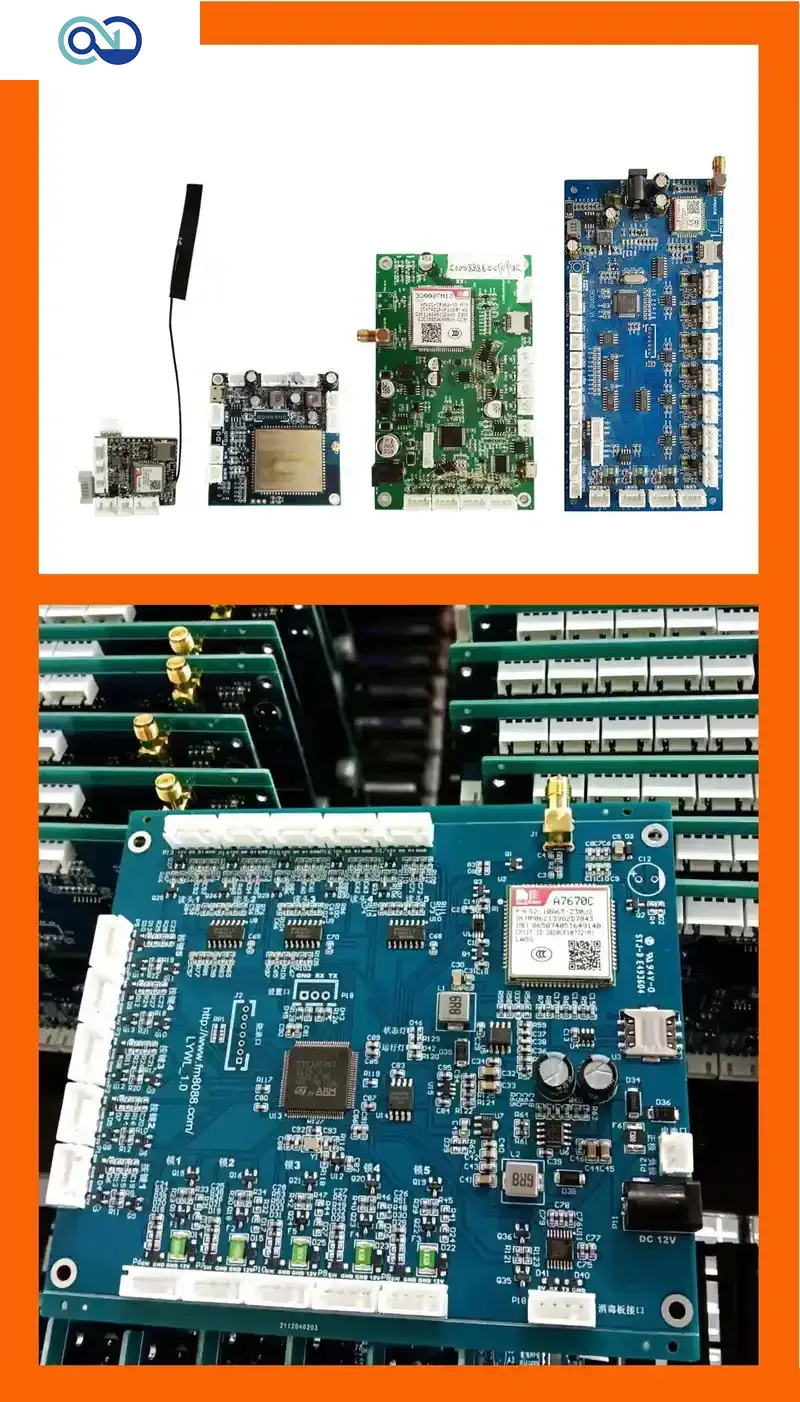

The Pivotal Role of PCBs in IIoT Architecture

Printed Circuit Boards (PCBs) are the backbone of Industrial IoT (IIoT) architecture, serving as the foundational platform upon which all IIoT devices operate. From intricate sensors collecting environmental data to sophisticated control systems managing industrial processes and gateways ensuring seamless data transmission, every element relies on the robust and reliable performance of PCBs.

The demand for high-quality, dependable, and specialized PCBs in IIoT is paramount due to the unique challenges presented by industrial environments. These challenges include:

- Demanding Conditions:

Industrial settings often expose PCBs to extreme temperatures, vibrations, humidity, and corrosive substances. PCBs must be designed and manufactured to withstand these harsh conditions to ensure continuous and reliable operation. - Continuous Operation:

IIoT devices are frequently required to operate 24/7, making PCB reliability critical for uninterrupted data collection, process control, and overall system functionality. Downtime due to PCB failure can lead to significant financial losses and operational disruptions. - Miniaturization:

Many IIoT applications require compact and lightweight devices. PCBs must be designed to minimize size and weight while maintaining high performance and reliability. - Wireless Communication:

Wireless communication is essential for many IIoT deployments. PCBs must be designed to support wireless communication protocols such as Wi-Fi, Bluetooth, Zigbee, and LoRaWAN. - Data Security:

IIoT devices often handle sensitive data. PCBs must be designed with security in mind to protect against unauthorized access and data breaches.

Therefore, selecting the right PCB manufacturer with expertise in IIoT applications is crucial for ensuring the success of any industrial smart IoT project.

Zero One Solution Limited's Expertise in IIoT PCB Prototyping

Zero One Solution Limited excels in rapid PCB prototyping and design tailored for Industrial IoT (IIoT) applications. Our expertise allows clients to quickly iterate and validate designs for complex industrial sensors, actuators, and communication modules, significantly accelerating their product development cycles. We provide the agility and technical proficiency needed to transform innovative IIoT concepts into tangible prototypes ready for deployment.

- Rapid Turnaround Times

We offer expedited PCB prototyping services, enabling quick design iterations and faster time-to-market for IIoT devices. Our streamlined processes ensure that clients receive prototypes in the shortest possible time, without compromising quality. - Design for Manufacturability (DFM) Expertise

Our team provides comprehensive DFM analysis to optimize PCB designs for efficient manufacturing. This proactive approach minimizes potential issues during mass production, reducing costs and improving overall product reliability. - Advanced Technology and Materials

We leverage cutting-edge PCB technologies and a wide range of materials to meet the demanding requirements of IIoT applications. This includes high-frequency materials for wireless communication modules and robust substrates for harsh industrial environments. - Comprehensive Testing and Validation

Zero One Solution employs rigorous testing protocols to ensure the performance and reliability of IIoT PCB prototypes. Our testing capabilities include functional testing, environmental testing, and signal integrity analysis, providing clients with confidence in their designs. - Customized Solutions

We understand that every IIoT application is unique. We offer customized PCB prototyping solutions tailored to specific requirements, whether it's miniaturized boards for compact sensors or high-power PCBs for industrial automation systems. - Expert Consultation and Support

Our experienced engineers provide expert consultation and support throughout the prototyping process. We work closely with clients to understand their needs and offer guidance on design optimization, material selection, and manufacturing considerations.

Custom PCB Solutions for Diverse Industrial IoT Needs

Zero One Solution Limited excels in delivering custom PCB solutions meticulously tailored for the varied demands of Industrial IoT (IIoT) applications. Recognizing that IIoT encompasses a broad spectrum of environments and functionalities, we provide specialized PCB manufacturing and assembly services that cater to everything from rugged PCBs designed for harsh conditions to miniaturized boards for compact smart sensors, and high-frequency PCBs essential for industrial wireless communication solutions. Our expertise ensures that every PCB solution aligns perfectly with the unique operational requirements of each IIoT deployment.

- Robust PCBs for Harsh Environments

We design and manufacture PCBs capable of withstanding extreme temperatures, humidity, vibration, and chemical exposure, ensuring reliable operation in challenging industrial settings. These PCBs utilize specialized materials and coatings to protect against corrosion and degradation, extending the lifespan of IIoT devices deployed in demanding environments. - Miniaturized Boards for Compact Smart Sensors

Our miniaturization capabilities allow for the creation of ultra-compact PCBs ideal for integration into small form-factor smart sensors. These boards maximize space efficiency without compromising performance, enabling the deployment of sophisticated sensing capabilities in space-constrained applications. - High-Frequency PCBs for Industrial Wireless Communication Solutions

Zero One Solution provides high-frequency PCB solutions optimized for wireless communication protocols used in industrial settings, such as Wi-Fi, Bluetooth, and Zigbee. These PCBs minimize signal loss and ensure reliable data transmission, supporting seamless connectivity across the IIoT network. - Material Selection and Optimization

We offer a wide range of PCB materials, including FR-4, Rogers, and metal core PCBs, and provide expert guidance on material selection to meet specific performance and environmental requirements. Our optimization process ensures that the chosen materials enhance signal integrity, thermal management, and overall reliability. - Advanced Manufacturing Techniques

Our state-of-the-art manufacturing facilities utilize advanced techniques such as laser direct structuring (LDS), microvia technology, and fine-line etching to create complex PCB designs with high precision. These techniques enable us to produce PCBs with increased functionality and improved performance. - Testing and Validation

We conduct rigorous testing and validation procedures to ensure that our custom PCB solutions meet the highest standards of quality and reliability. Our testing capabilities include electrical testing, impedance testing, thermal cycling, and environmental stress screening, providing assurance that our PCBs will perform flawlessly in demanding IIoT applications.

Ensuring Reliability and Performance in Industrial IoT Devices

In the realm of Industrial Smart IoT (IIoT), reliability and performance are not just desirable traits; they are fundamental necessities. Zero One Solution Limited recognizes this critical demand, employing stringent quality control measures and advanced testing protocols to guarantee the durability, dependability, and optimal functionality of PCBs integrated into industrial smart IoT devices. These measures are particularly vital for mission-critical applications and predictive maintenance solutions, where failure is not an option.

- What quality control measures does Zero One Solution Limited employ to ensure PCB reliability in IIoT devices?

Zero One Solution Limited implements rigorous quality control measures throughout the PCB manufacturing process, including automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT). These measures ensure that each PCB meets stringent quality standards and performs reliably in demanding industrial environments. We also maintain strict adherence to industry standards such as IPC-A-600 to guarantee the highest levels of quality and reliability. - What advanced testing protocols are used to assess the performance of PCBs in industrial IoT applications?

We employ a suite of advanced testing protocols to evaluate PCB performance under various conditions. These include thermal cycling tests, vibration tests, and humidity tests, which simulate the harsh environments encountered in industrial settings. Additionally, we conduct functional testing to verify that the PCB operates as designed and meets the specific requirements of the IoT application. These protocols help us identify and address potential issues early in the production process, ensuring that our PCBs deliver optimal performance and longevity. - How does Zero One Solution Limited address the challenges of PCB durability in harsh industrial environments?

To ensure PCB durability in harsh industrial environments, Zero One Solution Limited utilizes high-quality materials and advanced manufacturing techniques. We offer conformal coating services to protect PCBs from moisture, dust, and chemicals, and we can also incorporate ruggedized components to enhance resistance to shock and vibration. Additionally, we carefully design PCBs to minimize thermal stress and optimize heat dissipation, further improving their durability and reliability in demanding conditions. Before mass production, we also use HALT (Highly Accelerated Life Testing) to determine potential weak points of the PCB. - Can Zero One Solution Limited provide PCBs suitable for predictive maintenance solutions in IIoT?

Yes, Zero One Solution Limited specializes in providing custom PCB solutions tailored for predictive maintenance applications within IIoT systems. Our PCBs are designed to support the integration of sensors and monitoring devices that collect real-time data on equipment performance. By leveraging our expertise in PCB design and manufacturing, we enable our clients to develop robust and reliable predictive maintenance solutions that minimize downtime and optimize operational efficiency. Furthermore, we offer high TG (Transition Glass) materials, ensuring PCBs can withstand high temperatures. - How does Zero One Solution Limited ensure the optimal performance of PCBs in mission-critical IIoT applications?

Zero One Solution Limited understands the critical importance of optimal PCB performance in mission-critical IIoT applications. To ensure this, we employ a comprehensive approach that includes rigorous design validation, advanced simulation techniques, and thorough testing. We work closely with our clients to understand their specific requirements and tailor our PCB solutions to meet their exact needs. Our commitment to quality and performance ensures that our PCBs deliver the reliability and accuracy required for mission-critical operations. To add on this, we can provide impedance control for signal integrity, which is very important for mission-critical applications. - What certifications does Zero One Solution Limited hold to demonstrate its commitment to quality and reliability in PCB manufacturing?

Zero One Solution Limited holds several key certifications that demonstrate our commitment to quality and reliability in PCB manufacturing. These include ISO 9001:2015, which certifies our quality management system, and UL certification, which ensures that our PCBs meet stringent safety standards. These certifications provide our clients with the assurance that our products are manufactured to the highest levels of quality and reliability. We are also RoHS (Restriction of Hazardous Substances) compliant, demonstrating our commitment to environmental responsibility.

Seamless Integration: From PCB to Full IIoT System

Zero One Solution Limited offers a comprehensive, one-stop service model that streamlines the journey from initial PCB design to final manufacturing and assembly, ensuring seamless integration into complete Industrial Smart IoT (IIoT) systems. This integrated approach simplifies complex industrial automation projects by providing a cohesive solution that minimizes compatibility issues and accelerates deployment.

Our holistic service covers every stage of the PCB lifecycle, ensuring a smooth transition from design to implementation within larger IIoT ecosystems. This comprehensive support is crucial for clients aiming to deploy sophisticated industrial automation solutions efficiently.

- Design for Integration

We start with a design philosophy focused on seamless integration. Our PCB designs are created not just for functionality, but also for their ability to work effortlessly with other components in your IIoT system. This involves careful consideration of signal integrity, power distribution, and thermal management to ensure compatibility and optimal performance. - Rapid Prototyping and Validation

Our rapid prototyping services allow for quick iteration and validation of PCB designs within the intended IIoT environment. This early-stage testing helps identify and resolve potential integration issues before full-scale production, saving time and resources. - Manufacturing and Assembly Expertise

Zero One Solution’s expertise in PCB manufacturing and assembly ensures that the final product meets the highest standards of quality and reliability. Our advanced manufacturing processes and stringent quality control measures guarantee that the PCBs will function flawlessly within the demanding conditions of industrial IoT deployments. - Testing and Validation in System Context

Beyond standard PCB testing, we offer system-level testing to validate the performance of the PCB within a complete IIoT system. This includes simulating real-world operating conditions and testing the PCB’s interaction with other devices and software to ensure seamless integration and optimal performance. - Supply Chain Management

Our strategic positioning within the global PCBA supply chain network allows us to efficiently manage component sourcing and logistics, ensuring timely delivery and minimizing potential disruptions to your IIoT project timeline. - Comprehensive Support and Documentation

We provide comprehensive support and documentation throughout the entire process, from initial design consultation to final deployment. Our team of experienced engineers is available to answer your questions and provide guidance, ensuring a smooth and successful integration of our PCB solutions into your IIoT system.

Future Trends in Industrial Smart IoT and Zero One Solution's Vision

The Industrial Smart IoT landscape is rapidly evolving, driven by advancements in artificial intelligence (AI) at the edge, the integration of 5G technology, and the increasing importance of robust cybersecurity measures. Zero One Solution Limited is committed to staying at the forefront of these trends, continuously enhancing its PCB capabilities to meet the demands of future industrial IoT solutions. Our vision is to empower our clients with cutting-edge PCB solutions that enable them to unlock the full potential of IIoT, driving innovation and efficiency across their operations.

Here's a look at some key future trends in Industrial Smart IoT and how Zero One Solution is preparing for them:

- AI at the Edge

The shift towards processing data closer to the source, using edge computing, is crucial for reducing latency and improving real-time decision-making in IIoT. Zero One Solution is developing PCB solutions optimized for edge AI applications, incorporating powerful processors and efficient memory management to support complex algorithms directly on IoT devices. - 5G Integration

The advent of 5G technology promises to revolutionize IIoT by providing ultra-fast, reliable, and low-latency communication. Zero One Solution is designing high-frequency PCBs that support 5G connectivity, enabling seamless data transfer and remote control of industrial equipment. - Enhanced Cybersecurity

As IIoT devices become more interconnected, the risk of cyberattacks increases. Zero One Solution is implementing advanced security measures in its PCB designs, including hardware-based security features and secure boot capabilities, to protect sensitive data and prevent unauthorized access. - Miniaturization and High-Density Interconnects

The demand for smaller, more powerful IIoT devices is driving the need for miniaturized PCBs with high-density interconnects (HDI). Zero One Solution is investing in advanced manufacturing techniques to produce HDI PCBs that meet the stringent size and performance requirements of next-generation IIoT applications. - Predictive Maintenance and Digital Twins

IIoT enables predictive maintenance by collecting data from sensors to anticipate equipment failures. Digital twins, virtual replicas of physical assets, rely on this data for simulation and optimization. Zero One Solution's PCBs support the sensor integration and data transmission required for these advanced applications, contributing to increased uptime and reduced maintenance costs. - Sustainable and Eco-Friendly PCBs

With growing environmental concerns, there's increasing demand for sustainable and eco-friendly PCB manufacturing processes. Zero One Solution is exploring the use of environmentally friendly materials and implementing sustainable manufacturing practices to minimize our environmental footprint.

Zero One Solution Limited is dedicated to continuous innovation and is actively investing in research and development to support these future trends. By partnering with us, you can ensure that your IIoT solutions are equipped with the most advanced and reliable PCB technology, enabling you to stay ahead of the curve in this rapidly evolving industry.

FAQs about Industrial Smart IoT and PCB Solutions

This section addresses frequently asked questions concerning Industrial Smart IoT (IIoT) solutions and the critical role of PCBs in their implementation. It aims to clarify common queries related to the benefits, challenges, and deployment strategies of IIoT, with specific attention to how specialized PCB design and manufacturing contribute to successful project outcomes. Furthermore, it highlights what distinguishes Zero One Solution as a preferred partner in this domain.

- What are the primary benefits of implementing Industrial Smart IoT solutions?

IIoT solutions offer numerous benefits, including enhanced operational efficiency through automation, predictive maintenance to minimize downtime, improved data-driven decision-making, increased safety, and the ability to create new revenue streams through innovative services. These advantages lead to significant cost savings and improved competitiveness. - What are the key challenges in deploying Industrial Smart IoT solutions?

Key challenges include ensuring data security and privacy, integrating legacy systems with new IIoT infrastructure, managing the complexity of interconnected devices, addressing interoperability issues between different vendors, and handling the large volumes of data generated by IIoT devices. Adequate planning and robust cybersecurity measures are essential to overcome these hurdles. - How does specialized PCB design contribute to the success of IIoT deployments?

Specialized PCB design is crucial for optimizing the performance, reliability, and durability of IIoT devices. Custom PCBs can be tailored to meet the specific requirements of industrial environments, such as extreme temperatures, vibration, and humidity. They also enable the integration of advanced features like wireless communication, sensor interfaces, and power management, which are essential for IIoT applications. - What types of PCBs are commonly used in Industrial IoT applications?

Common PCB types include rigid PCBs for general-purpose applications, flexible PCBs for devices requiring bending or folding, high-frequency PCBs for wireless communication modules, and ruggedized PCBs designed to withstand harsh environmental conditions. The choice of PCB depends on the specific requirements of the IIoT device and its operating environment. - What makes Zero One Solution a preferred partner for IIoT PCB solutions?

Zero One Solution stands out due to its expertise in rapid PCB prototyping, custom PCB design and manufacturing, and comprehensive one-stop service model. Our ability to quickly iterate and validate designs, provide tailored solutions for diverse IIoT needs, and ensure the reliability and performance of PCBs in demanding industrial environments makes us a preferred partner for companies seeking to accelerate their IIoT product development cycles. - How does Zero One Solution ensure the reliability and performance of PCBs in harsh industrial environments?

Zero One Solution employs stringent quality control measures and advanced testing protocols to ensure the durability, reliability, and optimal performance of PCBs in industrial smart IoT devices. These include environmental stress testing, thermal cycling, vibration testing, and functional testing to verify that the PCBs can withstand the rigors of harsh industrial environments and meet the required performance specifications. - Can Zero One Solution help with the integration of PCBs into broader IIoT systems?

Yes, Zero One Solution offers a one-stop service model that streamlines the entire process from PCB design to manufacturing and assembly, facilitating seamless integration into broader Industrial Smart IoT systems. Our comprehensive solutions support complex industrial automation projects and ensure that the PCBs function effectively within the larger IIoT ecosystem.

The Industrial Smart IoT revolution is not merely a trend; it's a fundamental shift in how industries operate, driven by interconnected intelligence. Zero One Solution Limited stands at the forefront of this transformation, providing the foundational PCB technology that powers these advanced systems. Our commitment to rapid prototyping, design excellence, and one-stop manufacturing ensures that your IIoT innovations move swiftly from concept to reality, empowering you to unlock new efficiencies, enhance productivity, and secure a competitive edge. Partner with us to build the intelligent, interconnected future of industry. Contact Zero One Solution Limited today to explore how our PCB expertise can bring your Industrial Smart IoT vision to life and propel your business forward.

AnyPCBA

AnyPCBA