Mastering Perfboard: A Comprehensive Guide for Electronics Prototyping

In the realm of electronics prototyping, perfboard, also known as a prototyping board or dot PCB, serves as a versatile canvas for bringing your circuits to life. Unlike the predefined connections of breadboards or stripboards, perfboard offers the freedom to create custom layouts, paving the way for a wide array of DIY projects and intricate designs. This guide dives into the world of perfboard, from understanding its basic structure to mastering advanced techniques, providing a detailed roadmap to navigate and utilize perfboard effectively.

Understanding Perfboard Basics

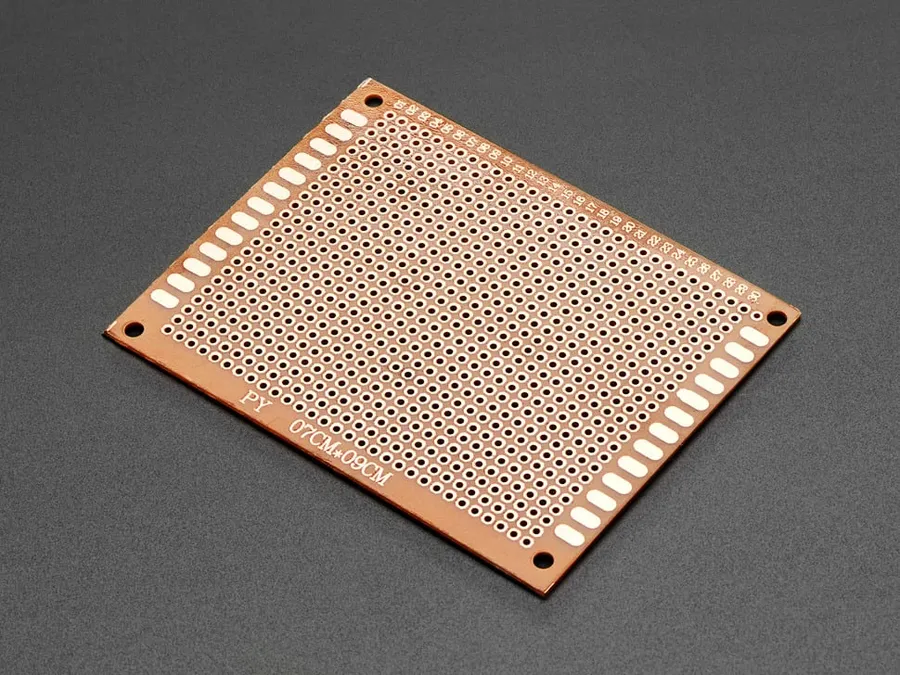

Perfboard, also known as prototyping board, is a fundamental building block in electronics prototyping, characterized by its grid of holes and lack of pre-defined conductive pathways, offering a flexible platform for constructing circuits. Unlike breadboards, perfboard requires permanent connections, typically achieved through soldering.

Perfboard's structure is simple yet versatile, primarily consisting of a substrate, typically made from materials like phenolic, fiberglass, or bakelite. These materials are chosen for their electrical insulating properties and mechanical strength. The surface is uniformly punctuated with a matrix of holes, usually spaced 0.1 inches (2.54 mm) apart to accommodate standard electronic components. These holes lack internal electrical connections, allowing designers to create custom circuits by connecting components with solder and wire.

Variations in perfboard cater to diverse project needs. Hole diameters are generally standardized, but board sizes range from small, hand-held pieces to large panels for extensive projects. Pad styles vary from simple through-holes to pads with surrounding copper rings (also called plated through-holes or PTH), facilitating improved solder adhesion and joint strength, whilst minimizing the risk of pad lifting.

| Characteristic | Description |

|---|---|

| Material Composition | Typically phenolic, fiberglass, or bakelite. |

| Hole Grid | Uniform matrix of holes, usually spaced 0.1 inch (2.54mm) apart. |

| Electrical Connections | No pre-defined connections; custom connections created by soldering. |

| Hole Size | Standardized diameter (approximately 0.04 inch or 1mm), to fit typical component leads. |

| Board Size | Available in various sizes, from small to large panels. |

| Pad Styles | Options include basic through-holes or plated through-holes (PTH) with surrounding copper rings. |

Breadboards and perfboards serve distinct purposes in electronics prototyping, with breadboards offering temporary, solderless connections ideal for rapid circuit testing, while perfboards provide a more permanent and flexible solution using soldering for more robust builds. This fundamental difference in connection methods dictates their appropriate use cases.

| Feature | Breadboard | Perfboard |

|---|---|---|

| Connection Type | Solderless | Soldered |

| Permanence | Temporary | Permanent |

| Flexibility | Limited to predefined rows and columns | Highly flexible in component placement and wiring |

| Ease of Modification | Easy to change and modify | Requires desoldering for changes |

| Durability | Suitable for temporary tests, less durable for long term usage | Durable for long term builds and better for rugged applications |

| Best Use Case | Quick testing and prototyping of basic circuits | More complex and robust builds, projects needing a permanent assembly |

Perfboard vs. Breadboard vs. Stripboard: Choosing the Right Tool

Selecting the appropriate prototyping platform—perfboard, breadboard, or stripboard—is crucial for efficient electronics development. Each offers unique characteristics that suit different project requirements. This section provides a detailed comparison to help you make informed choices.

| Feature | Perfboard | Breadboard | Stripboard |

|---|---|---|---|

| Connection Method | Soldered | Solderless | Soldered (typically) |

| Connection Structure | Isolated Holes | Internal Connected Rows & Columns | Parallel Tracks of Holes |

| Permanence | Permanent | Temporary | Semi-permanent |

| Flexibility | High (flexible layout) | Low (fixed layout) | Moderate (limited track layout) |

| Ease of Use | Moderate (requires soldering) | High (quick and easy) | Moderate (requires track cutting) |

| Complexity Handling | Handles complex circuits well with careful planning. | Limited to simpler circuits, can become difficult with complex wiring | Suited for medium-complexity circuits, requires planning |

| Best for | Permanent prototypes, custom layouts. | Quick testing, temporary circuits. | Medium-complexity circuits that require some permanence. |

Perfboard vs. Breadboard

Breadboards excel in providing a solderless environment for rapid prototyping and testing. Their internal, interconnected rows and columns allow for easy component insertion and circuit construction. Conversely, perfboards utilize a grid of isolated holes, which require soldering to create electrical connections. This makes perfboard a more permanent solution compared to the breadboard's temporary nature. Breadboards are ideal for initial circuit exploration and quick modifications, while perfboards are better suited for building more robust, enduring prototypes.

Perfboard vs. Stripboard

Stripboards feature pre-connected tracks of holes, which facilitates rapid prototyping and is suitable for circuits that follow a more linear design. These tracks can be easily cut, providing moderate flexibility, but are not as free-form as perfboard. Perfboards, with their isolated holes, demand point-to-point wiring or the use of jumpers to make connections between components. Perfboard offers maximum layout flexibility, where component placement is not dictated by existing tracks. Stripboards are better suited for circuits that align with their track structure, while perfboards are optimal for custom layouts and more complex connections, especially when point-to-point wiring is used effectively.

Perfboard and stripboard represent distinct approaches to prototyping electronics, primarily differing in their connection methods. While perfboard provides isolated holes requiring manual wiring for each connection, stripboard features pre-etched copper tracks, creating connected rows of holes. Understanding these differences is crucial for choosing the right board for your project, as they impact flexibility, ease of assembly, and the overall design of the circuit.

| Feature | Perfboard | Stripboard |

|---|---|---|

| Hole Connectivity | Isolated Holes | Connected Rows/Tracks |

| Wiring | Point-to-point or wire wrapping | Connections along tracks and jumpers |

| Flexibility | Highly flexible in routing | Less flexible in routing, requires planning |

| Ease of Use | More time consuming, requires planning and wiring | Easier for basic circuits, faster assembly |

| Best for | Complex or custom layouts | Simpler circuits with linear layouts |

| Component Placement | Can place components anywhere | Restricted to track layout |

Stripboard excels in situations where components can be easily aligned along the tracks. This is particularly useful for basic circuits or when a linear layout is suitable. However, the pre-defined tracks of stripboard can also limit flexibility and may require additional cutting of tracks to break connections and more planning to ensure no unintended shorts occur. Perfboard, with its isolated holes, allows for more intricate, free-form layouts, making it the preferred option for complex circuits with more customized connections. However this requires more point to point wiring which can be more time consuming and more prone to errors.

Essential Tools and Materials for Perfboard Projects

Successfully building electronics projects on perfboard requires a selection of specialized tools and materials. This section outlines the essential items, focusing on their selection and usage for optimal results, ensuring a beginner-friendly approach while maintaining professional standards.

| Tool/Material | Description | Selection Considerations | Beginner Tips |

|---|---|---|---|

| Soldering Iron | Heats solder to create electrical connections. | Adjustable temperature, fine tip for precision, wattage suitable for electronics (25-40W). | Practice on scrap material, clean the tip regularly, use a stand for safety. |

| Solder | Metal alloy used to join electronic components. | Lead-free solder preferred, 60/40 tin/lead for beginners (note lead content), rosin core for flux. | Use a small amount of solder, avoid creating large blobs, let the solder flow onto the joint. |

| Wire Strippers | Removes insulation from wires without damaging the conductor. | Adjustable gauge settings, comfortable grip, sharp cutting blades. | Match the gauge setting to the wire, gently squeeze to cut, avoid cutting the wire strands. |

| Wire (Solid core) | Connects components, typically 22-26 AWG for perfboard. | Solid core for reliable connections, insulated, various colors for organization. | Use appropriate gauge for current, plan wiring routes to minimize clutter, choose colors that aid circuit tracing. |

| Helping Hands | Provides stability while soldering. | Adjustable arms and clips, sturdy base. | Use to hold the board and components while soldering, position for easy access. |

| Multimeter | Measures voltage, current, and resistance. | Digital display, autoranging, continuity test function. | Learn basic measurement techniques, use to check for shorts and open circuits, verify component values. |

Planning Your Perfboard Layout: Best Practices

Effective perfboard projects hinge on meticulous planning before any soldering begins. A well-thought-out layout significantly reduces the likelihood of errors, simplifies debugging, and ensures a robust final circuit. This section outlines essential best practices for planning your perfboard layout.

- Start with a Schematic Diagram

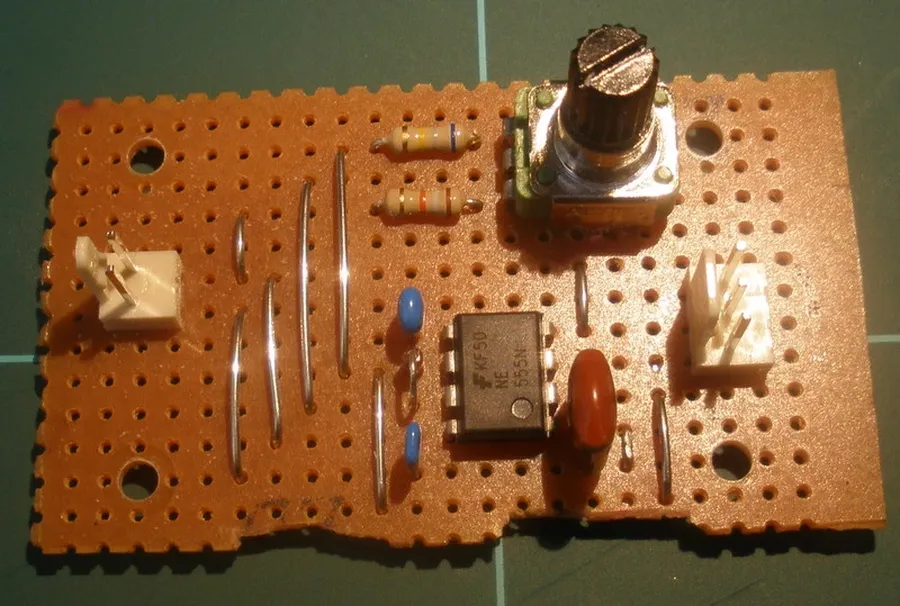

Always begin by creating or referencing a schematic diagram. This diagram serves as your blueprint, detailing all components and their interconnections. It is crucial for translating a theoretical circuit into a physical arrangement on the perfboard. Ensure the schematic is complete and accurate before proceeding. - Strategic Component Placement

Consider the physical dimensions of each component and plan their placement on the perfboard for the most efficient signal flow. Group related components together to minimize wire lengths and avoid signal path crossings. Place larger components first, using them as anchors for smaller components. Prioritize the arrangement of ICs, connectors, and power components, then move on to passives. - Power Distribution Planning

Plan your power rails (VCC and GND) to minimize voltage drops and noise. The power should be accessible and clean, with connections made as short as possible to every part of your board. Ensure that high-current components have dedicated power tracks or wires with sufficient gauge to handle the load. - Minimize Wire Crossings

Carefully arrange components to reduce the need for wires to cross over each other. Wire crossings can lead to difficulties in debugging, potential shorts, and a messy final product. Using a logical layout should minimize this and ensure your project is cleaner and easier to work with. - Maintain Logical Signal Flow

Plan the signal flow to be as logical and intuitive as possible. Follow the flow of the schematic and layout the perfboard so that the signal enters in one area and progresses smoothly through your circuit to the output. This can aid in troubleshooting and makes the circuit easier to comprehend. - Document Your Layout

Keep a record of your component placement, wiring scheme, and any notes about unusual configurations. A photo of the finished layout, or creating a diagram of the board, can be invaluable during later troubleshooting and for creating more iterations of the same project. If you ever need to disassemble it, you will be glad you have good documentation.

Soldering Techniques for Perfboard

Mastering soldering on perfboard is crucial for creating durable and reliable electronic prototypes. This section delves into techniques that ensure strong, electrically sound connections while avoiding common pitfalls.

Effective soldering on perfboard requires precision, proper equipment, and a clear understanding of the process. The following will help you ensure your components and circuits are attached correctly. Key to success are three points, preparation, process and post-soldering checks.

- Preparation: Essential Steps Before Soldering

Cleanliness is crucial, ensure both perfboard and component leads are clean. Pre-tinning component leads with a thin coat of solder can also make the soldering process easier. A suitable soldering iron with a clean tip at the correct temperature, along with appropriate solder is also essential. - Soldering Process: Creating a Reliable Joint

Heat the pad on the perfboard and the component lead simultaneously, and apply the solder, allowing it to flow onto the heated parts. Avoid creating a 'cold solder joint' by ensuring that both the lead and the pad are heated before applying solder. The solder should flow smoothly and form a small, concave 'volcano' shape. - Post-Soldering Checks: Ensuring Joint Quality

Inspect every solder joint visually. The solder should appear shiny, not dull. Check for solder bridges, where solder unintentionally connects two separate pads. Also check for insufficient solder or dry joints that look dull or granular.

| Technique | Description | Benefit | Common Pitfall |

|---|---|---|---|

| Standard Soldering | Heating the pad and component lead, then applying solder to the heated junction. | Strong and electrically sound joint. | Cold solder joints if not heated properly, solder bridges if too much solder is applied. |

| Drag Soldering | Apply solder to the iron tip, and drag across multiple points. | Faster for multiple connections | Difficult to control solder application and risk of short circuits. |

| Through Hole Soldering | Insert component lead through hole, then solder on the pad | Secure, suitable for larger components. | Risk of overheating the lead or pad and damaging components or the board. |

Specific solder recommendations for perfboard projects typically include lead-based solder with a rosin core (e.g., 60/40 Sn/Pb), as it offers lower melting point, and good conductivity while being easy to work with. Lead-free alternatives, like SnAgCu alloys, are also increasingly common, although their slightly higher melting points may require adjustments in soldering technique. Flux is key, both lead and lead-free solders should include a rosin flux core, this will promote flow and create better joints. Select the gauge or diameter of the solder wire appropriately for perfboard work, 0.8mm or less is usually best for precise applications and reducing solder bridging.

By applying these techniques, you will improve the strength and reliability of your perfboard projects, minimise common soldering errors, and ensure good electrical connections. Regular practice and careful attention to detail are key to becoming proficient at soldering.

Wiring and Connections on Perfboard

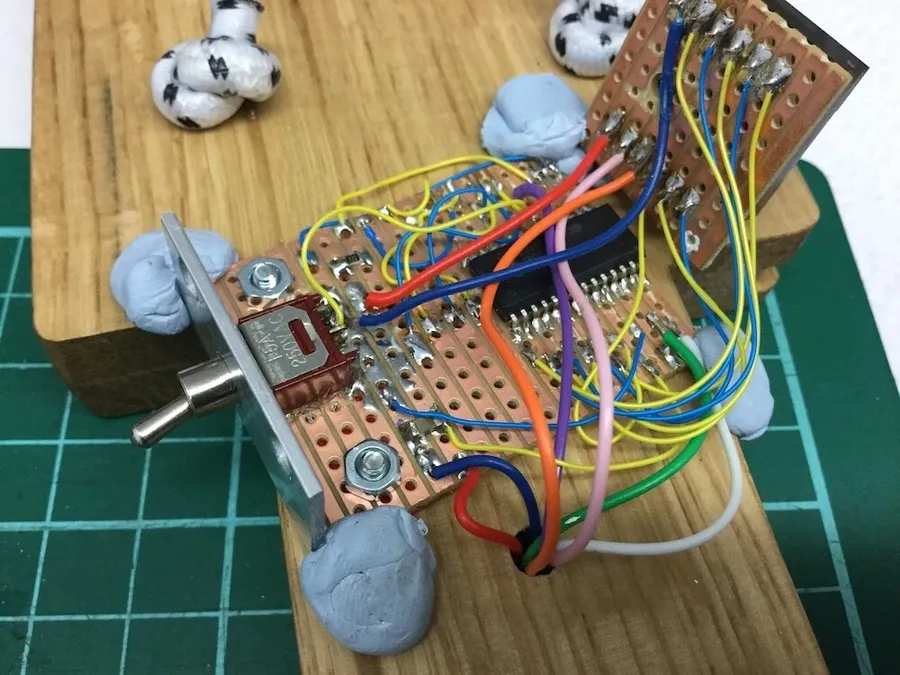

Effective wiring and connection techniques on perfboard are crucial for project functionality, signal integrity, and overall neatness. Proper methods ensure reliable electrical paths and ease of debugging, moving from prototyping to stable circuits. Various methods exist, each with advantages and disadvantages depending on the complexity and requirements of the electronic project.

Here are some of the most common techniques:

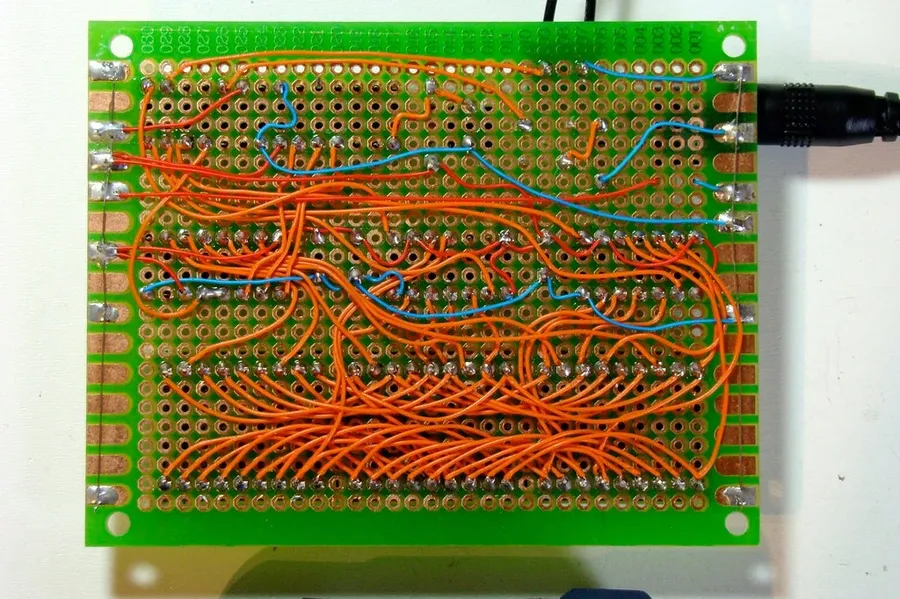

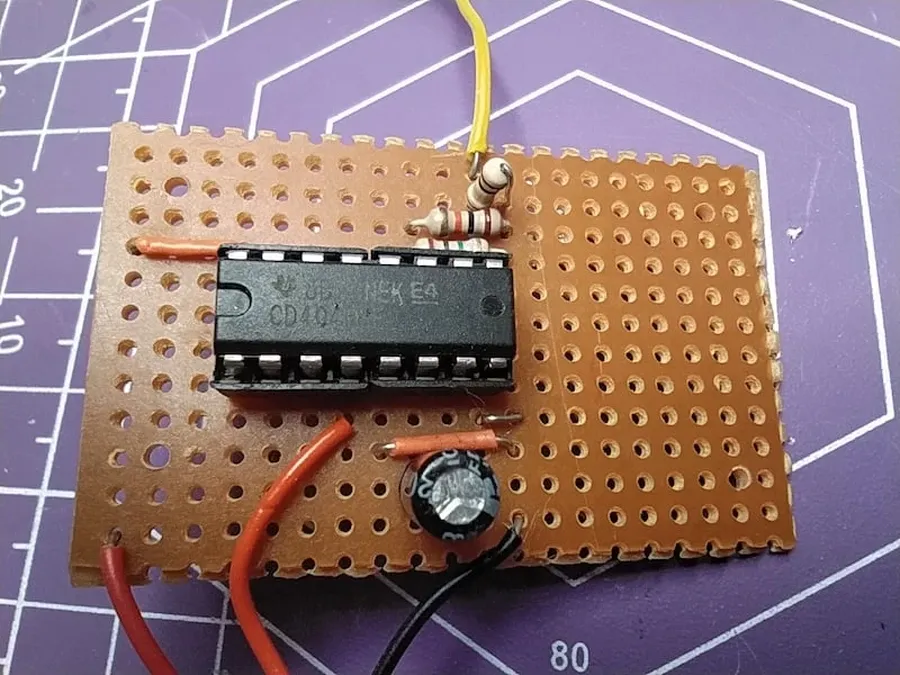

- Point-to-Point Wiring

This is a direct connection method, where wires are soldered directly between component leads or pads. It's ideal for simple circuits with few connections. Careful planning and execution can lead to a robust, albeit visually complex, circuit. The key is to use the shortest wire length possible to minimize signal path, and to make each solder joint secure. - Wire Wrapping

Utilizes a specialized tool to wrap wires tightly around component leads or posts, creating a gas-tight connection. While it eliminates the need for soldering, wire wrapping requires specialized tools and is not as robust in high-vibration environments. It is often used for more modular design and ease of changes during the prototype stage, but is not a recommended connection method for final products. - Using Jumpers

Pre-made or custom-made wires with soldered pins, are used for making connections between various points on the perfboard. Jumpers offer a flexible solution for connecting components that are not directly adjacent. They help facilitate changes and debugging of the circuit.

For managing wiring effectively, consider these best practices:

- Plan Your Wire Paths

Before soldering, visualize or sketch your wiring paths to minimize crossing wires and prevent shorts. This also aids in troubleshooting. - Use Different Colors of Wire

Using color-coded wires helps to visually distinguish between power, ground, and signal lines, and to avoid errors, especially in complex projects. This can significantly speed up the debugging process. - Secure Wires Properly

Secure wires with solder, wire wraps, or glue as appropriate to prevent accidental disconnections and improve the overall mechanical stability of the circuit. - Maintain Signal Integrity

Keep signal wires away from power and ground wires to avoid interference. Short wire lengths help in reducing signal distortion. This is important for more sensitive circuits, such as audio or high-frequency applications. - Keep Wires Neat

Neat wiring makes debugging and modifications easier, and using cable ties can help to achieve this. However, it's important to not over-tighten ties on fragile components. Proper wiring management is a key component of a professional-looking and functional design.

Frequently Asked Questions About Perfboard

This section addresses common queries regarding perfboard, providing concise answers to help you effectively use this versatile prototyping tool. We cover topics ranging from its basic comparisons with other boards to specific usage questions.

- Is a perfboard the same as a breadboard?

No, they serve different purposes. A breadboard is for temporary, solderless prototyping, allowing quick circuit changes. A perfboard, on the other hand, is used for more permanent circuits where components are soldered onto the board. - Can you cut a perfboard?

Yes, perfboard can be cut. For straight cuts, a score-and-snap method using a utility knife and straight edge is effective. For more complex shapes, tools such as a rotary tool with a cutting disk, or a coping saw can be used, and you will need to be careful to prevent injury. - What is the typical diameter of a perfboard hole?

The standard hole diameter on perfboards is typically 0.040 inches (approximately 1.02mm), designed to accommodate standard through-hole component leads. It is important to consider this size when choosing components and wiring. - What materials are perfboards typically made of?

Perfboards are typically made from phenolic, fiberglass or bakelite. These materials are chosen for their balance of cost, mechanical strength, and electrical insulation properties. The base material can influence the board's durability and soldering capability. For example, FR4 (fiberglass) is generally more robust and better for soldering than phenolic. - Where can I buy perfboard?

Perfboards are widely available from various electronics suppliers, both online and in physical stores. Major distributors like DigiKey, Mouser, and Amazon carry a variety of sizes and types of perfboard. Additionally, many local electronics shops also stock perfboards and related components. Local electronics shops are good sources for immediate small quantity purchases and allow for visual inspection of the product. - How do I choose the correct perfboard size for my project?

The required perfboard size depends on your circuit complexity and the number of components. Start by laying out your components on a piece of paper and noting the space required for your circuit. You should then add a small amount of space around the planned layout for wiring and connection points. For larger projects, consider a modular approach using multiple smaller boards. - What type of solder is best for perfboard?

A good quality 60/40 (tin/lead) or lead-free solder with rosin core is typically recommended for perfboard projects. The rosin core helps with solder flow and ensures good electrical connections. Using a solder with a small diameter (e.g., 0.8 mm) can also improve precision during soldering.

Advanced Perfboard Techniques and Troubleshooting

Mastering perfboard for complex electronics projects requires advanced techniques beyond basic soldering and wiring. This section focuses on multi-layer designs, working with surface-mount components (SMD), systematic troubleshooting, and employing a multimeter effectively. Understanding these methods elevates your perfboard proficiency, enabling robust and reliable circuit construction.

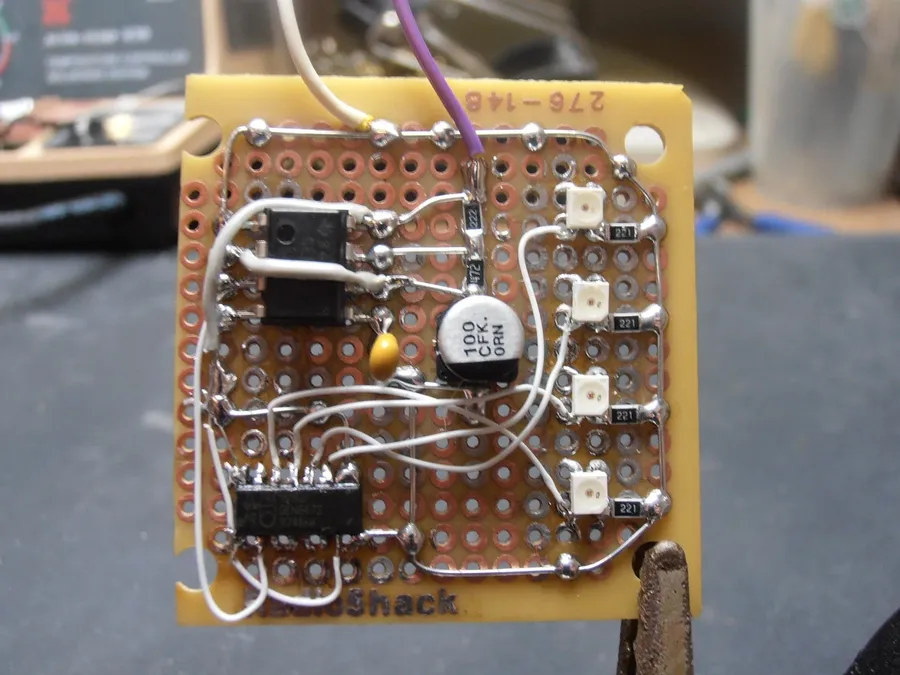

- Multi-Layer Perfboard Projects

Multi-layer perfboard projects involve stacking and interconnecting multiple perfboard layers to create denser circuit designs. This is accomplished with standoff hardware and insulated wires routed between layers and careful design to ensure all circuits are connected. - Surface Mount Components

Integrating surface mount components onto perfboard requires adaptation, because they do not have leads that fit into the holes. Techniques involve using adapter boards or soldering directly to pads. Fine-tipped soldering irons and precision tools are essential. - Troubleshooting Common Issues

Troubleshooting on perfboard involves identifying shorts, open circuits, and component failures. Careful visual inspection, using a multimeter to test connections, and a systematic approach to diagnosis are essential. Short circuits are often the result of solder bridges. Open circuits may be the result of a poor solder joint, a broken wire, or a component failure. Checking the schematic and testing individual connections is crucial. - Multimeter for Debugging

A multimeter is indispensable for perfboard debugging. Utilize it to measure voltage, current, and resistance to pinpoint faults and verify proper circuit operation. A multimeter is used to trace paths to diagnose connectivity, voltage, and current issues in a circuit. Continuity testing helps identify breaks in the circuit, and voltage and current measurements ensure circuit operation matches the design.

By adopting these advanced techniques and employing thorough troubleshooting methods, you will be able to effectively build robust and complex circuits on perfboard. These skills are essential to advance from beginner projects to more complicated designs.

Perfboard stands as an essential tool in the electronics enthusiast's arsenal, providing the flexibility for creating custom circuits while bridging the gap between temporary prototypes and permanent builds. Whether you are a beginner experimenting with basic circuits or an experienced maker tackling complex projects, understanding the nuances of perfboard is key to taking your designs to the next level. The tips and techniques discussed in this comprehensive guide, from proper planning and soldering to advanced layout methods, ensure that you can confidently start, and debug your perfboard projects with efficiency. As you continue to learn and refine your skills, perfboard will transform from a simple prototyping tool into a powerful instrument for your electronic innovations and beyond.

AnyPCBA

AnyPCBA