PCB GPU: Understanding the Heart of Your Graphics Card

In the world of gaming and high-performance computing, the GPU (Graphics Processing Unit) is a powerhouse. But behind every powerful GPU is a critical, yet often overlooked component: the PCB (Printed Circuit Board). Much like the nervous system of a human body, the PCB acts as the foundation, the 'brain circuit' of your graphic cards. This article will explore everything you need to know about PCBs in GPUs, from their components and purpose to their impact on performance and longevity, shedding light on a critical aspect of modern graphics technology.

What is a PCB in a GPU?

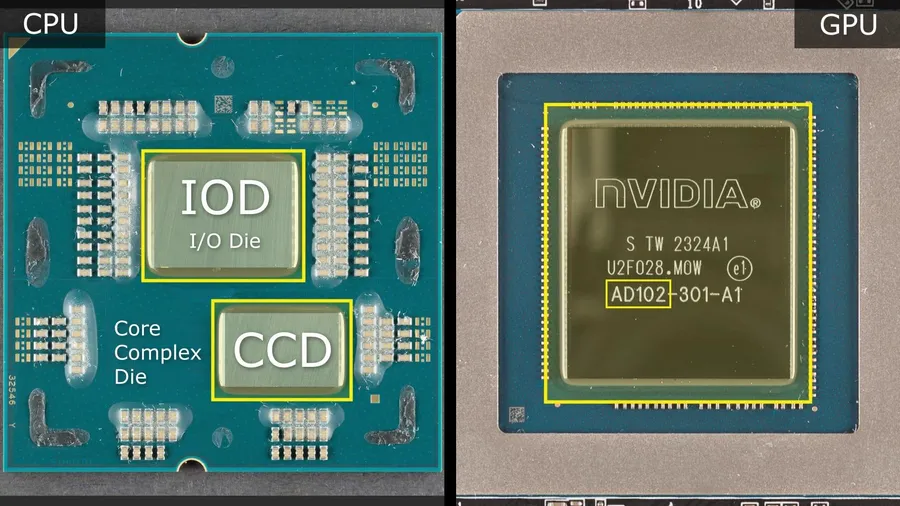

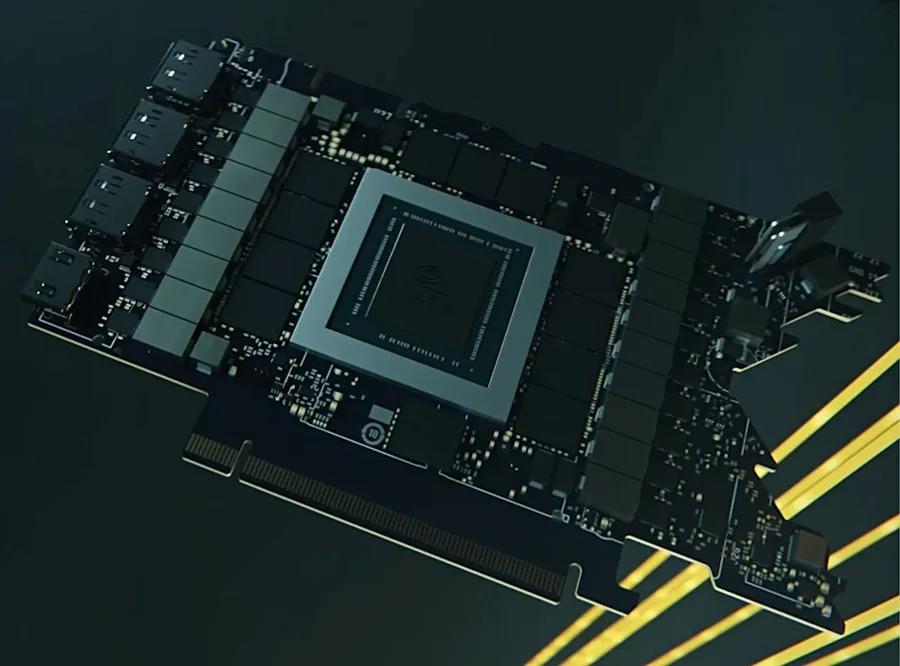

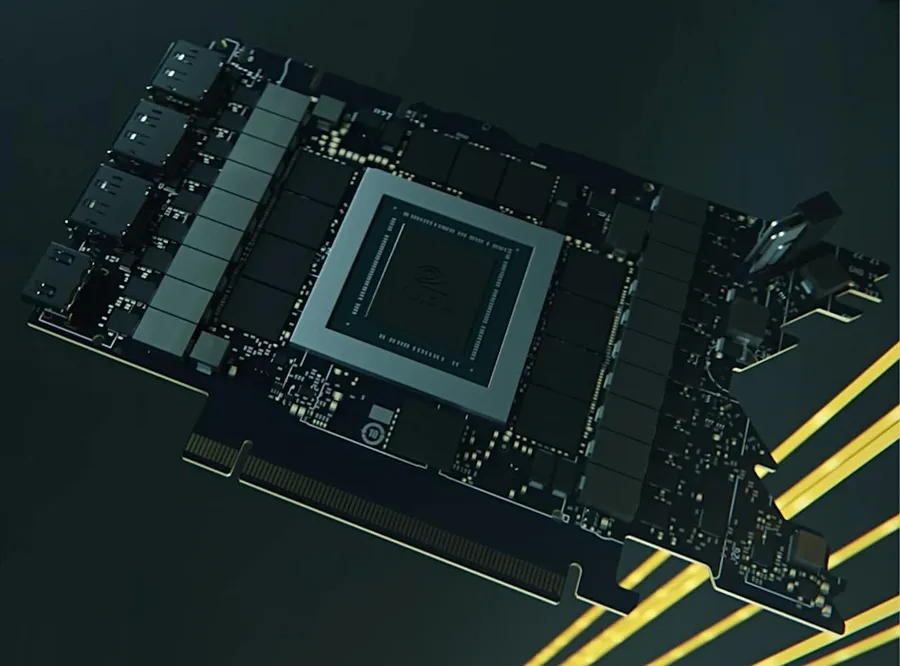

A Printed Circuit Board (PCB) in a GPU serves as the foundational platform for all its components. It is the laminate structure onto which the Graphics Processing Unit (GPU) die, memory modules, voltage regulation modules (VRMs), and various other electrical components are soldered. The PCB's primary functions are to provide both the structural support and the intricate electrical pathways necessary for these components to communicate and function cohesively, ensuring the GPU performs its graphical processing tasks.

Key Components on a GPU PCB

A GPU Printed Circuit Board (PCB) is a complex assembly hosting various critical components. These components work synergistically to enable the processing power of the graphics card. Understanding these components and their functions is crucial for comprehending how a GPU operates and identifying potential points of failure.

| Component | Function | Impact |

|---|---|---|

| GPU Chip | The central processing unit of the graphics card. It performs the complex calculations needed to render images and video. | The core determinant of graphics performance. Its architecture and clock speed dictate a card's capabilities. |

| VRMs (Voltage Regulator Modules) | Regulate and deliver stable power to the GPU core and memory. Convert the power from the PSU to the necessary levels for the GPU. | Crucial for stable operation, especially during high loads or overclocking. Poor VRMs can lead to instability, overheating, and reduced lifespan. |

| Memory Modules (VRAM) | Stores textures, frame buffers, and other temporary data. Provides fast access to data for the GPU. | Determines the amount of data the GPU can work with. Faster and higher-capacity memory leads to better performance. |

| Capacitors | Store electrical charge and help to smooth out the power delivery from the VRMs, reducing voltage fluctuations and electrical noise. | Enhance the power stability and reliability of the GPU. Can influence overclocking headroom and reduce chances of transient issues. |

| Inductors (Chokes) | Store energy in a magnetic field to filter out electrical noise and aid in power delivery stabilization from the VRMs. | Crucial for stable and efficient power delivery. High quality chokes reduce heat and noise. |

| PCB Traces | Copper pathways that conduct electrical signals between different components on the board. Design can influence signal integrity and thermal performance. | The quality of the traces (thickness, material, and layout) impacts power delivery and signal quality. Can affect signal latency, noise and overall GPU performance. |

| BIOS Chip | Contains the firmware for the graphics card. Provides basic instruction for bootup and power management. | Provides essential boot up parameters. Custom BIOSes can be used for different overclocks. |

Reference vs. Non-Reference GPU PCBs

The landscape of graphics card PCBs is largely divided into two categories: reference and non-reference designs. Understanding the distinction between these designs is crucial for comprehending the variations in performance, cooling, and overall capabilities of different graphics cards.

| Feature | Reference PCB | Non-Reference PCB |

|---|---|---|

| Design Origin | Designed by the GPU manufacturer (e.g., NVIDIA, AMD) | Custom-designed by AIB (Add-in-Board) partners (e.g., ASUS, MSI, Gigabyte) |

| Component Placement | Standardized layout and component selection | Varied layout and often includes premium components |

| Power Delivery | Typically features a basic VRM (Voltage Regulator Module) design | Often incorporates enhanced VRM designs for better power delivery |

| Cooling Solution | Usually comes with a stock cooler designed for adequate performance | May feature advanced cooling systems, such as larger heatsinks and additional fans |

| Clock Speeds | Operates at the manufacturer's base or boost clock speeds | May come factory-overclocked or provide greater overclocking headroom |

| Availability | Available from multiple vendors | Exclusive to the specific AIB partner brand |

| Pricing | Generally priced at the MSRP (Manufacturer's Suggested Retail Price) | Often sold at higher prices due to premium features |

In essence, reference PCBs serve as a baseline, while non-reference designs allow AIB partners to innovate and differentiate their products through improved power delivery, cooling efficiency, and performance capabilities. The choice between a reference or non-reference card often depends on individual preferences regarding performance, aesthetics, and budget considerations. Non-reference cards, while generally pricier, frequently offer superior performance and cooling, appealing to users seeking enhanced capabilities.

How PCB Design Affects GPU Performance

The printed circuit board (PCB) design is a critical factor influencing a GPU's performance, stability, and longevity. The layout, quality, and materials used in a PCB directly impact signal integrity, power delivery efficiency, and thermal management capabilities.

A well-engineered PCB is fundamental for optimal GPU operation, enabling higher clock speeds, better overclocking potential, and improved overall system stability.

| PCB Design Aspect | Impact on GPU Performance | Explanation |

|---|---|---|

| Trace Quality and Layout | Signal Integrity and Data Transfer Rates | High-quality traces with optimized routing reduce signal loss and interference, ensuring data reaches components with minimal degradation. This is critical for memory and PCIe communication. |

| Power Delivery System (VRMs) | Stability Under Load and Overclocking Potential | Robust VRMs with quality components provide clean and consistent power to the GPU core and memory, enabling higher clock speeds and stable operation, particularly under heavy load or during overclocking. |

| Cooling Solutions (Heat Sinks, Pads) | Thermal Management and Component Lifespan | Effective cooling solutions dissipate heat away from the GPU and other critical components. Insufficient cooling leads to thermal throttling, reduced performance and may shorten lifespan of the GPU. |

| Layer Count and Thickness | Signal Integrity, Thermal Dissipation, and Structural Rigidity | Higher layer counts and specific thicknesses can improve electrical performance, heat dissipation, and overall board strength. This leads to better performance stability and durability. |

| Ground Plane Design | Electromagnetic Interference (EMI) and Signal Integrity | A well-designed ground plane minimizes EMI and provides a stable reference for signals, improving signal quality and reducing the likelihood of errors and instability |

Common GPU PCB Issues and How to Identify Them

Identifying common issues with a GPU's Printed Circuit Board (PCB) is crucial for maintaining optimal performance and preventing hardware failure. These issues often manifest physically and can indicate underlying problems that, if left unchecked, may lead to significant damage. Understanding the symptoms can help in timely intervention.

- Cracked PCB

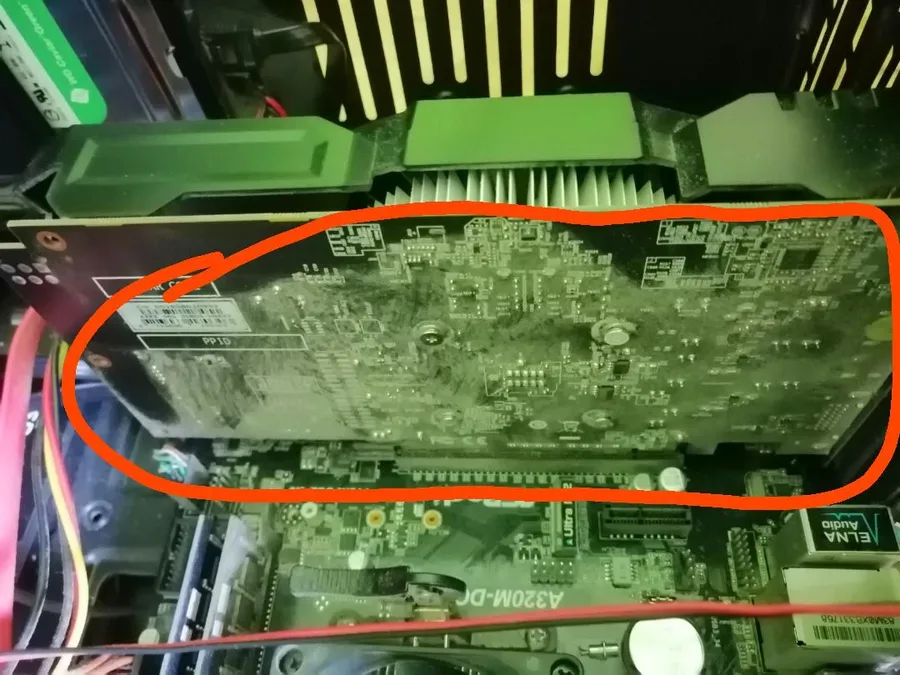

A cracked PCB is a serious issue usually caused by physical stress or impact. Visible cracks, even hairline ones, can disrupt electrical pathways, leading to erratic behavior, such as graphical glitches, system instability, or complete failure. Careful inspection, especially around mounting points and edges, is necessary. - Residue Buildup

Over time, dust, grime, and other residues can accumulate on the PCB. This buildup can act as an insulator, trapping heat and leading to thermal throttling and potential overheating. In addition, conductive residue may cause short circuits. Examine for discoloration or accumulation around components, and be thorough when cleaning. - Bent PCB

A bent PCB, which typically arises from improper handling or installation, can induce mechanical stress on solder joints and components. This can cause intermittent connection problems or total failure. Careful visual inspection of the board's flatness is essential, particularly when dealing with used or older cards. A warped PCB may exhibit issues ranging from instability to outright failure. - Component Damage

Physical damage to components, such as capacitors, resistors, or inductors, can be a sign of serious problems. Bulging or leaking capacitors, damaged resistors, or dislodged inductors should be addressed immediately, as they are signs of electrical stress or failure. Such issues may lead to erratic behavior or prevent the card from booting. - Burn Marks

Burn marks on the PCB are indications of overheating or short circuits. These marks, often accompanied by a burnt smell, are critical indicators of severe damage. Such occurrences often affect components or traces on the PCB, frequently rendering the board irreparable.

Cleaning and Maintaining Your GPU PCB

Maintaining a clean GPU PCB is crucial for optimal performance and longevity. Dust accumulation, residue buildup, and other contaminants can impede heat dissipation, potentially leading to overheating and component failure. Proper cleaning techniques, along with the right tools, can prevent damage and extend the lifespan of your graphics card.

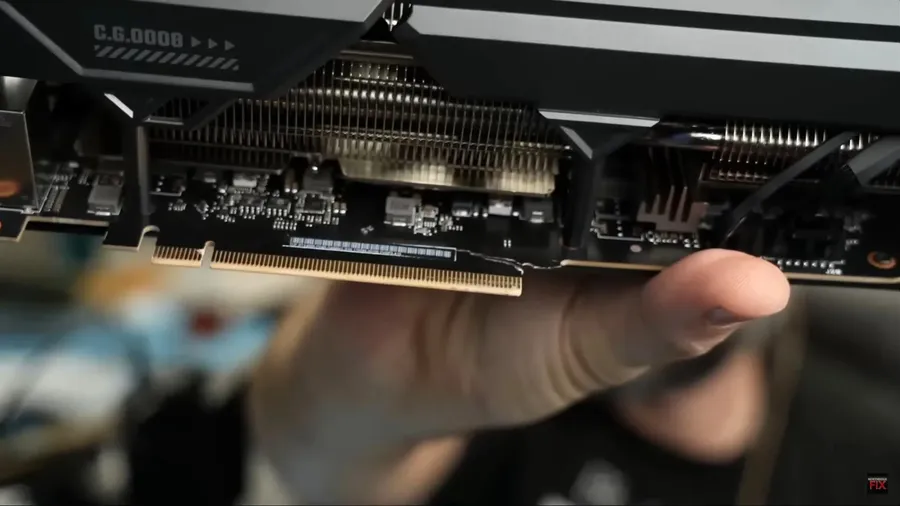

- Preparation: Essential Tools and Precautions

Before starting, gather the necessary tools: compressed air, a soft, anti-static brush, 99% isopropyl alcohol, and lint-free cloths or swabs. Ensure your workspace is well-lit and free of static electricity. Power down your computer and remove the GPU carefully before beginning. Avoid using tap water or harsh chemicals, as they can cause corrosion or damage to sensitive components. - Step 1: Removing Dust and Loose Particles

Use compressed air to gently blow away dust and loose particles from the PCB surface, heatsink, and fan. Hold the can upright and at a slight angle to avoid spraying liquid propellant. Focus on areas with visible buildup, and work in short bursts to prevent over-cooling. Pay particular attention to crevices and around the VRMs and memory modules. - Step 2: Cleaning with Isopropyl Alcohol

For stubborn residue or sticky substances, moisten a lint-free cloth or swab with 99% isopropyl alcohol. Gently wipe the affected areas, avoiding excessive pressure or saturation. The alcohol will evaporate quickly, removing the residue and leaving a clean surface. Be extra careful around delicate components like capacitors and surface-mount devices (SMDs). - Step 3: Using a Soft Brush

Use a soft, anti-static brush to carefully dislodge any remaining particles from the PCB. Gently brush in a consistent direction, paying attention to the crevices and areas with soldered components. This will help remove particles that the compressed air may not have dislodged. Be careful not to apply excessive force, which may dislodge small components. - Step 4: Reassembly

After the GPU PCB is completely cleaned and dry, carefully re-install the graphics card into your computer. Ensure that it's properly seated in the PCIe slot and that all screws are tightened. Before powering on, double-check all connections to ensure a successful re-installation. - Final Inspection

Once the cleaning is complete, inspect the PCB again for any missed areas. Ensure there's no visible dust or residue and that the components are securely attached. Proper cleaning will contribute to the stability and thermal performance of your GPU, preventing issues such as overheating or signal degradation. Periodical maintenance, every three to six months, can help extend the lifespan of your graphics card.

The Role of PCB Materials in GPU Durability

The selection of materials for a GPU's Printed Circuit Board (PCB) is paramount to its durability and overall performance. High-quality materials, particularly those that facilitate High Density Interconnect (HDI), are essential in preventing common issues such as PCB cracking and ensuring long-term stability. The composition and properties of these materials directly affect the card's ability to withstand thermal stress and mechanical strain.

| PCB Material Property | Impact on GPU Durability | Example Material |

|---|---|---|

| Thermal Conductivity | Dissipates heat more efficiently, preventing hotspots and material degradation. | Copper |

| Coefficient of Thermal Expansion (CTE) | Minimizes stress from thermal cycling, reducing the risk of trace fractures. | Specific Resin Blends |

| Flexural Strength | Provides mechanical robustness, preventing bending and cracking under pressure. | Fiberglass Reinforced Epoxy |

| Dielectric Strength | Ensures electrical insulation, preventing short circuits and signal interference. | FR-4 Laminate |

| HDI (High Density Interconnect) | Enables finer trace patterns, increasing component density and signal integrity while reducing layer counts and overall thickness. | Advanced Resin Systems |

The use of HDI in GPU PCBs is particularly noteworthy. HDI allows for more complex designs with finer trace widths and spacing, which are vital for high-speed signal transmission between the GPU chip, memory, and other components. The benefits of HDI include reduced signal latency and improved power delivery.

In summary, the materials used in GPU PCB fabrication are not merely structural; they are active components that contribute to the performance, durability, and overall lifespan of the graphics card. High-quality materials directly correlate with a GPU's ability to operate under demanding conditions while reducing the risk of premature failure.

Frequently Asked Questions about GPU PCBs

This section addresses common inquiries regarding GPU Printed Circuit Boards (PCBs), aiming to clarify their role, construction, and significance within graphics cards and computer systems.

- What is a PCB on a GPU?

A PCB (Printed Circuit Board) on a GPU is the foundational board that acts as a physical and electrical platform. It provides mechanical support, electrical connectivity, and thermal management for all the components of the graphics processing unit (GPU), such as the GPU die, memory modules, VRMs (Voltage Regulator Modules) and other controller chips. Think of it as the skeletal system of the GPU, where everything essential is interconnected and supported. - What does 'PBC' in GPU mean?

It's likely there's a minor typo and the user is referring to 'PCB'. There is no standard 'PBC' term in the context of GPUs. The term 'PCB' refers to the Printed Circuit Board, which is the core structure that houses all of the electronic components of a GPU. - What does 'onboard GPU' mean?

An 'onboard GPU,' also known as an integrated GPU, is a graphics processing unit that is built directly into the CPU (Central Processing Unit) or the motherboard. Unlike dedicated GPUs which are standalone cards plugged into the motherboard, onboard GPUs share system memory and typically have lower performance capabilities, though they are adequate for basic display needs and less demanding graphics tasks. - What is a PCB on a PC?

In the context of a PC (Personal Computer), a PCB is a board that houses the electronic components of various devices, such as the motherboard, graphics card, RAM modules, etc. It provides the structural support and electrical connections required for all components to work together. All electronic components within a PC are mounted on and connected through PCBs. - Can the PCB affect GPU performance?

Absolutely. The quality of the PCB and the design layout significantly affects performance. Aspects such as trace impedance, power delivery through VRMs, and the cooling solutions attached to the PCB all impact thermal management, stability, and overclocking potential. A well-designed PCB facilitates better signal integrity and efficient power delivery, thus enhancing GPU performance. - What materials are used in GPU PCB manufacturing?

GPU PCBs primarily use materials such as FR-4 (Flame Retardant 4), a glass-reinforced epoxy laminate that forms the primary substrate. High-end GPUs may utilize advanced materials like HDI (High Density Interconnect) PCB to allow for increased trace density and reduced impedance. Copper is commonly used for the conductive traces and thermal layers. The choice of these materials impacts durability, signal integrity, and thermal performance of the board. - How can I protect my GPU's PCB?

Protecting a GPU PCB involves handling the card carefully, avoiding bending, and ensuring proper ventilation within your PC case. Prevent dust accumulation with regular cleaning and always ground yourself before handling the GPU. Avoid any physical contact with components unless necessary. When cleaning, using compressed air is best, avoid using liquid cleaners directly.

The PCB within a GPU, often unseen, is a vital component. From providing power to supporting high-speed data transfer, its design and materials play a significant role in the performance and longevity of your graphics card. Understanding the PCB not only helps in better maintenance but also enables an informed decision when choosing a graphics card. The PCB is the unsung hero behind every frame rendered and every pixel pushed by your GPU, acting as the critical bridge between silicon and visual output. As PCB technology evolves, so too will the capabilities of our GPUs.

AnyPCBA

AnyPCBA