Lloyd AC PCB Price Guide: Understanding Costs and Repair Options

The performance of your Lloyd air conditioner hinges significantly on its Printed Circuit Board (PCB), the electronic brain of the system. When issues arise, understanding the 'Lloyd AC PCB price' becomes crucial for repair or replacement decisions. This article navigates through the complexities of PCB costs, repair considerations, and offers valuable insights to keep your AC running efficiently, blending technical details with everyday concerns.

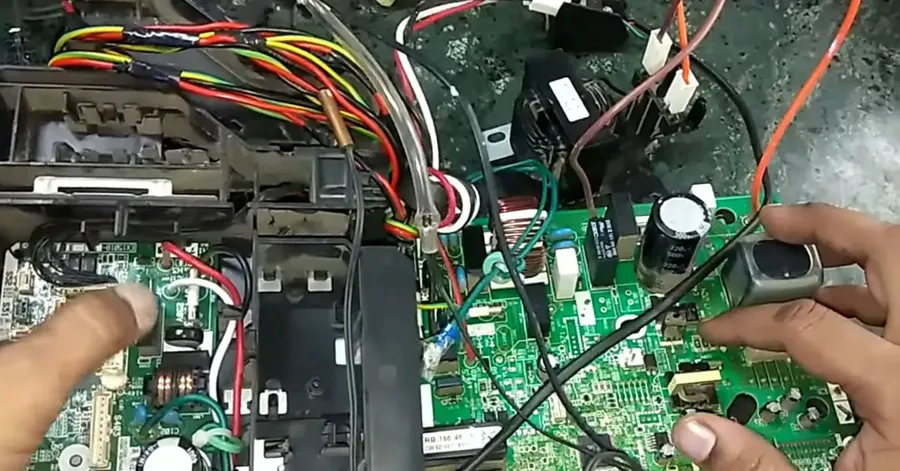

Understanding the Role of the AC PCB

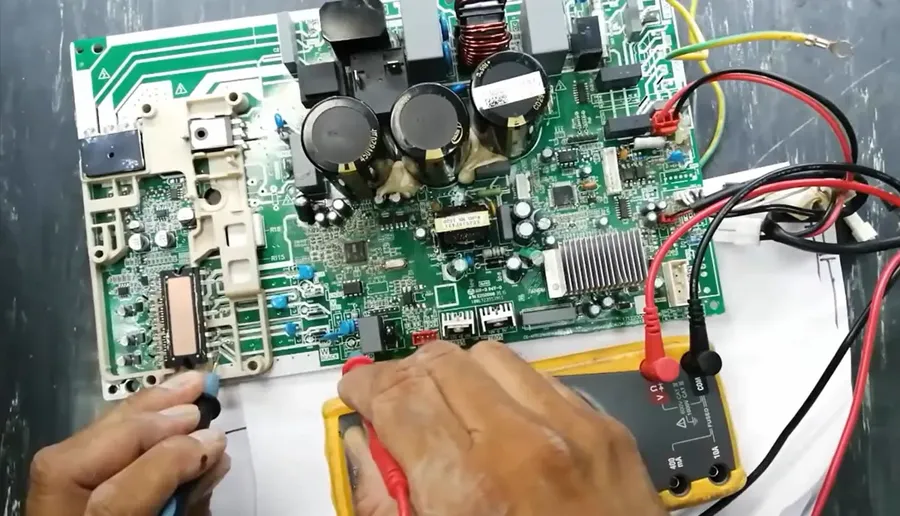

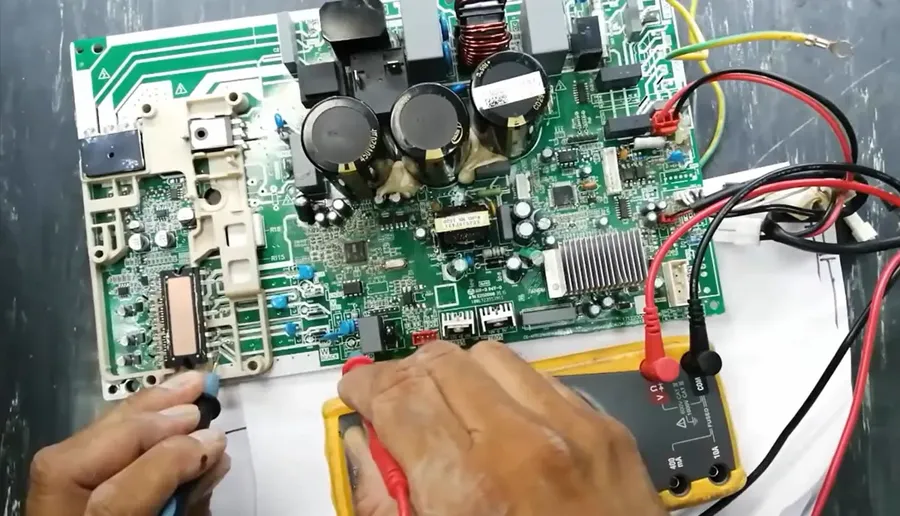

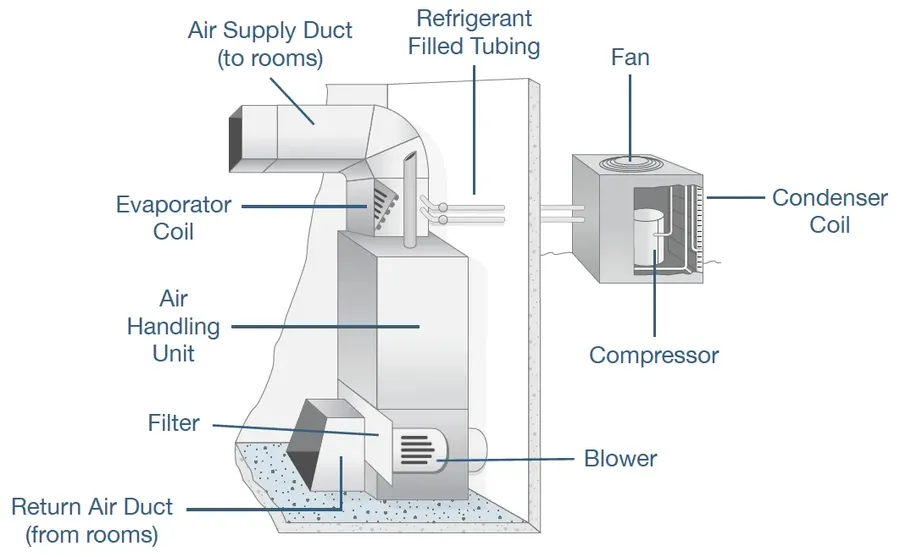

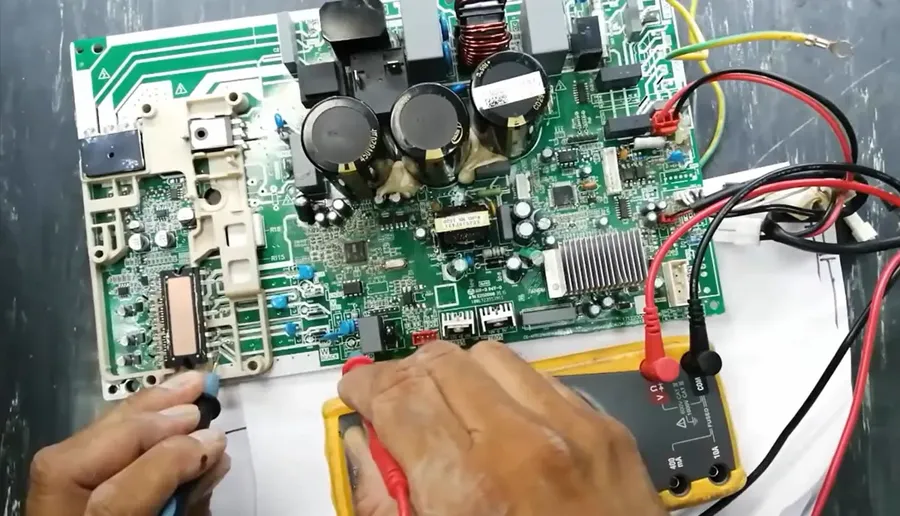

The Printed Circuit Board (PCB) is the central control unit of your Lloyd Air Conditioner, acting as the brain that manages various functions like the compressor, fan, and temperature sensors. Its proper operation is essential for optimal AC performance. A malfunctioning PCB can lead to a variety of issues, significantly impacting the cooling efficiency and overall functionality of your unit.

Consider the PCB as the central nervous system of your AC; any disruption in its function can manifest as a range of problems. Understanding its role is the first step towards efficient AC maintenance and troubleshooting. Here’s a breakdown of key functionalities:

- Compressor Control:

The PCB regulates the compressor's operation, determining when and how intensely it cools, ensuring consistent output. - Fan Speed Regulation:

It controls the fan's speed, adjusting airflow based on the desired cooling settings. - Temperature Monitoring:

The PCB receives signals from temperature sensors, enabling it to adjust cooling output to meet set levels. - System Protection:

It integrates safety mechanisms to prevent damage from overloads or other operational issues.

When the AC PCB fails, symptoms can range from the unit not turning on to intermittent cooling, unusual noises, and a total system shutdown. Inverter ACs, in particular, rely heavily on the PCB for variable speed control and energy efficiency. Due to this, their PCB failures may be more subtle, such as a gradual decrease in cooling efficiency.

Factors Affecting Lloyd AC PCB Price

The price of a Lloyd AC Printed Circuit Board (PCB) is not fixed and varies based on several key determinants. Understanding these factors is crucial for both budget planning and making informed decisions about repair or replacement. This section delves into the specific elements that impact the cost of a Lloyd AC PCB.

- AC Type

The type of air conditioner significantly influences PCB costs. Split AC units typically have more complex PCBs compared to window ACs, and therefore their PCBs tend to be more expensive. - Inverter vs. Non-Inverter Technology

Inverter ACs, known for their energy efficiency and variable speed compressor control, require more sophisticated PCBs. Consequently, inverter AC PCBs are generally pricier than non-inverter models due to increased component complexity. - Model and Year of Manufacture

Older AC models or those with less common configurations may have PCBs that are harder to source, potentially increasing their price. Furthermore, the technological advancements in newer models tend to result in more complex and hence expensive PCBs. - Indoor vs. Outdoor Unit PCB

The PCB location within the AC system affects its cost. Outdoor unit PCBs usually bear the brunt of environmental exposure and require more robust components, often leading to higher prices compared to indoor unit PCBs. - PCB Complexity and Features

The functionality of the PCB significantly impacts its price, PCBs with more sophisticated features and control logic will generally cost more.

| Factor | Impact on PCB Price |

|---|---|

| Split AC vs Window AC | Split AC PCBs generally more expensive |

| Inverter AC vs Non-Inverter AC | Inverter AC PCBs generally more expensive |

| Model and Year | Newer models may have complex PCBs. Older models may be costly due to scarcity. |

| Indoor vs Outdoor PCB | Outdoor PCBs tend to be more expensive |

Average Lloyd AC PCB Prices

Understanding the typical cost of a Lloyd AC PCB is essential for budgeting repairs or replacements. Prices can vary significantly based on several factors, but this section provides a general overview of expected costs for both indoor and outdoor units.

| PCB Type | Typical Price Range (INR) | Notes |

|---|---|---|

| Indoor Unit PCB | ₹1,799 - ₹2,500 | Prices may vary based on model and supplier. |

| Outdoor Unit PCB (Non-Inverter) | ₹3,000 - ₹4,000 | Prices may vary based on model and supplier. |

| Outdoor Unit PCB (Inverter) | ₹4,500 - ₹5,500+ | Inverter PCBs are generally more expensive due to added complexity and functionality. |

It's crucial to recognize that these price ranges are approximate. The actual cost can depend on the specific model and year of your Lloyd AC unit. Prices are also subject to change due to market fluctuations and variations among suppliers.

- Market Fluctuations:

Prices can vary due to supply and demand. - Supplier Pricing:

Different suppliers may offer different prices. - Location:

Geographical location can influence prices.

New vs. Repairing Lloyd AC PCB: Which Option to Choose?

The decision to replace or repair a Lloyd AC PCB hinges primarily on the severity of the damage. While minor component failures like faulty capacitors or resistors can often be rectified through repair at a lower cost, extensive damage affecting the core functionality of the PCB might necessitate a full replacement. A careful evaluation of the damage is crucial to making an economically sound and reliable decision.

| Factor | Repair | Replacement |

|---|---|---|

| Damage Extent | Minor component issues (e.g., capacitors, resistors) | Extensive damage, core component failure, corrosion |

| Cost | Lower initial cost, but labor costs apply. | Higher upfront cost but potentially more reliable long-term. |

| Reliability | Potentially less reliable long-term if other components are aged or stressed. | Higher reliability, assuming the new PCB is genuine and from a reputable source. |

| Time | Faster turnaround time than sourcing and installing a new PCB. | May take longer to source the correct PCB and install it |

| AC Unit Age | More suitable for relatively newer units with readily available components. | More reasonable for older units with extensive damage, where a full replacement will be more reliable for the remaining lifespan of the AC. |

| Warranty | May not come with a warranty, or a limited warranty if the repair is done by a third party. | New PCBs typically come with a manufacturer's warranty. |

When assessing your options, consider not only the immediate costs but also the long-term reliability and potential future issues. A seemingly cheaper repair might lead to more problems down the line, especially if other parts of the PCB are already nearing the end of their lifespan.

Key Considerations When Choosing Between Repair and Replacement

- Detailed Damage Assessment:

Thoroughly examine the PCB to determine the extent of the damage. - Cost-Benefit Analysis:

Compare the repair cost with the price of a new PCB. - Long-term Reliability:

Consider the overall lifespan of the AC unit and the potential for future issues. - Availability of Parts:

Determine if genuine replacement components are readily available if repair is chosen. - Warranty of Repair:

Check if the repair service provides any warranty.

When is PCB Repair the Right Choice?

Deciding to repair a Lloyd AC PCB instead of replacing it hinges on a careful assessment of the damage and associated costs. Repair is often a viable and economical option when the issue is confined to specific components and the overall condition of the PCB is good.

Here's a detailed breakdown of scenarios where PCB repair is a reasonable course of action:

- Isolated Component Failure

When the problem is traced back to a small number of components such as capacitors, resistors, or diodes, repair is often feasible. Replacing these individual components is typically much less expensive than a full PCB replacement. - PCB Age and Condition

If the PCB is relatively new or not excessively corroded or physically damaged, repair is a more practical option. Older PCBs might have underlying issues or weakened solder joints, making repair less reliable. - Cost-Effectiveness

A key factor is the cost comparison between repair and replacement. If the repair cost, including labor, is significantly lower than the cost of a new PCB, repair should be considered. As a general rule, if the estimated repair cost is less than 50% of the replacement cost it is worth considering a repair. - Availability of Replacement Parts

If the needed replacement parts are readily available and affordable, repair becomes a more attractive choice. If you cannot get the correct replacement part, then replacement will become your only option.

It's critical to have a qualified technician diagnose the issue before making a repair or replacement decision. Attempting a repair by yourself can lead to further damage or make a repair impossible. An expert technician will also have the ability to determine if there is an underlying problem that will cause the PCB to fail again.

To further clarify this, here's a table summarizing the conditions ideal for PCB repair:

| Condition | Repair Suitability |

|---|---|

| Failure of a few discrete components (e.g., capacitors, resistors) | Highly Suitable |

| Relatively new PCB with minimal corrosion or damage | Highly Suitable |

| Repair cost is significantly lower than replacement cost (Less than 50%) | Highly Suitable |

| Availability of needed replacement parts | Highly Suitable |

| Extensive damage to PCB | Not Suitable |

| PCB is old and has pre-existing issues | Not Suitable |

| Repair cost is close to replacement cost | Not Suitable |

The decision to repair should be based on a professional evaluation, a comparison of the cost vs replacement and the feasibility of the repair.

When is PCB Replacement Necessary?

PCB replacement becomes the necessary course of action when the extent of damage to your Lloyd AC's printed circuit board is beyond economical repair or poses a reliability risk. This decision typically involves a cost-benefit analysis, considering the severity of the damage and the long-term viability of the unit.

- Severe Damage

Extensive physical damage, such as cracked boards, burn marks, or significant component damage rendering the PCB unreliable. - Corrosion

Presence of rust or corrosion due to moisture exposure, which can cause intermittent failures and further component degradation. - Multiple Component Failures

When multiple components are failing simultaneously, it indicates a fundamental issue that might be too complex or costly to repair. - High Repair Costs

If the estimated repair cost approaches or exceeds 70% of the price of a new PCB, replacement is often the more logical choice. - Age of the Unit

If the AC unit is old, sourcing original parts for PCB repair becomes difficult, and a replacement is more effective for long term performance. - Core Component Failure

If the microcontroller, processor, or other core components of the PCB are failing, repair becomes significantly more complex, unreliable, and costly.

When considering replacement, it's essential to weigh the cost of a new PCB against the potential for recurring issues with a heavily damaged board. Furthermore, consider the overall age of your AC unit. If it's nearing the end of its expected lifespan, investing in a replacement PCB might not be the most economical option and a new AC unit should be considered. Finally, check on the availability of spare parts as that is also a contributing factor to making the repair or replacement choice.

| Factor | Repair | Replacement |

|---|---|---|

| Damage Extent | Minor, isolated component failure | Severe, widespread damage or corrosion |

| Number of Failing Components | Few or single | Multiple component failures |

| Repair Cost | Significantly less than replacement cost | Approaching or exceeding 70% of replacement cost |

| Long-Term Reliability | Potential for future issues if not resolved completely | Provides a more reliable long-term solution |

| AC Unit Age | If AC unit is not that old | If AC unit is old and sourcing of original parts is difficult |

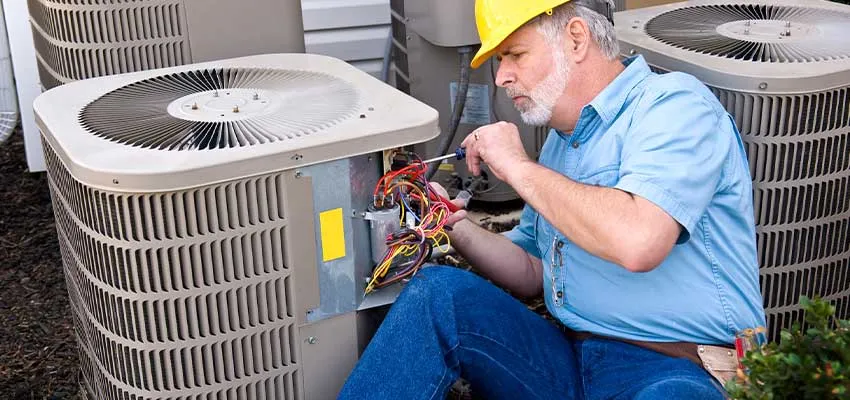

Finding a Reputable Supplier or Repair Service for Your Lloyd AC PCB

Securing a reliable supplier or repair service is paramount when dealing with a faulty Lloyd AC PCB. The integrity of the replacement part or the expertise of the technician directly impacts the longevity and performance of your air conditioning unit. This section emphasizes the critical steps in identifying trustworthy providers to ensure a cost-effective and dependable solution.

When you need a new PCB or a repair service, it is imperative to proceed with due diligence. The market contains both genuine suppliers and less scrupulous ones; therefore, taking a measured approach to selection is critical.

- Check for Genuine Parts

Verify that the supplier offers authentic Lloyd AC PCBs. Counterfeit parts can lead to further malfunctions and reduce your AC's lifespan. Look for packaging that clearly shows the Lloyd brand and part number, and be wary of extremely low prices, which may indicate a fake. - Verify Experience and Credentials

Ensure that the technician or service provider has a proven track record of working with Lloyd AC systems. Look for certifications or affiliations with recognized HVAC organizations. Experienced technicians are more likely to diagnose and fix the issue correctly the first time. - Read Reviews and Seek Recommendations

Before making a decision, read reviews from other customers to gauge the supplier's or technician's reliability and service quality. Ask friends, family, or online forums for recommendations to find reputable providers. Prioritize those with consistently positive feedback. - Verify Online Sellers

When purchasing online, carefully check the authenticity of the seller's profile. Look for secure payment gateways, customer service options and clear return or warranty policies. If possible, contact the seller before purchase to assess their response and professionalism.

| Criteria | Description | Why it Matters |

|---|---|---|

| Authenticity of Parts | Verifying the product as genuine from Lloyd. | Ensures proper performance and longevity of the PCB. |

| Technician Expertise | Credentials and proven experience in AC repair. | Reduces the risk of misdiagnosis and poor repair work. |

| Customer Reviews | Positive feedback from previous clients. | Indicates a history of reliable and satisfactory service. |

| Online Platform Security | Secure payment processing and return policies. | Protects against fraud and ensures a safe transaction. |

While online platforms can provide competitive pricing and convenient purchasing options, it’s important to remain cautious. The potential for counterfeit goods and illegitimate sellers exists and requires rigorous checks for authenticity and seller credibility.

Lloyd AC PCB Frequently Asked Questions: Repair Costs, Lifespan, and Options

This section addresses common queries regarding Lloyd AC PCBs, focusing on repair costs, lifespan, and repair feasibility. Understanding these aspects can help users make informed decisions about maintenance and repairs.

What is the typical AC PCB repair cost?

The cost to repair an AC PCB varies significantly based on the extent of the damage and the specific components needing attention. Minor repairs, such as replacing capacitors or resistors, might range from ₹500 to ₹1500. More complex repairs, or those involving specialized components, could cost between ₹1500 to ₹3000. For a precise estimate, it's recommended to consult a qualified technician after a thorough diagnosis.

How long does an AC PCB usually last?

The lifespan of an AC PCB is influenced by several factors, including the quality of the components, operating conditions, and maintenance practices. Typically, an AC PCB can last anywhere from 5 to 10 years. However, extreme conditions such as voltage fluctuations, excessive moisture, or lack of regular maintenance can significantly shorten its lifespan. Proper care and the use of a voltage stabilizer can help to maximize the lifespan of your AC PCB.

Can an AC PCB be repaired?

Yes, an AC PCB can often be repaired, but the feasibility depends on the nature and extent of the damage. If the issue involves easily replaceable components like capacitors, resistors, or relays, repair is often a viable and cost-effective option. However, if the PCB suffers severe damage, such as burn marks, corrosion, or damage to the microcontroller, replacement might be necessary. It is imperative to consult a professional for a complete diagnosis to ascertain the repairability of your PCB.

Preventive Measures to Extend Lloyd AC PCB Life

Extending the lifespan of your Lloyd AC's PCB (Printed Circuit Board) is achievable through simple preventive measures, minimizing the need for costly repairs or replacements. Proper care focuses on maintaining optimal operating conditions and protecting the sensitive electronic components from external stressors.

- Regular Cleaning

Dust and debris accumulation can lead to overheating and component failure. Regularly clean the AC unit, especially around the PCB area, using a soft brush or vacuum cleaner. - Ensuring Proper Ventilation

Adequate airflow is crucial for heat dissipation. Ensure that the AC unit has enough space around it for proper ventilation, avoiding any obstructions. Do not block vents or the back of the unit. - Voltage Fluctuation Protection

Voltage spikes and fluctuations can severely damage sensitive PCB components. Install a voltage stabilizer to protect the PCB from irregular power supply. - Regular AC Maintenance

Schedule professional AC maintenance at recommended intervals. Certified technicians can identify and rectify minor issues before they escalate into significant problems affecting the PCB. This includes checking for loose connections, component wear, and refrigerant leaks.

| Preventive Measure | Frequency | Purpose |

|---|---|---|

| AC Unit Cleaning | Monthly | Prevent overheating and component failure caused by dust accumulation |

| Ventilation Check | Monthly | Ensure proper airflow for heat dissipation |

| Voltage Stabilizer | Permanent Installation | Protect PCB from voltage spikes and fluctuations |

| Professional Maintenance | Annually | Identify and resolve potential issues before they damage the PCB. |

By consistently implementing these measures, you can significantly prolong the life of your Lloyd AC PCB, reducing the likelihood of unexpected breakdowns and ensuring the continued efficient operation of your air conditioning system. Furthermore, consider the environmental conditions where your AC is located. High humidity can increase the risk of corrosion, therefore, consider dehumidifying or using anti-corrosion products where appropriate.

Understanding the nuances of 'Lloyd AC PCB price' and maintenance is essential for keeping your air conditioner functioning efficiently. Whether you choose to repair or replace the PCB, informed decision-making, combined with professional service, can save both money and hassle. By being proactive about care and understanding the factors influencing cost, you can ensure reliable cooling while optimizing the life of your AC system. Remember that professional advice is key for accurate diagnosis and appropriate action related to your Lloyd AC PCB, and that cost fluctuates depending on market conditions and vendor markups.

AnyPCBA

AnyPCBA