PCBBUY: Your Guide to Fast & Affordable PCB Manufacturing

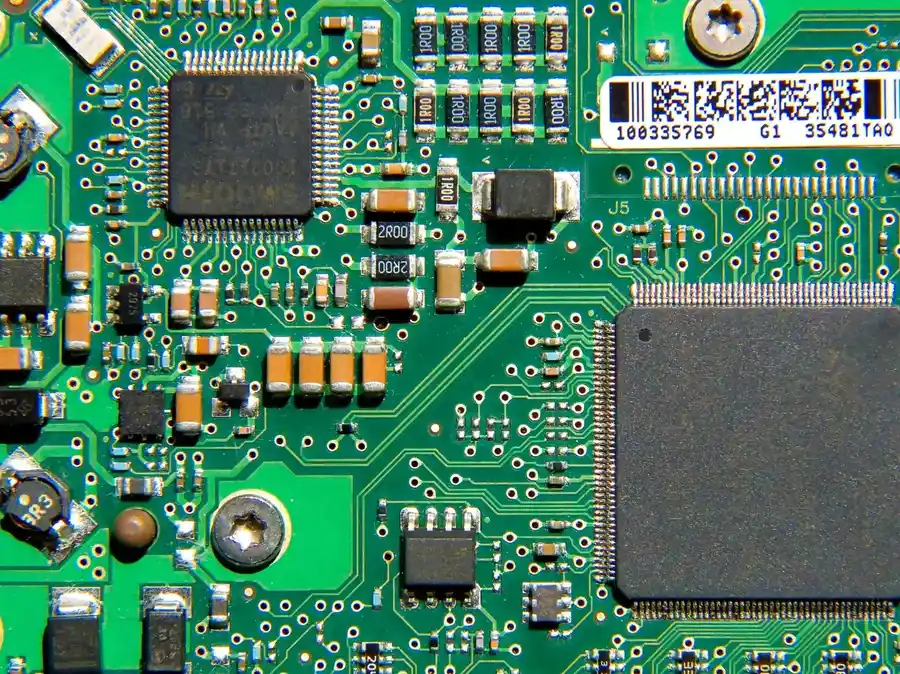

In today's fast-paced electronics industry, quick and reliable PCB manufacturing is critical. [pcbbuy] emerges as a solution, offering streamlined processes for prototype and production PCBs. This guide dives deep into what makes [pcbbuy] a go-to for circuit board needs, ensuring your projects come to life efficiently and affordably.

Introduction to PCBBUY's Services

PCBBUY provides comprehensive PCB manufacturing solutions, encompassing rapid prototyping, advanced fabrication, and efficient assembly services, all underpinned by an intelligent, technology-driven approach to manufacturing. This ensures high-quality PCBs delivered with speed and precision to meet diverse project needs.

PCBBUY's intelligent manufacturing approach integrates automation and data-driven processes across the entire production workflow, from initial design to final product delivery, enhancing efficiency and minimizing errors.

PCB Prototype Services at PCBBUY

PCBBUY's rapid prototyping services are engineered to provide fast and flexible solutions for electronic design validation. Their focus is on accelerating the development cycle by delivering high-quality prototype boards quickly, allowing for iterative design improvements.

Key aspects of PCBBUY's prototype services include:

- Materials

Offers a range of materials such as FR-4, aluminum, and polyimide, with varying thermal and electrical properties to match diverse application requirements. The selection of materials impacts the performance and cost of the prototype. - Layer Options

Provides options from single-layer to multi-layer PCBs. This allows for complex circuit routing and design, with options that can be customized based on the application's design needs. - Pricing Structure

Implements a competitive pricing model that is transparent and flexible. The structure typically considers factors such as layer count, board size, material type, and quantity, ensuring that projects of any scale can access their services. - Speed

Prioritizes fast turnaround times, allowing engineers to receive prototype boards in a time frame that does not impede progress. Their processes are optimized for both speed and accuracy to help meet tight deadlines. - Flexibility

Provides the ability to quickly adapt to design changes, allowing for more innovative designs. This agility is particularly useful for projects that are in the early stages of development, where changes are frequent.

PCBBUY's commitment to quality, combined with their rapid prototyping capabilities, makes them a robust partner for electronic engineers needing to quickly and effectively validate their designs. Their services are designed to be accessible, no matter how complex or basic the project.

| Feature | Description |

|---|---|

| Material Options | FR-4, Aluminum, Polyimide and more |

| Layer Count | Single to multi-layer |

| Turnaround Time | Fast turnaround for time-sensitive projects |

| Customization | Highly customizable options |

PCB Fabrication and Production at PCBBUY

PCBBUY excels not only in rapid prototyping but also in scaling production to meet mass manufacturing demands, maintaining rigorous quality control and accommodating varying volume requirements. This transition from prototype to large-scale fabrication is a core strength, ensuring consistent quality and performance across all production volumes.

| Feature | Description | Significance |

|---|---|---|

| Production Scaling | Seamless transition from small batch prototyping to large-scale manufacturing. | Ensures consistent product quality and availability as demand increases. |

| Quality Control | Stringent measures are in place to check for defects, proper layering, and material compliance. | Minimizes defects, improves product reliability, and reduces costs associated with recalls or failures. |

| Volume Capabilities | Capable of handling small batch orders for testing to massive quantities for bulk manufacturing. | Offers flexibility to meet diverse project sizes and production needs. |

| Manufacturing Capacity | PCBBUY's production lines are designed for efficient processing, utilizing advanced machinery and automated processes. | Reduces lead time, increases throughput, and reduces overall costs. |

| Process Optimization | Constantly refining fabrication processes to reduce waste and optimize efficiency. | Improves sustainability and lowers production cost. |

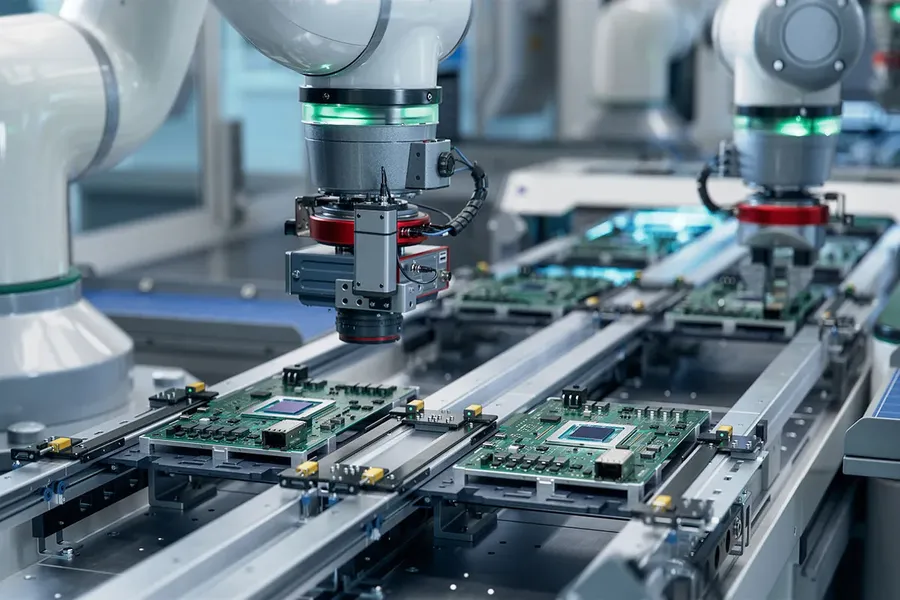

PCBBUY's Technology and Manufacturing Capabilities

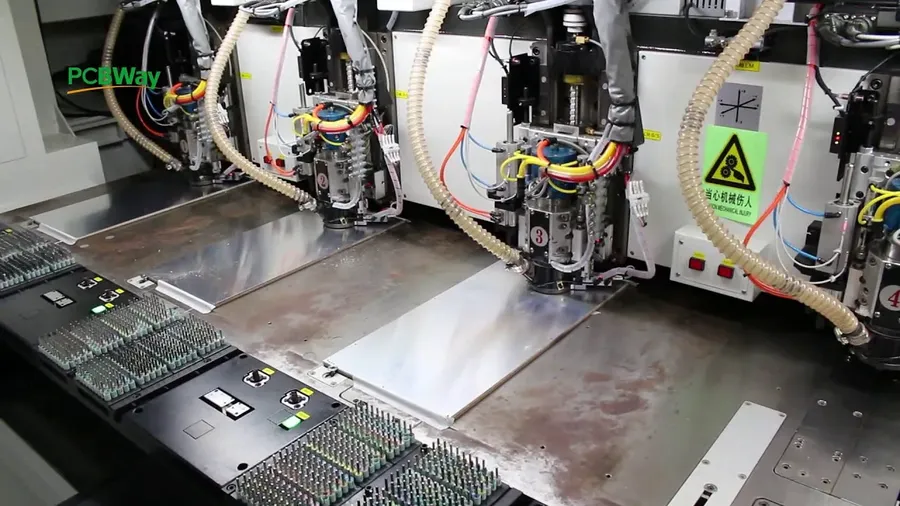

PCBBUY distinguishes itself through its commitment to advanced manufacturing technologies and intelligent factory operations. This ensures high precision, efficient production, and superior quality in their printed circuit board (PCB) manufacturing processes.

PCBBUY's manufacturing capabilities are anchored by several key technologies:

- Automated Optical Inspection (AOI)

AOI systems are used throughout the manufacturing process to verify the quality and accuracy of each PCB, detecting potential defects early on to ensure reliable performance. - Direct Imaging Technology

This technology provides higher accuracy and resolution than traditional film-based imaging, allowing for finer features and greater design precision on the PCBs. - High-Speed Drilling and Milling Machines

Equipped with high-precision machinery, PCBBUY can produce complex designs with tight tolerances, allowing for more compact and feature-rich electronic products. - Surface Mount Technology (SMT) Assembly Lines

Automated SMT lines with advanced placement and soldering equipment ensure high-quality assembly with minimal human error. - Smart Factory Integration

PCBBUY implements an intelligent manufacturing system which provides real-time monitoring and data analysis, optimizing production efficiency, reducing waste, and improving overall process control.

The sophisticated integration of these technologies ensures that PCBBUY's manufacturing process is not only precise and efficient but also responsive to the evolving needs of its clients.

The PCBBUY Ordering Process: A Step-by-Step Guide

Navigating the PCBBUY ordering process is straightforward, designed to ensure a smooth transition from design to delivery. This section provides a detailed breakdown of the necessary steps, from initial file preparation to final delivery.

- 1. File Preparation

Begin by preparing your PCB design files, typically in Gerber format. Ensure all layers, drill files, and component placement data are accurate and complete. PCBBUY also accepts other formats; it's essential to check their website for the most updated specifications. - 2. Design Review and Verification

Thoroughly review your design files before submitting them. Pay close attention to trace widths, spacing, hole sizes, and other design rule checks (DRC). It is recommended to use professional PCB design software such as Altium Designer, Eagle, or KiCad. PCBBUY's website may offer tools or guidance for this step. Design issues at this stage can cause production delays and increase costs. - 3. Quote Request

Submit your prepared files to the PCBBUY platform. Specify the quantity, material type, layer count, board dimensions, and any special requirements such as surface finish and impedance control. PCBBUY will then generate a quote based on these specifications. - 4. Order Confirmation and Payment

After receiving the quote, review all details and confirm your order. Select your preferred payment method, which could include options like credit cards, PayPal, or bank transfers. PCBBUY should provide a secure payment gateway. - 5. Production and Quality Check

Once payment is confirmed, PCBBUY initiates the manufacturing process. They conduct rigorous quality checks throughout the process to ensure the final product meets your specified standards. This involves automated optical inspection (AOI) and other quality control measures. - 6. Delivery and Logistics

Once the PCBs pass the quality inspection, PCBBUY will package and ship them to your specified address. Delivery times and logistics depend on location and chosen service. You will receive shipment tracking information to monitor the delivery progress.

PCBBUY Customer Support and Community

PCBBUY is committed to providing robust customer support and fostering a strong community around its PCB manufacturing services. This commitment is demonstrated through various channels, ensuring users can easily access assistance and engage with peers.

PCBBUY offers multi-channel customer support, including direct contact with their support team via email and telephone, and through comprehensive online resources. Customers can expect knowledgeable and responsive assistance for a smooth user experience.

- Direct Support Channels

Customers can reach out to PCBBUY's support team through email or telephone for prompt and personalized assistance. - Online Resources

PCBBUY's website features a comprehensive knowledge base, including FAQs, tutorials, and design guides to assist users at every stage of their projects. - Active Community Engagement

PCBBUY actively engages with its community on social media platforms such as X (formerly Twitter), LinkedIn, and YouTube, facilitating discussions, sharing updates, and providing a platform for users to connect and learn.

PCBBUY vs Competitors: What Makes Them Different

The competitive landscape for PCB manufacturing is dense, with numerous players vying for market share. PCBBUY distinguishes itself through a strategic combination of rapid turnaround times, competitive pricing, and a focus on intelligent manufacturing. While specific metrics fluctuate based on project specifics and competitor strategies, key differentiators are typically seen in the balance between cost, speed, quality, and customer service.

| Feature | PCBBUY | Competitor A (Example: PCBGOGO) | Competitor B (Example: JLCPCB) | Competitor C (Example: NextPCB) |

|---|---|---|---|---|

| Price | Competitive, Often lower for simple boards | Often competitive for medium volumes | Very Competitive for small volumes | Competitive with volume discounts |

| Delivery Speed | Fast prototyping, scalable production timelines | Generally fast, with options for expedited service | Fast, particularly for standard PCBs | Good speed, multiple shipping options |

| Service Quality | Focus on customer support and intelligent manufacturing. | Good, with a range of support channels | Good online support and customer service | Responsive customer service with technical support |

| Technology/Capabilities | Advanced facilities, smart factory operations | Good for standard PCBs and some advanced builds | Focus on high-volume production, with a range of capabilities | Wide range of manufacturing capabilities |

| Focus Area | Balancing cost, speed, and advanced manufacturing | Good value, range of features and services. | High Volume, Low cost | Rapid prototyping and mass production |

Frequently Asked Questions (FAQs) about PCBBUY

This section addresses common questions regarding PCBBUY's services, order process, manufacturing capabilities, and delivery options, providing concise answers to help you navigate their offerings effectively.

- What types of PCB services does PCBBUY offer?

PCBBUY offers a comprehensive suite of services including PCB prototyping, fabrication, and assembly. This covers single-sided, double-sided, and multi-layer PCBs, catering to diverse project requirements. - What file formats does PCBBUY accept for PCB design?

PCBBUY primarily accepts Gerber files (RS-274X format), which is the industry standard for PCB manufacturing. Additionally, they may support other formats, such as EAGLE, Altium Designer, or KiCad files through conversion tools, but Gerber is the standard and most reliable. - What is the typical lead time for PCB prototyping at PCBBUY?

Lead times for PCB prototyping at PCBBUY are typically short, often ranging from 24 hours to a few days, depending on the complexity of the design and the materials selected. They aim for a rapid turnaround to meet project timelines. Specific lead times can vary, so it is best to confirm these with PCBBUY during the order process. - What materials are available for PCB manufacturing at PCBBUY?

PCBBUY offers a wide array of materials including FR-4 (the industry standard), aluminum substrates for thermal management, and flexible materials for specific applications. The selection depends on the application’s requirements for temperature, electrical properties, and mechanical stress. - How does PCBBUY ensure the quality of manufactured PCBs?

PCBBUY employs stringent quality control measures including Automated Optical Inspection (AOI), electrical testing, and dimensional checks throughout the manufacturing process. They adhere to industry standards such as IPC Class 2 and offer documentation to demonstrate the quality of their finished products. - What are the shipping options and delivery times offered by PCBBUY?

PCBBUY offers a range of shipping options, including express delivery via major carriers such as DHL, FedEx, and UPS. Delivery times vary based on the shipping method and destination but are generally within a few business days for express options and longer for standard options. It's important to note that delivery times start after fabrication is complete. - What support does PCBBUY provide if I have questions about my order?

PCBBUY provides robust customer support through various channels including email, live chat, and phone support. They also offer comprehensive online resources such as FAQs and tutorials. Their customer service team is equipped to assist with queries related to file preparation, order tracking, and technical specifications.

[pcbbuy] provides a streamlined solution for PCB manufacturing, combining speed, affordability, and quality. Whether you’re prototyping a new design or scaling for production, their services are designed to meet diverse needs. With [pcbbuy], you have a reliable partner for getting your electronic projects off the ground quickly and efficiently. Embrace their smart factory approach for all your circuit board requirements.

AnyPCBA

AnyPCBA