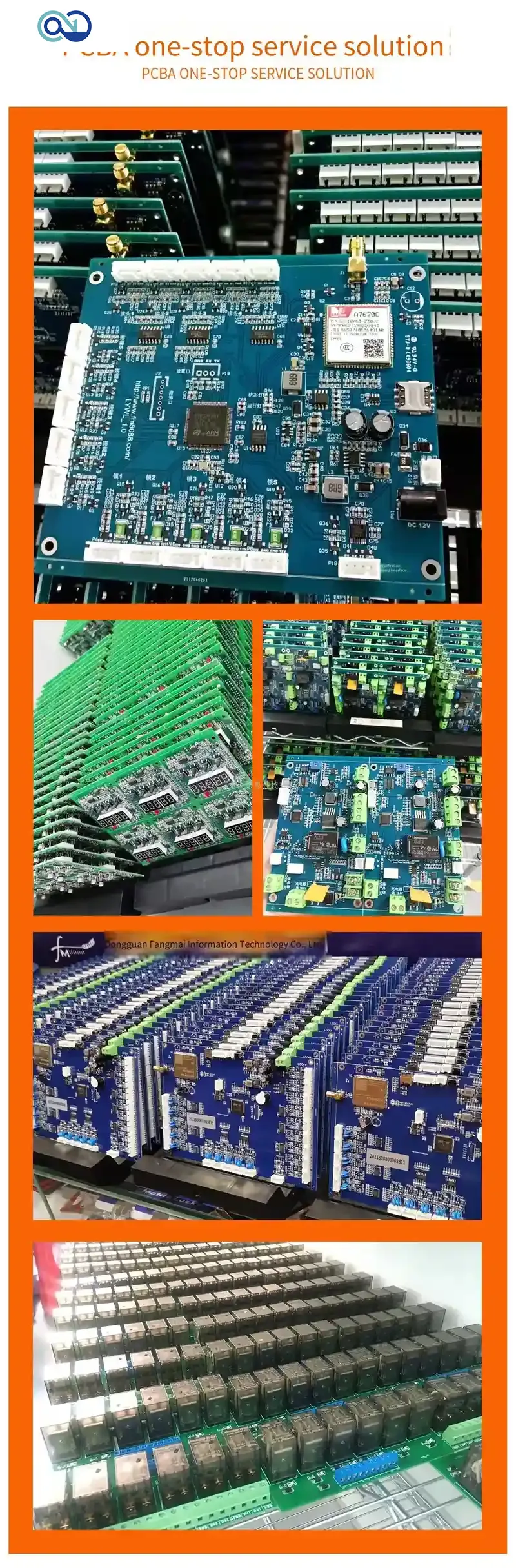

PCBA One-Stop Service Solution

In the dynamic world of electronics, bringing innovative products to market demands not just groundbreaking ideas, but also an agile, efficient, and reliable manufacturing partner. This is where the concept of a PCBA One-Stop Service Solution becomes indispensable. At Zero One Solution Limited, we understand the complexities and challenges inherent in product development, from initial PCB design to final assembly. Since our inception in 2011, we've dedicated ourselves to simplifying this journey for our clients, especially those focused on rapid-response R&D prototype manufacturing. But what exactly does a comprehensive one-stop PCBA service entail, and how can it fundamentally transform your product realization process?

Understanding the Core of PCBA One-Stop Service

A PCBA (Printed Circuit Board Assembly) one-stop service solution is more than just assembling components onto a PCB. It's a comprehensive suite of integrated services designed to take a product from initial concept to a fully functional assembly. This encompasses PCB design, component procurement, assembly, testing, and even after-sales support. The core idea is to provide a seamless, streamlined process under a single vendor, simplifying project management and accelerating time to market.

Here's a breakdown of the key elements typically included in a PCBA one-stop service:

- PCB Design:

This involves creating the layout and schematics for the PCB, ensuring it meets the product's functional and performance requirements. This stage often includes DFM (Design for Manufacturing) and DFA (Design for Assembly) analysis to optimize the board for efficient production. - Component Procurement:

Sourcing and purchasing all the necessary electronic components, from resistors and capacitors to integrated circuits and connectors. A one-stop service provider leverages its established supply chain to ensure competitive pricing and component availability. - PCB Manufacturing:

Fabricating the bare PCB according to the design specifications. This includes etching, drilling, plating, and applying solder mask and silkscreen. - Assembly:

Populating the PCB with the procured components using automated assembly equipment (e.g., pick-and-place machines, reflow ovens). This stage requires precision and expertise to ensure proper component placement and soldering. - Testing:

Performing various tests, such as in-circuit testing (ICT), functional testing, and visual inspection, to verify the assembled PCB meets the required performance standards and identify any defects. - Quality Assurance:

Implementing quality control measures throughout the entire process to ensure the highest levels of reliability and adherence to industry standards. This includes inspections, audits, and process monitoring. - Logistics and Fulfillment:

Handling the packaging, shipping, and delivery of the assembled PCBs to the customer.

Why a One-Stop Solution is Crucial for Modern Electronics

In today's fast-paced electronics industry, a PCBA one-stop solution is more than just a convenience—it's a necessity for staying competitive. By integrating design, procurement, assembly, and testing, businesses can significantly reduce lead times, improve cost efficiency, streamline communication, and enhance overall quality control. This is especially vital for rapid prototyping PCBA, where speed and accuracy are paramount.

- Reduced Lead Times

Integrating all PCBA processes under one roof eliminates delays associated with coordinating multiple vendors. This streamlined approach accelerates the entire production cycle, from initial design to final product. - Cost Efficiencies

A one-stop solution can lead to significant cost savings by optimizing resource allocation, minimizing transportation expenses, and leveraging economies of scale in component procurement and manufacturing. - Streamlined Communication

Having a single point of contact for all PCBA-related activities simplifies communication, reduces the risk of misunderstandings, and ensures that everyone is on the same page throughout the project. - Enhanced Quality Control

With all processes managed internally, a one-stop solution provides greater control over quality. This includes rigorous testing and inspection at each stage, ensuring that the final product meets the highest standards. - Rapid Prototyping

Essential for quickly iterating and testing new designs, a one-stop service allows for faster turnaround times on prototypes, enabling companies to bring innovative products to market more quickly.

Zero One Solution Limited: Our Expertise in PCBA Solutions

Zero One Solution Limited stands at the forefront of PCBA solutions, driven by over a decade of dedicated experience. We specialize in rapid prototyping, enabling our clients to swiftly transform innovative ideas into tangible products. Our commitment to excellence positions us as a leading provider in the PCB assembly industry, consistently delivering high-quality, efficient, and cutting-edge solutions.

- Decade-Plus Experience

Since our founding in 2011, Zero One Solution Limited has cultivated extensive expertise in PCBA solutions, giving us a deep understanding of industry best practices and emerging technologies. - Specialization in Rapid Prototyping

We excel in rapid-response R&D prototype manufacturing, empowering clients to quickly iterate designs, test functionality, and accelerate their time to market. Our rapid prototyping services are designed to support innovation and agility in product development. - Commitment to Innovation

Innovation is at the core of our operations. We continuously invest in advanced equipment, technologies, and training to stay ahead of industry trends and provide our clients with the most advanced PCBA solutions available. - Comprehensive Service Offering

From initial PCB design to manufacturing and assembly, we offer a complete suite of services to streamline the entire PCBA process. This one-stop approach reduces complexity and ensures seamless integration across all stages of production. - Strategic Global Presence

With headquarters in Shenzhen, China's electronic manufacturing hub, and a branch office in Dubai, we operate within a global PCBA supply chain network, providing unparalleled access to resources and support for our clients worldwide. This strategic positioning optimizes logistics and ensures efficient delivery of services.

The Comprehensive Stages of Our PCBA One-Stop Service

Zero One Solution Limited's PCBA one-stop service encompasses a structured, multi-stage process designed to transform your concepts into tangible products. From the initial spark of an idea to the final, rigorously tested assembly, we manage every detail with precision and expertise. This integrated approach ensures seamless transitions between stages, minimizes errors, and accelerates your time to market.

- Initial Design Consultation & DFM/DFA Analysis

Our process begins with a thorough consultation to understand your project's objectives, specifications, and constraints. We then conduct Design for Manufacturing (DFM) and Design for Assembly (DFA) analyses. DFM ensures the PCB design is optimized for efficient manufacturing, identifying potential issues early on. DFA focuses on streamlining the assembly process, reducing costs and improving reliability. - Component Sourcing

Leveraging our extensive global network, we procure high-quality components from trusted suppliers. Our experienced sourcing team ensures competitive pricing, timely delivery, and authenticity of all parts, mitigating the risks of counterfeit components and supply chain disruptions. We handle everything from active and passive components to connectors and enclosures. - PCB Manufacturing

We utilize state-of-the-art manufacturing facilities to produce PCBs that meet the highest industry standards. Our capabilities include single-layer, multi-layer, rigid, flexible, and rigid-flex PCBs. We offer a wide range of materials, finishes, and technologies to suit your specific application, whether it's a simple prototype or a complex, high-density design. - Assembly

Our skilled technicians meticulously assemble components onto the PCBs using advanced equipment, including automated pick-and-place machines, reflow ovens, and wave soldering systems. We offer various assembly services, including Surface Mount Technology (SMT), Through-Hole Technology (THT), and mixed technology assembly. IPC-A-610 standards are rigorously followed. - Rigorous Quality Assurance

Quality is paramount at every stage of our PCBA one-stop service. We conduct comprehensive testing and inspection to ensure the assembled boards meet your specifications and perform flawlessly. Our quality control processes include Automated Optical Inspection (AOI), X-ray inspection, In-Circuit Testing (ICT), and functional testing. We provide detailed test reports and documentation for full traceability.

Leveraging Global Supply Chain and Strategic Locations

Zero One Solution Limited strategically positions itself within the global PCBA supply chain by operating in Shenzhen, China, and Dubai, UAE. This dual presence ensures unparalleled access to a vast network of resources, cutting-edge technologies, and optimized logistics, which are essential for delivering efficient and cost-effective electronics manufacturing services to our clients worldwide. Our strategic locations enable us to navigate the complexities of global sourcing, reduce lead times, and provide comprehensive support throughout the entire PCBA process.

- How does Zero One Solution Limited benefit from its location in Shenzhen, China?

Shenzhen, often hailed as the 'Silicon Valley of Hardware,' offers unparalleled access to a comprehensive ecosystem of electronic components, manufacturing expertise, and technological innovation. Our presence here allows us to tap into a vast network of suppliers, reduce procurement costs, and leverage the latest advancements in PCB technology. This ensures we can offer our clients cutting-edge solutions at competitive prices. - What advantages does the Dubai branch provide to Zero One Solution Limited's global supply chain?

Our Dubai branch serves as a crucial hub for logistics and distribution, strategically located at the crossroads of Europe, Asia, and Africa. This location facilitates efficient transportation and reduces shipping times to clients across these regions. Additionally, it allows us to navigate international trade regulations effectively and provide localized support to our global clientele, ensuring smooth and timely delivery of PCBA solutions. - How does Zero One Solution Limited optimize logistics for efficient electronics manufacturing services?

We leverage our strategic locations and established relationships with global logistics providers to optimize every aspect of the supply chain. This includes streamlined component sourcing, efficient inventory management, and real-time tracking of shipments. Our expertise in international trade and customs regulations allows us to minimize delays and ensure cost-effective transportation, ultimately benefiting our clients with faster turnaround times and reduced expenses. - What measures does Zero One Solution Limited take to ensure supply chain resilience?

Recognizing the potential disruptions in global supply chains, we have implemented robust risk mitigation strategies. This includes diversifying our supplier base, maintaining buffer stocks of critical components, and establishing alternative transportation routes. Our proactive approach ensures that we can continue to deliver uninterrupted PCBA services to our clients, even in the face of unforeseen challenges. - Can Zero One Solution Limited assist with navigating import and export regulations?

Yes, our team possesses extensive knowledge of international trade regulations and customs procedures. We provide comprehensive support to our clients in navigating import and export requirements, ensuring compliance with all applicable laws and regulations. This includes assisting with documentation, tariff classification, and customs clearance, simplifying the process and minimizing potential delays or penalties. - How does Zero One Solution Limited ensure the quality of components sourced from its global supply chain?

Quality is paramount in our operations. We implement rigorous quality control measures throughout the supply chain, from initial supplier selection to final component inspection. We partner only with reputable suppliers who meet our stringent quality standards and conduct thorough audits to ensure compliance. Additionally, we utilize advanced testing equipment to verify the authenticity and performance of all components before they are integrated into our PCBA solutions. - Does Zero One Solution Limited offer support for global product distribution?

Yes, in addition to PCBA manufacturing and assembly, we offer comprehensive support for global product distribution. Leveraging our strategic locations and logistics expertise, we can assist clients with warehousing, packaging, and shipping their products to customers worldwide. Our end-to-end solutions streamline the entire process, enabling our clients to focus on their core competencies while we handle the complexities of global distribution.

Accelerating Innovation with Rapid-Response R&D Prototyping

In the fast-paced electronics industry, the ability to rapidly prototype and iterate designs is paramount. Zero One Solution Limited understands this critical need, offering rapid-response R&D prototyping services that empower clients to accelerate their innovation cycles and bring cutting-edge products to market faster.

Our rapid prototyping PCBA services are designed to provide a streamlined and efficient process for testing and refining designs. By leveraging our state-of-the-art facilities and experienced engineering team, we enable clients to quickly validate concepts, identify potential issues, and optimize their products for performance and manufacturability.

- Faster Time-to-Market:

Rapid prototyping significantly reduces the time it takes to bring a product from concept to market. Quick iteration cycles allow for faster design validation and issue resolution. - Efficient Design Validation:

Prototyping allows for the validation of design concepts and the identification of potential problems early in the development process. - Cost-Effective Iteration:

Identifying and addressing design flaws during prototyping is much more cost-effective than discovering them later in the production process. - Optimized Performance:

Prototyping enables the optimization of product performance through testing and refinement of design parameters. - Competitive Advantage:

Companies that can rapidly prototype and iterate designs gain a significant competitive advantage in the fast-paced electronics market.

With Zero One Solution Limited, you gain a partner committed to helping you accelerate your innovation journey. Our rapid prototyping services are not just about speed; they are about empowering you to create better products, faster.

Key Advantages of Partnering with Zero One Solution Limited

Partnering with Zero One Solution Limited provides a multitude of distinct advantages, ensuring your project's success from conception to completion. Our commitment to cost-effectiveness, superior quality, dedicated project management, and cutting-edge technological expertise translates into tangible benefits for our clients.

- Cost-Effectiveness Through Optimized Processes

We optimize every stage of the PCBA process, from design to assembly, to minimize costs without compromising quality. Our strategic sourcing and efficient manufacturing techniques translate into significant savings for our clients. - Unwavering Commitment to Superior Quality

Quality is at the core of everything we do. Our rigorous quality control processes, adherence to industry standards, and experienced team ensure that your PCBA meets the highest performance and reliability standards. - Dedicated Project Management for Seamless Execution

Each project is assigned a dedicated project manager who acts as your single point of contact, ensuring clear communication, efficient coordination, and on-time delivery. We keep you informed every step of the way. - Access to Advanced Technological Expertise

We invest in the latest technologies and employ a team of highly skilled engineers and technicians. This allows us to tackle even the most complex PCBA challenges and deliver innovative solutions. - Rapid Prototyping for Accelerated Time-to-Market

Our rapid prototyping capabilities enable you to quickly iterate on your designs, test their functionality, and bring your products to market faster. This agility gives you a competitive edge in today's fast-paced electronics industry. - Global Supply Chain Network for Efficient Sourcing

Our strategic presence in Shenzhen and Dubai provides access to a vast network of component suppliers, ensuring competitive pricing and timely delivery of the parts you need.

Frequently Asked Questions About Our PCBA One-Stop Services

Navigating the complexities of PCBA manufacturing often brings up numerous questions. At Zero One Solution Limited, we believe in transparency and providing clear answers to address your concerns. This section compiles frequently asked questions about our PCBA one-stop services, covering lead times, order quantities, design specifications, and the overall scope of our integrated solutions, designed to provide you with a comprehensive understanding of our offerings.

- What is the typical lead time for a PCBA project with Zero One Solution Limited?

Lead times vary depending on the complexity of the design, component availability, and order quantity. However, our rapid prototyping service aims for quick turnaround, typically within 1-3 weeks. For standard production, lead times are usually between 4-8 weeks. We always strive to provide the most accurate estimate during the initial consultation. - What is the minimum order quantity (MOQ) for PCBA services?

We cater to a wide range of needs, from prototype runs to large-scale production. While MOQs can vary based on specific project requirements, we are flexible and can accommodate low-volume orders, especially for R&D and prototyping purposes. Contact us to discuss your specific volume requirements. - What design specifications are required for PCBA manufacturing?

We require Gerber files (RS-274X format preferred), a bill of materials (BOM) with approved manufacturer part numbers, component placement data (centroid file), and any special instructions or requirements. Our team can also assist with DFM/DFA analysis to optimize your design for manufacturability and assembly. - Can Zero One Solution Limited handle component sourcing?

Yes, we offer comprehensive component sourcing services. Leveraging our global supply chain network and strategic locations, we can efficiently source components, ensuring quality and competitive pricing. We handle everything from procurement to inventory management, streamlining the process for our clients. - What quality control measures are in place?

Quality is paramount at Zero One Solution Limited. We implement rigorous quality control measures throughout the entire PCBA process, including automated optical inspection (AOI), X-ray inspection, in-circuit testing (ICT), and functional testing. All our processes adhere to industry standards such as IPC-A-610 to ensure the highest level of reliability. - Do you offer design assistance or DFM/DFA analysis?

Yes, we offer comprehensive design support, including DFM (Design for Manufacturing) and DFA (Design for Assembly) analysis. Our experienced engineers can review your design to identify potential issues and optimize it for efficient manufacturing and assembly, reducing costs and improving reliability. - What industries do you serve with your PCBA one-stop services?

We serve a diverse range of industries, including telecommunications, medical devices, industrial automation, consumer electronics, and automotive. Our expertise in rapid prototyping and flexible manufacturing allows us to adapt to the unique needs of each industry, providing tailored PCBA solutions.

In essence, Zero One Solution Limited's PCBA One-Stop Service Solution is more than just a manufacturing offering; it's a strategic partnership designed to empower innovation and accelerate market entry. By consolidating your PCB design, manufacturing, and assembly needs under one roof, we eliminate complexities, enhance collaboration, and deliver exceptional value. Our global network, rapid prototyping capabilities, and unwavering commitment to quality ensure your projects move from concept to reality with unparalleled efficiency. Ready to transform your electronic product development? Contact Zero One Solution Limited today and discover how our integrated PCBA solutions can be the catalyst for your next success.

AnyPCBA

AnyPCBA