JLCPCB 3D Printing: A Comprehensive Guide to Custom Enclosures and Parts

In today's rapid prototyping and manufacturing landscape, 3D printing is transforming how products are developed, with companies like JLCPCB leading the charge with their services. By offering accessible and high-quality 3D printing, JLCPCB is enabling engineers, designers, and hobbyists to bring their visions to life more efficiently than ever before. This guide will delve into the world of JLCPCB 3D printing, showcasing its potential, processes, and practical applications, which is an extension of the same technology used for traditional PCB assembly, allowing for end-to-end product creation.

Understanding JLCPCB's 3D Printing Services

JLCPCB, primarily known for its PCB manufacturing services, extends its capabilities into 3D printing, offering a diverse range of services from rapid prototyping to custom enclosure fabrication. This expansion allows users to realize complete product development cycles—encompassing both electronic circuits and mechanical structures—all from a single source. The service targets a wide audience, including hobbyists, engineers, and businesses seeking cost-effective, high-quality 3D-printed parts and enclosures.

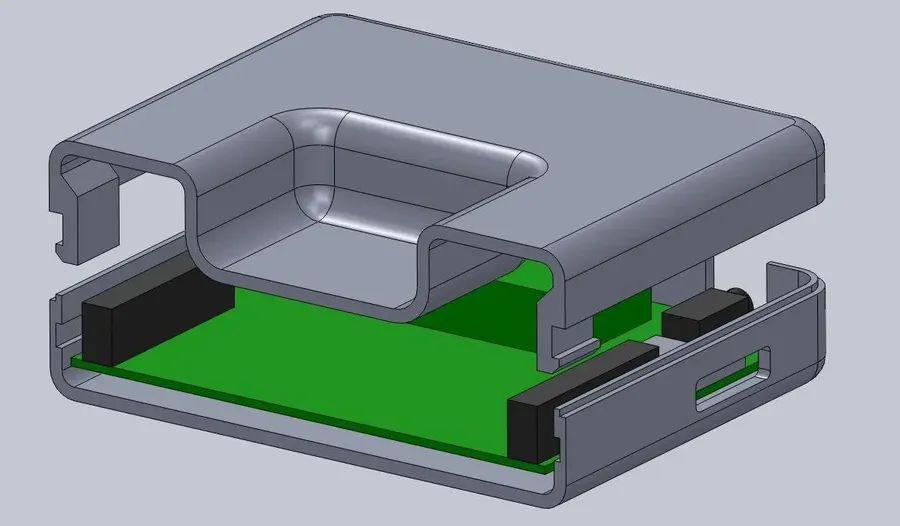

JLCPCB's 3D printing services focus primarily on two main areas: enclosures and custom parts. Enclosures are critical in electronic projects for protection and functionality, while custom parts serve a myriad of applications, from prototypes to bespoke mechanical components. This dual focus makes JLCPCB a versatile service provider in the 3D printing landscape.

Materials and Technologies Offered by JLCPCB

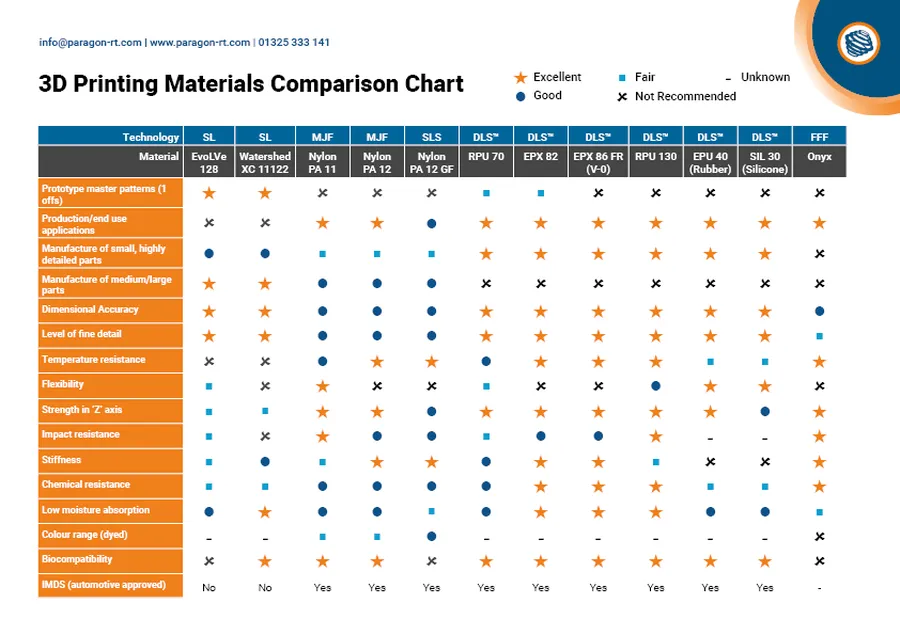

JLCPCB offers a diverse range of materials and advanced 3D printing technologies to cater to varied project requirements, from prototyping to functional parts. The selection includes metals, resins, and plastics, each with unique properties, allowing for the creation of parts with specific mechanical, thermal, and aesthetic characteristics. This is accomplished using various printing techniques that are suitable for each material.

| Material | Technology | Description | Typical Applications | Material Properties |

|---|---|---|---|---|

| Resins | SLA (Stereolithography) | Uses UV light to cure liquid resin, resulting in high-resolution and smooth surface finishes. | High-detail models, prototypes, jewelry molds, dental applications. | Good detail, smooth surfaces, but often brittle, less suitable for mechanical load-bearing. |

| Nylon (PA12) | MJF (Multi Jet Fusion) and SLS (Selective Laser Sintering) | Powder-based process using a fusing agent or laser, respectively. MJF uses a fusing agent and heat and SLS uses laser to sinter the powder particles. | Functional prototypes, mechanical parts, durable enclosures. | Strong, flexible, good chemical resistance. |

| Metals (Stainless Steel) | SLM (Selective Laser Melting) | Uses a high-power laser to melt metal powder, layer by layer, resulting in fully dense metal parts. | Functional prototypes, end-use parts, small batch production | High strength, durable, good heat resistance, requires support structures. |

| ABS (Acrylonitrile Butadiene Styrene) | FDM (Fused Deposition Modeling) | Melts and extrudes thermoplastic filament, layer by layer. | Cost effective prototypes and mechanical components. | Durable, impact resistant and good for functional testing. |

| Polypropylene (PP) | FDM (Fused Deposition Modeling) | Melts and extrudes thermoplastic filament, layer by layer. | Prototypes and consumer goods. | Flexible and chemically resistant. |

| Other Thermoplastics (PC, TPU) | FDM (Fused Deposition Modeling) | Melts and extrudes thermoplastic filament, layer by layer. | Specialty application prototypes. | High-strength, heat-resistant, flexible. |

Designing for JLCPCB 3D Printing

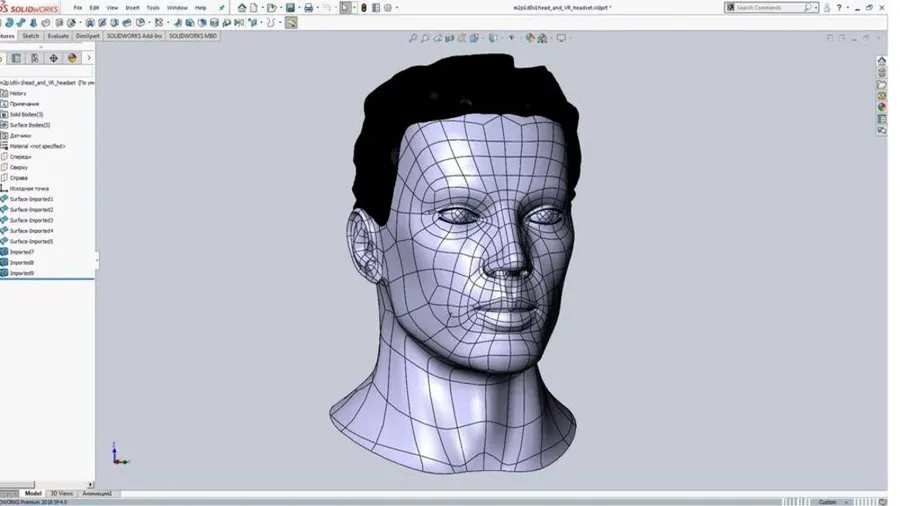

Effective 3D printing with JLCPCB requires careful preparation of your 3D models. This involves selecting appropriate file formats, adhering to specific design considerations, and optionally leveraging JLCPCB's free CAD software, EasyEDA Pro, for a streamlined workflow. Proper design is crucial for achieving the desired structural integrity, dimensional accuracy, and surface finish of your printed parts.

- File Formats

JLCPCB primarily accepts STL and STP/STEP file formats for 3D printing. STL is a standard for 3D printing and represents the surface geometry of a 3D model using a collection of triangles, while STEP is a more robust CAD file format, storing the model's true shape, with associated feature data. Ensure your files are clean with no open edges, self-intersecting surfaces or non-manifold issues. - Design Considerations

Key design parameters to consider are wall thickness (at least 0.8mm for most materials), minimum feature sizes (0.5mm - 1.0mm depending on materials and technologies), and clearances (0.2 - 0.5mm for fitting parts). Overhangs beyond 45 degrees might require support structures that can affect surface finish. Designing parts with appropriate fillets and radii will also enhance the print's structural integrity and improve finish. Avoiding thin protruding features will reduce the likelihood of breakage. - Utilizing EasyEDA Pro

JLCPCB provides EasyEDA Pro, a free online CAD tool which integrates with their 3D printing service. You can design parts or import existing models, then directly order your 3D prints from within the software. This greatly simplifies the process, especially when designing electronics enclosures where printed parts must align with PCBs made through the JLCPCB manufacturing process.

| Design Parameter | Recommended Value | Notes |

|---|---|---|

| Minimum Wall Thickness | 0.8 mm | Varies based on material and application |

| Minimum Feature Size | 0.5 - 1.0 mm | Dependent on material and technology |

| Clearance for Fitting Parts | 0.2 - 0.5 mm | Important for mechanical assemblies |

| Overhang Angle | <= 45 degrees | Avoids need for excess support material |

JLCPCB 3D Printing vs. Other Services

When evaluating 3D printing services, JLCPCB presents a compelling option, particularly when compared to other providers. This analysis focuses on key differentiators such as cost-effectiveness, lead times, and quality, providing a clear understanding of JLCPCB's position in the market.

| Factor | JLCPCB | Typical Competitors | Analysis |

|---|---|---|---|

| Cost | Generally lower, especially for standard materials and volumes. | Often higher, with varied pricing structures. | JLCPCB excels in cost-effectiveness, especially for volume orders and common materials, due to its vertically integrated supply chain. |

| Lead Time | Competitive, with options for expedited services. | Can vary significantly based on provider and technology. | JLCPCB maintains a consistent lead time, often faster than smaller competitors, particularly for standard manufacturing processes. |

| Material Variety | Offers a good selection including standard plastics, resins, and some metals. | May offer a wider selection of specialized materials at a premium cost. | While not offering the widest variety of very niche materials, JLCPCB covers the majority of user needs with its range of common plastics, resins, and certain metals, achieving cost-effectiveness. |

| Quality | Good quality for standard prints, with high precision in certain technologies. | Can vary from provider to provider, with some excelling in certain areas. | JLCPCB provides high quality prints, especially for SLA and MJF technologies, meeting industry standards for precision and surface finish. |

| Design Support and Software | EasyEDA Pro integration; offers some basic design verification. | Design support and integration vary widely. | JLCPCB's tight integration with EasyEDA Pro provides a streamlined design-to-manufacturing process, a unique advantage for users already within this ecosystem. |

| Customer Support | Generally responsive, but support for complex or non-standard scenarios may be limited. | Ranges from excellent to poor based on provider. | While JLCPCB provides good support, users requiring highly specific technical assistance for niche applications might find other service providers more suited to their specific needs. |

Metal 3D Printing with JLCPCB

JLCPCB extends its 3D printing services to include metal options, enabling the creation of robust and functional parts with properties unattainable through plastics or resins. This capability is particularly valuable for applications demanding high strength, heat resistance, or specific electrical characteristics. Their metal 3D printing primarily leverages Selective Laser Melting (SLM) technology, a powder bed fusion process ideal for producing complex geometries with high precision.

| Material | Description | Technology | Typical Applications |

|---|---|---|---|

| Stainless Steel | Offers excellent strength, corrosion resistance, and biocompatibility. | SLM | Functional prototypes, medical devices, and parts for harsh environments. |

The Selective Laser Melting (SLM) process involves using a high-powered laser to selectively melt and fuse fine layers of metal powder. This additive manufacturing method allows for intricate designs and internal structures that would be challenging or impossible to achieve with traditional manufacturing techniques. JLCPCB's expertise in SLM enables the production of strong, durable metal parts with fine details and excellent material properties.

Key advantages of utilizing JLCPCB for metal 3D printing include:

- High Precision and Accuracy:

SLM allows for the creation of parts with high dimensional accuracy and fine features, essential for functional and intricate designs. - Material Properties:

Stainless steel provides excellent mechanical properties such as high tensile strength, heat resistance, and corrosion resistance, suitable for demanding applications. - Complex Geometries:

The additive nature of SLM allows for designs with complex internal structures and intricate details that would be difficult or impossible to produce with conventional methods. - Cost-Effective Prototyping:

JLCPCB’s metal 3D printing service provides a cost-effective route for producing metal prototypes and small batches of functional parts.

Real-World Applications of JLCPCB 3D Printing

JLCPCB's 3D printing service facilitates the creation of diverse functional parts and enclosures, extending beyond simple prototypes to encompass end-use components. This versatility positions it as a valuable tool across various industries and applications.

- Electronics Enclosures

Custom enclosures precisely tailored to house PCBs, sensors, and other electronic components, providing protection and a professional finish. 3D printing allows for intricate designs with necessary mounting points and ventilation. - Prototyping

Rapidly create physical models to validate design concepts, test fit, and assess ergonomics before committing to mass production. This significantly reduces the time and cost associated with traditional prototyping methods. - Custom Mechanical Parts

Produce functional mechanical parts such as gears, brackets, and housings with precise dimensions and material properties, addressing specific project requirements. This eliminates the need for costly tooling and allows for customization. - Robotics Components

Fabricate lightweight and durable parts for robotics projects, such as custom brackets, grippers, and housings, enabling the rapid iteration and personalization of robotic designs. - Architectural Models

Generate detailed architectural models with complex geometries and intricate features for presentations and design reviews. 3D printing allows for realistic scaled representations, enhancing the overall design and communication process. - Educational Aids

Develop custom teaching aids and models for educational purposes, enabling a more interactive and tangible learning experience. This is particularly useful for visualizing complex concepts in science and engineering disciplines. - Consumer Product Parts

Design and produce unique or replacement parts for consumer products, offering a cost-effective solution for minor repairs or customizations, extending the lifespan of existing products.

Frequently Asked Questions About JLCPCB 3D Printing

This section addresses common questions regarding JLCPCB's 3D printing services, providing clear and concise answers to help users understand the process, costs, and capabilities.

- What is the typical cost of 3D printing at JLCPCB?

The cost of 3D printing at JLCPCB varies depending on several factors, including the material selected, the complexity of the design, the volume of the part, and the chosen printing technology. It's essential to upload your design to their platform to get an accurate quote. JLCPCB is generally considered to be a cost-effective option, especially for prototyping and small to medium volume runs when compared with other providers. - What are the typical tolerances achieved with JLCPCB's 3D printing services?

Dimensional tolerances in 3D printing depend on the specific technology and material utilized. JLCPCB provides tolerance guidelines for each available material and method. Generally, SLA and MJF processes provide higher precision with tighter tolerances compared to FDM. It's important to consult the technical specifications before finalizing your design, but standard tolerances can range from 0.1 mm to 0.3 mm, depending on the process and material chosen. - How long does JLCPCB take to process a 3D printing order?

The lead time for 3D printing at JLCPCB depends on the specific process and order volume. Generally, less complex prints in standard materials are completed within a few days, and more complex prints or parts with large volumes or specific materials may take longer. JLCPCB's platform will provide estimated delivery timelines during the quotation phase based on all chosen parameters. Production and shipping times may also be impacted by the service provider's backlog, so checking their site for updates is always recommended. - What file formats are accepted for 3D printing at JLCPCB?

JLCPCB primarily accepts STL, STEP, and STP file formats for 3D printing. These are common formats for 3D models, and their platform will handle the slicing and printing parameters. Ensuring your models are properly prepared and watertight before submitting will help minimize any issues. - What post-processing options are available for JLCPCB 3D printed parts?

JLCPCB provides limited post-processing services such as surface finishing, painting, or specialized treatments. These options vary based on the material and the process chosen for production. The details can be found by consulting the JLCPCB ordering system during the quote phase. It is important to note that post-processing options may add to the total cost and lead time of the project. - What are the shipping options and costs when ordering from JLCPCB?

JLCPCB offers various shipping options, including standard and express delivery, with corresponding costs varying by the location and speed of delivery. You can select the option that best fits your needs when placing your order. It is worth noting that the delivery time, and sometimes the total shipping costs, will be influenced by the part size and the delivery location. It is recommended to review their website for a current estimate of transit time and costs based on the specific order details. - Can JLCPCB handle large volume 3D printing orders?

JLCPCB is equipped to manage both small and large volume 3D printing orders. While they excel at small to medium quantity production runs, they also have the capacity to accommodate larger orders. It is recommended to submit your specific order requirements to their site and request a quotation to determine the feasibility and lead time associated with higher volume production runs.

Tips for Getting the Best Results with JLCPCB 3D Printing

Optimizing your designs and material choices is crucial for achieving high-quality 3D printed parts from JLCPCB. This section provides actionable advice to ensure your prints meet your specifications and functional requirements, focusing on design best practices, material selection, and understanding the nuances of the printing process.

- Design for Manufacturability (DFM) Principles

Adhering to DFM principles is crucial for successful 3D printing. Avoid overly complex designs with excessive overhangs or thin walls, which can lead to print failures or structural weaknesses. Ensure minimum wall thicknesses are met based on the chosen printing method and material. - Wall Thickness and Feature Size Considerations

Refer to JLCPCB's material guidelines for minimum wall thickness and feature size specifications. Thin walls are susceptible to deformation or breaking during printing. Small, intricate details might not be accurately reproduced. Adjust design elements to match the capabilities of the chosen technology. - Orientation and Support Structures

Carefully consider the part orientation during printing. Proper orientation can reduce the need for support structures, improve surface finish, and minimize material usage. Analyze the model in your CAD software to determine the optimal printing orientation, taking into account the location of critical features that need dimensional accuracy. - Material Selection Based on Application

Choosing the correct material is paramount. Consider the mechanical and thermal properties of each material and evaluate against the application requirements. For structural parts needing strength, engineering plastics like PA12 or metals might be necessary. For aesthetic parts or prototypes, resins or standard plastics may suffice. Reference the datasheet for each material to make a well informed decision. - Tolerances and Fit

Factor in tolerances for mating parts. 3D printed parts might have dimensional variations based on the printing process and material. Ensure parts that fit together have appropriate clearances to accommodate the variations, this is particularly important for mechanical assemblies that require precision. Consult JLCPCB's tolerance guidelines to create the proper fits. - File Format and Preparation

Save your 3D models in an appropriate file format for 3D printing. STL or STEP files are generally accepted by most printing services. Before submitting your model, double-check that the file has no errors. Check your model's orientation and ensure it’s ready for printing in the right scale - Post-Processing Considerations

Think about any required post-processing steps, such as sanding, painting, or surface finishing. This may influence the material selection. Plan your design with the post-processing in mind.

JLCPCB’s 3D printing services provide a powerful tool for product development, offering a range of materials and technologies to meet diverse needs. By combining PCB assembly and 3D printing, JLCPCB is positioned as a one-stop shop for bringing innovative designs from concept to reality, paving the way for the future of rapid and customized manufacturing. This guide has highlighted the key aspects to consider when leveraging JLCPCB’s services, allowing readers to utilize the service to its full potential and stay ahead in an evolving field.

AnyPCBA

AnyPCBA