NextPCB: Your One-Stop Solution for PCB Prototyping and Manufacturing

In today's rapidly evolving tech landscape, the demand for high-quality printed circuit boards (PCBs) is ever-increasing. Whether you're an individual maker or a large corporation, finding a reliable PCB manufacturer is crucial. NextPCB emerges as a one-stop solution, offering PCB prototyping, fabrication, and assembly services. This article will explore the capabilities and advantages of choosing NextPCB for your electronics projects, bridging the gap between ideas and physical reality.

Overview of NextPCB Services

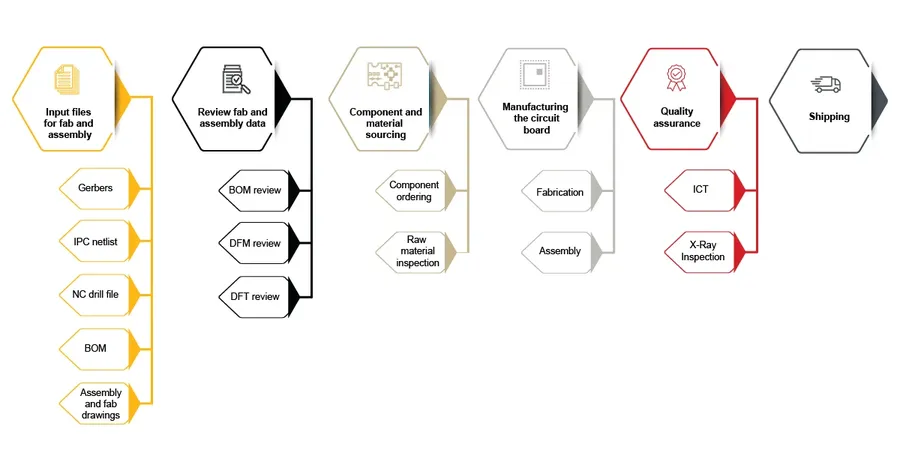

NextPCB stands as a comprehensive solution provider in the realm of printed circuit boards (PCBs), offering a diverse suite of services that span from initial prototyping to full-scale manufacturing and assembly. Their vertically integrated approach ensures a seamless experience for clients, whether they require a single prototype or large production volumes. The core services include PCB fabrication, surface mount technology (SMT) assembly, and component procurement.

- PCB Prototyping

Rapid and cost-effective prototyping services to validate designs and optimize performance before mass production. - PCB Manufacturing

High-precision fabrication of PCBs, including multilayer, flexible, and rigid-flex options. - PCB Assembly

Turnkey assembly services encompassing component sourcing, SMT, and through-hole assembly, simplifying the production process. - Component Sourcing

Providing access to a broad range of electronic components, ensuring the availability of needed parts.

PCB Prototyping at NextPCB

Rapid PCB prototyping is a critical step in the electronic product development cycle, allowing designers to validate their concepts and iterate quickly. NextPCB offers efficient and cost-effective PCB prototyping services designed to facilitate this process, enabling engineers and designers to thoroughly test their circuit designs before moving to mass production.

The core benefit of using NextPCB for prototyping lies in its ability to significantly reduce time-to-market. By providing quick-turnaround prototypes, NextPCB allows for design optimization and problem-solving early in the development phase. This iterative process helps identify design flaws, improve performance, and prevent costly mistakes in mass production.

- Fast Turnaround Times

NextPCB is geared towards minimizing the time it takes to receive your prototype PCBs, which supports rapid iterations and design enhancements. - Cost-Effective Solutions

Prototypes are available at competitive prices, allowing you to manage your budget effectively during the initial stages of product development. - Design Validation

Prototyping with NextPCB gives you an opportunity to test if the design parameters are met before committing to mass production, thus reducing the risk of costly errors. - Early Problem Detection

By testing prototypes, you can identify and correct any design problems, such as electrical or layout issues, early in the production cycle. - Design Optimization

The process of creating prototypes allows for design adjustments to improve performance, functionality, and manufacturability.

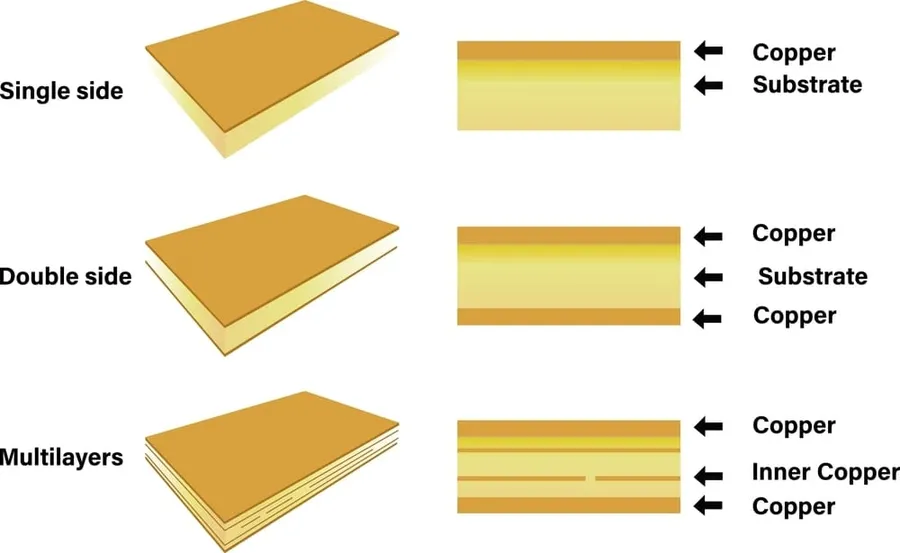

PCB Fabrication Capabilities

NextPCB's fabrication capabilities are designed to meet diverse and demanding PCB requirements, offering a wide range of options including multilayer PCBs, flexible PCBs, and various surface finishes. These capabilities ensure high precision and reliability across all manufactured PCBs, adhering to the highest industry standards.

| Feature | Description | Details |

|---|---|---|

| Multilayer PCBs | Fabrication of PCBs with multiple layers of conductive material. | Offers increased circuit density and complexity, commonly used in advanced electronics. |

| Flexible PCBs | Production of PCBs designed to bend or flex. | Suitable for applications requiring non-rigid circuits and dynamic flexing. |

| Surface Finishes | Variety of finishes applied to the PCB surface. | Includes options like HASL, ENIG, Immersion Tin, and OSP to provide solderability and corrosion protection. |

| Material Options | Support for different PCB materials. | Covers standard FR-4, high-frequency materials, and other specialized substrates. |

| Precision Manufacturing | Advanced manufacturing process. | Maintains tight tolerances to ensure high accuracy and reliability in PCB performance. |

NextPCB ensures that all fabricated PCBs meet stringent industry standards through rigorous quality control and precision manufacturing techniques. The company accommodates diverse design needs and material requirements, emphasizing the reliability of the final product.

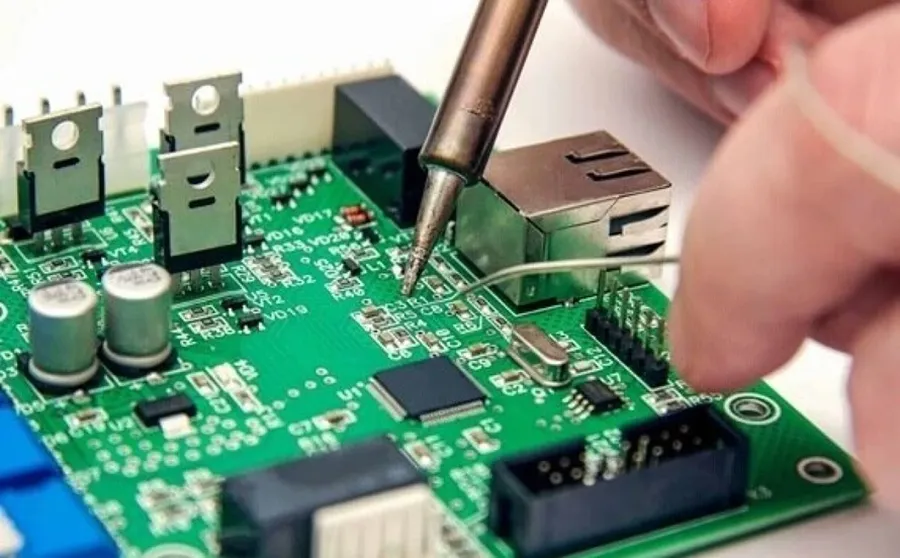

Comprehensive PCB Assembly Services

NextPCB streamlines the PCB manufacturing process by providing comprehensive turnkey assembly services, encompassing component sourcing, Surface Mount Technology (SMT) assembly, and through-hole assembly. This integrated approach offers a one-stop solution for customers, simplifying project management and ensuring consistent quality from design to finished product.

NextPCB's assembly services are scalable, accommodating both small-batch prototypes and large-scale production runs, making them a versatile choice for projects of any volume.

| Service | Description | Benefits |

|---|---|---|

| Component Sourcing | Procurement of all necessary electronic components. | Ensures genuine, high-quality parts; simplifies supply chain management. |

| SMT Assembly | Automated placement of surface mount components. | Precise and efficient assembly, ideal for high-density designs. |

| Through-Hole Assembly | Manual or automated insertion and soldering of through-hole components. | Reliable for larger components and connections requiring mechanical strength. |

Benefits of Choosing NextPCB

NextPCB distinguishes itself in the PCB manufacturing sector by offering a suite of benefits that cater to both prototyping and mass production needs. These advantages stem from a commitment to competitive pricing, stringent quality control, dependable delivery schedules, and superior customer support, all underpinned by an intuitive online ordering system.

- Competitive Pricing

NextPCB is dedicated to providing cost-effective PCB solutions, making it an attractive option for projects with budgetary constraints. They achieve this through efficient manufacturing processes and strategic material sourcing. They also provide options to choose cheaper PCB material to fit in the budget. - High-Quality Manufacturing

Employing rigorous quality control measures, NextPCB ensures that all manufactured PCBs meet the highest industry standards. This includes precise fabrication techniques, thorough testing, and adherence to strict quality protocols to guarantee reliability and performance. - Reliable Delivery

NextPCB prioritizes on-time delivery, understanding that project timelines are critical. They offer transparent tracking and manage their logistics effectively to ensure PCBs arrive on schedule, minimizing potential delays for their clients. - Excellent Customer Support

Clear and responsive customer support is a cornerstone of NextPCB's service. They provide comprehensive assistance throughout the entire production cycle, from the initial design phase to the final product delivery, ensuring a smooth and transparent process for the clients. - Intuitive Online Ordering System

NextPCB's online platform is designed for ease of use, enabling clients to navigate the ordering process seamlessly. This streamlined interface includes simple steps for file upload, specification configuration, and order tracking, making the entire process user-friendly and efficient.

NextPCB vs. Competitors

Choosing the right PCB manufacturer is crucial for the success of any electronics project. This section provides a comparative analysis of NextPCB against other prominent players in the market, namely JLCPCB, PCBWay, and PCBGOGO. This comparison focuses on critical factors such as pricing, delivery timelines, material options, and customer support, empowering users to make well-informed decisions.

| Feature | NextPCB | JLCPCB | PCBWay | PCBGOGO |

|---|---|---|---|---|

| Pricing | Competitive, varies based on specs and volume | Generally lower for small orders | Mid-range, with options for premium services | Competitive pricing, offers volume discounts |

| Delivery Time | Moderate, depending on complexity and region | Fast, especially for standard PCBs | Varies, with express options available | Standard and expedited options |

| Material Variety | Wide range, including FR-4, aluminum, and flexible materials | Good selection of standard materials | Extensive, includes advanced materials | Offers standard and advanced materials |

| Customer Support | Responsive, with online chat and email options | Good, with active online communities | Strong, with dedicated account managers | Responsive customer service team |

| Specialization | Full range of PCB services including assembly | Focus on high volume, and low cost | Offers a wide range of advanced services | Focus on diverse needs and custom solutions |

| Assembly Services | Comprehensive SMT and through-hole assembly | Offers assembly services | Offers both SMT and through-hole assembly | Full turnkey assembly services |

Frequently Asked Questions About NextPCB Services

This section addresses common questions and concerns regarding NextPCB's services, covering topics such as Design for Manufacturability (DFM), Gerber files, material options, and other essential aspects to ensure a smooth and efficient production process.

- What file format should I use to submit my PCB design?

NextPCB requires Gerber files (RS-274X format) for PCB fabrication. Additionally, drill files in Excellon format are necessary. For assembly services, a bill of materials (BOM) and centroid file (pick and place file) are also required. Ensure all files are accurate to avoid delays in production. - What is DFM and why is it important for my PCB design?

Design for Manufacturability (DFM) is a crucial process that ensures your PCB design can be manufactured effectively and reliably. NextPCB offers DFM checks to identify potential issues such as incorrect clearances, trace width, via sizes, and other design flaws that could lead to fabrication or assembly problems. Early DFM analysis is important to prevent costly errors and ensure a smooth production run. - What materials options does NextPCB offer for PCB fabrication?

NextPCB provides a variety of material options for PCB fabrication including standard FR-4, aluminum substrate, flexible materials (Flex PCB) and high-frequency materials. The selection of material depends on the specific requirements of the application, such as thermal conductivity, impedance control, mechanical flexibility, and operating frequency. - How does NextPCB ensure the quality of my fabricated PCBs?

NextPCB implements rigorous quality control processes throughout the fabrication process. This includes automated optical inspection (AOI), electrical testing, and dimensional accuracy checks. They also comply with IPC standards to ensure the highest quality standards of all manufactured boards. - What are the minimum and maximum PCB dimensions that NextPCB can handle?

NextPCB can handle a wide range of PCB sizes, from small prototypes to large boards. However, they do have specific minimum and maximum dimensions based on the service type and the layer count of PCB, it's important to verify their current capabilities on their website or by contacting their support. Check their website for the most accurate and up to date dimensional specifications. - Can NextPCB handle complex PCB designs?

Yes, NextPCB is equipped to handle complex PCB designs, including multilayer PCBs, high-density designs, and boards with fine pitch components. Their advanced equipment and experienced engineers can fabricate and assemble PCBs with high precision, meeting the intricate requirements of modern electronic devices. - What is the typical lead time for PCB fabrication and assembly at NextPCB?

The lead time for PCB fabrication and assembly at NextPCB depends on the complexity of the design, the quantity of boards, and the selected service. Typically, fabrication lead times range from a few days for simple boards to a few weeks for more complex designs. Assembly lead times will vary depending on component availability, it's best to check directly with NextPCB for accurate estimates.

How to Get Started with NextPCB

Embarking on your PCB manufacturing journey with NextPCB is designed to be straightforward and efficient. This section provides a step-by-step guide to help you navigate the process, from uploading your design files to tracking your order.

- Step 1: Account Creation or Login

Begin by creating a new account on the NextPCB website or logging in if you're an existing user. This allows you to save designs, track orders, and manage account settings. - Step 2: File Upload and Project Setup

Upload your Gerber files, which are essential for PCB fabrication. Specify your PCB parameters including the layer count, board dimensions, material type, and any special requirements. The NextPCB platform supports a wide range of file formats for ease of use. - Step 3: Specify Assembly Requirements

If you require PCB assembly services, indicate your assembly requirements at this stage. This includes specifying component sourcing needs, whether surface-mount or through-hole assembly, and any special handling instructions. You can provide your Bill of Materials (BOM) and component placement details. - Step 4: Review and Quotation

After uploading your design and specifying assembly requirements, review your project specifications in detail. Request a quote from NextPCB. They will provide an estimated price and lead time, allowing you to assess your project cost. - Step 5: Order Placement and Payment

Once you're satisfied with the quote, proceed to place your order. NextPCB offers secure online payment options. Make your payment, ensuring accuracy and adherence to the provided quotation. - Step 6: Order Tracking

After your order is placed and payment is confirmed, you will receive a tracking number. Use this to monitor your order's progress through the various stages of production, from initial fabrication to assembly and shipping. NextPCB’s platform is designed to provide updates regularly. - Step 7: Post-Delivery Support

Upon receiving your order, verify that the PCBs and assembled boards meet your expectations. NextPCB's customer support team is available to address any issues or concerns that you may have and will ensure your satisfaction.

NextPCB offers an extensive selection of services designed to support users throughout their PCB design and manufacturing process. Their website provides valuable tools and resources to help you get the best possible results for your projects. From design validation to mass production, NextPCB aims to provide a seamless experience for all of its customers.

NextPCB offers a comprehensive, one-stop solution for all your PCB manufacturing needs, from prototyping to mass production. Their commitment to quality, competitive pricing, and reliable service makes them an ideal partner for your next electronics project. Whether you are working on a simple project or a complex design, NextPCB provides all you need to bring your ideas to life. Trust NextPCB to bridge the gap between concept and reality.

AnyPCBA

AnyPCBA