Order Printed Circuit Boards: Your Comprehensive Guide

From smartphones to space exploration, printed circuit boards (PCBs) are the unsung heroes of modern technology. If you're ready to bring your electronics project to life or scale your production, knowing where and how to order printed circuit boards is crucial. This guide will walk you through the essential steps, exploring options from online platforms to specialized manufacturers, ensuring you make informed decisions for your specific needs and achieve your technical and business goals.

Understanding Your PCB Needs Before Ordering

Prior to initiating an order for printed circuit boards (PCBs), a meticulous assessment of project-specific requirements is crucial. This involves detailed consideration of board dimensions, the number of conductive layers needed, the selection of appropriate substrate materials, and the specification of desired performance characteristics. Furthermore, it is essential to determine whether the need is for a prototype quantity, facilitating iterative design refinement, or for a full-scale production run.

| Requirement | Description | Considerations |

|---|---|---|

| Board Size | Dimensions of the PCB | Fit within enclosure, component placement |

| Number of Layers | Quantity of conductive layers | Circuit complexity, signal routing |

| Material | Substrate material for PCB | FR-4, Aluminum, Flex, Thermal, Electrical properties |

| Performance | Specific board performance | Impedance control, thermal management, operating frequency |

| Order Quantity | Number of PCBs needed | Prototype runs, medium or large production |

Online PCB Ordering Platforms vs. Custom Manufacturers

When placing an order for printed circuit boards (PCBs), a critical decision involves choosing between online ordering platforms and traditional custom manufacturers. Each option presents distinct advantages and disadvantages concerning speed, cost, customization, and customer service. Understanding these differences is essential for selecting the best approach for your project's unique requirements.

| Feature | Online PCB Platforms (e.g., JLCPCB, PCBWay) | Custom PCB Manufacturers |

|---|---|---|

| Speed | Generally faster turnaround times for standard designs and smaller quantities. | Potentially longer lead times, particularly for complex or large-scale orders, due to manual processes and production schedules. |

| Cost | Often more cost-effective for small to medium quantities and standard specifications. | Typically more expensive for prototyping and smaller runs but potentially more competitive for very large production volumes. |

| Customization | Offers limited customization options based on pre-defined templates and parameters. | Provides extensive customization options for materials, layers, and other advanced design specifications. |

| Customer Service | Customer service is generally provided through ticketing systems or email and is less personalized. | Offers more direct and personalized customer service, with dedicated account managers and engineering support. |

| Minimum Order Quantity (MOQ) | Usually low MOQs, suitable for prototypes and small projects. | May have higher MOQs, making them more suitable for mass production. |

| Design Complexity | Better suited for standard and moderately complex designs. | Capable of handling very complex designs and intricate features. |

| Real-time Tracking | Typically provides online order tracking and updates. | Tracking may be less transparent, requiring direct contact with the manufacturer. |

| Quotation Process | Instant quoting based on online specifications. | Quoting process often requires sending design files and waiting for a manual review, thus longer turn around. |

Online platforms like JLCPCB and PCBWay streamline the ordering process with automated tools for quotation and order placement. This is ideal for projects with standard specifications and quick prototyping needs. However, if your PCB design requires specialized materials, non-standard dimensions, or stringent performance characteristics, engaging directly with a custom manufacturer might be the more appropriate choice. Custom manufacturers provide greater flexibility and can better meet specific or complex requirements.

Key Factors in Choosing a PCB Manufacturer

Selecting the right PCB manufacturer is critical for ensuring the quality and functionality of your printed circuit board. This choice significantly impacts not only the cost of your project, but also its success, reliability and time to market. Key factors to consider include quality standards, material options, manufacturing capabilities, turnaround times, and cost-effectiveness, each requiring careful evaluation to align with your project's unique needs.

| Factor | Description | Importance |

|---|---|---|

| Quality Standards | Certifications like ISO 9001 and IPC standards compliance ensure that manufacturing processes meet specific quality benchmarks. | Critical for reliability and performance. Ensures consistent manufacturing practices and minimizes defects. |

| Material Options | Availability of materials such as FR-4, aluminum, and flexible substrates to match design requirements. | Impacts thermal properties, mechanical strength, and overall PCB performance in specific applications. |

| Manufacturing Capabilities | Layer count, minimum trace width and spacing, drilling precision, and surface finishing options available from the manufacturer. | Determines design complexity and the precision with which the design can be manufactured. Directly influences the functionality of high-density circuits. |

| Turnaround Times | The time required from submitting design files to receiving the manufactured boards. | Essential for meeting project deadlines. Rapid prototyping and production can speed up the overall development cycle. |

| Cost-Effectiveness | Pricing structure including setup fees, material costs, and volume discounts to fit your budget. | Directly affects project feasibility and scalability. Balancing cost and quality is essential to achieving a cost effective PCB. |

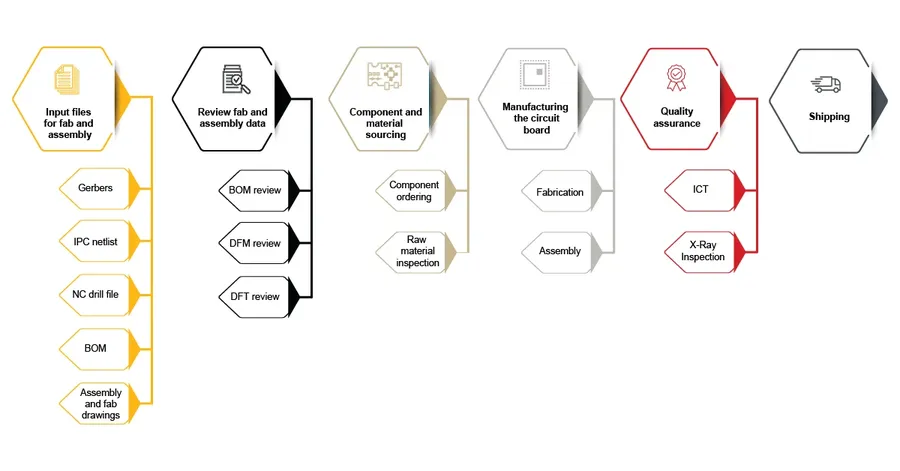

Navigating the PCB Design File Preparation Process

Preparing your design files accurately is paramount for a successful printed circuit board (PCB) manufacturing outcome. This section details the essential files required, focusing on Gerber files, the Bill of Materials (BOM), and common pitfalls to avoid when preparing your documentation for your order printed circuit board.

The Gerber format, being the industry standard, is used to communicate the design to the PCB manufacturer. Each layer of your PCB, including copper, solder mask, and silkscreen, is represented by individual Gerber files. Therefore, it is imperative to generate these files correctly to ensure the accurate fabrication of your printed circuit board.

A precise Bill of Materials (BOM) is another critical document when you order printed circuit board. The BOM lists all the components needed for the assembly, including their part numbers, manufacturer names, footprints, and quantities. An accurate BOM helps to avoid delays and errors during the manufacturing process, and ensures that the correct components are used.

| File Type | Description | Importance |

|---|---|---|

| Gerber Files | Represent each PCB layer (copper, silkscreen, solder mask) | Essential for accurate PCB fabrication |

| Bill of Materials (BOM) | Lists all components, their part numbers, and quantities | Necessary for correct component sourcing and assembly |

| Drill Files | Specify hole locations and sizes | Critical for proper drilling of vias and component holes |

| Pick and Place File | Contains component locations and orientations for automated assembly | Used for automated component placement if assembling the PCB |

Common errors in file preparation include incorrect units, missing layers, and inaccurate part numbers in the BOM. To mitigate these issues, utilize design software's built-in checking tools, review all generated files manually, and compare the file outputs against the original design schematic. Always consult the manufacturer's specifications and preferred file formats before submitting your order printed circuit board.

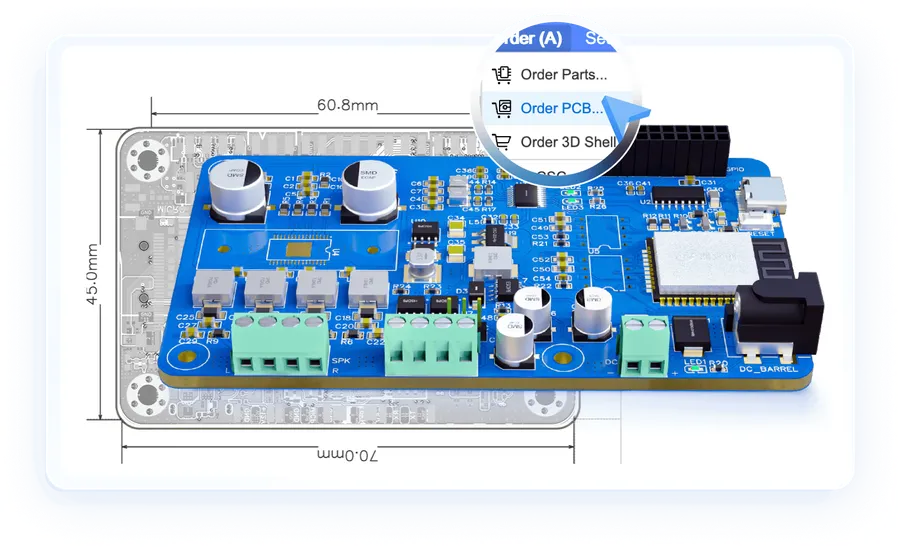

Step-by-Step Guide: How to Order Printed Circuit Boards Online

Ordering printed circuit boards (PCBs) online has become a streamlined process, offering convenience and efficiency for both prototyping and mass production. This section provides a practical, step-by-step guide on navigating popular online platforms to ensure your order is placed correctly and efficiently.

- Account Setup

Begin by creating an account on your chosen online PCB platform. This typically involves providing basic contact information and setting up login credentials. Some platforms may also offer options for team collaboration. - File Preparation and Upload

Before uploading, ensure that your PCB design files are in the correct format (usually Gerber RS-274X). ZIP these files into a single archive. Upload the archive through the platform's interface. Many sites offer online Gerber viewers to preview the layout. - Specification Selection

Carefully select the specifications for your PCB order. Common options include board dimensions, layer count, material (FR-4, aluminum, flex), copper thickness, surface finish (HASL, ENIG), solder mask color, and silk screen options. Pay close attention to the minimum trace width and spacing. - Quantity and Panelization

Specify the number of PCBs you require. For large orders, some platforms offer panelization options, where multiple PCBs are fabricated on a single panel. This can reduce manufacturing costs, but may not be suitable for prototyping. - Special Requirements and Options

If you have any special requirements such as impedance control, blind vias, buried vias or controlled impedance, indicate these within the specified fields of the ordering form. - Review and Finalize

Carefully review all specifications, quantities, and costs before adding the PCBs to your shopping cart. Many platforms provide an opportunity to review the Gerber files online, and an automated Design For Manufacturability check, to ensure there are no issues - Order Placement and Payment

Proceed to the checkout and complete payment using the available methods. Double-check your order before finalizing. Once paid, your order will be scheduled for manufacturing and shipment.

Cost Considerations and Budgeting for Your PCB Order

Understanding the various cost factors involved in printed circuit board (PCB) manufacturing is crucial for effective budgeting and cost optimization. This section delves into the key elements that influence the final price of your PCB order, providing strategies to balance cost with quality.

| Cost Factor | Description | Optimization Strategies |

|---|---|---|

| Material Costs | Price of the base material (e.g., FR-4, aluminum, flex) varies based on type and thickness. | Choose standard materials if performance requirements allow, optimize board thickness, consider material alternatives for non-critical applications. |

| Setup Fees | One-time charges for preparing tooling, generating manufacturing files, and initial setup. | Batch multiple designs together for a single production run to reduce per-board setup fees; plan thoroughly to avoid iterations and additional setups. |

| Board Size and Complexity | Larger boards, higher layer counts, and intricate designs increase material usage and processing time. | Optimize board size and layout for efficient use of space; reduce layer count wherever feasible without impacting performance. |

| Layer Count | Each layer in a multilayer PCB adds to material and manufacturing complexity. | Design with the minimum number of layers necessary to meet the circuit requirements. |

| Quantity | Unit cost decreases with larger production runs due to economies of scale. | Consolidate orders or consider ordering in larger quantities if future needs are anticipated. |

| Surface Finish | Different finishes (e.g., HASL, ENIG) have varying costs depending on performance requirements. | Select the most appropriate finish based on your application needs rather than opting for the most expensive if not required. |

| Specialized Processes | Processes like blind vias, buried vias, and impedance control add cost. | Avoid specialized processes unless critical to the functionality of your PCB. |

| Testing Requirements | More thorough testing (e.g., electrical testing, flying probe tests) will incur more expense, however testing is often needed to ensure functionality. | Balance the cost of testing with the risk of failures by selecting only the necessary tests. |

| Shipping Costs | Delivery speed and distance influence the final shipping price. | Plan production timelines to avoid express shipping; compare quotes from different carriers; consolidate shipping when possible. |

To further reduce costs, consider these additional strategies: choosing standard components to reduce component costs and assembly costs; optimizing designs to reduce complexity and layer count which ultimately affects raw material costs; clearly communicating requirements to avoid errors and additional processing; planning ahead to consolidate orders and take advantage of bulk discounts; and regularly reviewing and refining designs for ongoing cost reduction. Utilizing online quoting tools from PCB manufacturers to get a range of price points is also vital in understanding your cost.

PCB Assembly Options: From Prototype to Full Production

The decision to order bare PCBs or opt for full PCB assembly significantly impacts the project timeline, cost, and complexity. Understanding these differences is crucial for efficient electronics manufacturing. Choosing the right assembly option can streamline your project, ensuring that you receive printed circuit boards ready for integration or testing.

| Feature | Bare PCB | PCB Assembly |

|---|---|---|

| Components | No components | Includes components placement and soldering |

| Manufacturing Stage | PCB fabrication only | PCB fabrication, component sourcing, and assembly |

| Lead Time | Shorter | Longer |

| Cost | Lower initial cost | Higher initial cost, potentially lower total cost for larger production |

| Complexity | Simpler process | More complex, requires specialized equipment and skills |

| Typical Use Case | Prototyping, testing, or in-house assembly | High-volume production, specialized projects, or when assembly resources are limited |

| Testing | Manual testing | Automated and comprehensive testing options available |

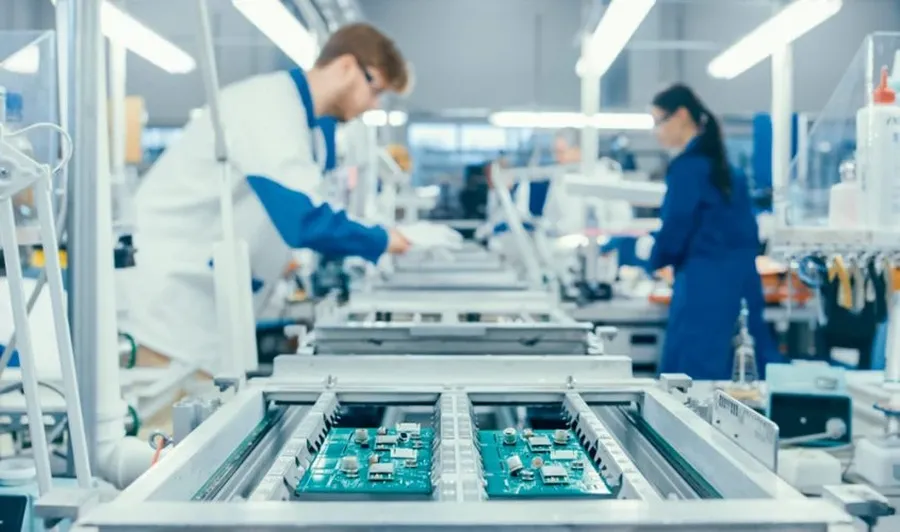

- Component Placement

PCB assembly services offer automated component placement using pick-and-place machines. These machines ensure high precision and speed in placing components, including surface mount devices (SMD) and through-hole components. Manual placement is possible for small-scale prototypes, but may not be suitable for larger production runs. - Soldering Techniques

Various soldering techniques are available, including reflow soldering for SMDs and wave soldering for through-hole components. The appropriate method depends on the component type and the project's specifications. Proper soldering is vital for electrical connectivity and circuit reliability. - Testing

PCB assembly includes rigorous testing procedures to ensure functionality and reliability of the assembled board. Common tests include in-circuit testing (ICT) and functional testing. These tests identify potential manufacturing defects and ensure the assembled PCB meets all performance specifications. Opting for assembly services provides the advantage of a tested and ready-to-use PCB, potentially reducing time-to-market for the end-product. - Assembly Levels

From prototype to full production, assembly services offer scalability. For prototypes, a small-batch or manual assembly might be suitable. However, for larger production runs, it is more practical to utilize full automated assembly lines to guarantee consistent quality and efficiency.

Shipping and Delivery of Your PCBs

Efficient shipping and delivery are crucial when you order printed circuit boards, impacting project timelines and costs. Understanding the available options and potential challenges is essential for a successful outcome. This section will guide you through shipping methods, delivery times, customs management, and the critical inspection process.

- Shipping Options

Common shipping methods include standard postal services, express couriers (such as DHL, FedEx, UPS), and freight options for large orders. Express options are generally faster but more expensive, while standard shipping is more economical but takes longer. Consider the urgency and cost implications when selecting a method. - Delivery Times

Delivery times vary based on the chosen shipping method, the manufacturer's location, and your location. Domestic shipments typically arrive within a few business days, while international shipments can take several days to weeks. Be sure to factor in processing times at both the manufacturing and shipping stages, and plan accordingly. Always track your shipment for real-time delivery status. - Customs and Import Duties

International shipments may be subject to customs duties, taxes, and import fees, determined by the destination country's regulations. These costs are usually the buyer's responsibility. Consult with the manufacturer or a customs broker to understand potential fees to avoid unexpected expenses. Ensure all necessary import documents are completed correctly to prevent delays. Failure to do so can result in significant delays or even forfeiture of your order. - Best Practices for Receiving PCBs

Upon arrival, inspect the packaging carefully for any signs of damage that might indicate mishandling during transit. Compare the received boards with your order specifications, looking for any discrepancies in quantity, type, or finishing. Document any damage or issues immediately, and contact the manufacturer to discuss solutions, including replacements or refunds. Proper handling and storage procedures after delivery are also important. PCBs are sensitive to humidity and should be stored in a dry place, preferably in their original packaging.

| Shipping Option | Speed | Cost | Pros | Cons |

|---|---|---|---|---|

| Standard Postal Service | Slower (Several Days to Weeks) | Economical | Cost-Effective for non-urgent orders | Longer delivery times, limited tracking |

| Express Couriers (DHL, FedEx, UPS) | Faster (Few Business Days) | More Expensive | Quick delivery, comprehensive tracking | Higher cost, may require customs clearance expertise |

| Freight Shipping | Variable (Days to Weeks) | Cost-Effective for large orders | Suitable for large volumes of PCBs | Longer transit time, requires careful planning |

Frequently Asked Questions About Ordering PCBs

This section addresses common questions regarding the process of ordering printed circuit boards, providing clear and concise answers to help clarify any doubts you might have.

- How much does a printed circuit board (PCB) cost?

The cost of a PCB varies significantly based on several factors, including the board's size, number of layers, material type (e.g., FR-4, aluminum), complexity of the design, quantity ordered, and the chosen manufacturer. Prototype runs can be more expensive per unit than larger production batches due to setup costs. It's best to get a quote from the manufacturer based on your specific requirements. - What is the difference between a printed wiring board (PWB) and a printed circuit board (PCB)?

The terms PWB and PCB are often used interchangeably, but strictly speaking, a PWB is a board with conductive pathways (wires) printed on it, whereas a PCB is a PWB with electronic components attached. In common use, PCB is the prevailing term and is understood to mean a board that incorporates both wiring and components. - What is the best PCB manufacturer for my order?

The "best" PCB manufacturer depends greatly on your needs. For hobbyists and smaller prototype runs, online services like JLCPCB and PCBWay are popular due to their low prices and fast turnaround times. For more complex designs or high-volume orders, specialized manufacturers with advanced capabilities and better customer support are recommended. Consider factors such as quality, turnaround time, price, and available capabilities when making your selection. - What file formats are required to order PCBs?

Most manufacturers require Gerber files, which are industry-standard files containing information about each layer of the board, drill hole locations, and other manufacturing data. Additionally, you typically need a Bill of Materials (BOM) file, which lists all the components needed for assembly, along with their manufacturer part numbers, quantities, and other relevant information. A pick and place file may be necessary for automated assembly. - How long does it take to get my PCBs manufactured and shipped?

Manufacturing and shipping times depend on the chosen manufacturer and the specific type of order (e.g. prototype or production). Typical production times can range from a few days for express services to a couple of weeks for more complex orders. Shipping times can also vary depending on location and the service selected, from a few days with express options to a week or more with standard options. Always verify the estimated timelines before placing your order. - Can I order a PCB prototype before committing to a large production run?

Yes, ordering a PCB prototype is a highly recommended practice to verify your design before moving to mass production. This allows you to identify any design flaws, fitment issues, or performance concerns early in the process, allowing you to modify the design, if necessary before large scale production. Most PCB manufacturers offer prototyping services, which may also provide a cost-effective option to test the production and assembly process. - What are the common materials used for PCB manufacturing?

The most common material for PCBs is FR-4 (Flame Retardant 4), a fiberglass-reinforced epoxy laminate. Other materials include aluminum for better thermal management, flexible polyimide for flexible circuit boards and Teflon (PTFE) for high-frequency applications. The selection of material depends heavily on the specific performance and environmental requirements of the application.

Ordering printed circuit boards doesn't have to be daunting. By understanding your project needs, evaluating your manufacturing options, and properly preparing your designs, you can successfully order printed circuit board from online platforms or specialized manufacturers. With meticulous planning and attention to detail, you'll bring your innovative electronics projects from idea to physical reality, achieving efficient, high-quality results. Whether it’s prototyping or large-scale production, a well-executed ordering process is crucial to the overall success of your electronic endeavor.

AnyPCBA

AnyPCBA