PCBWay 3D Printing: A Comprehensive Guide to Rapid Prototyping & Manufacturing

In today’s fast-paced world, the ability to rapidly prototype and manufacture custom parts is crucial for innovation. PCBWay 3D printing services bridge the gap between imagination and reality, offering a suite of technologies to bring your ideas to life. From functional test parts to intricate custom designs, explore how PCBWay's advanced additive manufacturing can accelerate your projects, just as advancements in social sciences and technology continue to shape our world.

Understanding PCBWay's 3D Printing Capabilities

PCBWay offers a comprehensive suite of 3D printing technologies, enabling rapid prototyping and manufacturing of diverse parts. Their capabilities span various methods, each with unique advantages tailored to specific applications. These technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Multi Jet Fusion (MJF), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS).

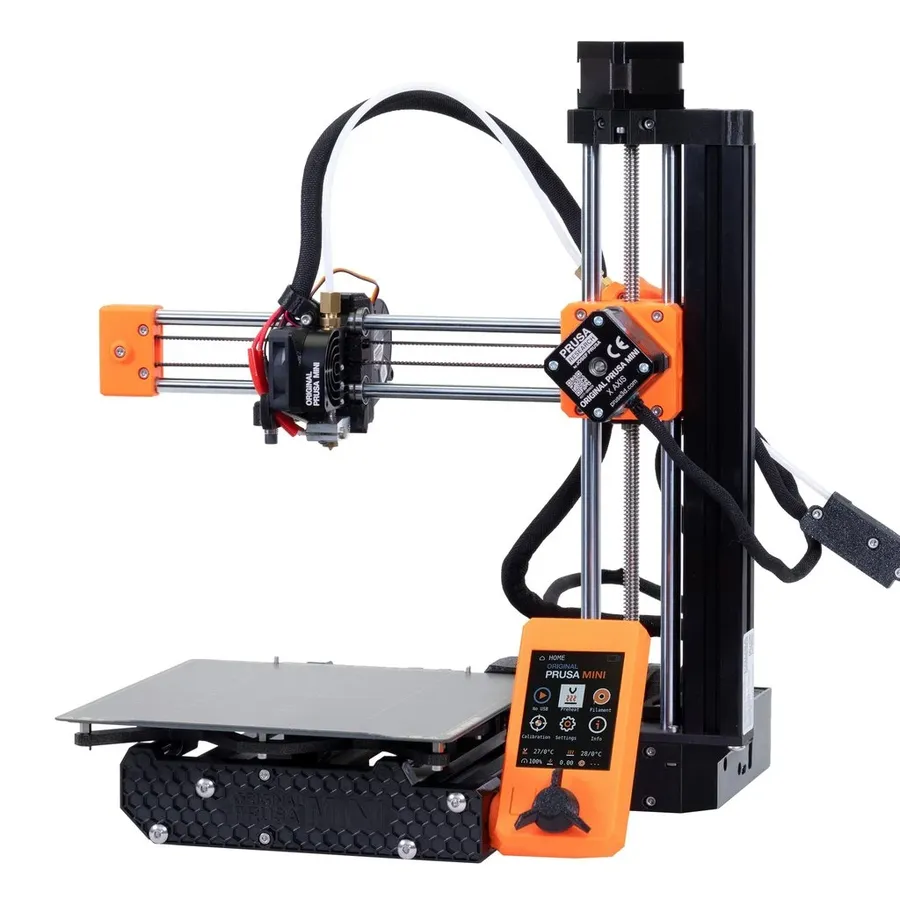

- Fused Deposition Modeling (FDM)

FDM is an extrusion-based process ideal for cost-effective prototyping with a wide range of thermoplastics. It is suitable for concept models, functional parts with moderate detail, and jigs/fixtures. FDM excels in speed and low cost, but may not achieve the precision or surface finish of other methods. - Stereolithography (SLA)

SLA utilizes a UV laser to cure liquid resin, allowing for high-precision parts with smooth surfaces. It is ideal for detailed prototypes, investment casting patterns, and parts requiring excellent dimensional accuracy and fine details. SLA's primary limitations are material choice (limited to resins), higher cost, and a slightly weaker part compared to other technologies. - Multi Jet Fusion (MJF)

MJF employs a powder bed and a fusing agent to create functional, durable parts with consistent mechanical properties. It offers excellent part density and precision. MJF is suited for functional prototypes and end-use parts in various industries. MJF excels at production-level quantities with excellent repeatability. Limitations include material choice (mostly nylon-based) and the requirement for a specific support structure which is typically nylon powder. - Selective Laser Sintering (SLS)

SLS is another powder-based process, using a laser to fuse powder particles together. SLS is beneficial for creating strong, functional parts with complex geometries. It is excellent for prototypes, production parts, and those requiring mechanical robustness and chemical resistance. SLS can handle a broader range of thermoplastic materials than MJF but often involves more cost for the support removal and post-processing compared to FDM. - Direct Metal Laser Sintering (DMLS)

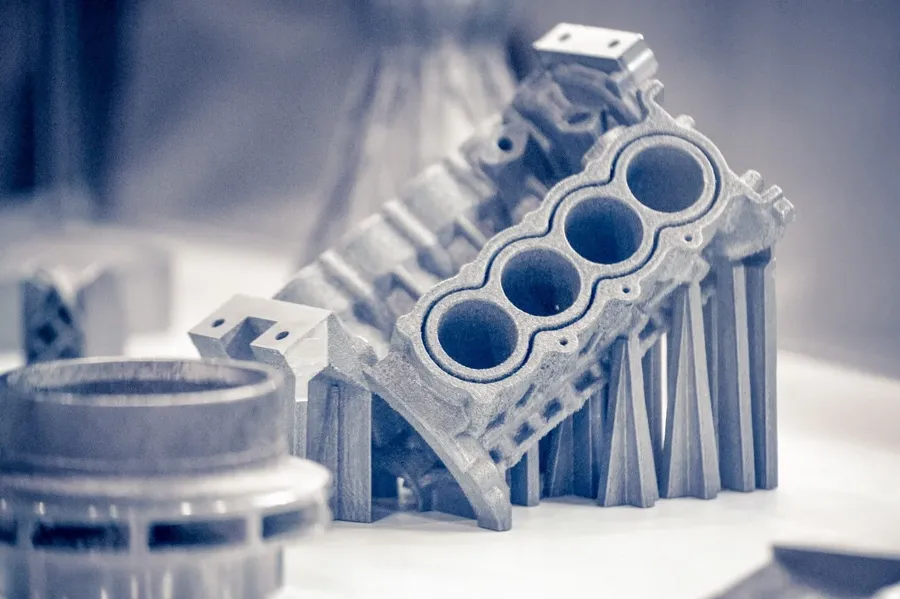

DMLS utilizes a laser to melt and fuse metal powder, which enables the production of strong, complex metal parts with excellent mechanical properties. DMLS is suitable for producing functional metal prototypes and end-use components across the aerospace, automotive, and medical industries. DMLS has a higher cost than other methods, along with potential limitations due to part size and support structure requirements.

Materials Available for PCBWay 3D Printing

PCBWay offers a diverse selection of materials for its 3D printing services, catering to a wide array of applications from rapid prototyping to functional part production. These materials encompass various polymers, metals, and composites, each possessing unique properties that dictate their suitability for different use cases. The selection includes resins for fine details, metals for high-strength and durability, and specialized materials for specific requirements.

| Material Type | Specific Material | Key Properties | Typical Applications |

|---|---|---|---|

| Resins (SLA/DLP) | Standard Resin, Tough Resin, Flexible Resin, Clear Resin | High precision, smooth surface finish, variety of mechanical properties | Prototypes with fine features, detailed models, visual aids |

| Polymers (FDM) | PLA, ABS, PETG, Nylon | Cost-effective, good impact resistance, various temperature tolerances | Functional prototypes, jigs and fixtures, mechanical parts |

| Nylon (MJF/SLS) | PA12, PA11 | High strength, good chemical resistance, excellent durability | Complex parts, housings, mechanical components, end-use parts |

| Metals (DMLS/SLM) | Stainless Steel 316L, Tool Steel, Aluminum | High strength, high temperature resistance, excellent durability | Functional metal parts, high-performance components, industrial tools |

| Other Specialty Materials | Carbon Fiber Composites, Polycarbonate | High strength-to-weight ratio, high stiffness, chemical resistance | Aerospace, automotive, high-performance applications |

The choice of material is critical to the success of a 3D printing project. PCBWay provides detailed material data sheets, allowing users to evaluate key characteristics such as tensile strength, flexural modulus, chemical resistance, and thermal properties. For instance, stainless steel 316L is ideal for components needing high corrosion resistance, while a tough resin can be appropriate for functional prototypes requiring some flexibility. The selection process should also factor in the intended operating environment and any specific regulatory requirements.

Choosing the Right 3D Printing Material

Selecting the appropriate material for your 3D printing project is crucial for achieving desired functionality, aesthetics, and cost-effectiveness. The choice hinges on understanding the interplay between material properties, the intended application of the part, and the capabilities of the chosen 3D printing technology.

| Material | Technology Suitability | Tensile Strength | Chemical Resistance | Key Applications | Cost Consideration |

|---|---|---|---|---|---|

| Standard Resin | SLA, DLP | Moderate | Fair to Good | Detailed prototypes, aesthetic models | Low |

| Tough Resin | SLA, DLP | High | Good | Functional prototypes with impact resistance | Medium |

| Nylon (PA12) | MJF, SLS | High | Excellent | Functional parts, end-use products, snap-fit assemblies | Medium to High |

| Stainless Steel 316L | DMLS | Very High | Excellent | High-strength parts, medical devices, corrosion-resistant components | High |

| Tool Steel | DMLS | Very High | Excellent | High-wear tooling, molds, inserts | Very High |

| ABS | FDM | Medium | Fair | General-purpose prototyping, enclosures | Low to Medium |

| PLA | FDM | Low | Poor | Simple prototypes, educational purposes | Low |

Surface Finish Options for 3D Printed Parts

The surface finish of a 3D printed part significantly impacts its aesthetics, functionality, and overall performance. PCBWay offers a variety of post-processing techniques to achieve desired surface qualities, ranging from basic removal of support structures to advanced treatments that enhance mechanical properties and appearance.

Understanding the available surface finish options and their implications is crucial for selecting the most appropriate treatment for a given application. These options can influence factors such as dimensional accuracy, smoothness, color, and resistance to environmental factors.

| Surface Finish Option | Description | Impact on Appearance | Impact on Functionality | Typical Applications |

|---|---|---|---|---|

| Support Removal | Basic removal of support structures after printing. | Leaves a slightly rough surface, often with visible remnants of supports. | Essential for part usability but has minimal impact on other functional aspects. | All 3D printed parts |

| Sanding | Manual or mechanical abrasion of the surface to improve smoothness. | Can achieve a smoother finish with reduced visible layer lines. | Improves fit and feel, but may not significantly enhance performance. | Parts where smooth surface is important |

| Polishing | Mechanical or chemical treatment to create a glossy or mirror-like finish. | Achieves a highly refined and reflective surface. | Improves smoothness and reduces surface friction. Can also improve light reflection for optical applications. | Aesthetic parts, optical components, wear surfaces |

| Painting | Application of paint to the surface for color or protective coating. | Allows for a wide range of colors and finishes. | Can enhance protection against UV, chemicals, or wear. May add a layer of material that could affect tolerances. | Cosmetic parts, protective components |

| Vapor Smoothing | Exposure to chemical vapors to melt and fuse the surface layers. | Results in a very smooth surface, eliminating layer lines. | Improves surface strength and seals the material. May affect fine details. | Functional parts requiring smooth surfaces, medical devices |

| Media Blasting | Using abrasive media to etch the surface for a matte or textured finish. | Creates a uniform matte finish with good adhesion properties. | Prepares parts for painting or adhesive bonding. Can slightly alter part dimensions. | Parts that need good paint adhesion, textured surfaces |

How to Get a 3D Printing Quote from PCBWay

Obtaining a precise quote for your 3D printing project with PCBWay involves a straightforward process focused on accurately defining your project requirements. This section outlines the necessary steps to upload your design, select materials and finishes, and ultimately receive a cost estimate.

- Prepare Your 3D Model Files

Ensure your design is saved in a compatible format. PCBWay commonly accepts STL, STEP, IGS, and OBJ files. Verify that your model is watertight (no open edges or gaps) and correctly scaled to avoid printing issues. - Navigate to the PCBWay 3D Printing Quote Page

Access the PCBWay website and locate the 3D printing service section. You’ll typically find an 'Instant Quote' or similar button to start the process. - Upload Your 3D Model

Use the upload tool on the PCBWay platform to submit your prepared 3D model file. Wait for the file to process, ensuring successful upload before proceeding. - Select Your Material

Choose the desired material from the provided list. PCBWay offers a wide array of options, from various resins for SLA/DLP printing to metals and engineering-grade plastics. Consider material properties like strength, heat resistance, and finish requirements. - Specify Surface Finish

Define your surface finish needs. Options might include as-printed, polished, painted, or other post-processing techniques. Select finishes that align with your project’s aesthetic and functional needs. - Review and Submit Your Quote Request

Carefully review all chosen parameters - material, finish, and quantities. Ensure everything is accurate before submitting your request. After confirming, submit to receive your quote. - Receive and Review Your Quote

PCBWay will provide a detailed breakdown of costs. Review all charges. If you have questions or need to adjust options, do so before placing an order.

To optimize your 3D printing results, provide clear instructions for critical features and any post-processing requirements. Pre-orienting models for optimal support during printing can reduce costs and improve part quality, consider this before uploading. When requesting a quote, use the support provided by the platform, or contact customer service for guidance as required.

PCBWay 3D Printing for Functional Prototypes

PCBWay's 3D printing services provide a crucial pathway for engineers and designers to move from conceptual ideas to tangible, testable prototypes. Functional prototypes, unlike purely visual models, are designed to perform intended mechanical, thermal, or other physical functions, allowing for rigorous testing and validation before committing to mass production. This capability significantly reduces the risk of costly design flaws being discovered later in the product development cycle.

By utilizing PCBWay's 3D printing capabilities, functional prototypes can be rapidly iterated upon. If a design doesn't perform as expected, alterations can be implemented swiftly, and new prototypes can be printed, thus accelerating the design process and optimizing product functionality.

Here are some use case examples highlighting the application of PCBWay 3D printing for functional prototypes:

- Mechanical Component Testing

Engineers can 3D print gears, brackets, housings, and other mechanical parts using materials with the required strength and flexibility to test under load conditions. For instance, a new gear design could be printed in Nylon or a similar material to assess its performance before metal injection molding is considered. - Thermal Management Prototypes

For electronic devices, heatsinks and enclosures can be 3D printed using materials with specific thermal properties to evaluate heat dissipation efficiency. This is crucial in ensuring that electronics can operate reliably without overheating. For example, a prototype heat sink might be printed using a material with high thermal conductivity to check for its effectiveness. - Fluid Flow Validation

Complex parts involving fluid flow, like valves, nozzles, or housings with integrated channels, can be 3D printed to test flow rates and pressures. These functional prototypes enable engineers to quickly identify areas needing adjustments. An example would be a new nozzle design being 3D printed to check its fluid dispersal pattern. - Custom Tooling and Fixtures

Beyond product prototyping, 3D printing can be used to create specialized jigs, fixtures, and tools that enhance assembly processes. This can reduce manual labor and improve production efficiencies. An example would be using 3D printed fixtures to assist in assembling circuit boards. - Ergonomic Design Validation

3D printing enables the creation of prototypes of enclosures, housings, and hand-held devices to validate ergonomic designs and user interface. This allows design engineers to quickly make adjustments to ensure ease-of-use and user satisfaction. An example would be 3D printing a new mouse design to test user-friendliness.

Community Projects and Inspiration

The PCBWay 3D printing community serves as a vibrant hub for innovation, collaboration, and knowledge exchange. This section showcases the ingenuity of users and their impactful projects, highlighting the diverse possibilities of PCBWay's 3D printing services. These examples not only inspire but also provide practical insights into leveraging these technologies.

This section will also highlight the community's commitment to collaboration and knowledge sharing. Users regularly provide feedback, support one another, and contribute to the collective growth of 3D printing expertise. This sense of community fosters a rich learning environment for both novice and experienced users.

Below, we present a variety of projects that demonstrate the range of applications achievable through PCBWay 3D printing, along with their impact and community engagement:

- Custom Drone Components

Users have designed and manufactured custom drone parts using PCBWay's 3D printing services, allowing for optimized aerodynamics, weight reduction, and improved performance. These projects often involve the use of durable materials like carbon fiber-filled nylon for increased resilience. - Enclosures for Electronics Projects

Many makers have designed and printed custom enclosures for their electronics projects, providing durable and aesthetically pleasing protection for their circuits. This is popular for projects using microcontrollers, sensors, and other electronic components. - Robotics Parts and Assemblies

The PCBWay community produces intricate parts for robotics projects, from end effectors to complex gear systems. These projects demonstrate the precision and strength that PCBWay's 3D printing can offer, often utilizing metal 3D printing for demanding applications. - Architectural Models and Scale Replicas

Users often create detailed architectural models and scale replicas, showcasing the precision of SLA and other technologies that are used for intricate, high-resolution prints with fine details. These models are used for a variety of applications, including presentations and education. - Custom Jigs and Fixtures

Engineers and hobbyists have designed and fabricated custom jigs and fixtures for a variety of assembly and manufacturing processes, which is a useful application of 3D printing for quickly creating custom tools and aids. - Artistic and Creative Designs

The PCBWay 3D printing community also includes artists who utilize this medium to bring their designs to life, showcasing the aesthetic flexibility and creative potential of 3D printing technology.

We encourage all users to share their projects within the community, participate in discussions, and contribute to the collective knowledge base. This vibrant exchange of ideas and experiences is what makes the PCBWay 3D printing community such a valuable resource for makers, engineers, and enthusiasts alike.

Frequently Asked Questions About PCBWay 3D Printing

This section addresses common questions regarding PCBWay's 3D printing services, focusing on crucial aspects like turnaround times, cost determinants, accepted file formats, and minimum order requirements, providing essential information for users engaging with their rapid prototyping and manufacturing capabilities.

- What are the typical turnaround times for PCBWay 3D printing?

Turnaround times vary depending on the chosen 3D printing technology, material, part complexity, and order volume. Generally, simpler FDM parts might be completed in a few days, while more complex SLS or metal parts could take one to two weeks. PCBWay provides estimated lead times during the quoting process, and it's best to consult their website for the most up-to-date information. Complex post processing or higher volume parts will also increase the lead time. - How is the cost of PCBWay 3D printing determined?

Several factors influence the cost, including the material type, volume of material used, printing time, support structures, selected post-processing steps, and order volume. Highly complex geometries will take longer to print and require more support material, increasing costs. You will receive a detailed cost breakdown when using the online quoting tool. - What 3D file formats are accepted by PCBWay?

PCBWay typically accepts STL, STEP, and OBJ files, which are standard in the 3D printing industry. For optimal results, it's crucial to ensure your files are watertight (closed solid) and accurately represent your desired model. Some CAD software will allow you to check these aspects before exporting your files. Other formats may be accepted, but it's advisable to contact customer support if you have files in other formats. - Are there minimum order quantities for PCBWay 3D printing?

PCBWay typically does not have strict minimum order quantities, allowing for single prototypes and small batches. However, the pricing structure means that larger orders may benefit from economies of scale, which result in lower per unit costs. There may be minimum quantities for certain technologies or materials. It is best practice to use the quoting tool on the website to establish pricing for specific requirements. - Can I request specific tolerances for my 3D printed parts?

Yes, you can specify tolerances, but it's crucial to understand that 3D printing processes have inherent limitations. Different technologies will have different achievable tolerance levels, with some higher precision technologies offering tighter tolerances. It is vital to specify critical dimensions and tolerances in your files, and PCBWay’s engineers will make recommendations if tolerances cannot be achieved due to chosen technologies. - What surface finish options are available with PCBWay 3D printing?

PCBWay offers a range of surface finish options such as sanding, polishing, painting, and various plating options depending on the material and technology used. The selection depends on your desired aesthetic and functional requirements. Some materials such as resin based prints can be very smooth as printed, while other materials will require surface finishing to improve their finish. - What is the difference between FDM, SLA, SLS, and MJF in terms of cost, material properties, and application?

FDM (Fused Deposition Modeling) is generally the lowest cost, suitable for rapid prototyping but has lower resolution. SLA (Stereolithography) offers higher resolution and finer details with more brittle, resin-based materials. SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) provide functional parts with superior material properties for engineering-grade use but at a higher cost. SLS and MJF can also create complex geometries with less need for support structures.

PCBWay 3D printing services offer a powerful solution for rapid prototyping and manufacturing, enabling you to bring your innovative ideas to life quickly and efficiently. From material selection to surface finishing, PCBWay provides a complete suite of services to meet your 3D printing needs. Just like the continuous evolution of technology and social sciences, PCBWay is continually improving and innovating, allowing for rapid progress in engineering and design, and contributing to a more advanced and efficient future. Explore their capabilities and start transforming your ideas into tangible realities today.

AnyPCBA

AnyPCBA